0.40x with visaton frs8 impressions

I' ve just finished my mini karlsonators. I used visatons frs8 driver that I removed from my needles in order to paint them.

I was very pleased with them and I decided to built the mini k's as a test built, before I go for the biggest 0.53 with dual 3FE25 drivers.

My impressions:

1. Build process:

a. Foamboard is quite expensive here in Greece, I should had built them out of plywood.

b. Working with foam was quite awkward and I ve found it difficult to maintain straight cuts.

c. I used white glue cause that was available and I didn't want to spent money on this.

2. Listening impressions:

For now I am listening to them without the K aperture, as I ve run out of foam. They sound good even without it, but cannot tell till they are finished. I ll post more when I am ready.

I' ve just finished my mini karlsonators. I used visatons frs8 driver that I removed from my needles in order to paint them.

I was very pleased with them and I decided to built the mini k's as a test built, before I go for the biggest 0.53 with dual 3FE25 drivers.

My impressions:

1. Build process:

a. Foamboard is quite expensive here in Greece, I should had built them out of plywood.

b. Working with foam was quite awkward and I ve found it difficult to maintain straight cuts.

c. I used white glue cause that was available and I didn't want to spent money on this.

2. Listening impressions:

For now I am listening to them without the K aperture, as I ve run out of foam. They sound good even without it, but cannot tell till they are finished. I ll post more when I am ready.

I' ve just finished my mini karlsonators. I used visatons frs8 driver that I removed from my needles in order to paint them.

I was very pleased with them and I decided to built the mini k's as a test built, before I go for the biggest 0.53 with dual 3FE25 drivers.

My impressions:

1. Build process:

a. Foamboard is quite expensive here in Greece, I should had built them out of plywood.

b. Working with foam was quite awkward and I ve found it difficult to maintain straight cuts.

c. I used white glue cause that was available and I didn't want to spent money on this.

2. Listening impressions:

For now I am listening to them without the K aperture, as I ve run out of foam. They sound good even without it, but cannot tell till they are finished. I ll post more when I am ready.

Thanks for sharing and for trying. The foam board makes a difference in sound quality. Plywood does not sound as good.

In US, foam boards are 20in x 30in and $1 ea at Dollar Stores. Nice quality Elmers brand is $6 sheet and much more durable and harder to cut.

Cutting straight requires laying on carpeted floor, use nice metal straightedge like drywall ruler, use sharp utility knife with new edge (breakaway type blades are perfect for this). Cut 3-5 strokes deeper each time to make clean cuts. Takes practice but is far easier than pulling out a table saw and making dust.

Use hot melt glue to tack pieces together and PVA to seal. Hot melt is key because your hands are the "clamps" that hold it until it sets in 40 seconds. Other glues require clamps to hold for hours.

It does sound quite good without K aperture. Bass will be deeper and soundstage will be wider and more uniform with aperture.

yianemma (and others on the sidelines)

Lots of good stuff from xrk!!! He's the master of this format!!

Two Main Things from this last post!

>>Cut 3-5 strokes deeper each time to make clean cuts.<< with a fresh razor edge

>>Use hot melt glue to tack pieces together and PVA to seal. Hot melt is key because your hands are the "clamps" that hold it until it sets in 40 seconds.<<

If you follow those two hints, your chances for a quick, neat, successful build are greatly enhanced.

Thanks xrk for all your knowledge, efforts, and enthusiasm in promoting this design!!

Lots of good stuff from xrk!!! He's the master of this format!!

Two Main Things from this last post!

>>Cut 3-5 strokes deeper each time to make clean cuts.<< with a fresh razor edge

>>Use hot melt glue to tack pieces together and PVA to seal. Hot melt is key because your hands are the "clamps" that hold it until it sets in 40 seconds.<<

If you follow those two hints, your chances for a quick, neat, successful build are greatly enhanced.

Thanks xrk for all your knowledge, efforts, and enthusiasm in promoting this design!!

Last edited:

Thanks xrk for all your knowledge, efforts, and enthusiasm in promoting this design!!

I second that.

Still enjoying the dual 3FE25-16 0.53X Mini Karlsonators.

I've tried to look through the thread for a drawing of the .53 in centimeters, I can find a lot of good drawings for the .40 but not for the .53 , have I missed something?

hehejaa,

you'll find them in post #1, I had to look thru it a few times myself in order to track it down...

