Very interesting, any idea on what something like this might cost?

The cost will depend on several factors..

I tried to get most of the parts (except the diaphragm) manufactured in China / Taiwan, but I was not able to get the quality I wanted.

I ended up with production of the metal parts in Norway (and bought special stamping tools to get the needed quality), the holding / folding box for the diaphragm are made by a German company by 3D CNC and are made of "pertinax".

Only the neodym N52 magnets are manufactured in China.

You then add Norwegian labour cost for the assembly of the parts..

As it is now the AMTs will be expensive...

Hi Ray!

Congrat´s with this extremely interesting project. Looks for sure very promising. Have you had a chance to measure distortion (k2, k3...) for this unique driver? What is the sensitivity?

Karsten

I have to make new measurements on the final version of the AMTs,

but the sensitivity will be between 90 and 96dB as I can choose some levels of the magnet field strength.

On the prototypes the strongest magnet field gave best sound quality when listening, but the worst measurements - so the sensitivity will be decided next week.

I have also designed a wave-guide for the AMT that will increase the sensitivity with some dBs and give better directivity.

The distortion on the prototypes when measured at 100dB @ 1 meter was -45dB (2nd) and -56dB (3rd).

There are some myths regarding AMTs - high temperatures of the diaphragms are one of them - with some amusing explanations..

When I designed my AMT I designed them to manage high temperatures and they can operate at up to 200 degree Celsius..

But when I measured temperatures I only got 1 to 2 degree temperature rise from the ambient.

I investigated both mine AMTs and several other brands and I found the reason for this "problem".

The traces of the "coils" shorts due to poorly quality of the folding of the diaphragms or driving the diaphragms above Xmax.

On the Heils and copies of those there is possible to have major shorting and even sparks can be seen...

That this results in distortion should be obvious.

But when measured with as an example Arta software this clearly audible distortion are not clearly shown...

I used an high power heat blower and heated the diaphragm until its shape became distorted and parts of the diaphragm was shorted.

Now It sounded highly distorted and the distortion / noise was more dominant than the audio....

But when measuring with Arta there was still not show any obvious differences on distortion....

When I designed my AMT I designed them to manage high temperatures and they can operate at up to 200 degree Celsius..

But when I measured temperatures I only got 1 to 2 degree temperature rise from the ambient.

I investigated both mine AMTs and several other brands and I found the reason for this "problem".

The traces of the "coils" shorts due to poorly quality of the folding of the diaphragms or driving the diaphragms above Xmax.

On the Heils and copies of those there is possible to have major shorting and even sparks can be seen...

That this results in distortion should be obvious.

But when measured with as an example Arta software this clearly audible distortion are not clearly shown...

I used an high power heat blower and heated the diaphragm until its shape became distorted and parts of the diaphragm was shorted.

Now It sounded highly distorted and the distortion / noise was more dominant than the audio....

But when measuring with Arta there was still not show any obvious differences on distortion....

Hmmmm.... in my old QC days we would "cook" things for 24 hour - but it was only at around 93.3 Celsuis (200f). The vibration table (shake - rattle - n - roll) was always fun to watch (from behind the protective bullet proof glass). But those days are long past and the only way I have to simulate those temperatures now is when SHMBO gets upset at some of my antics  - followed by a few hours of a very chilly atmosphere.

- followed by a few hours of a very chilly atmosphere.

I knew one of the guys at ESS that came up with the fixture to fold the diaphragms (if I remember his name was Robinson - not sure tho - it's was 35 years ago). It is the folding of the diaphragms and then their "mating" with the holding frame that was very difficult to do at first. They (ESS) did finally get it developed to a level that was acceptable in a QC fashion - but there were a lot of lessons to be learned along the way. That is usually the way things happen in the world of making something on a production line - a bit of trial and error to get things put right - especially so when fooling around with stuff that has not been done before and is a new technology.

- especially so when fooling around with stuff that has not been done before and is a new technology.

To get your diaphragms to operate at these temp's and remain reliable is a great accomplishment - Congratulations!

- followed by a few hours of a very chilly atmosphere.

- followed by a few hours of a very chilly atmosphere.

I knew one of the guys at ESS that came up with the fixture to fold the diaphragms (if I remember his name was Robinson - not sure tho - it's was 35 years ago). It is the folding of the diaphragms and then their "mating" with the holding frame that was very difficult to do at first. They (ESS) did finally get it developed to a level that was acceptable in a QC fashion - but there were a lot of lessons to be learned along the way. That is usually the way things happen in the world of making something on a production line - a bit of trial and error to get things put right

- especially so when fooling around with stuff that has not been done before and is a new technology.

- especially so when fooling around with stuff that has not been done before and is a new technology.To get your diaphragms to operate at these temp's and remain reliable is a great accomplishment - Congratulations!

Last edited:

Potentially "Disruptive" technology...

Hi Ray,

Quote

"I used an high power heat blower and heated the diaphragm until its shape became distorted and parts of the diaphragm was shorted.

Now It sounded highly distorted and the distortion / noise was more dominant than the audio....

But when measuring with Arta there was still not show any obvious differences on distortion.... "

99% of all commercial audio is designed and then marketed by "technicians" who don’t know what behaviour / properties to measure or how relevant these are to the goal of life like sonic reproduction.

Clearly you are in the rare 1% group of designers ( not just a technician) who do know what to measure, how to measure it and how relevant the data is.

Congratulations on developing potentially "disruptive" loudspeaker technology.

I hope your huge effort and commitment will be rewarded financially, how (or if...!) you do will depend on many factors, including :

(1) Reducing manufacturing costs to a point where mass market production and sales will be attractive to VC companies / licensing to a PLC.

(2) Defendability of your patents, IP and trade marks

(3) Broad base appeal i.e. on wall and in wall home cinema, commercial premises - restaurants / bars etc, licensing to loudspeaker manufacturers.

Small niche markets like DIY or high end audio are only useful to "prove your case" and strengthen your negotiation position with the big PLC licence deals.

Many more things too but I just wanted to give you a heads up cause you seem to have a tiger by the tail, and they can bite...!

"Keep your friends close and enemies closer" ...

Good luck and once again congratulations on getting this far.

All the best

Derek.

Hi Ray,

Quote

"I used an high power heat blower and heated the diaphragm until its shape became distorted and parts of the diaphragm was shorted.

Now It sounded highly distorted and the distortion / noise was more dominant than the audio....

But when measuring with Arta there was still not show any obvious differences on distortion.... "

99% of all commercial audio is designed and then marketed by "technicians" who don’t know what behaviour / properties to measure or how relevant these are to the goal of life like sonic reproduction.

Clearly you are in the rare 1% group of designers ( not just a technician) who do know what to measure, how to measure it and how relevant the data is.

Congratulations on developing potentially "disruptive" loudspeaker technology.

I hope your huge effort and commitment will be rewarded financially, how (or if...!) you do will depend on many factors, including :

(1) Reducing manufacturing costs to a point where mass market production and sales will be attractive to VC companies / licensing to a PLC.

(2) Defendability of your patents, IP and trade marks

(3) Broad base appeal i.e. on wall and in wall home cinema, commercial premises - restaurants / bars etc, licensing to loudspeaker manufacturers.

Small niche markets like DIY or high end audio are only useful to "prove your case" and strengthen your negotiation position with the big PLC licence deals.

Many more things too but I just wanted to give you a heads up cause you seem to have a tiger by the tail, and they can bite...!

"Keep your friends close and enemies closer" ...

Good luck and once again congratulations on getting this far.

All the best

Derek.

I hope your huge effort and commitment will be rewarded financially, how (or if...!) you do will depend on many factors, including :

(1) Reducing manufacturing costs to a point where mass market production and sales will be attractive to VC companies

Derek.

*Great* work Raymond!

I hope you will be able to put those into production. What about discussing the matter with Beyma or Mundorf?

Looking forward to see more detailed measurements, especially off-axis SPL. How low do you think they can go without baffle? (in a baffle-less dipole).

I hope you will be able to put those into production. What about discussing the matter with Beyma or Mundorf?

Looking forward to see more detailed measurements, especially off-axis SPL. How low do you think they can go without baffle? (in a baffle-less dipole).

Thanks for all replies in this thread!

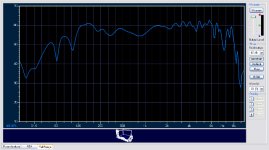

Attached a measurement @ 75 degrees...

The measurement is done in my listening room that have 60 cm thick concrete walls with 25 mm solid oak "panel", the floor are 25 mm solid oak and are floating on "mother earth" via 5 cm compact isolation, the roof are three layers of sheetrock and one layer of MDF and there are no curtains, no absorbents, no damping at all..

The measurements done here get some extra peaks and bump due to the undamped room - listening is great as long as proper equipment are used.

Attached a measurement @ 75 degrees...

The measurement is done in my listening room that have 60 cm thick concrete walls with 25 mm solid oak "panel", the floor are 25 mm solid oak and are floating on "mother earth" via 5 cm compact isolation, the roof are three layers of sheetrock and one layer of MDF and there are no curtains, no absorbents, no damping at all..

The measurements done here get some extra peaks and bump due to the undamped room - listening is great as long as proper equipment are used.

Attachments

listening is great as long as proper equipment are used.

Uh-oh - nooooowwwww I'm in trouble

SWMBO is not going to be happy with me nailing up several layers of sheet rock and MDF onto "her ceiling" - let alone adding to the "electronics stuff".

Congrat's on the response curves - they look pretty nice for "in-room" measurements

measurement looks like some wave guide adding efficience in region of lowmids will be usefull?

A wave-guide are designed and will be used when the AMT (as a dipol) will be used as a midrange / tweeter and crossed over at 100 - 300Hz.

The measurement was taken at 75 degrees off-axis in a reflective room, and in a horn enclosure designed for five AMTs.

The four remaining "holes" are not properly acoustically sealed and interferes and give some dB misreading (both plus and minus).

The measured results are only coarse indications of how the AMT operates in general...

StigErik:

I measured the AMT in free air without a baffle and it the drops in level from 1500Hz even if voices still are relatively "good" - much better than expected.

when they will be availble for purchase?

Good question...

The AMT have caused much more attention than I had expected and I believe your question need to be answered at a later point of time...

I have read a lot of opinions claiming that making AVT big for fullrange causes unacceptable distirsions .. did you manage to vercome that?

Really interested in that but knowing norwegian selfcosts little bit afraid of price))

As I designed the AMT for this bandwidth, and used my own variation of the principles of operation and my own implementation after my own calculations and with materials after my own evaluations - I really do not know why other AMTs effectively do not work properly below 1 - 2kHz.

As I only flipped through the patent papers to verify the most basic principles of operation and was not "bothered" by how other AMTs are designed I believe I was having the needed "freedom" to realize my own goals.

The measured distortion with the current builds are perfect down to 300Hz, and from 300Hz and down to 100Hz there are a rise of 5dB, and from 100Hz and down to 20Hz there are a rise of another 10dB in distortion.

This increase in distortion are related to the physical abilities of the AMT and due to the falling SPL level.

To keep the distortion level down to the perfect level at lower frequencies - then 4 AMTs are need to cover the frequencies below 300Hz etc..

I expect there will be questions regarding the practical usability of the AMTs.

When only on AMT are used pr. channel with an enclosure or suitable baffle and run with the full frequency spectrum, 65 to 70 dB average and 90dB peak in the listening position are possible without any kind* of distortion or noise.

This are when using a completely DC coupled system.

*meaning I cannot hear any distortion or noise

When only on AMT are used pr. channel with an enclosure or suitable baffle and run with the full frequency spectrum, 65 to 70 dB average and 90dB peak in the listening position are possible without any kind* of distortion or noise.

This are when using a completely DC coupled system.

*meaning I cannot hear any distortion or noise

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- The One and Only Full Range AMT