If you're building a normal BR or ported box, then lining the walls with foam is the accepted practice and quite adequate. But I design and build TLs, sometimes long and tapered with a terminus where the line's 1/4-wavelength frequency is the sole tuning mechanism, or sometimes shorter with constant area lines whose natural 1/4-wavelength resonant frequency isn't low enough and needs a mass-loading port to complete the tuning.

Paul

Paul

Hi Paul

As you can see from the following video, the sealed section uses fiber, while the bass reflex ported uses straight acoustic foam

https://www.youtube.com/watch?v=JMV6RlQx2BE

hi, I can confirm that stuffing the cabinet will increase the sound quality tremendously.

why I say so ? because I'm just tunning 1 pair of cheap Chinese surround speaker with no brand and absolutely no drive info to excess. however the tuning work so well until I'm quite sick to find out that a lot of song in my music library sound so bad until I wanted to stop tuning it further.

my set it up as the b&w subwoofer, I use those black insulation pad in the wall and polyfill just to fill up the space.

please don't laugh at the speaker.

Sent from my Redmi Note 2 using Tapatalk

why I say so ? because I'm just tunning 1 pair of cheap Chinese surround speaker with no brand and absolutely no drive info to excess. however the tuning work so well until I'm quite sick to find out that a lot of song in my music library sound so bad until I wanted to stop tuning it further.

my set it up as the b&w subwoofer, I use those black insulation pad in the wall and polyfill just to fill up the space.

please don't laugh at the speaker.

Sent from my Redmi Note 2 using Tapatalk

OnAudio, you need to remember what you said that I first responded to, "TLs work better with multi-fold lines whose walls are lined with egg crate acoustic foam". We're not talking about sealed boxes or typical BRs/vented boxes and you have not yet presented any "proof" of your claim.

Paul

Paul

Hi Paul

As you can see from the following video, the sealed section uses fiber, while the bass reflex ported uses straight acoustic foam

https://www.youtube.com/watch?v=JMV6RlQx2BE

Was it Dickason's Cookbook that went into the thermodynamic effects of fiberglass insulation in a speaker cabinet? Seems like polyfill wasn't the preferred material, something about the glass fibers converting motion to heat better.

Been too long, I just barely recall the highlights. And that might have been for cabinet lining, not fill, but it seems like if one fiber was better, it'd be better in both instances.

Been too long, I just barely recall the highlights. And that might have been for cabinet lining, not fill, but it seems like if one fiber was better, it'd be better in both instances.

Fiberglass and polyester fibers work the same way and have the same type of effect, differing only in the the densities required, less with the fiberglass (about 70% of that from polyester). Again, I'm talking only about TLs.

Paul

Paul

Was it Dickason's Cookbook that went into the thermodynamic effects of fiberglass insulation in a speaker cabinet? Seems like polyfill wasn't the preferred material, something about the glass fibers converting motion to heat better.

Been too long, I just barely recall the highlights. And that might have been for cabinet lining, not fill, but it seems like if one fiber was better, it'd be better in both instances.

I would like to add some info to this discussion. I haven't read through all the posts so if I repeat something, forgive me. First of all, it is important to start with the observation that any speaker box alignment, sealed, ported, TL, contains some volume of air. That air has a capacitance, or ability to store and release energy. In a sealed or ported box it is usual to consider the entire box volume as a single capacitance. In a TL the line may be subdivided into several sections with a capacitance assigned to each section. The first is referred to as a lumped parameter model, the TL as a distributed parameter model. In either case, variations in volume are related to variations in pressure through the capacitance,

dV = C dP.

So what is C?

C is determined by the physics of how the air pressure changes with a change in volume. In general this can be expressed as a polytrophic relationship,

PV^k = constant.

Note that from the definition of C, C = dV/dP,

The value of k can take on any value between 1 and the thermodynamic property, gamma, which is the ration of specific heats of the gas, gamma= 1.4 for air. K- 1 corresponds to a constant temperature process. K = gamma an isentropic (lossless) process.

From this C can be determined.

dV/dP = - V/(kP) = C

In acoustics changes in volume and pressure are considered small compared to the initial state so

C = - Vo / (kPo) where the "o" indicated the initial state.

Note that Po = RHOo x So^2 / gamma, so

C = - gamma x Vo /(k x RHOo x So^2)

(RHO = density of air, S = speed of sound)

Here is where stuffing come in with regard to capacitance. Stuffing will, obviously, reduce the volume of the air in the box. Thus Vo would be reduced making the capacitance smaller, as in a smaller box. But the stuffing also has a much higher ability to store heat than air. Now, when air is compressed it generally heats up somewhat. When it expands, it cools. But due to the presence of the stuffing any increase in temperature is quickly absorbed by the stuffing and any cooling of the air results in heat returned to the air from the stuff. In effect, the stuffing acts as a heat storage device, receiving and giving back heat energy to the air. This tends to make the expansion/compression process occur at nearly constant temperature.

So lets look at some numbers. In that absence of stuffing (empty box) the best the compression/expansion process can be is isentropic. In that case k = gamma and C = - Vo/(RHOo x So^2).

On the other hand, if the stuffing could absorb and give back all the heat of the compression/expansion process the air temperature would remain constant and k would equal 1.0 giving C = - 1.4 x Vo / (RHOo x So^2) .

As you can see, theoretically, stuffing could increase the capacitance by a factor of 1.4, or the same value of the capacitance of an empty box 40% larger. Thus the idea that stuffing can make the box look as much as 40% bigger comes from the fact that stuffing, under the most ideal conditions, can increase the capacitance of the air volume by 40%.

The second issue is the resistance the stuffing provides. In this case, as an acoustic wave propagates the air accelerates and decelerates and moves back and fourth as the pressure increases an decreases. The motion of the air results in friction (resistance) between the air and the stuffing which generates heat. In this case it doesn't matter whether it is an expansion of compression, the motion always generates heat as the air gives up kinetic energy as the motion is dissipated in the form of heat. Again, since the stuffing has much higher heat capacity than the air, the increase in the stuffing temperature is very small. So the resistance to flow through the stuffing results in dissipation of the kinetic energy of motion of the air as heat, damping the acoustic wave. This effect is much more significant at higher frequencies than low frequencies. As a result, stuffing in a box or TL tends to damp high frequency waves and resonances more significantly than lower frequencies. Thus, stuffing contributes two effects, increasing the capacitance in the system and providing additional resistance to propagating waves at higher frequencies.

dV = C dP.

So what is C?

C is determined by the physics of how the air pressure changes with a change in volume. In general this can be expressed as a polytrophic relationship,

PV^k = constant.

Note that from the definition of C, C = dV/dP,

The value of k can take on any value between 1 and the thermodynamic property, gamma, which is the ration of specific heats of the gas, gamma= 1.4 for air. K- 1 corresponds to a constant temperature process. K = gamma an isentropic (lossless) process.

From this C can be determined.

dV/dP = - V/(kP) = C

In acoustics changes in volume and pressure are considered small compared to the initial state so

C = - Vo / (kPo) where the "o" indicated the initial state.

Note that Po = RHOo x So^2 / gamma, so

C = - gamma x Vo /(k x RHOo x So^2)

(RHO = density of air, S = speed of sound)

Here is where stuffing come in with regard to capacitance. Stuffing will, obviously, reduce the volume of the air in the box. Thus Vo would be reduced making the capacitance smaller, as in a smaller box. But the stuffing also has a much higher ability to store heat than air. Now, when air is compressed it generally heats up somewhat. When it expands, it cools. But due to the presence of the stuffing any increase in temperature is quickly absorbed by the stuffing and any cooling of the air results in heat returned to the air from the stuff. In effect, the stuffing acts as a heat storage device, receiving and giving back heat energy to the air. This tends to make the expansion/compression process occur at nearly constant temperature.

So lets look at some numbers. In that absence of stuffing (empty box) the best the compression/expansion process can be is isentropic. In that case k = gamma and C = - Vo/(RHOo x So^2).

On the other hand, if the stuffing could absorb and give back all the heat of the compression/expansion process the air temperature would remain constant and k would equal 1.0 giving C = - 1.4 x Vo / (RHOo x So^2) .

As you can see, theoretically, stuffing could increase the capacitance by a factor of 1.4, or the same value of the capacitance of an empty box 40% larger. Thus the idea that stuffing can make the box look as much as 40% bigger comes from the fact that stuffing, under the most ideal conditions, can increase the capacitance of the air volume by 40%.

The second issue is the resistance the stuffing provides. In this case, as an acoustic wave propagates the air accelerates and decelerates and moves back and fourth as the pressure increases an decreases. The motion of the air results in friction (resistance) between the air and the stuffing which generates heat. In this case it doesn't matter whether it is an expansion of compression, the motion always generates heat as the air gives up kinetic energy as the motion is dissipated in the form of heat. Again, since the stuffing has much higher heat capacity than the air, the increase in the stuffing temperature is very small. So the resistance to flow through the stuffing results in dissipation of the kinetic energy of motion of the air as heat, damping the acoustic wave. This effect is much more significant at higher frequencies than low frequencies. As a result, stuffing in a box or TL tends to damp high frequency waves and resonances more significantly than lower frequencies. Thus, stuffing contributes two effects, increasing the capacitance in the system and providing additional resistance to propagating waves at higher frequencies.

Back in the day, of closed box acoustic suspension an' all that, people used to seriously stuff cabinets with heavy scratchy fibreglass and half the contents of the Sofa or the odd pillow.

We don't do the heavy stuff any more. Possibly because most modern drivers are big-magnet reflex types, where you can only damp panels and line absorbent materials round the sides, where most of their effect is on the midrange above 2kHz. As you know, reflex relies on free flow of air.

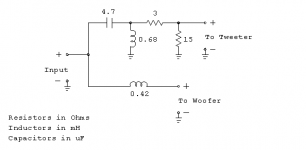

I just reminded myself of the sort of stuff somebody would find in an old Acoustic Research speaker. I also dug up that audio great Marshall Leach's lovely old Vifa P17 polycone/metal tweeter project. He was ahead of his time, IMO. It's quite home-cinema, isn't it?

We don't do the heavy stuff any more. Possibly because most modern drivers are big-magnet reflex types, where you can only damp panels and line absorbent materials round the sides, where most of their effect is on the midrange above 2kHz. As you know, reflex relies on free flow of air.

I just reminded myself of the sort of stuff somebody would find in an old Acoustic Research speaker. I also dug up that audio great Marshall Leach's lovely old Vifa P17 polycone/metal tweeter project. He was ahead of his time, IMO. It's quite home-cinema, isn't it?

Attachments

I would like to add some info to this discussion...

Thus, stuffing contributes two effects, increasing the capacitance in the system and providing additional resistance to propagating waves at higher frequencies.

Thanks for the explanation of the underlying physics behind how stuffing works in speaker systems! I've never seen it explained like that before, but it makes sense.

Hi Sam,

You could make cute pillows with this Speaker Grill Cloth & Fabric in the Speaker Components Department at Parts Express | 319

You could make cute pillows with this Speaker Grill Cloth & Fabric in the Speaker Components Department at Parts Express | 319

Agreed, but with a dome like that in place (you also get small ones for condiments and for children to play with) you can experiment with other stuffing materials. Eg, small thermocoal balls - what they use for making thermocoal sheets etc.

So long as you have a consistent foam supplier and you have carried out tests and build a model,

(assuming the manufacturer doesn't provide some nice curves), the accuracy should be at par with fiber or better

(assuming the manufacturer doesn't provide some nice curves), the accuracy should be at par with fiber or better

Can you predict with confidence from modeling what the results will be using foam lining? I find it not at all inconvenient to use polyester fiber and I can model its predicted effects quite accurately, so if I build exactly what I model, I will get the expected results. I should say, though, that I've found a stuffing density of 0.75 lb/ft3 to be almost universally optimum, needing only to use different stuffing lengths from the beginning of the lines to achieve what I want. That allows me to use Dacron batting, instead of loose fill, which is 1 inch thick and has an inherent density of 0.75 lb/ft3. No weighing is necessary as you just cut it into rectangles that mimic the internal dimensions of the line and layer it in without any compression of teasing, and it stays put.

Paul

How hot and how fast does the air heat up without stuffing? Is it significant enough that the driver will see a smaller box size by the stiffer air assuming sealed box (ported should be able to vent the heat out, I do have a non stuffed ported box from a global manufacturer and the air coming out isn't that warm although am thinking that has to do with the voice coil venting heat, although you cant crank this baby up), is the speed of sound significantly affected by this ?

I would like to add some info to this discussion. I haven't read through all the posts so if I repeat something, forgive me. First of all, it is important to start with the observation that any speaker box alignment, sealed, ported, TL, contains some volume of air. That air has a capacitance, or ability to store and release energy. In a sealed or ported box it is usual to consider the entire box volume as a single capacitance. In a TL the line may be subdivided into several sections with a capacitance assigned to each section. The first is referred to as a lumped parameter model, the TL as a distributed parameter model. In either case, variations in volume are related to variations in pressure through the capacitance,

dV = C dP.

So what is C?

C is determined by the physics of how the air pressure changes with a change in volume. In general this can be expressed as a polytrophic relationship,

PV^k = constant.

Note that from the definition of C, C = dV/dP,

The value of k can take on any value between 1 and the thermodynamic property, gamma, which is the ration of specific heats of the gas, gamma= 1.4 for air. K- 1 corresponds to a constant temperature process. K = gamma an isentropic (lossless) process.

From this C can be determined.

dV/dP = - V/(kP) = C

In acoustics changes in volume and pressure are considered small compared to the initial state so

C = - Vo / (kPo) where the "o" indicated the initial state.

Note that Po = RHOo x So^2 / gamma, so

C = - gamma x Vo /(k x RHOo x So^2)

(RHO = density of air, S = speed of sound)

Here is where stuffing come in with regard to capacitance. Stuffing will, obviously, reduce the volume of the air in the box. Thus Vo would be reduced making the capacitance smaller, as in a smaller box. But the stuffing also has a much higher ability to store heat than air. Now, when air is compressed it generally heats up somewhat. When it expands, it cools. But due to the presence of the stuffing any increase in temperature is quickly absorbed by the stuffing and any cooling of the air results in heat returned to the air from the stuff. In effect, the stuffing acts as a heat storage device, receiving and giving back heat energy to the air. This tends to make the expansion/compression process occur at nearly constant temperature.

So lets look at some numbers. In that absence of stuffing (empty box) the best the compression/expansion process can be is isentropic. In that case k = gamma and C = - Vo/(RHOo x So^2).

On the other hand, if the stuffing could absorb and give back all the heat of the compression/expansion process the air temperature would remain constant and k would equal 1.0 giving C = - 1.4 x Vo / (RHOo x So^2) .

As you can see, theoretically, stuffing could increase the capacitance by a factor of 1.4, or the same value of the capacitance of an empty box 40% larger. Thus the idea that stuffing can make the box look as much as 40% bigger comes from the fact that stuffing, under the most ideal conditions, can increase the capacitance of the air volume by 40%.

The second issue is the resistance the stuffing provides. In this case, as an acoustic wave propagates the air accelerates and decelerates and moves back and fourth as the pressure increases an decreases. The motion of the air results in friction (resistance) between the air and the stuffing which generates heat. In this case it doesn't matter whether it is an expansion of compression, the motion always generates heat as the air gives up kinetic energy as the motion is dissipated in the form of heat. Again, since the stuffing has much higher heat capacity than the air, the increase in the stuffing temperature is very small. So the resistance to flow through the stuffing results in dissipation of the kinetic energy of motion of the air as heat, damping the acoustic wave. This effect is much more significant at higher frequencies than low frequencies. As a result, stuffing in a box or TL tends to damp high frequency waves and resonances more significantly than lower frequencies. Thus, stuffing contributes two effects, increasing the capacitance in the system and providing additional resistance to propagating waves at higher frequencies.

How did you evaluate those results, by measurements or simply by ear? If by ear only, then all you've done is make the result sound like you prefer which may or may not actually be better. Will the results from the model you built translate to similar, but not identical multi-fold TLs, like having more or fewer folds of different lengths, and how would you know without being able to predict before making one bit of sawdust? Nevertheless, you haven't presented any proof to your claim that I originally questioned that foam lining works better in a multi-fold TL compared to polyester fill.

Paul

Paul

So long as you have a consistent foam supplier and you have carried out tests and build a model,

(assuming the manufacturer doesn't provide some nice curves), the accuracy should be at par with fiber or better

I think this would be more of a concern with horns, where the air pressure variations in the rear chamber and throat regions are quite large. In fact, I would even be concerned about dew point.How hot and how fast does the air heat up without stuffing? Is it significant enough that the driver will see a smaller box size by the stiffer air assuming sealed box (ported should be able to vent the heat out, I do have a non stuffed ported box from a global manufacturer and the air coming out isn't that warm although am thinking that has to do with the voice coil venting heat, although you cant crank this baby up), is the speed of sound significantly affected by this ?

Temperature changes are not an issue. A sealed box is never really sealed. It needs to have some small leakage to adjust to atmospheric pressure. Thus, regardless of the temperature the pressure in the box is always Po, atmospheric pressure.

Remember, P = RHO x T = RHO x S^2 / gamma, so since P = Po, any increase in T (or S^2) is countered by a reduction in RHO.

Bigger issues are changes in Po due to weather or altitude. Weather can vary Po by +/-10%.

Remember, P = RHO x T = RHO x S^2 / gamma, so since P = Po, any increase in T (or S^2) is countered by a reduction in RHO.

Bigger issues are changes in Po due to weather or altitude. Weather can vary Po by +/-10%.

You are talking about average temperature and pressure. I am talking about the adiabatic properties of a gas, in this case, air. For each half cycle, the air in the rear chamber will be made to expand, and compressed in the other half cycle. When compressed, the temperature will rise; when expanded, the temperature will drop.Temperature changes are not an issue.

Average temperature doesn't change much - just rises slightly over a significant period due to coil dissipation.

Could the fiber density or material change Something ?

For instance : metal fiber instead glass, or wool instead glass fiber, or foam fiber instead hard foam... ? I mean they have certainly not the same way to convert/absorb the heat ?

Or is it simply the total surface of the fiber to air ? Density of the material ?

For instance : metal fiber instead glass, or wool instead glass fiber, or foam fiber instead hard foam... ? I mean they have certainly not the same way to convert/absorb the heat ?

Or is it simply the total surface of the fiber to air ? Density of the material ?

I can't speak to characteristics that foam and metal fiber have, but differences in wool, fiberglass or polyester do require different densities to have the same effects (in a TL, which is the only application I've been addressing). That does not mean that one fiber is literally better than the others, however.

Paul

Paul

Could the fiber density or material change Something ?

For instance : metal fiber instead glass, or wool instead glass fiber, or foam fiber instead hard foam... ? I mean they have certainly not the same way to convert/absorb the heat ?

Or is it simply the total surface of the fiber to air ? Density of the material ?

Thanks, It seems this is more the fine tuning (multiple tries & error to find the good equilibrium) than the material at the end... We saw more and more hifi fibers stuff solded by hifi parts shops and it's always more expensive...

The good choice is maybe the material with the less V.O.C. for family health... even sealed there are always dust from it !

The good choice is maybe the material with the less V.O.C. for family health... even sealed there are always dust from it !

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- The truth about fiber fill and why you need it