I have been thinking about suitable 18" speaker for my project.

Now comes to mind as a good compromise (Qts/Xmax) B&C 18PS100:

B&C 18PS100 18" 1400W SUBWOOFER

Any other suggestions? In the range of $300-$500 (max €450)

Thanks guys

Danny

Now comes to mind as a good compromise (Qts/Xmax) B&C 18PS100:

B&C 18PS100 18" 1400W SUBWOOFER

Any other suggestions? In the range of $300-$500 (max €450)

Thanks guys

Danny

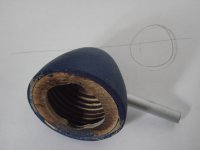

Guys I WANT TO ASK FOR ONE FAVOR FROM SOMEONE WHO HAS 168E Sigmas

I need to measure the thickness of the lip on the speaker front, marked on the picture...

O dont have the drivers here with me...

And I just came to the opportunity to have the enclosures made of wood, laminated, and finished on a very big lathe

If all goes well, should be finished within a month (as work permits, still on the business trip)

Please help with this.

Thank you very much

Danny

I need to measure the thickness of the lip on the speaker front, marked on the picture...

O dont have the drivers here with me...

And I just came to the opportunity to have the enclosures made of wood, laminated, and finished on a very big lathe

If all goes well, should be finished within a month (as work permits, still on the business trip)

Please help with this.

Thank you very much

Danny

Attachments

OK the wood is bought

Nice 3m2 of Russian (i hope) plywood 16mm thick, cut to 5 boards of 1.2x0.6m for transportation purposes. On some weekend will be the cutting done to many many rings....actually 72 of them

Can somebody help with the flush mount depth? I can remember it is something about 4mm but not 100% sure....

Danny

Nice 3m2 of Russian (i hope) plywood 16mm thick, cut to 5 boards of 1.2x0.6m for transportation purposes. On some weekend will be the cutting done to many many rings....actually 72 of them

Can somebody help with the flush mount depth? I can remember it is something about 4mm but not 100% sure....

Danny

Attachments

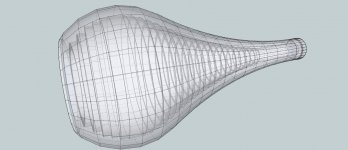

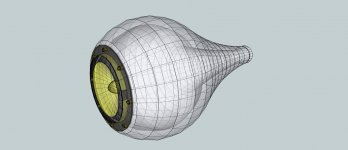

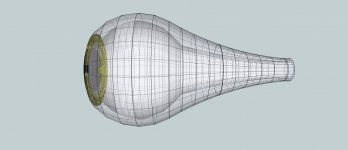

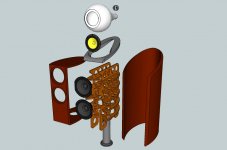

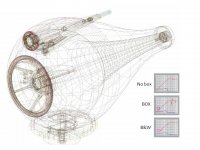

OK some updates:

- as per Planet10 (Dave) and his replies in other threads, I decided that the inside shape should be different than just scaled down version of the outside shape.

He suggested that it has as close as possible shape to B&W

- speaker cutout = inside sphere joining point to the tapered tube

- front half of inside sphere = back half of the same inside sphere

- closed enclosure, back part stuffed with some wool (tests must be done)

- the inside will be zigzag shape (?) because of the square nature of the cuts, but the space between the two cuts will be filled with filler. I am not sure if everybody gets it.

IF ANYBODY IS INTERESTED, I CAN SEND THEM THE CUTTING PLAN AND THE SKETCHUP DRAWINGS WHEN IT IS FINISHED. That means the sketchup contains all the measurements, so just take the sizes and off you go

I done a lot of reading on the B&W site, inspected the pictures, made measurements according to their drawings.... I hope it works

1pic=1000words:

- as per Planet10 (Dave) and his replies in other threads, I decided that the inside shape should be different than just scaled down version of the outside shape.

He suggested that it has as close as possible shape to B&W

- speaker cutout = inside sphere joining point to the tapered tube

- front half of inside sphere = back half of the same inside sphere

- closed enclosure, back part stuffed with some wool (tests must be done)

- the inside will be zigzag shape (?) because of the square nature of the cuts, but the space between the two cuts will be filled with filler. I am not sure if everybody gets it.

IF ANYBODY IS INTERESTED, I CAN SEND THEM THE CUTTING PLAN AND THE SKETCHUP DRAWINGS WHEN IT IS FINISHED. That means the sketchup contains all the measurements, so just take the sizes and off you go

I done a lot of reading on the B&W site, inspected the pictures, made measurements according to their drawings.... I hope it works

1pic=1000words:

Attachments

Last edited:

I remember seeing a youtube vid of a guy crafting a speaker enclosure out of a round block of wood by mounting the block to a machine that rotates (something like a horizontally mounted drill) and a crafting knife. Sorry I didn't take any woodwork class when I was in high school so I can't really recall what that is called.

joe58:

the filler will be applied on each part as I go, so i glue and clamp first and second ring together, apply filler, leave it dry, then sand it. Then another ring, apply filler ....etc

Boris:

yes, its called wood lathe (although its made of metal ), simply rotates the piece very fast and you can use hand tool for hand carving. My friend has just a lathe like this.

), simply rotates the piece very fast and you can use hand tool for hand carving. My friend has just a lathe like this.

During the work i will take many pictures, so you will se the procedure up close.

Danny

the filler will be applied on each part as I go, so i glue and clamp first and second ring together, apply filler, leave it dry, then sand it. Then another ring, apply filler ....etc

Boris:

yes, its called wood lathe (although its made of metal

During the work i will take many pictures, so you will se the procedure up close.

Danny

Yep I've done something similar for a year 12(17 years old for non uk peeps) project and I made these tiny(I had no idea of speaker building) curved enclosures. Lots of rings of ply laser cut and then wack it on the lathe. First time I had never used a lathe and found it very simple and therapeutic...

Edit: The image is part way through to being modified for something else, hence the new bit in the front and not finished.

Edit: The image is part way through to being modified for something else, hence the new bit in the front and not finished.

Attachments

Last edited:

started cutting some wood

well, some wood has been cut. Although only 6pcs as the rain started and I managed to break the router bit (c**p quality, will have to buy good one).

cutting is actually very fast, the setup takes longer time then cutting.

Some pics:

https://picasaweb.google.com/101292885356793975790/BWStyleFREnclosure?authuser=0&feat=directlink

well, some wood has been cut. Although only 6pcs as the rain started and I managed to break the router bit (c**p quality, will have to buy good one).

cutting is actually very fast, the setup takes longer time then cutting.

Some pics:

https://picasaweb.google.com/101292885356793975790/BWStyleFREnclosure?authuser=0&feat=directlink

Well, still waiting for good weather and weekend so I can cut the rest of the big circles for the teardrops. As of now, I only have 8 rings from 68

Getting back to basic design...802D clone that is.

The open baffles or ripoles would be nice and something unusual, but WAF kicked in, no space for them in my small apartment living room.

Some exploded view:

Getting back to basic design...802D clone that is.

The open baffles or ripoles would be nice and something unusual, but WAF kicked in, no space for them in my small apartment living room.

Some exploded view:

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- FE168E Sigma teardrop enclosure