Failed through platings? That's odd. The Modulus-86 Rev. 2.x was a two-layer board and all the components have pins so that seems like an unlikely explanation. OTOH Rev. 2.3 was the last to be manufactured in China. I've since then pulled the production to Canada. Rev. 2.4 and beyond are made in Canada and have been electrically tested by the manufacturer.

The OPA1612 has a kink in the phase response in the 1-10 MHz region which makes it very difficult to use in a composite amp with an LM3886. I have yet to find a compensation scheme that would work well.

The LM4562/LME49720 is only a year or two older than the OPA1612 so it's not ancient relatively speaking.

Tom

The OPA1612 has a kink in the phase response in the 1-10 MHz region which makes it very difficult to use in a composite amp with an LM3886. I have yet to find a compensation scheme that would work well.

The LM4562/LME49720 is only a year or two older than the OPA1612 so it's not ancient relatively speaking.

Tom

The OPA627 is also $32 @ QTY 1. It's marginally better than the $2.85 LM4562NA on THD and slightly worse than the $6.39 OPA1612AIDR.

My point was: I don't see any reason to use an OPA2134 today. At least not in the Modulus-86. The LM4562 beats it on THD, noise, and price. The LM4562 is about half the cost of the OPA2134.

I'm also not saying that I don't see any use for the OPA627 or OPA2134 (or NE5534 for that matter) at all. All would likely be strong candidates for the input stage in an MC phono stage. The LM4562 would not be my first choice in that application due to its rather high input current.

Then again, if I was designing an MC input phono stage I would look at the OPA1612+JFE150 or LM4562+JFE150 combo way before considering the OPA627 simply due to the cost of the OPA627.

Tom

My point was: I don't see any reason to use an OPA2134 today. At least not in the Modulus-86. The LM4562 beats it on THD, noise, and price. The LM4562 is about half the cost of the OPA2134.

I'm also not saying that I don't see any use for the OPA627 or OPA2134 (or NE5534 for that matter) at all. All would likely be strong candidates for the input stage in an MC phono stage. The LM4562 would not be my first choice in that application due to its rather high input current.

Then again, if I was designing an MC input phono stage I would look at the OPA1612+JFE150 or LM4562+JFE150 combo way before considering the OPA627 simply due to the cost of the OPA627.

Tom

Tom, I wasn't advocating the use of the OPA627. My point is that a "modern Op Amp", to quote a previous post, isn't necessarily 'better' as the OPA627 has excellent performance yet is 30+ years old. A lot of factors, both technical and economic, weigh into component choice. As you point out, one cannot arbitrarily drop a different op-amp into any application circuit and expect the resulting circuit to work.

I'm about to order a chassis from Modushop for my Mod-86 build. One thing I was wondering about is the connection between Neutrik XLR sockets and the chassis.

Assuming a black anodized aluminum case, it will get some holes drilled and threaded for the XLR sockets. The inside of the threaded holes will be clean aluminum (no anodization) so the conductivity there should be good enough.

The XLR sockets have 3 pins and a ground tab. Pin 1 should be soldered to the ground tab, then the ground tab connects to the chassis by extending into the hole on the XLR socket that houses the screw.

I've seen black screws being used for this. Won't that mess up the ground connection between the XLR socket and the chassis? I'm assuming the ground connection is supposed to be through the screw.

In extension to the above, what about an aluminum chassis that consist of black anodized panels and black screws (and heat sinks). Will there be good conductivity between the panels? The chassis is supposed to be a Faraday cage connected to ground right?

Assuming a black anodized aluminum case, it will get some holes drilled and threaded for the XLR sockets. The inside of the threaded holes will be clean aluminum (no anodization) so the conductivity there should be good enough.

The XLR sockets have 3 pins and a ground tab. Pin 1 should be soldered to the ground tab, then the ground tab connects to the chassis by extending into the hole on the XLR socket that houses the screw.

I've seen black screws being used for this. Won't that mess up the ground connection between the XLR socket and the chassis? I'm assuming the ground connection is supposed to be through the screw.

In extension to the above, what about an aluminum chassis that consist of black anodized panels and black screws (and heat sinks). Will there be good conductivity between the panels? The chassis is supposed to be a Faraday cage connected to ground right?

Last edited:

Yeah... There are a few unicorns out there.OPA627 has excellent performance yet is 30+ years old.

... or work well. Yep. That was my point.As you point out, one cannot arbitrarily drop a different op-amp into any application circuit and expect the resulting circuit to work.

That said, the differential receiver in the Modulus-86 Rev. 3.0 is one place where one can play a little bit. It's hard to make it better though. The OPA1612 could be better, but it's SMD-only. I've also seen it ring quite a bit on the transient response when used in differential receivers, so you'll need to add some compensation caps. You'd then need to verify the performance of the circuit after and hope that it's better than the LM4562 that I specify. I dunno... It seems like a lot of trouble to go through to spend five times as much on an opamp (or 2.5x at QTY 1). But maybe that's just me.

Tom

This is what I do:I'm about to order a chassis from Modushop for my Mod-86 build. One thing I was wondering about is the connection between Neutrik XLR sockets and the chassis.

I don't think any more is needed, but you can connect that ground tab to the chassis if you wish. I'd use a solder lug attached by one of the screws that hold the connector.

I usually find that the panels in a ModuShop chassis end up connected together (at least at DC) when I just assemble the chassis. I do add serrated lock washers on the mounting screws for the front and rear panel.Will there be good conductivity between the panels? The chassis is supposed to be a Faraday cage connected to ground right?

The chassis will never be a perfect Faraday cage unless you don't drill any holes in it - including vent holes - and you weld it shut. Have a look at how RF enclosures are made for example. We're talking fancy conductive seals, feed-through capacitors, and more screws than you can shake a stick at and even they are only good up to some frequency (where the wavelength of the signal approaches the distance between the screws).

I honestly wouldn't worry too much about getting a perfect Faraday cage. The chassis will terminate some radiated fields and attenuate others. The wiring connecting to the chassis is more likely to pick up RF than the circuit inside the chassis is. That's why I have RFI filters in the MOD86. The chassis will offer some attenuation of mains hum, but not an earthshaking amount. It's relatively thin (3 mm) aluminum after all.

In summary: Fair point to geek out about but don't sweat it too much.

Tom

Tom, thanks for that reality check on enclosures as a Faraday cage for RF. As a layperson, I had seen descriptions of real Faraday cage desktop equipment enclosures, and wondered about the need for the conductive gaskets, and the use of feedthrough caps and ferrite beads. Given that, I was wondering whether focusing on the case for RF shielding was likely to be an effective endeavor. I’m now thinking that focusing on the circuitry to either filter incoming arc or to design the bandwidth so that the circuit does not pick up and amplify RF is more profitable. Which means that as a layperson I have to look for good designs!

can i get this type of XLR/microphone cable from amazon to use in the mod 86?

I see a copper braided shield i think i strip/fray or is it the aluminum foil that i split and fray for wiring the XLR to the mod 86 boards?

thank you in advance

link:

https://www.amazon.com/dp/B096LJXDRD?ref=ppx_yo2ov_dt_b_product_details&th=1

I would shy away from the cables with braided jackets. If you don't have a hot knife the jacket is likely to fray and unravel on you. I've had that happen with tech flex in the past.

That particular cable looks to me like it has a foil shield with a drain wire. That's okay-ish for the ground connection, but it would be better to use the copper shield for that.

I would look elsewhere if I were you. I buy Canare cable locally, but if you don't have a local supplier the GLS brand XLR cables at Bezos' Bookstore are quite good. They used to have their own website but it looks like they're now only on Farcebook, Bezos', etc. Heck, even Walmart carries GLS cables, apparently.

Tom

That particular cable looks to me like it has a foil shield with a drain wire. That's okay-ish for the ground connection, but it would be better to use the copper shield for that.

I would look elsewhere if I were you. I buy Canare cable locally, but if you don't have a local supplier the GLS brand XLR cables at Bezos' Bookstore are quite good. They used to have their own website but it looks like they're now only on Farcebook, Bezos', etc. Heck, even Walmart carries GLS cables, apparently.

Tom

A lot of marketing starts with a grain of truth/fact/science and extrapolates from there. It sounds like this is one of those cases.Tom, thanks for that reality check on enclosures as a Faraday cage for RF. As a layperson, I had seen descriptions of real Faraday cage desktop equipment enclosures, and wondered about the need for the conductive gaskets, and the use of feedthrough caps and ferrite beads.

I'm always half disgusted, half amused when I see truck commercials on TV that proudly advertise, "best in class disc brakes" (based on rotor diameter). Whatever "best" means in that context. And never mind that a large brake disc can still mean crappy brakes if the caliper piston doesn't apply enough force.

It's also easy to be "best in class" if you're in a class of your own. Just as I like to point out that I was one of the top two goaltenders in today's hockey game.

Tom

thank you tom, ill check into the other cable brands. ill re-watch the build video to see if i can get more of my questions figured out

i ordered a stereo mod 86 kit and a unpopulated power 86. after i got the mouser project link, i couldnt finish the order because they wont offer fed ex ground for the wake field thermal material. dropped it and ordered arctic silver 5 from amazon instead. my computers never was treated this well, always used the free thermal paste that a CPU cooler provides.

i ended up ordering a quad 405 clone case as it saved some money and did some cutting for me already. Purchased the T brackets and i hope they will fit.

i havent figured out : layout, stand offs , additional screws, additional wires, gauges for those wires, how to wire things i never wired from a ACA build

i havent sat down to go over the build documentation in detail yet though, but im going through this entire thread for pictures/suggestions(saw links to screws/stand off vendors) but i am not sure what i already have on hand and what i need.

waiting on ali express deliveries

looking forward to working on these over the next few months

i ordered a stereo mod 86 kit and a unpopulated power 86. after i got the mouser project link, i couldnt finish the order because they wont offer fed ex ground for the wake field thermal material. dropped it and ordered arctic silver 5 from amazon instead. my computers never was treated this well, always used the free thermal paste that a CPU cooler provides.

i ended up ordering a quad 405 clone case as it saved some money and did some cutting for me already. Purchased the T brackets and i hope they will fit.

i havent figured out : layout, stand offs , additional screws, additional wires, gauges for those wires, how to wire things i never wired from a ACA build

i havent sat down to go over the build documentation in detail yet though, but im going through this entire thread for pictures/suggestions(saw links to screws/stand off vendors) but i am not sure what i already have on hand and what i need.

waiting on ali express deliveries

looking forward to working on these over the next few months

That's fine. It's only the rectifier on the Power-86 that needs a little dab of thermal goop. The LM3886es come with Keratherm thermal pads and shoulder washers in the kit.ordered arctic silver 5 from amazon instead

Once you get the chassis, PCBs, and power transformer I suggest that you assemble the chassis and move the boards and components around inside it to find a good layout. Keep in mind that you'll need room for wire entry. And also keep in mind that connectors protrude into the chassis.

Tom

thanks tom, if the layout will need the T brackets, ill be using the arctic silver I assume(T bracket mounted to the heatsink)

forgot to mention, if anyone is on the fence on buying the stereo kit from tom directly

please do so

you dont need to deal with inventory of the LM3886 (dont want to bother with fakes)

you get keratherm pads

you get professionally made output inductors

etc!

all in a pre packaged kit. i did not enjoy rechecking mouser had the right parts during checkout out (it was accurate and you can argue does not need double checking though)

i returned my order for the XLR cable and ordered

i don t think ill be populating any boards until i get the case and start trying to imagine where everything will be.

forgot to mention, if anyone is on the fence on buying the stereo kit from tom directly

please do so

you dont need to deal with inventory of the LM3886 (dont want to bother with fakes)

you get keratherm pads

you get professionally made output inductors

etc!

all in a pre packaged kit. i did not enjoy rechecking mouser had the right parts during checkout out (it was accurate and you can argue does not need double checking though)

i returned my order for the XLR cable and ordered

GLS Audio 12ft Mic Cable Patch Cords - XLR Male to XLR Female.

i don t think ill be populating any boards until i get the case and start trying to imagine where everything will be.

I'm not sure what T-brackets you're referring to.

The Modulus-86 Stereo Kit comes with mounting brackets for mounting the boards to the heat sink. So that takes care of two of the mounting holes. The other two mounting holes should be tied to the bottom of the chassis with standoffs. If you stack the boards I'd get some short male-female standoffs for the bottom board and some longer female-female standoffs for the top board. McMaster-Carr is your friend in need: www.mcmaster.com

Tom

The Modulus-86 Stereo Kit comes with mounting brackets for mounting the boards to the heat sink. So that takes care of two of the mounting holes. The other two mounting holes should be tied to the bottom of the chassis with standoffs. If you stack the boards I'd get some short male-female standoffs for the bottom board and some longer female-female standoffs for the top board. McMaster-Carr is your friend in need: www.mcmaster.com

Tom

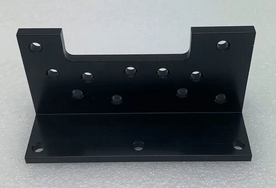

these are the T brackets

they mount to the heatsink

i will be heavily inspired from this post

https://www.diyaudio.com/community/threads/modulus-86-build-thread.267802/page-293#post-7059344

https://www.diyaudio.com/community/attachments/img_1829-jpg.1067685/

i will have a toroidal transformer instead of the square/E

they mount to the heatsink

i will be heavily inspired from this post

https://www.diyaudio.com/community/threads/modulus-86-build-thread.267802/page-293#post-7059344

https://www.diyaudio.com/community/attachments/img_1829-jpg.1067685/

i will have a toroidal transformer instead of the square/E

From tomlang's build, i figure i would buy the brackets just in case i can/should use them. I would prefer to mount the modulus 86 boards directly to the heatsink, but fortunately able to spend a little bit more for convenience vs more planning work(i dont really work in the realm of doing layout work, measurements, models, etc) so i rather physically have everything in my hands to plan the layout. I think it was shared you can have 1:1 paper replicas of all the devices and create your layout plans that way(or convert them into a CAD environment) but i can just spend $9 and just have it all in my physical hands lol

the risk i see is the brackets were bought from 1 vendor, the quad 405 clone from another vendor, and i hope they will fit together without drilling. i have no backup plans on this part

in the quad 405 layout, i am thinking about a bigger departure from what the standard 405 layout for all the inputs/output ports. i was thinking of putting all the outputs on the right side(picture for refernce here)

on the right side is all the outputs, then i and move the transformer away (and hopefully more wiring) away from the outputs. Ill change the left side to the inputs instead of the center posts. i read a few times that its more important to isolate any noise from the outputs instead of the input as the reasoning behind this. I also read that its not a significant issue too, so we will see how well everything fits together if i can min/max go for that(i assume its all impercievable too)

im still reading the past posts in this thread to get more ideas though. in the end, whatever is achievable that can be lined up with good practice is all i want to do. i am novice with working with tools and a chasis, and i dont have tools that gives anything a professional look lol. measure once cut twice

the risk i see is the brackets were bought from 1 vendor, the quad 405 clone from another vendor, and i hope they will fit together without drilling. i have no backup plans on this part

in the quad 405 layout, i am thinking about a bigger departure from what the standard 405 layout for all the inputs/output ports. i was thinking of putting all the outputs on the right side(picture for refernce here)

on the right side is all the outputs, then i and move the transformer away (and hopefully more wiring) away from the outputs. Ill change the left side to the inputs instead of the center posts. i read a few times that its more important to isolate any noise from the outputs instead of the input as the reasoning behind this. I also read that its not a significant issue too, so we will see how well everything fits together if i can min/max go for that(i assume its all impercievable too)

im still reading the past posts in this thread to get more ideas though. in the end, whatever is achievable that can be lined up with good practice is all i want to do. i am novice with working with tools and a chasis, and i dont have tools that gives anything a professional look lol. measure once cut twice

Last edited:

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread