stereodude27:

no decided yet, will be buying filler next week. you have any suggestion? remember, i am in europe (Sicilli, Catania right now)...

the enclosure wont be transmitting any low notes, so i think any filler should suffice.

Danny

I have no idea what kind of filler is available overseas. My first choice would be a marine epoxy.

If not, then I would suggest making friends with an auto body repair shop. They can possibly suggest something.

Cool build though.

Last edited:

bigfishe:

yes, smoothing the inside with some cheap filler, then line with epoxy as you suggested.

The outside will be smoothed out on a lathe, then of course filler. But I will give it to professionals in painting business.

or I hope I will ))

))

perhaps I will have a go on my own. And you two part filler (usually used on car bodies)

Danny

yes, smoothing the inside with some cheap filler, then line with epoxy as you suggested.

The outside will be smoothed out on a lathe, then of course filler. But I will give it to professionals in painting business.

or I hope I will

perhaps I will have a go on my own. And you two part filler (usually used on car bodies)

Danny

bigfishe

its just about 7 000 miles....that's nothing

I am thinking some beautiful pearl white (to please the wife).

cuttings come a long slowly, couple of rings per couple of days (work does not permit)

anyway, should make some update during the weekend (working weekend )

)

Danny

its just about 7 000 miles....that's nothing

I am thinking some beautiful pearl white (to please the wife).

cuttings come a long slowly, couple of rings per couple of days (work does not permit)

anyway, should make some update during the weekend (working weekend

Danny

bernardodda:

I want to line the inside with Dynamat (or similar) produkt so there is no need for really smooth surface. the dynamat has significant thicknes, what you suggest is a good idea, but labor intensive. and there is not that much time in my busy schedule...

but please keep the ideas flowing

I want to line the inside with Dynamat (or similar) produkt so there is no need for really smooth surface. the dynamat has significant thicknes, what you suggest is a good idea, but labor intensive. and there is not that much time in my busy schedule...

but please keep the ideas flowing

hello everybody, update time:

The tom shells are done, the rough part anyway. next week i take them to a workshop for final shape turning. then off to painting. Stainless steel back end tubes are done, Delta 12 LF drivers ordered for the FAST part of the speaker.

I will post some pics of the shells when i get to hotel.

Danny

The tom shells are done, the rough part anyway. next week i take them to a workshop for final shape turning. then off to painting. Stainless steel back end tubes are done, Delta 12 LF drivers ordered for the FAST part of the speaker.

I will post some pics of the shells when i get to hotel.

Danny

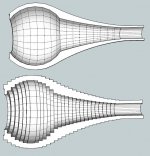

Nice work Barakuda. What about making teardrop out of ceramic or clay with potters wheel? What if you could find similar vase in store and modify? Of course it won't have profile to match B&W. The shape is really to prevent any back reflections like a semi infinite tube, not sure if exact profile is critical, volume probably more important.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- FE168E Sigma teardrop enclosure