Fiber fill is one of the most misunderstood subjects in audio circles. There are claims that it makes your box bigger. Really how fiber fill works is by becoming part of your driver and as such changing some of your drivers Thiele/Small parameters.

Think of a cars suspension system, you have the spring as well as the shock absorber. The air in your sealed cabinet is the spring. Introduce the fibers and they absorb some of the shock from the back wave, now note that they are occupying the space that was meant for air and are wiggling https://www.youtube.com/watch?v=K6m40W1s0Wc at every shock wave. While they can wiggle they can absorb the backwave. However as you continue stuffing you restrict their movement and they start becoming a barrier that unfortunately has eaten up our air or spring as such the driver sees a very much reduced box volume and behaves accordingly

This is a very simplistic approach to what is actually happening

Think of a cars suspension system, you have the spring as well as the shock absorber. The air in your sealed cabinet is the spring. Introduce the fibers and they absorb some of the shock from the back wave, now note that they are occupying the space that was meant for air and are wiggling https://www.youtube.com/watch?v=K6m40W1s0Wc at every shock wave. While they can wiggle they can absorb the backwave. However as you continue stuffing you restrict their movement and they start becoming a barrier that unfortunately has eaten up our air or spring as such the driver sees a very much reduced box volume and behaves accordingly

This is a very simplistic approach to what is actually happening

Fiber fill is one of the most misunderstood subjects in audio circles. There are claims that it makes your box bigger. Really how fiber fill works is by becoming part of your driver and as such changing some of your drivers Thiele/Small parameters.

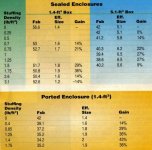

Not claims, just how it is: Real world results using a driver and box setup with various stuffing densities and measured with a MLSSA analyzer.

Attachments

Maybe this would happen in the acoustic near-field. After a portion of a wavelength the sound gains an independence from the driver. It is normally suggested to leave some 'breathing space' behind a driver and I suspect this is the reason. Enclosure standing waves appear to be enough of a box related issue to be treated as such, where their interaction with the driver is less fundamental and more of an external stimulus. The dimensions of the box are such that for a standing wave to happen, the sound would have some acoustic spacing from the origin. Then, the less coherent back wave is best dissipated.becoming part of your driver

Maybe this would happen in the acoustic near-field. After a portion of a wavelength the sound gains an independence from the driver. It is normally suggested to leave some 'breathing space' behind a driver and I suspect this is the reason.

More or less. If you have too great a packing density in close proximity to the driver you can mass-load the powertrain (moving components) and alter the resonant profile of the cone, which obviously has particular significance for wideband drivers that produce the majority of their BW through controlled resonance, but still has significance for other units.

As for 'the truth' -it's only partially so I'm afraid, transmission lines and QW variations being two of the more obvious examples of damping exerting primary effects upon enclosure resonances, not the mechanical behaviour of the drive unit as expressed in mathematical T/S terms. While various types of damping material can & do exhibit differing conversion properties the basic principles are well understood & have been for years. This applies equally, as Alan notes, to other types of enclosure as well. A vented box assumes Helmholtz conditions i.e. a uniform internal air-particle density & no standing waves present. Almost impossible to achieve in practice, especially with floorstanding types, and an impedance sweep will show any unwanted Eigenmodes present in the enclosure quite clearly, which may then be damped as required. This has nothing to do with the driver, nor any change to its mechanical behaviour: it is purely a box effect caused by a specific set of internal dimensions that cause standing waves to develop. You can see similar effects in sealed boxes if the dimensions are such that standing waves develop.

Fiber fill is one of the most misunderstood subjects in audio circles. There are claims that it makes your box bigger. Really how fiber fill works is by becoming part of your driver and as such changing some of your drivers Thiele/Small parameters.

Think of a cars suspension system, you have the spring as well as the shock absorber. The air in your sealed cabinet is the spring. Introduce the fibers and they absorb some of the shock from the back wave, now note that they are occupying the space that was meant for air and are wiggling https://www.youtube.com/watch?v=K6m40W1s0Wc at every shock wave. While they can wiggle they can absorb the backwave. However as you continue stuffing you restrict their movement and they start becoming a barrier that unfortunately has eaten up our air or spring as such the driver sees a very much reduced box volume and behaves accordingly

This is a very simplistic approach to what is actually happening

Shock absorbers are one of the most misunderstood automotive components in North America and so confuse most who create analogies using them.

Springs are the actual shock absorbers and the thing that is called a shock absorber in North America is actually a damper that controls the rate of the movement that an undamped spring would have. If you have springs but no "shock absorber" the car will sit at it's normal height at rest but will bounce, unrestrained and repetitively, when in motion. If you have a car with "shock absorbers" but no springs, it will sit bottomed out at the fully compressed state until it is relieved of it's load. It will then slowly react to the new balance between the weight of the suspension and the weight of the car while in motion over an uneven surface.

I see this automotive analogy used often and in circumstances as different as audio and economics but rarely as the mechanical system actually works.

There's more but you probably didn't want this much info

Thanks for localizing the analogy

Shock absorbers are one of the most misunderstood automotive components in North America and so confuse most who create analogies using them.

