My Modulus 86 all wired up, plugged in... shoes on, hand in pocket, wife nearby....fuse in Front LED on, no smoke measured +/- 35V, still no smoke.

I will call that a success thanks to a good video (and emails) from Tom.

I'm giving myself a pat on the back for wiring up the power LEDs in the right order (orange-blue / standby-on)

Tomorrow I will wire up to the speakers. Wish me luck.

I will call that a success thanks to a good video (and emails) from Tom.

I'm giving myself a pat on the back for wiring up the power LEDs in the right order (orange-blue / standby-on)

Tomorrow I will wire up to the speakers. Wish me luck.

So the instructions from Tom resulted in a fantastic afternoon of listening to music on my new modulus-86. Amazingly it worked first time, DC offset as expected, sounds great. Thanks to Tom for answering my pretty rudimentary questions and supporting throughout! My electronics background is limited so thats a testament to the instructions and guidance.

It replaces a Schiit Vidar and an Akitika GT-102 poweramp and unlike a number of hifi related changes I can hear a noticeable difference. I would say a much cleaner sound, perhaps equivalent to looking through slightly dirty and cleaned glasses. All subjective, but I think its sounds fresher, drums and cymbals sound cleaner and more realistic and I would say some of female vocals don't sound as harsh. The cymbals "crash" a bit more and the bass drums have more of a solid thump. I would also say the sound stage has more separation. Could I differentiate in a blind test.. who knows (but maybe).

For those interested: Khozmo passive preamp, schiit modi DAC, a WIIM pro steamer.,CSS P215X speakers. I have a REL T-zero sub but didn't use that yet, bass was pretty solid. Thinking of a balanced DAC direct to the modulus-86.

I'm based in Europe, the build wasn't cheap, but it was a cool project which I was looking for (instead of watching netflix at night or whatever) and I'm happy with it.

I was looking at the case options from hifi2000 etc, but actually the neurochrome case isn't that much more expensive and saves drilling all the holes so I thought it was worth it. Its also super nice and really well made.

It replaces a Schiit Vidar and an Akitika GT-102 poweramp and unlike a number of hifi related changes I can hear a noticeable difference. I would say a much cleaner sound, perhaps equivalent to looking through slightly dirty and cleaned glasses. All subjective, but I think its sounds fresher, drums and cymbals sound cleaner and more realistic and I would say some of female vocals don't sound as harsh. The cymbals "crash" a bit more and the bass drums have more of a solid thump. I would also say the sound stage has more separation. Could I differentiate in a blind test.. who knows (but maybe).

For those interested: Khozmo passive preamp, schiit modi DAC, a WIIM pro steamer.,CSS P215X speakers. I have a REL T-zero sub but didn't use that yet, bass was pretty solid. Thinking of a balanced DAC direct to the modulus-86.

I'm based in Europe, the build wasn't cheap, but it was a cool project which I was looking for (instead of watching netflix at night or whatever) and I'm happy with it.

I was looking at the case options from hifi2000 etc, but actually the neurochrome case isn't that much more expensive and saves drilling all the holes so I thought it was worth it. Its also super nice and really well made.

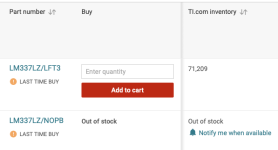

In other news. TI has quietly discontinued the TO-92 versions of the LM317L and LM337L regulators used in the Modulus-86. It looks like the surface mount options get to continue. The TO-92 version of the LM317L is made by other manufacturers as well so that's no issue, but the LM337L in TO-92 is TI-only. So that's a bit of an issue for the Modulus-86.

I'm not one to cry "the end is near!" but in this case the end could be on the horizon.

I see at least a couple different ways of dealing with this:

Anyway. Those are my thoughts this morning. I'm currently leaning mostly in the direction of buying a lifetime supply of the ICs so I can keep selling kits for another year or two. But the other options have not been ruled out either. And right now there's no need to panic. When TI announces a lifetime buy they usually give their customers a year or so to order before the part becomes obsolete, so here's still time and still parts in stock.

Tom

I'm not one to cry "the end is near!" but in this case the end could be on the horizon.

I see at least a couple different ways of dealing with this:

- Make a life-time buy of LM317L and LM337L from TI and keep selling Modulus-86 Stereo Kits until they run out.

- Redesign the regulator portion of the MOD86 to either use a different regulator IC or zener regulator.

- Let the Modulus-86 fade out with the LM317L and LM337L.

Anyway. Those are my thoughts this morning. I'm currently leaning mostly in the direction of buying a lifetime supply of the ICs so I can keep selling kits for another year or two. But the other options have not been ruled out either. And right now there's no need to panic. When TI announces a lifetime buy they usually give their customers a year or so to order before the part becomes obsolete, so here's still time and still parts in stock.

Tom

Attachments

I hesitate to offer boards with the SMD devices installed. Due to the startup fees, it would add a relatively large cost to have it done professionally and having me hand-solder however many boards per year is a non-starter. I'd rather design cool circuits than solder devices by hand.

The other reason I hesitate to sell boards with pre-assembled SMD parts is that I run the risk of having those parts die due to electrostatic discharge. I used to offer the Input Selector (Rev. 1.0) as an SMD pre-populated board and around 20% of builders had issues with fried relay drivers (the one SMD part). Now, that part is probably a bit more sensitive than most, but still. I take ESD precautions during assembly but I can't guarantee that my customers do the same.

Right now a lifetime buy looks the most attractive.

Tom

The other reason I hesitate to sell boards with pre-assembled SMD parts is that I run the risk of having those parts die due to electrostatic discharge. I used to offer the Input Selector (Rev. 1.0) as an SMD pre-populated board and around 20% of builders had issues with fried relay drivers (the one SMD part). Now, that part is probably a bit more sensitive than most, but still. I take ESD precautions during assembly but I can't guarantee that my customers do the same.

Right now a lifetime buy looks the most attractive.

Tom

My vote would be to keep the Mod 86 as diy as possible as it is the only true Neuro diy left.....I think

SMD may not be hard for some people but many seem to prefer thru hole as they perceive that to be easier to solder

Tom may have some customer feedback on customer issues.

t

SMD may not be hard for some people but many seem to prefer thru hole as they perceive that to be easier to solder

Tom may have some customer feedback on customer issues.

t

Was this by any chance the DRV777 from TI? That part turned out to be extremely susceptible to ESD in my experience. this was a few years ago and since then I’ve taken some additional precautions to prevent static buildup in the workshop, but besides discrete transistors I’ve never encountered another part that was that sensitive.[..] I run the risk of having those parts die due to electrostatic discharge. I used to offer the Input Selector (Rev. 1.0) as an SMD pre-populated board and around 20% of builders had issues with fried relay drivers (the one SMD part).

Any updates on this...Look what just landed on my lab bench (pardon the crappy colour balance in the picture). Thanks Sami!

View attachment 1241072

This is the real deal! It certainly presents itself as a professionally made product. I'm looking forward to testing it.

Supposedly it'll deliver 400 W continuously. It also features power factor correction. Oh, and Sami also verifies the EMC compliance to EN55032 Class B and electrical safety to EN62368-1. I'm pretty stoked about this. I hope that the supply performs as well as it looks. If it does I might consider buying a stack of them and have them for sale in my store.

Tom

I'm impressed so far. The over-current limit kicks in around 8.7 A. It's a pretty soft limit. There's also the option of adding capacitance on the output, so I think this will be plenty for an audio amp. I would like to evaluate it with the Modulus-686 before committing to a large order of them.

I ran it for 20-30 minutes at 180 W and it got a little more than lukewarm (45 ºC).

If it works well with the Modulus-686 and Sami can make a version that's adjustable from ±30 to ±36 V I could potentially see carrying them as a product in my store. The supply I have covers ±32 to ±38 V, so extending the range a bit shouldn't be a show stopper. I just need to verify that it works with the MOD686, but I have a few other things on my plate these days as well so I can't promise that I'll get to it immediately.

Tom

I ran it for 20-30 minutes at 180 W and it got a little more than lukewarm (45 ºC).

If it works well with the Modulus-686 and Sami can make a version that's adjustable from ±30 to ±36 V I could potentially see carrying them as a product in my store. The supply I have covers ±32 to ±38 V, so extending the range a bit shouldn't be a show stopper. I just need to verify that it works with the MOD686, but I have a few other things on my plate these days as well so I can't promise that I'll get to it immediately.

Tom

Not very. But some refuse to touch surface mounted components of any kind. It's just outside their comfort zone.How hard is a lm337 to solder in a SMT version? I am not opposed to having to solder SMT components.

I could use the TO-220, 1.5 A versions: LM337 and LM317. I really don't like having those stand up straight without support, so I'd probably lay them flat on the board. This would increase the board area, but at least they'd be all through-hole and DIY-friendly.

Nah. ULN2003LV. It really surprises me that this IC is so sensitive to ESD. That said, the inputs connect directly to a 3.3 V compatible MOS gate, so maybe...Was this by any chance the DRV777 from TI?

It's also worth noting that the ESD protection on chip is intended to protect the IC during assembly in an ESD-controlled environment. It's not intended to protect the IC against you shuffling your feet on nylon carpet and zapping it.

Tom

Hello Tom,

In case you have not considered this idea already :

Mount the TO-220's back-to-back with an insulator in between them. This will provide a smaller footprint than planar mounting, as well as a very rigid structure. DIY assembly should be easy (e.g. preassemble the TO-220's, then insert.), and it comes with a de-minimis cost bump.

David

In case you have not considered this idea already :

Mount the TO-220's back-to-back with an insulator in between them. This will provide a smaller footprint than planar mounting, as well as a very rigid structure. DIY assembly should be easy (e.g. preassemble the TO-220's, then insert.), and it comes with a de-minimis cost bump.

David

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread