Hi Hrmmf,

The port inlet and outlet velocities will be very similar (but theoretically not identical) at those frequencies where the port tube axial length is small relative to the wavelength.

You are not measuring anything, you are simulating - that is why I asked the original questions . As far as inlets and outlets are concerned, it depends on how you define the direction of volume velocity. With a standard bass-reflex system for example, when the diaphragm moves back into the enclosure, the air from the enclosure moves outward through the port tube, entering the tube at the "inlet" and exiting at the "outlet".

. As far as inlets and outlets are concerned, it depends on how you define the direction of volume velocity. With a standard bass-reflex system for example, when the diaphragm moves back into the enclosure, the air from the enclosure moves outward through the port tube, entering the tube at the "inlet" and exiting at the "outlet".

With my original questioning I was more interested in the measuring technique you were using to establish the accuracy of the simulations, and how you were taking those measurements, rather being concerned with the simulations themselves.

Kind regards,

David

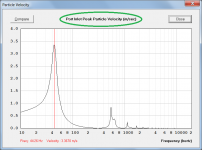

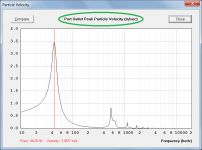

Attached is script and port velocity sims at node 130 and 170. They show identical velocity,

The port inlet and outlet velocities will be very similar (but theoretically not identical) at those frequencies where the port tube axial length is small relative to the wavelength.

Am I measuring at inlet an outlet?

You are not measuring anything, you are simulating - that is why I asked the original questions

With my original questioning I was more interested in the measuring technique you were using to establish the accuracy of the simulations, and how you were taking those measurements, rather being concerned with the simulations themselves.

Kind regards,

David

Correct me if I am wrong but hornresp measures velocity at throat or mouth and not at port in or outlet?

Hi Hrmmf,

Hornresp can do both horns and ports.

Port tube inlet and outlet velocity examples attached - note the slight difference in results, as mentioned in my previous message.

Kind regards,

David

Attachments

I kinda deserved that oneHi Hrmmf,

You are not measuring anything, you are simulating - that is why I asked the original questions.

Like you said I'm not measuring anything, I'm simulatingWith my original questioning I was more interested in the measuring technique you were using to establish the accuracy of the simulations, and how you were taking those measurements, rather being concerned with the simulations themselves.

- Thomas

Hi Hrmmf,

Hornresp can do both horns and ports.

Port tube inlet and outlet velocity examples attached - note the slight difference in results, as mentioned in my previous message.

Kind regards,

David

I guees I am way behind using hornresp. I'll get back on the school bench.

Thank you, David

- Thomas

Hi guys, I'm thinking about drilling holes in a large WG to try the synergy concept.

Info:

- The WG is close to 90x60 pattern and a mouth size is about 30" x 20".

- I will use a JBL D2430K for this experiment. It works nicely down to 800hz and has the best top end I've heard from a large format driver.

- On the low end I'm gonna use the TD-18H+ from AE.

-I would like the midrange to extend down as low as possible as I would like to keep the horn itself a two-way. (18" in a seperate box)

- I will be using DSP, so I can do alot with EQ, time delay, even phase EQ.

All in all, concept is very similar to the S2 and PSE-144 designed by Paul Spencer.

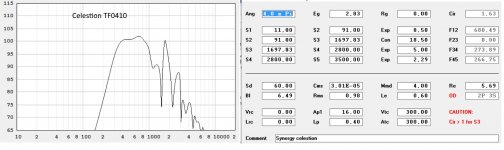

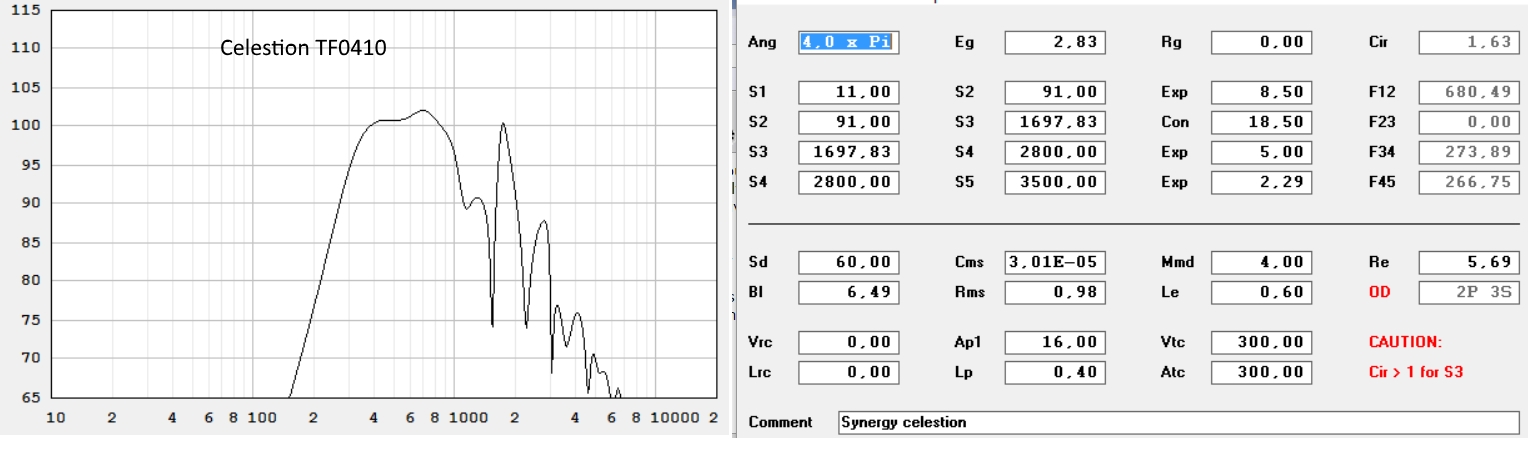

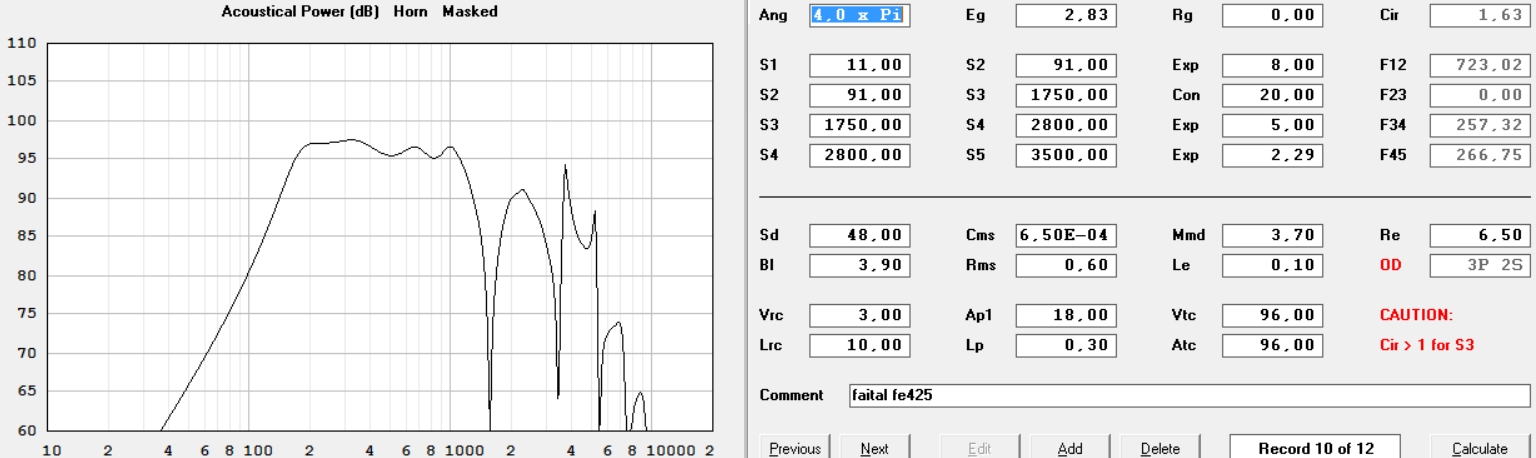

Because of this I started out with copying Paul's hornresp parameters using the Celestion 4" drivers that Paul and several other use for this application, and got this:

Bandwith looks narrow, rolling off earlier than I wish for. But this is maybe what you have to expect when using a fast flaring horn?

Then I tried several other candidates, some did go a bit deeper, some were louder, but the best result I've had so far is the FaitalPro 4FE35:

http://www.faitalpro.com/products/files/4FE35/8/4FE35_datasheet_8.pdf

To me that looks very usable.

Am I on to something, or am I doing something wrong here?

The faital looks like a quality midrange. And they are reasonably priced.

I have read that several people don't want to use rubber surround for longevity reasons. To me, this is not a great concern.

Another question:

How do you calculate an asymmetrical horn in hornresp?

My model at this point assumes a symmetrical 90x90 horn. So in reality it should load slightly better than the simulations?

To you all: This thread has been extremely helpful in understanding many aspects of the synergy horn, thank you to everyone who contributes.

Info:

- The WG is close to 90x60 pattern and a mouth size is about 30" x 20".

- I will use a JBL D2430K for this experiment. It works nicely down to 800hz and has the best top end I've heard from a large format driver.

- On the low end I'm gonna use the TD-18H+ from AE.

-I would like the midrange to extend down as low as possible as I would like to keep the horn itself a two-way. (18" in a seperate box)

- I will be using DSP, so I can do alot with EQ, time delay, even phase EQ.

All in all, concept is very similar to the S2 and PSE-144 designed by Paul Spencer.

Because of this I started out with copying Paul's hornresp parameters using the Celestion 4" drivers that Paul and several other use for this application, and got this:

Bandwith looks narrow, rolling off earlier than I wish for. But this is maybe what you have to expect when using a fast flaring horn?

Then I tried several other candidates, some did go a bit deeper, some were louder, but the best result I've had so far is the FaitalPro 4FE35:

http://www.faitalpro.com/products/files/4FE35/8/4FE35_datasheet_8.pdf

To me that looks very usable.

Am I on to something, or am I doing something wrong here?

The faital looks like a quality midrange. And they are reasonably priced.

I have read that several people don't want to use rubber surround for longevity reasons. To me, this is not a great concern.

Another question:

How do you calculate an asymmetrical horn in hornresp?

My model at this point assumes a symmetrical 90x90 horn. So in reality it should load slightly better than the simulations?

To you all: This thread has been extremely helpful in understanding many aspects of the synergy horn, thank you to everyone who contributes.

Attachments

Another question:

How do you calculate an asymmetrical horn in hornresp?

My model at this point assumes a symmetrical 90x90 horn. So in reality it should load slightly better than the simulations?

To you all: This thread has been extremely helpful in understanding many aspects of the synergy horn, thank you to everyone who contributes.

You can export in hornresp asymmetrical. I do not now if it will change sim.

Fredrik,Another question:

How do you calculate an asymmetrical horn in hornresp?

My model at this point assumes a symmetrical 90x90 horn. So in reality it should load slightly better than the simulations?

An asymmetrical conical horn can be modeled (roughly) as the average of the two angles, 90+60 =150/2=75 degrees.

You will find the 75 degree approximation to be closer to reality than a 90 x 90.

The secondary flare angle of double the first at roughly 2/3 the total horn length(as used in Unity/Synergy horns) also makes a conical horn behave more like an exponential horn at lower frequencies, loading lower than a straight conical.

And if you want to extend range lower, a high Q bass reflex port can get close to the horn output for a narrow range below horn cutoff- with the HF driver you have chosen, using 8" or 10" mid drivers extension down to 80 Hz (or a bit lower) is possible.

Art

Weltersys,

Thanks for the advice about asymmetrical horns in hornresp.

In practice that would mean making the mouth of the horn smaller and keeping the same length the same right?

As for driver choice, yes I agree that it's logical to use the ability of the large format driver to combine with larger mid-bass drivers. Danley does the same I think. 8" with the 1,4" HF drivers.

Here are my initial thoughts:

I know the D2430K is comfortable at 800hz, but lower than this I am not sure, it certainly has a steeper roll-off than the classic 4" large format drivers I worked with before.

This makes me aim for reasonable 1khz output from the mid drivers. And this influences the placement of the port, size of the port and also choice of mid drivers. They must physically fit and be small enough to not ruin the HF.

Second, I have limited faith in that lowering the crossover much below 200hz is a great benefit, because the horn is geting acoustically small at these frequencies and room influence will have starten to play a role by then. Do you think its important to have a point source that low?

But, if it can be done without other comprimises sure, but can it?

Do you have some specific drivers worth taking a look at?

Am I totally off aiming for good midrange output up to 1kHz for an intended crossover of about 800hz?

Thank you,

Fredrik

Thanks for the advice about asymmetrical horns in hornresp.

In practice that would mean making the mouth of the horn smaller and keeping the same length the same right?

As for driver choice, yes I agree that it's logical to use the ability of the large format driver to combine with larger mid-bass drivers. Danley does the same I think. 8" with the 1,4" HF drivers.

Here are my initial thoughts:

I know the D2430K is comfortable at 800hz, but lower than this I am not sure, it certainly has a steeper roll-off than the classic 4" large format drivers I worked with before.

This makes me aim for reasonable 1khz output from the mid drivers. And this influences the placement of the port, size of the port and also choice of mid drivers. They must physically fit and be small enough to not ruin the HF.

Second, I have limited faith in that lowering the crossover much below 200hz is a great benefit, because the horn is geting acoustically small at these frequencies and room influence will have starten to play a role by then. Do you think its important to have a point source that low?

But, if it can be done without other comprimises sure, but can it?

Do you have some specific drivers worth taking a look at?

Am I totally off aiming for good midrange output up to 1kHz for an intended crossover of about 800hz?

Thank you,

Fredrik

Fredrik,1)In practice that would mean making the mouth of the horn smaller and keeping the same length the same right?

2)Second, I have limited faith in that lowering the crossover much below 200hz is a great benefit, because the horn is geting acoustically small at these frequencies and room influence will have starten to play a role by then. Do you think its important to have a point source that low?

3)But, if it can be done without other comprimises sure, but can it?

4)Do you have some specific drivers worth taking a look at?

5)Am I totally off aiming for good midrange output up to 1kHz for an intended crossover of about 800hz?

1) The area of the mouth for a 90 x 60 or a 75 would be the same for the same length.

2) I can identify the location of a 200 Hz source even in a small room, but at 100 Hz it is difficult to locate the source, making sub location optional. At 200 Hz, I'd want the woofer to be co-located with the mid.

3) Bass reflex ports to achieve a lower response from a small horn cabinet are a compromise I'm willing to live with.

4) You could take a look at the SynTripP post

http://www.diyaudio.com/forums/mult...ual-single-point-source-horn.html#post4114406

I used B&C 10CL51 in it, and have used Eminence Alpha 8 in other 2 way offset horn designs.

5)Not totally off by any means, but I have found a good performing acoustic crossover at around 1 kHz is possible even with the mid driver reaching about 800 Hz before the band pass. The 3" diaphragm drivers I have used may have a bit more low extension (just a guess, have not seen any comparisons on the same horn) than the D2430K, but considering how low it is crossed to a 15" with the stubby M2 horn I wouldn't think you would need to be concerned.

Art

1) Indeed.

2) Yes me to. But my 18" woofers will be located right below the horns, and are great drivers for this frequency range.

3) Okey, I am skeptical to highly tuned BR's in general, but open minded about it working in this concept.

I was also thinking about larger drivers also needing bigger holes in the horn to use their capacity, and that this negatively affects linear distortion.

4) Thanks, will do!

5) Okey, probably when you have the design nailed you don't need flexibility. In fact the lowest possible band pass is a good thing because you need less XO components (if passive) and filter out distortion lower in frequency.

I Would have never tried to build a synergy without this forum, that is for sure ^^

But the complexity is also one of the things making it interesting.

2) Yes me to. But my 18" woofers will be located right below the horns, and are great drivers for this frequency range.

3) Okey, I am skeptical to highly tuned BR's in general, but open minded about it working in this concept.

I was also thinking about larger drivers also needing bigger holes in the horn to use their capacity, and that this negatively affects linear distortion.

4) Thanks, will do!

5) Okey, probably when you have the design nailed you don't need flexibility. In fact the lowest possible band pass is a good thing because you need less XO components (if passive) and filter out distortion lower in frequency.

I Would have never tried to build a synergy without this forum, that is for sure ^^

But the complexity is also one of the things making it interesting.

Last edited:

Fredrik,

Just a non-mathematical, empirical-determined observation: The top end on my midrange simulations have ALWAYS been optimistic, show good output higher than I actually got when built. I think it has to do with the fact that the distance from ports to the HF driver should be actually to the surface of the HF diaphram, not just the HF driver's entrance onto the horn throat -- the horn actually starts down in there.

But for whatever reasons, if you're concerned about the HF driver going low enough, I'd design the mid to have a bit more margin up top.

Just a non-mathematical, empirical-determined observation: The top end on my midrange simulations have ALWAYS been optimistic, show good output higher than I actually got when built. I think it has to do with the fact that the distance from ports to the HF driver should be actually to the surface of the HF diaphram, not just the HF driver's entrance onto the horn throat -- the horn actually starts down in there.

But for whatever reasons, if you're concerned about the HF driver going low enough, I'd design the mid to have a bit more margin up top.

I stopped stimulating them a long time ago. I just use the same locations as Danley. If you do that, It Just Works. Here's where they're located in an SH50:

Midrange taps are 3/4" in diam, 3.5" from throat

Woofer taps are 2.5" in diam, 10.5" from throat

Woofer ports are 2.5" in diam, 14.5" from throat

Midrange taps are 3/4" in diam, 3.5" from throat

Woofer taps are 2.5" in diam, 10.5" from throat

Woofer ports are 2.5" in diam, 14.5" from throat

Oh, I've screwed up a few -- had response notches I couldn't fill between mid and tweeter (mid ports too far out), weird off-axis responses (mid ports too far from each other, in an attempt to push the ports into the corners). They probably would have still sounded pretty good (notches aren't that audible, if narrow, and the off-axis stuff was found via careful measurements, not listening). But doing these in wood, at least, involves a fair bit of work (not a huge amount, but more than foam core or fiberglas would I think), so it pays to get them as good as possible.

Keep the ports close to the throat, at least if you're going for a 90x50 degree arrangment (SH50 is 50x50 and crosses rather low, so the ports are easier to handle).

Keep the ports close to the throat, at least if you're going for a 90x50 degree arrangment (SH50 is 50x50 and crosses rather low, so the ports are easier to handle).

@Patrick, thank you for the advise on the ports and distances used by Danley. I will place them very similary. The sims are mainly for analyzing how much low end, sensitivty and capacity I can get. From the sims, there seems to be another octave of output with certain drivers compared to the Celestions. I understand they work excellent when you are building a 3-way horn though.

@bwaslo,

excactly this kind of emipircal experience I need, thank you. I hope to get the port placement/layout right enough the first time, so that the rest can be fixed with DSP.

@bwaslo,

excactly this kind of emipircal experience I need, thank you. I hope to get the port placement/layout right enough the first time, so that the rest can be fixed with DSP.

Greets!

To get 'in the ballpark', find one that either is a closed back unit that resonates at ~SQRT(200*1400) = ~529 Hz, or if open back, then ~529 = 2*Fs/Qes. How you get there doesn't matter if you're not trying to get max efficiency out of it with 'X' diameter x 'Y' long vents. IIRC, TD's prototype driver's published specs were ~2*250 Hz/0.99 = 505 Hz, so I wouldn't get too hung up on the apparent need for a low Qt just because it's a horn app.

GM

Now that Tymphany is selling prosound drivers, we have a couple more candidates that look good. I'm currently building some Synergy horns using the Vifa TC6, but this one looks even better:

Tymphany TC10

This one's designed for line arrays. At 357hz, it's a little on the low side, but I've noticed that the smaller drivers tend to go quite a bit higher than the sims would predict. And I like the fact that it uses a cloth surround; literally have of the midranges I've used in Unity and Synergy horns have wound up in the trash because the surround disintegrates due to being 'pressed' up against the edge of the horn. You really want a cloth surround for these apps.

This driver isn't quite as good as the Celestion 4" for these apps, but at least it's inexpensive and readily available.

A way to avoid the surround getting crushed against the horn is to rout a ring on the wood where the surround would otherwise touch to provide clearance. Makes another detail to do, though not really difficult if you're handy with a router and hole guide.

Though, I usually just opt for drivers that are recessed enough that the surround can't protrude out, as that would be easier for others to use should they want to use my design (on occasions when the designs work, that is!) and not want to mess with a router.

Though, I usually just opt for drivers that are recessed enough that the surround can't protrude out, as that would be easier for others to use should they want to use my design (on occasions when the designs work, that is!) and not want to mess with a router.

Yep. Luckily I'm mostly doing everything in 3D now.

I had about half a dozen Unity horn projects collecting dust in my garage, and when I dismantled them to recover the drivers, I found that about half of the midranges were trashed. The drivers with foam surrounds, like the Pyle, were mostly OK. The cloth surrounds looked as good as new. The ones with rubber surrounds were mostly trashed.

I had about half a dozen Unity horn projects collecting dust in my garage, and when I dismantled them to recover the drivers, I found that about half of the midranges were trashed. The drivers with foam surrounds, like the Pyle, were mostly OK. The cloth surrounds looked as good as new. The ones with rubber surrounds were mostly trashed.

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn.