Art, as always, thanks for your informed reponse!

I'll dig up some links of Nate Hansen's paraline Synergy. It was mentioned quite a while back in this thread, briefly:

http://www.diyaudio.com/forums/multi-way/217298-square-pegs-43.html#post3458538

DIY Synergy/Unity spreadsheet

That's all I could find for now.

I did wonder about the compression ratio side of things - it seems like strong motors would be a necessity. Taking the Synergy approach however, would it be possible to mount a number of weaker drivers to the same paraline to compensate?

Frequency response: something that's feasible (150Hz was an ideal), so 200 or 300Hz

Sensitivity: nothing essentially extreme. "In the 90s"?

Pattern control: Something like Bill Waslo's Synergy, which I think goes down to 320Hz (from memory)

Edit: Patrick, did you ever post the plans of the Paraline you'd built in post #1? Also, would adding a horn flare to that allow a lower frequency response (i.e. lower than the 500Hz stated in the video)?

For the most part, I've lost interest in Paralines. I built a few of them, but I found that no matter how flat the response was, they were fatiguing to listen to. I'm guessing the problem is High Order Modes.

If you look at the geometry, you'll realize that a fraction of the output is going to get reflected back to the throat, and that's going to generate HOMs.

Art was telling me this for a couple of years, it just took a while to sink in

If I needed a waveguide with narrow directivity, I would build a conventional one and use DSP to 'line up' the wavefronts.

Having said all that, I've seen some videos of Jericho horns and they don't seem to suffer from the HOMs like mine do. My 'hunch' is that Tom's Paraline's are small enough that the HOMs are 'pushed' up into the last couple of octaves, where they're less audible.

If you compare my Paralines to Tom's Paralines, you'll notice Tom's are much much smaller.

https://www.facebook.com/video.php?v=689673804462030

Those 3FE22's are one of the best - you won't be disappointed. They really kick out some sound and are very smooth and flat in response. I use them to drive a tractrix and they load very well with a powerful motor.

I kept raving about the 3FE20, and Planet10 told me the FF85WK was better.

IMHO, he is correct. The Faital is good but the Fostex is great.

I have heard lots of glowing reviews of the 85wk too. Should try it one of these days - it has a tiny xmax though if that means anything. The Faitals are more sensitive I believe and have a lower Qts which makes them suitable for certain alignments. They look better than the Faitals which are kind of ugly as they are meant for rear mounting. Big price difference though.

You lost interest in Paraline huh? If I can make it in less than an hour with foam core I will give it a try.

You lost interest in Paraline huh? If I can make it in less than an hour with foam core I will give it a try.

I have heard lots of glowing reviews of the 85wk too. Should try it one of these days - it has a tiny xmax though if that means anything. The Faitals are more sensitive I believe and have a lower Qts which makes them suitable for certain alignments. They look better than the Faitals which are kind of ugly as they are meant for rear mounting. Big price difference though.

You lost interest in Paraline huh? If I can make it in less than an hour with foam core I will give it a try.

The higher order modes are going to get generated by the 180 degree bend in the Paraline.

Danley's latest design uses a Paraline that's about 7cm wide.

With such a narrow width, the HOMs are going to start around 0.5 milliseconds.

My Paralines were much larger; about twice the size. Due to that, the HOMs will start to occur around one millisecond.

I think that's the big difference. If you're going to make a Paraline, make it small, make it out of something that isn't porous. From looking at the Yorkville and VTC websites, it looks like the Paralines were wood at first (porous) but it appears they're aluminum or plastic now.

Non-porous is good. At the very least, if you're going to use wood, seal it.

Danley has confirmed this in posts in this thread. Porous = bad.

I think paraline could be improved by using only the outer parts of the curve,

thus you are getting better smear of reflections back at the throat. So, imagine

a centerless paraline, interleaved with another centerless paraline. Using solid

triangles to exclude the middle part of the parabola aimed back at the driver.

I think I tried to draw that earlier, but my drawing sucked to the point it was

not able to convey a convincing message.

The Cassegrain Smith thing has exit time smear going for it, but still has a bit

of center that might reflect back at the throat. And dubious arrayability that

makes centerless interleave beyond my immediate imagination. Not sure its

severe enough to worry about. We are bending away from the driver, making

for much less center than the paraline case. Experiment will tell.

thus you are getting better smear of reflections back at the throat. So, imagine

a centerless paraline, interleaved with another centerless paraline. Using solid

triangles to exclude the middle part of the parabola aimed back at the driver.

I think I tried to draw that earlier, but my drawing sucked to the point it was

not able to convey a convincing message.

The Cassegrain Smith thing has exit time smear going for it, but still has a bit

of center that might reflect back at the throat. And dubious arrayability that

makes centerless interleave beyond my immediate imagination. Not sure its

severe enough to worry about. We are bending away from the driver, making

for much less center than the paraline case. Experiment will tell.

Last edited:

I think paraline could be improved by using only the outer parts of the curve,

thus you are getting better smear of reflections back at the throat. So, imagine

a centerless paraline, interleaved with another centerless paraline. Using solid

triangles to exclude the middle part of the parabola aimed back at the driver.

The reticulated foam that Geddes uses could help a lot.

I have a thread called "homster" where I filled a diffraction horn with reticulated foam and the difference was dramatic.

IMHO, the foam that Geddes uses works more dramatically on bad horns than good horns.

You *will* lose a lot of efficiency when you apply it to a diffraction horn, but we have efficiency to burn when we use a compression driver.

The reticulated foam that Geddes uses could help a lot.

I have a thread called "homster" where I filled a diffraction horn with reticulated foam and the difference was dramatic.

IMHO, the foam that Geddes uses works more dramatically on bad horns than good horns.

You *will* lose a lot of efficiency when you apply it to a diffraction horn, but we have efficiency to burn when we use a compression driver.

I suggested much the same in #708

An externally hosted image should be here but it was not working when we last tested it.

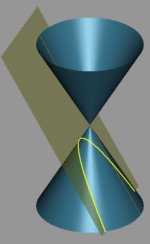

I'm curious if something like the Duevel horn could work.

The Duevel eliminates the 180 degree bends of the Paraline.

I heard their speakers about nine years ago, and they were the company that got me interested in BMS compression drivers. I don't think that omnipolar is the way to go, but you could make them cardioid fairly easily, using the reticulated foam.

Yes, it works just like a 360 degree bent version of the "Smith" horn, AKA the DSH (diffraction) horn.I'm curious if something like the Duevel horn could work.

"Bend me, shape me, any way you want me, long as you love me, it's alright"...

Lyrics from the band "American Breed".

Art

Last edited:

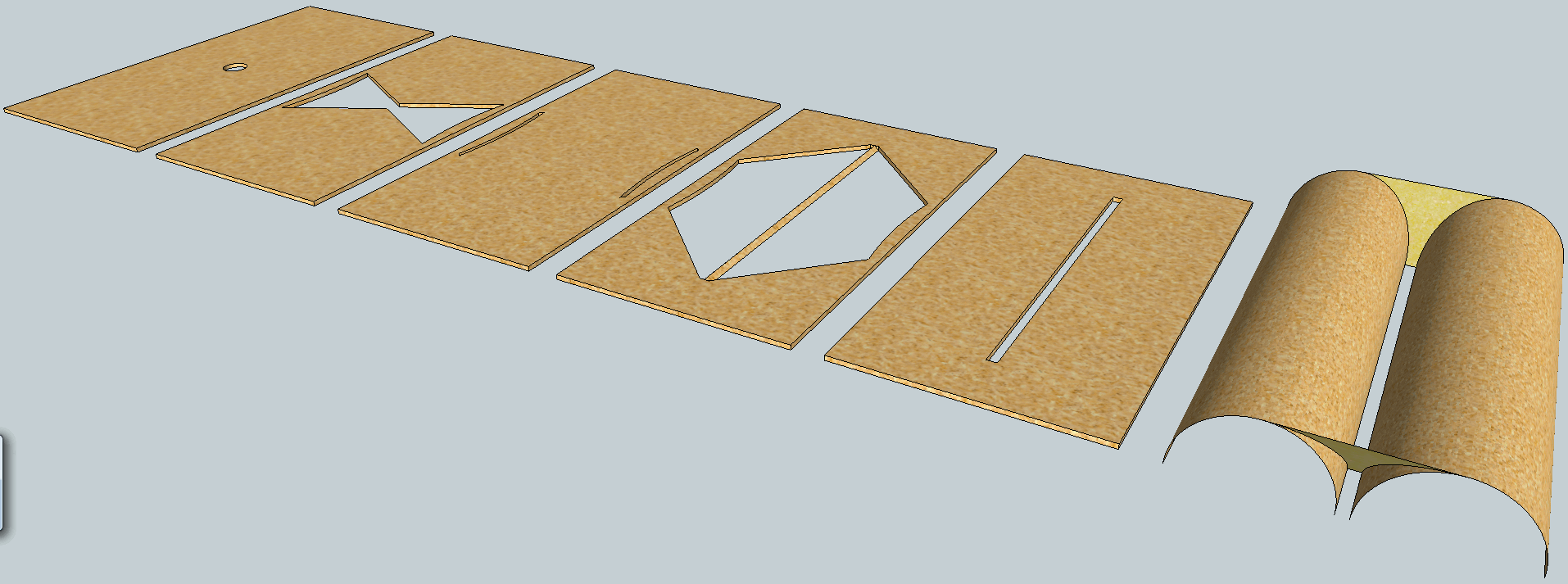

DOSC a looks reasonably simple phase plug to cut.

A cone with two parabolic slices that meet in the middle.

For a flat sound bubble: From above should look like a diamond.

Sum of edges of the symmetrical diamond the same as the apex

of the cone to the cone's rim (triangle as-if seen from the side).

For curved bubble: The center of that diamond shifts backward

toward the driver. To shorten the middle paths by the amount

you want the bubble's center to lead. If you want to tilt the aim

above or below center, I'm not sure if thats a flat cut anymore?

If you squash the cone infinately short and flat, strangely it may

eventually become the same thing as paraline. You can only guess

from the shape of the parabola and the sound bubble wether and

how far the centerline of the DOSC diamond is virtually displaced.

A cone with two parabolic slices that meet in the middle.

For a flat sound bubble: From above should look like a diamond.

Sum of edges of the symmetrical diamond the same as the apex

of the cone to the cone's rim (triangle as-if seen from the side).

For curved bubble: The center of that diamond shifts backward

toward the driver. To shorten the middle paths by the amount

you want the bubble's center to lead. If you want to tilt the aim

above or below center, I'm not sure if thats a flat cut anymore?

If you squash the cone infinately short and flat, strangely it may

eventually become the same thing as paraline. You can only guess

from the shape of the parabola and the sound bubble wether and

how far the centerline of the DOSC diamond is virtually displaced.

Attachments

Last edited:

The higher order modes are going to get generated by the 180 degree bend in the Paraline.

Danley's latest design uses a Paraline that's about 7cm wide.

With such a narrow width, the HOMs are going to start around 0.5 milliseconds.

My Paralines were much larger; about twice the size. Due to that, the HOMs will start to occur around one millisecond.

I think that's the big difference. If you're going to make a Paraline, make it small, make it out of something that isn't porous. From looking at the Yorkville and VTC websites, it looks like the Paralines were wood at first (porous) but it appears they're aluminum or plastic now.

Non-porous is good. At the very least, if you're going to use wood, seal it.

Danley has confirmed this in posts in this thread. Porous = bad.

Thanks for the summary Patrick! I'm going to try with some hardboard at some point, as it's smooth, and relatively easy to smooth any cuts with some fine-grained sandpaper. It's thin too.

"Bend me, shape me, any way you want me, long as you love me, it's alright"

Art

Ok, so I'm ready to experiment.

I have:

* Multiple sheets of Elmer's Foam Core Board

* 2 FaitalPRO 3FE25s

* 2 Pyle Pro compression drivers (PDS521)

* 2 Eminence Alpha 8as

* 8 6.5" Polycone woofers (the ones from Parts Express)

Aims:

* Point Source

* Mid and high frequency coverage like a Synergy horn

* Reasonable pattern control - let's say 350Hz

* Sensitivity around 90-100dB

350Hz = 38.63 inches...possibly too big? 8 inches wide, 16 inches high?

I have:

* Multiple sheets of Elmer's Foam Core Board

* 2 FaitalPRO 3FE25s

* 2 Pyle Pro compression drivers (PDS521)

* 2 Eminence Alpha 8as

* 8 6.5" Polycone woofers (the ones from Parts Express)

Aims:

* Point Source

* Mid and high frequency coverage like a Synergy horn

* Reasonable pattern control - let's say 350Hz

* Sensitivity around 90-100dB

350Hz = 38.63 inches...possibly too big? 8 inches wide, 16 inches high?

The Danley Paralines are between 6" and 8" tall.

Is a 16" Paraline too big?

IMHO, it is.

Follow in Danley's footsteps...

Here's a pair of paralines in the VTC EL210, each Paraline is about 6" tall.

Here's a pair of Paralines in the Yorkville PSA1. Eadch Paraline is (you guessed it) about 6" tall.

Is a 16" Paraline too big?

IMHO, it is.

Follow in Danley's footsteps...

Here's a pair of paralines in the VTC EL210, each Paraline is about 6" tall.

An externally hosted image should be here but it was not working when we last tested it.

Here's a pair of Paralines in the Yorkville PSA1. Eadch Paraline is (you guessed it) about 6" tall.

Kenpeter,

This design looks really cool, where would you suggest mid injection ports be located? Perhaps in the middle of the triangular area expanding immediately after the CD inlet? This looks like something fun to try in foam core. The semi porous foam edges can be sealed with PVA glue or even hot melt glue. Could a cheap Mylar tweeter be used rather than a CD? I so have a question though, shouldn't the first 180 fold be shaped like an arc with radius equal to distance from CD inlet to ensure the equidistant requirement for flow paths?

Last edited:

Turn everything you know on its side. Its not a paraline, its a Smith horn.

It features non-equidistant path lengths and is not a line source on purpose.

The curve of the fold bends away to match the 45 degree triangle to the 90.

Waveform leaves the front slot in a curved 90 degree horizontal arc. Put the

mids wherever. I left you lots of options including to hide mids under the tubes

and insert after the fold. But depending your xover point, maybe thats too far

from the throat and you need to go to the backside. I was shooting for 3fe22 by

itself, maybe close to full range with no synergy xover if the Faital can handle it.

Crossed conventionally to my 18" Karlson sub in a whole other cabinet.

-----

16" Paraline too big? I dunno about that. Zobsky and I built one nearly 2 feet

tall whilst drunk and totally slopped the internal measurements, and it still

turned out fine. The highest highs are a little attenuated, but I have to blame

our own imprecision and use of random scrap material, not size of the exit.

That one was loaded with an old style 50oz Eminence compression driver.

-----

I predict Elmers foam core will be too soft. You should at least make the middle

layer of something much denser, like hardboard. And the outside layers too if

possible. Layers with the hollow eye shaped cutouts are probably OK in foam,

especially if you are willing to glaze over the exposed foam edges with glue.

If the middle layer is not dense enough: Some treble will leak straight through

and interfere with treble taking the long path around.

It features non-equidistant path lengths and is not a line source on purpose.

The curve of the fold bends away to match the 45 degree triangle to the 90.

Waveform leaves the front slot in a curved 90 degree horizontal arc. Put the

mids wherever. I left you lots of options including to hide mids under the tubes

and insert after the fold. But depending your xover point, maybe thats too far

from the throat and you need to go to the backside. I was shooting for 3fe22 by

itself, maybe close to full range with no synergy xover if the Faital can handle it.

Crossed conventionally to my 18" Karlson sub in a whole other cabinet.

-----

16" Paraline too big? I dunno about that. Zobsky and I built one nearly 2 feet

tall whilst drunk and totally slopped the internal measurements, and it still

turned out fine. The highest highs are a little attenuated, but I have to blame

our own imprecision and use of random scrap material, not size of the exit.

That one was loaded with an old style 50oz Eminence compression driver.

-----

I predict Elmers foam core will be too soft. You should at least make the middle

layer of something much denser, like hardboard. And the outside layers too if

possible. Layers with the hollow eye shaped cutouts are probably OK in foam,

especially if you are willing to glaze over the exposed foam edges with glue.

If the middle layer is not dense enough: Some treble will leak straight through

and interfere with treble taking the long path around.

Last edited:

Zobsky and I built one nearly 2 feet

tall whilst drunk and totally slopped the internal measurements, and it still

turned out fine.

You guys have way too much fun.

This seems to be an exciting next project that is quick and easy. Can't wait to start...

- Home

- Loudspeakers

- Multi-Way

- Square Pegs