Springs are the actual shock absorbers and the thing that is called a shock absorber in North America is actually a damper that controls the rate of the movement that an undamped spring would have. If you have springs but no "shock absorber" the car will sit at it's normal height at rest but will bounce, unrestrained and repetitively, when in motion. If you have a car with "shock absorbers" but no springs, it will sit bottomed out at the fully compressed state until it is relieved of it's load. It will then slowly react to the new balance between the weight of the suspension and the weight of the car while in motion over an uneven surface.

I see this automotive analogy used often and in circumstances as different as audio and economics but rarely as the mechanical system actually works.

There's more but you probably didn't want this much info

simple-science-behind-polyfill

Hi All,

Agree..

b

PS: http://www.diyaudio.com/forums/subw...stuffing-my-explanation-well.html#post4957283

.. the basic principles are well understood & have been for years...

Hi All,

Agree..

b

PS: http://www.diyaudio.com/forums/subw...stuffing-my-explanation-well.html#post4957283

When you roll up a bunch of measurements into a table, you are rolling up all of the interpretation of the data into a conclusion. The interpretation of the data may be right, or it may be wrong. No way to tell from the table.

Well, interpretation of results or interpretation of mode of action?

If i put a driver in a 14 L box measure Fr and Q, and then put the same driver in a 10 L box and get higher Q and Fr. Then lastly add fibers to the 10L box get the same Fr as a 14 L box i demonstrate a increase in apparent box volume. If the Q is lower in the filled 10 L box than the 14L empty box, the fibers has added resistive losses.

How this come about by adiabatic effects, velocity changes or something else, that is not answered by these measurements.

If i put a driver in a 14 L box measure Fr and Q, and then put the same driver in a 10 L box and get higher Q and Fr. Then lastly add fibers to the 10L box get the same Fr as a 14 L box i demonstrate a increase in apparent box volume. If the Q is lower in the filled 10 L box than the 14L empty box, the fibers has added resistive losses.

How this come about by adiabatic effects, velocity changes or something else, that is not answered by these measurements.

While sealed does well with fiber fill, bass reflex ported/passive, Transmission lines (egg crate) etc work better with foam

Sonic Barrier 1/2" Acoustic Sound Damping Foam with PSA 18" x 24"

http://www.parts-express.com/pedocs/more-info/sonic-barrier-msds.pdf

https://www.amazon.com/Acoustic-Foam-2-1-24-18/dp/B0002ZPLP2

Sonic Barrier 1/2" Acoustic Sound Damping Foam with PSA 18" x 24"

http://www.parts-express.com/pedocs/more-info/sonic-barrier-msds.pdf

https://www.amazon.com/Acoustic-Foam-2-1-24-18/dp/B0002ZPLP2

The physics behind the 20% or so increase in effective volume is as follows: Compression and rarefaction of the air inside an unstuffed box occurs under adiabatic conditions, i.e. there is virtually no transfer of heat to or from the air, and it heats up and cools down during the cycle.

A stuffed box converts this largely adiabatic process to a largely isothermal one, because the high thermal mass of the stuffing "keeps the air at a constant temperature". The net effect is that, for a given cone excursion, there is reduced variation in air pressure, therefore higher compliance, and the result is increased effective box size.

A stuffed box converts this largely adiabatic process to a largely isothermal one, because the high thermal mass of the stuffing "keeps the air at a constant temperature". The net effect is that, for a given cone excursion, there is reduced variation in air pressure, therefore higher compliance, and the result is increased effective box size.

Last edited by a moderator:

But thee T/S parameters, does the stuffing change the damping of the outside cone (I mean to a point it affects the motor parameters?) ?

Some says that too much damping remove some clearness or détails resolution ? Is it a myth ! I can understand a T/S parameter change can give a different curve so sound signature, but détails ??? total Qtc changed enough with more stuffing ?

Is there good practices or the stuffing is just to adapt the Qts with more ease than changing the box size ?

Some says that too much damping remove some clearness or détails resolution ? Is it a myth ! I can understand a T/S parameter change can give a different curve so sound signature, but détails ??? total Qtc changed enough with more stuffing ?

Is there good practices or the stuffing is just to adapt the Qts with more ease than changing the box size ?

Eldam, audiophiles worry too much. Stuffing fibers are used to supress air resonances, especially when these fall in the passband. At the same time Qms of a driver in the box lowers somewhat which is known to add to the total damping of the cone around its Fs in the box. There is no bad consequences to using stuffing as long as one doesn't make silly mistakes like going to the extreme. Measurements will tell you how things are developing so you should trust them. If you simulate a driver in a box and change the Qa (value for absorption due to stuffing) from like 5-100, you will notice some small spl decrease around Fs.

I would like to see your measurements showing how TLs work better and in what way with foam lining than with fiber fill. I'm not saying you're incorrect but I suspect that it's like saying that fiberglass works better than polyester fiber (Polyfil or Acousta Stuf for instance) when in fact, they both work the same way but require different densities or stuffing lengths to create the same end result.

Paul

Paul

While sealed does well with fiber fill, bass reflex ported/passive, Transmission lines (egg crate) etc work better with foam

Sonic Barrier 1/2" Acoustic Sound Damping Foam with PSA 18" x 24"

http://www.parts-express.com/pedocs/more-info/sonic-barrier-msds.pdf

https://www.amazon.com/Acoustic-Foam-2-1-24-18/dp/B0002ZPLP2

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- The truth about fiber fill and why you need it