Post 198 has a nice CAD drawing of the dual driver 0.53x plans by Tb46.

diyAudio

and while that's a nice representation, with all the correct dimensions, I had some difficulty with the darned pdf and how troublesome it is to scale it up to a nice readable, PRINTABLE file. Curse you Adobe!!

Do yourself a favor and print MudJester's .40 Karlsonator referenced in line 1 of post #1 for how it SHOULD be done. (Thanks Mike!) By studying both plans, you'll give yourself a clear plan of action for your own build.

Latest 0.40x K'nator Score-N-Fold Plans by Mudjester available here: Mini Karlsonator (0.53X) with Dual TC9FD's

Best of Luck!

hehejaa,

you'll find them in post #1, I had to look thru it a few times myself in order to track it down...

Post 198 has a nice CAD drawing of the dual driver 0.53x plans by Tb46.

diyAudio

and while that's a nice representation, with all the correct dimensions, I had some difficulty with the darned pdf and how troublesome it is to scale it up to a nice readable, PRINTABLE file. Curse you Adobe!!

Do yourself a favor and print MudJester's .40 Karlsonator referenced in line 1 of post #1 for how it SHOULD be done. (Thanks Mike!) By studying both plans, you'll give yourself a clear plan of action for your own build.

Latest 0.40x K'nator Score-N-Fold Plans by Mudjester available here: Mini Karlsonator (0.53X) with Dual TC9FD's

Best of Luck!

yianemma (and others on the sidelines)

>>Use hot melt glue to tack pieces together and PVA to seal. Hot melt is key because your hands are the "clamps" that hold it until it sets in 40 seconds.<<

Mainly this, as my cuts were clean and straight. My main problem was that I tried to cut the foam from side to side, so I started from 165 mm and ended to 162mm. Filling the gaps took me some time. I used PVA for the side, no problem with this. Pins were used to keep the pieces in place.

I have to say that not using hot glue helped me to make some adjustments while the glue was drying.

I have just finished the K Apertures, placed them in place with pins and plastic tape for testing. They do make a difference, although they vibrate enough since they are not glued.

I really like them. For sure they beat my three 5.1 systems.

Soundstage is big!!!, it feels like sound is coming through the back wall. I have to cross them with my (cheap) sub about 80 Hz for best results, but depending on the music, I could skip that.

/

The other thing I noticed is that radio music is not so annoying to my ears with these speakers. They are more balanced, more relaxing.

They also seem to fill the room with music. The sound is everywhere, it is not pointing in a sitting location. I can move and still here the same thing.

I was impressed when I listened to the first seconds of Pink Floyd's "Money". Stereo image was very good, music was travelling from right to left and back.

I cannot decide if the needles sounded better than these. Its the same driver in different enclosures, but I prefer these, as long as they are matched with a sub.

Just one question please. Would it be OK to apply some leather coating on the speakers?

Mainly this, as my cuts were clean and straight. My main problem was that I tried to cut the foam from side to side, so I started from 165 mm and ended to 162mm. Filling the gaps took me some time. I used PVA for the side, no problem with this. Pins were used to keep the pieces in place.

I have to say that not using hot glue helped me to make some adjustments while the glue was drying.

I have just finished the K Apertures, placed them in place with pins and plastic tape for testing. They do make a difference, although they vibrate enough since they are not glued.

I really like them. For sure they beat my three 5.1 systems.

Soundstage is big!!!, it feels like sound is coming through the back wall. I have to cross them with my (cheap) sub about 80 Hz for best results, but depending on the music, I could skip that.

/

The other thing I noticed is that radio music is not so annoying to my ears with these speakers. They are more balanced, more relaxing.

They also seem to fill the room with music. The sound is everywhere, it is not pointing in a sitting location. I can move and still here the same thing.

I was impressed when I listened to the first seconds of Pink Floyd's "Money". Stereo image was very good, music was travelling from right to left and back.

I cannot decide if the needles sounded better than these. Its the same driver in different enclosures, but I prefer these, as long as they are matched with a sub.

Just one question please. Would it be OK to apply some leather coating on the speakers?

Sounds like a success to me. Make the K apertures double thickness of foam and that helps reduce vibrations. Certainly leather is nice but may change the character of the sound as the foam box walls emits some sound for the ambiance. You may be the first with a leather Karlsonator.

I've tried to look through the thread for a drawing of the .53 in centimeters, I can find a lot of good drawings for the .40 but not for the .53 , have I missed something?

hehejaa,

you'll find them in post #1, I had to look thru it a few times myself in order to track it down...

Post 198 has a nice CAD drawing of the dual driver 0.53x plans by Tb46.

diyAudio

and while that's a nice representation, with all the correct dimensions, I had some difficulty with the darned pdf and how troublesome it is to scale it up to a nice readable, PRINTABLE file. Curse you Adobe!!

Do yourself a favor and print MudJester's .40 Karlsonator referenced in line 1 of post #1 for how it SHOULD be done. (Thanks Mike!) By studying both plans, you'll give yourself a clear plan of action for your own build.

Latest 0.40x K'nator Score-N-Fold Plans by Mudjester available here: Mini Karlsonator (0.53X) with Dual TC9FD's

Best of Luck!

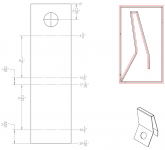

I still have my x0.4 files. It would be easy to re-scale it to x0.53 and make a new drawing. I can also make it inches or mm very easily. The k-aperature probably wouldn't fit on a single page anymore at 1:1. And I don't know if score-and-fold would still make sense, but I can give it a try.

Would anyone be interested in that?

Edit: Oh, looks like I already started. Worth completing?

Attachments

Last edited:

Absolutely, would be useful for sure .I still have my x0.4 files. It would be easy to re-scale it to x0.53 and make a new drawing. I can also make it inches or mm very easily. The k-aperature probably wouldn't fit on a single page anymore at 1:1. And I don't know if score-and-fold would still make sense, but I can give it a try.

Would anyone be interested in that?

Edit: Oh, looks like I already started. Worth completing?

I noticed a difference in the .40 and the .53 also, the .40 is as wide as it is deep while the .53 is deepter then its wide from the drawings I have seen, is that for any specific reason?

I finished them!!! K aperture is glued and sound is awsome. Much better now, xrk thank you again. Very rich bass, pleasant and relaxing. The only thing I noticed is that voices seem to come from a tunnel or a cave, but only in some songs.

Right now I am building a temporary case from the spare foamboard for my tda.

For now the visatons stay in the karlsonators. Needles need sanding amd painting.

Soon I ll go for the dual 3fe25 in 0.53x.

Right now I am building a temporary case from the spare foamboard for my tda.

For now the visatons stay in the karlsonators. Needles need sanding amd painting.

Soon I ll go for the dual 3fe25 in 0.53x.

Yianemma,

Nice work! If you line the inside of the front chamber with thick (real) felt (sides, back of K aperture, and angled panel above the driver), it will really help reduce the tunnel sound effect. Alternative to felt is BASF acoustic sound abatement foam made of open cell reticulated melamine foam. This foam can also be found as "Magic Erasor" pads for household cleaning of stains on walls and appliances.

60 BULK PACK Cleaning Magic Sponge Eraser Melamine Cleaner multi-functional foam | eBay

Prices from China are unbelievable - qnty 100 for $5 shipping included.

100x Multiuse Magic Sponge Eraser Kitchen Cleaning Melamine Foam Cleaner Healthy | eBay

It absorbs sound better than anything else I have tried. You can take a sharp utlility knife and cut to thinner sheets. Cuts easily a hot knife through butter.

Nice work! If you line the inside of the front chamber with thick (real) felt (sides, back of K aperture, and angled panel above the driver), it will really help reduce the tunnel sound effect. Alternative to felt is BASF acoustic sound abatement foam made of open cell reticulated melamine foam. This foam can also be found as "Magic Erasor" pads for household cleaning of stains on walls and appliances.

60 BULK PACK Cleaning Magic Sponge Eraser Melamine Cleaner multi-functional foam | eBay

Prices from China are unbelievable - qnty 100 for $5 shipping included.

100x Multiuse Magic Sponge Eraser Kitchen Cleaning Melamine Foam Cleaner Healthy | eBay

It absorbs sound better than anything else I have tried. You can take a sharp utlility knife and cut to thinner sheets. Cuts easily a hot knife through butter.

Last edited:

I'm also considering building the dual 3fe25 in 0.53x for our living room. I'd like to dress the boxes up a bit. Has anyone tried a wood veneer over the foam board yet? Or should I go with thin plywood (aircraft grade or underlayment type) and veneer over that? May have to experiment to see what sounds best, unless anyone has any opinions???

@XRK971 can you suggest what thickness to cut the magic sponge foam to?Yianemma,

Nice work! If you line the inside of the front chamber with thick (real) felt (sides, back of K aperture, and angled panel above the driver), it will really help reduce the tunnel sound effect. Alternative to felt is BASF acoustic sound abatement foam made of open cell reticulated melamine foam. This foam can also be found as "Magic Erasor" pads for household cleaning of stains on walls and appliances.

60 BULK PACK Cleaning Magic Sponge Eraser Melamine Cleaner multi-functional foam | eBay

Prices from China are unbelievable - qnty 100 for $5 shipping included.

100x Multiuse Magic Sponge Eraser Kitchen Cleaning Melamine Foam Cleaner Healthy | eBay

It absorbs sound better than anything else I have tried. You can take a sharp utlility knife and cut to thinner sheets. Cuts easily a hot knife through butter.

I still have my x0.4 files. It would be easy to re-scale it to x0.53 and make a new drawing. I can also make it inches or mm very easily. The k-aperature probably wouldn't fit on a single page anymore at 1:1. And I don't know if score-and-fold would still make sense, but I can give it a try.

Would anyone be interested in that?

Edit: Oh, looks like I already started. Worth completing?

If you make .53x score and fold plans you'll be my hero

@XRK971 can you suggest what thickness to cut the magic sponge foam to?

Slice to half thickness or about 8mm to 12mm depending on sponge size. For regions like immediately adjacent to back of driver use full thickness.

If you make .53x score and fold plans you'll be my hero

Lol, sounds like there's a desire for it. I'll do it.

Since I'm not planning a build for myself right now, I'd love some input (to help with all the minor design decisions that goes into something like this). Should I do score-and-fold plans, as much as makes sense? How should I make the aperture diagrams (multiple sheets, larger sheet, scaled down image, any of these would have dimensions of course)? I'll do two versions, one in mm one in inches.

Any other requests? If I'm going to spend the time on this, I might as well do a good one.

XRK, do you know what the best aperture starting width, depth (straight portion), and distance down from the top is?

Thankyou Michael!

So glad that your arm was so easily twisted!!

I'm perfectly happy with metric dimensions...we North Americans should get in step and recognize the Benefit of a More Universal Language! (and milimeters nudges us so gently toward tighter tolerances)

I don't have much more to offer here other than the 20"x30" board might be the most easily sourced...

Let me close with

YOU'RE THE MAN!!!

So glad that your arm was so easily twisted!!

I'm perfectly happy with metric dimensions...we North Americans should get in step and recognize the Benefit of a More Universal Language! (and milimeters nudges us so gently toward tighter tolerances)

I don't have much more to offer here other than the 20"x30" board might be the most easily sourced...

Let me close with

YOU'RE THE MAN!!!

Well, just got my tax return, so going to start working on the 0.53x scale speakers. I'm going to use these primarily for music, maybe some home theater mains as well. If I need 8 ohms total, what would be my best bet in the $20-30 per speaker range? I was thinking either two per side of the TC9FD00-04 in series, or one of the PA-130 per side would work. The only thing I'm unsure of is how the 4 ohm TC9's compare to the 8 ohm versions we all know and love... Is there anything else around that price range from places like Parts Express that would be a good idea? I even was thinking maybe four of the TG9 since they are still $9 each over at Madisound.

Keep in mind I do tube amps primarily, so I have to stick to 8 ohm for the most part. 16 ohm total I can work with if I have to, but limits my options too much really... Although it gives a good excuse to build another amplifier i suppose

Partially related, but has anybody had experience with the TC10FG00-04? It looks like a potentially interesting driver for use in a 0.6x or so dual driver build, or maybe a 0.5x single...

Keep in mind I do tube amps primarily, so I have to stick to 8 ohm for the most part. 16 ohm total I can work with if I have to, but limits my options too much really... Although it gives a good excuse to build another amplifier i suppose

Partially related, but has anybody had experience with the TC10FG00-04? It looks like a potentially interesting driver for use in a 0.6x or so dual driver build, or maybe a 0.5x single...

Go with Qnty 2 x 3FE25 in 16ohms wired in parallel for 8ohms nominal. It will give you 97dB at 2.83v speakers which are very suitable for fleawatt tube amps. The 3FE25 sound great too and $19 ea. This was Skylar's setup and he loves it. I believe him.

FaitalPRO 3FE25 3" Professional Full-Range Woofer 16 Ohm

FaitalPRO 3FE25 3" Professional Full-Range Woofer 16 Ohm

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs