See how it goes once the bits arrive...

Basic idea for an MDF template... would make the spiral & outer walls 15mm thick.

Seems a shame to hide it in MDF... maybe perspex sides to allow it to be seen?

Jonnoshore,

Neat idea. What this does is to completely change the alignment to a spiral TL with driver located in an enlarged midpoint. It will have more bass extension of course, but the smooth curves leading to the horn mouth will let a lot of HF and mids escape and mess with coherence of the single point source. A model of this would help to determine what the overall spiral lengths (going inwards as well as out and final expansion opening). You may just build one for fun and let us know how it sounds.

Neat idea. What this does is to completely change the alignment to a spiral TL with driver located in an enlarged midpoint. It will have more bass extension of course, but the smooth curves leading to the horn mouth will let a lot of HF and mids escape and mess with coherence of the single point source. A model of this would help to determine what the overall spiral lengths (going inwards as well as out and final expansion opening). You may just build one for fun and let us know how it sounds.

BMS,

If you have a table jig saw Perspex (Plexiglas) cuts very cleanly and easily like butter. A disc sander can really clean up the edges and if you buff it you can get glossy edges too. It sort of prevents you from putting any damping material in there as that would spoil the look.

You may want to make the middle MDF layer to serve as ribs in the radial direction to reduce panel vibrations on the curves walls once all bonded together. Although 1 inch is too thick, perhaps use a thin 1/4 in thick plywood sheet (or Masonite as it stronger than thin MDF) as the middle "rib" layer and you could scroll cut lots of cool curved braces like how I cut all the individual foam braces.

If you have a table jig saw Perspex (Plexiglas) cuts very cleanly and easily like butter. A disc sander can really clean up the edges and if you buff it you can get glossy edges too. It sort of prevents you from putting any damping material in there as that would spoil the look.

You may want to make the middle MDF layer to serve as ribs in the radial direction to reduce panel vibrations on the curves walls once all bonded together. Although 1 inch is too thick, perhaps use a thin 1/4 in thick plywood sheet (or Masonite as it stronger than thin MDF) as the middle "rib" layer and you could scroll cut lots of cool curved braces like how I cut all the individual foam braces.

X... neat idea about the thinner middle layer for the bracing. Would be easy enough to do. Will investigate specific cutting blades for the Perspex... maybe an all Perspex model just for show!?

Mad idea.. saw the early post of the exploded diagram from a B&W patent for the rear wave guide/ TL guide, and got thinking about a basic rear wave guide to help focus & direct the sound wave rearward... don't even now if something like this would work or already tried and junked!?

Mad idea.. saw the early post of the exploded diagram from a B&W patent for the rear wave guide/ TL guide, and got thinking about a basic rear wave guide to help focus & direct the sound wave rearward... don't even now if something like this would work or already tried and junked!?

Attachments

An all Perspex see through Nautaloss would be very cool indeed. In this case the spiral walls can be formed by warming the Perspex in an oven then bending it to fit into a jig or fixture made from jig sawed mdf. Tinted smoke colored side walls and maybe contrasting blue tinted or pink tinted curved walls.

I am not sure there is any point in the radially curved channels that B&W used - although one way to make it is same as making the Cornu except the spirals are closed on the edges with a taper. I guess it lets one make a flat wall mount Nautaloss. You will need a deflector cone behind the driver to prevent the first reflection back to driver though.

I am not sure there is any point in the radially curved channels that B&W used - although one way to make it is same as making the Cornu except the spirals are closed on the edges with a taper. I guess it lets one make a flat wall mount Nautaloss. You will need a deflector cone behind the driver to prevent the first reflection back to driver though.

Transparent smoked with blue tinted inner would be awesome ... Pimp my Nautaloss

From what I gather, the curved channels act as multiple small TL's. B&W still use it on the backs of their CT800 series tweeter & midrange drivers, plus in automotive installations where rear space is limited...

Tried that little experiment from the B&W vid with a spiral shape. It was great to watch the ripples in the water, they looked like they were draw into the spiral, away from the source of agitation.

From what I gather, the curved channels act as multiple small TL's. B&W still use it on the backs of their CT800 series tweeter & midrange drivers, plus in automotive installations where rear space is limited...

Tried that little experiment from the B&W vid with a spiral shape. It was great to watch the ripples in the water, they looked like they were draw into the spiral, away from the source of agitation.

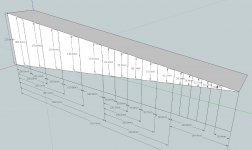

Tonight, I've had the pleasure of sitting down and doing the first drawing of the spiral on paper. Using the 5"x9" baffle and 36" length for the TL, I put together a SketchUp to help with measurements...

Doing a direct translation of these measures to paper makes for a larger enclosure, roughly 12" x 16". X, I'll use your drawings for the FC build, but use these for the MDF build.

Spiral still looks amazing and very close to the SketchUp drawings done so far. It just looses ~45° of spiral at the thin end, and the expansion of the chamber mimics the triangle shape.

Doing a direct translation of these measures to paper makes for a larger enclosure, roughly 12" x 16". X, I'll use your drawings for the FC build, but use these for the MDF build.

Spiral still looks amazing and very close to the SketchUp drawings done so far. It just looses ~45° of spiral at the thin end, and the expansion of the chamber mimics the triangle shape.

Attachments

BMS,

You know, the length and exact geometry of that spiral is not all that important - just approximate is good enough because the purpose is for it to gradually taper and absorb that back wave. The overall volume to provide sufficient bass extension or cone excursion control is probably more important. If you want to maintain overall envelope dimensions first then do that and force the spiral to conform. That is what I did. I defined the envelope the hand sketched the spiral and it just all worked out. But my sims confirm that 3 or 5 inches longer or shorter is no big deal. Do what is easy and looks good. Check the volume to match the Vb you want for an equivalent sealed alignment.

The dagger you drew looks good btw. Someone should try it to see how it sounds. Probably just as good.

You know, the length and exact geometry of that spiral is not all that important - just approximate is good enough because the purpose is for it to gradually taper and absorb that back wave. The overall volume to provide sufficient bass extension or cone excursion control is probably more important. If you want to maintain overall envelope dimensions first then do that and force the spiral to conform. That is what I did. I defined the envelope the hand sketched the spiral and it just all worked out. But my sims confirm that 3 or 5 inches longer or shorter is no big deal. Do what is easy and looks good. Check the volume to match the Vb you want for an equivalent sealed alignment.

The dagger you drew looks good btw. Someone should try it to see how it sounds. Probably just as good.

Think I've got it now... So if I need a Vb of 5L or 6.4L for a specific driver, I just decrease/increase the envelope size and squeeze in the spiral so its volume matches the required Vb... Your 5"x9"x12" gives a Vb of ~5.4L (?) compared to 13.3L for the dagger [(5"x9"x36")/ 2]...

Intentional or not, to get the spiral squeezed into the box dimensions, it roughly follows the golden section ratio thingy. Which makes volume calculations much easier

Intentional or not, to get the spiral squeezed into the box dimensions, it roughly follows the golden section ratio thingy. Which makes volume calculations much easier

Acoustics and Phi, the Golden RatioBMS,

What do you mean by it follows golden ratio - you mean the 9 x 12 envelope?

I am not asking what is the GR, I know that - I just don't see how it shows up when you add the spiral walls. The GR is meant to prevent standing waves and resonances because there are non integer ratios so that the eigenvalues for the modes can't easily form. That is the point of the tapered spiral - to suppress that min the first place.

Last edited:

The importance of the golden ratio, in fact, its very value in speaker design is way overblown. The golden ratio, which is the limit of the Fibonacci series for those who don't know, is simply the most irrational number there is. The importance to the Greeks was that any rectangle with a ratio less than the golden ratio was "uninteresting". In speaker design, using the golden ratio guarantees the least possibility of constructive harmonics. Any irrational number will produce the same results, starting with 2^0.5. Basically, avoid 1/1 and 1/2 ratios and you will be OK if there is any damping in the box at all. Indeed, I have build several MLTL's with 1/1 cross-sections and once lined with fiberglass, there is no hint of a peak or valley at the expected frequency.

Bob

Bob

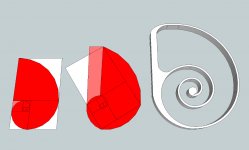

Ouch... sorry X, I meant the path of the spiral resembles a Golden Ratio spiral. The outer wall certainly does, but to get the required length of pathway squeezed into the envelope calls for tighter internal curves than GR spiral gives.

Translating the dagger shape into a spiral hits the GR bang-on. I'll take a few photo's of the curves I've drawn and compare them with the required spiral pathway for the Nautaloss.

Looking ahead, an outer curve generated by utilising the GR would give a real smooth outer line, then free licence on the inner spiral to get the pathway in. My FC and Faital Pro 4FE32's have arrived at my parents and I'll go collect them in the morning

Also, using my new found wood working skills to make some cupboard doors for the Parents. Needed two 2'x4' sheets, but it's cheaper to get a single 4'x8' and have it cut down. I get the cut-offs as payment which will go towards the MDF version

Translating the dagger shape into a spiral hits the GR bang-on. I'll take a few photo's of the curves I've drawn and compare them with the required spiral pathway for the Nautaloss.

Looking ahead, an outer curve generated by utilising the GR would give a real smooth outer line, then free licence on the inner spiral to get the pathway in. My FC and Faital Pro 4FE32's have arrived at my parents and I'll go collect them in the morning

Also, using my new found wood working skills to make some cupboard doors for the Parents. Needed two 2'x4' sheets, but it's cheaper to get a single 4'x8' and have it cut down. I get the cut-offs as payment which will go towards the MDF version

Last edited:

BMS,

Ok I see you mean a Fibonacci spiral - same as GR spiral. That would work really well as a horn even. Good deal on getting free cut-off wood for your speakers. Looking forward to see what you come up with. You will be quite amazed at the smoothness when you measure it for the first time.

Ok I see you mean a Fibonacci spiral - same as GR spiral. That would work really well as a horn even. Good deal on getting free cut-off wood for your speakers. Looking forward to see what you come up with. You will be quite amazed at the smoothness when you measure it for the first time.

Really looking forward to hearing them. Going to try both the Vifa and Faital Pro units, but will probably use the Faital Pro units for the MDF build...

Yes, the Fibonacci spiral, I really should try a little harder with my descriptions... Doing a SketchUp comparison is much easier

Yes, the Fibonacci spiral, I really should try a little harder with my descriptions... Doing a SketchUp comparison is much easier

Attachments

idea...

If the outside edge was made with flexi plywood... and the inner spiral was made with foam core the baffle and sides could be made with Thick MDF with the channels cut or routed to accept the ply or the foam core inner... this may be the quickest way to make these and make them look half decent as a "propper" pair of speakers? Thoughts? They could also be clamped side to side with bolts if needed to make them tuneable to get the stuffing correct maybe and help damp the sides panels, just an idea...

Nice CAD work BMS.

John

Really looking forward to hearing them. Going to try both the Vifa and Faital Pro units, but will probably use the Faital Pro units for the MDF build...

Yes, the Fibonacci spiral, I really should try a little harder with my descriptions... Doing a SketchUp comparison is much easier

If the outside edge was made with flexi plywood... and the inner spiral was made with foam core the baffle and sides could be made with Thick MDF with the channels cut or routed to accept the ply or the foam core inner... this may be the quickest way to make these and make them look half decent as a "propper" pair of speakers? Thoughts? They could also be clamped side to side with bolts if needed to make them tuneable to get the stuffing correct maybe and help damp the sides panels, just an idea...

Nice CAD work BMS.

John

Jonnoshore,

Good idea with flexible or bendy ply (or bendy mdf) for the curved walls and FC internally as the bends get tight. This speaker would look really nice finished in wood with the very organic shape. Granite side walls and hardwood front baffle would look very cool. Even slate or soapstone could be used. You just need a kitchen counter top granite shop to cut the sides. As BMS said, you could really pimp out your Nautaloss.

Good idea with flexible or bendy ply (or bendy mdf) for the curved walls and FC internally as the bends get tight. This speaker would look really nice finished in wood with the very organic shape. Granite side walls and hardwood front baffle would look very cool. Even slate or soapstone could be used. You just need a kitchen counter top granite shop to cut the sides. As BMS said, you could really pimp out your Nautaloss.

- Home

- Loudspeakers

- Full Range

- The Nautaloss Ref Monitor