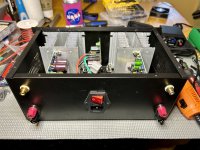

Big mess, big reward. Yes, it’s a bit crowded and I cheated with Wago-like Connectors, but it’s got a total silent background.

Playing very well through my test speakers. I don’t think this will last long before I put it in the main system.

Can I kick it? Yes, I can.

Thanks again, @tomchr, for a great audio product.

Playing very well through my test speakers. I don’t think this will last long before I put it in the main system.

Can I kick it? Yes, I can.

Thanks again, @tomchr, for a great audio product.

Attachments

hi everyone

thank you to everyone sharing your builds, i am hoping it gives me some ideas on how to be a bit crafty to save a bit here and there.

im looking to try see if i can plan what i need and was looking for some help and feedback

modulus website indicated it can be built $400-$450 but im having some issues trying to hit that mark (you think this is per-inflation numbers? lol)

i think i already $550 at this point. Im trying to find another chassis ideas though or other ways to see if i can save costs

Other questions:

i saw that tom recommends having XLR balanced input, but i dont even know if i have that. I use my PC > HDMI Out > HDMI splitter > RCA into a Amp camp Amp. how do i figure out balanced/unbalanced in this situation? I saw you can convert a RCA to XLR adapters, but can that be used?

Does anyone think a nibbler hand tool can cut into the 3mm aluminum panel in a Dissipante ?

link to the tool for reference: https://www.amazon.com/ProsKit-900-215-Nibbler/dp/B000BN60XW/ref=sr_1_67?crid=28KHPFGYNTU5G&keywords=steel+nibbler+tool&qid=1697945164&sprefix=STEEL+nibbler,aps,562&sr=8-67

I have M-Audio AV40 that i converted into passive speakers. I think these are 20W max (into 4 ohms?) is this something i can continue to use with a stereo modulus 86 but just dont crank the volume to max?

thank you in advance,

thank you to everyone sharing your builds, i am hoping it gives me some ideas on how to be a bit crafty to save a bit here and there.

im looking to try see if i can plan what i need and was looking for some help and feedback

modulus website indicated it can be built $400-$450 but im having some issues trying to hit that mark (you think this is per-inflation numbers? lol)

| Dissipante 02/300N 2U 4mm BLACK | 142.00€ |

| Modulus 86 stereo parts | $279 |

| Power-86 | $50 |

| Power 86 mouser | $35 |

| Antek AS-2222 | $48.50 |

i think i already $550 at this point. Im trying to find another chassis ideas though or other ways to see if i can save costs

Other questions:

i saw that tom recommends having XLR balanced input, but i dont even know if i have that. I use my PC > HDMI Out > HDMI splitter > RCA into a Amp camp Amp. how do i figure out balanced/unbalanced in this situation? I saw you can convert a RCA to XLR adapters, but can that be used?

Does anyone think a nibbler hand tool can cut into the 3mm aluminum panel in a Dissipante ?

link to the tool for reference: https://www.amazon.com/ProsKit-900-215-Nibbler/dp/B000BN60XW/ref=sr_1_67?crid=28KHPFGYNTU5G&keywords=steel+nibbler+tool&qid=1697945164&sprefix=STEEL+nibbler,aps,562&sr=8-67

I have M-Audio AV40 that i converted into passive speakers. I think these are 20W max (into 4 ohms?) is this something i can continue to use with a stereo modulus 86 but just dont crank the volume to max?

thank you in advance,

Last edited:

You can build the Modulus-86 with RCA inputs if you desire. Personally I would build it with XLR inputs and either make RCA-XLR cables or use RCA-XLR adapters. That way you can just unplug and plug in a source with balanced out at some point in the future.

I'm curious what you need the nibbler for. The panels are easy to drill into. For the larger holes I use carbide tipped hole saws. For rectangular holes, here's my trick:

There are some chassis options on eBay. The BZ4309 that's available from a few sellers springs to mind. There's also a Quad 405 clone chassis that someone here used for their Modulus-86 build. Alternatively, get one of the 2U x 300 mm heat sinks from ModuShop and make your own chassis around it.

Tom

I'm curious what you need the nibbler for. The panels are easy to drill into. For the larger holes I use carbide tipped hole saws. For rectangular holes, here's my trick:

There are some chassis options on eBay. The BZ4309 that's available from a few sellers springs to mind. There's also a Quad 405 clone chassis that someone here used for their Modulus-86 build. Alternatively, get one of the 2U x 300 mm heat sinks from ModuShop and make your own chassis around it.

Tom

thanks tom, i posted a thank you when you had it on youtubeYou can build the Modulus-86 with RCA inputs if you desire. Personally I would build it with XLR inputs and either make RCA-XLR cables or use RCA-XLR adapters. That way you can just unplug and plug in a source with balanced out at some point in the future.

I'm curious what you need the nibbler for. The panels are easy to drill into. For the larger holes I use carbide tipped hole saws. For rectangular holes, here's my trick:

There are some chassis options on eBay. The BZ4309 that's available from a few sellers springs to mind. There's also a Quad 405 clone chassis that someone here used for their Modulus-86 build. Alternatively, get one of the 2U x 300 mm heat sinks from ModuShop and make your own chassis around it.

Tom

the nibbler, if it can be used, was something i felt i had a lot of control over but i think i just wanted someone to tell me its ok to use it on 3mm aluminum. if the nibbler broke after i finished the chassis, i wouldnt even mind.

the drill is definitely the next plan but i tried drilling multiple holes to make a square into a ATX power supply case and wasnt successful. the nibbler was a perfect tool when the sheet metal was that gauge though. I am thinking i can get a punch to guide all the drill holes if i go this route(and a file)

thanks for answering about the RCA to XLR adapter. i hope you are getting some sleep!

im having a rough time with a chassis when it comes to shipping. the BZ4309 pricing is either just a bit under modushop but it has no heat sinks ($78 shipping to hawaii). i saw someone repurpose a sony receiver case so im hoping i come across one of those as a thrift store

the Quad 405 looks good with a number of the inputs already cut out! thank you! thank you for the suggestion. it has a good price on aliexpress. $65 and under + $80 shipping and under

thank you this was on the list. i think price of the chasis look OK but i dont know shipping yetYou might want to give this supplier a look.

Par-Metal

They have many different, decent quality chassis and components.

Mike

was trying to figure out the heatsink issue first(buy heatsinks seperately and buy a chasis from par metal/else where) or find one that integrates the heatsink in the chasis alreardy

i never heard of the quad 405 until now and i am on page 200 on this thread(i started in 200 something and was moving my way towards the end lol)

Thank you for your thank you. Sorry. I don't keep track of who said what to whom on which platform. That's why the dots didn't connect.i posted a thank you when you had it on youtube

Ah. I see the ePay vendors have started to use BZ4309 for anything 430x90 mm. Grr... That's OK. ModuShop offers a consistent product for the same price. But for completeness, this is what I was referring to: eBay item ID: 161816586829. It definitely has heat sinks.BZ4309 pricing is either just a bit under modushop but it has no heat sinks

That can be a good route. You can also buy a heat sink from ModuShop, eBay, or a metal scrap yard or eWaste recycler and make your own chassis. When I was in high school and early college I made quite a few chassis that way. I'd buy scrap sheet aluminum and scrap heat sinks and make a chassis. I'd either sand or sandblast the chassis and apply a coat of clear enamel. It's work but it can be made to look good.i saw someone repurpose a sony receiver case so im hoping i come across one of those as a thrift store

There's also Heatsink USA: https://www.heatsinkusa.com/ Their serrated fin options are pretty efficient.

Tom

thanks tom for the link, that one is $120 + $98 shipping, im not sure if thats normal for everyone or its my hawaii location lol. after doing all this searching, the modushop is good value (efficient heatsinks, anodized/painted panels, i already seen the quality from the ACA). if i am not making my own chassis, its so far the best value i can see. the quad 405 clone is great price but it is ali express, i have never ordered anything this expensive so im debating the risks.

i was thinking getting a plank of wood and a sheet of aluminum and just bending it into a case (open on the ends) but i am willing to spend more to get a enclosure for the aesthetics and convienence.

i was thinking getting a plank of wood and a sheet of aluminum and just bending it into a case (open on the ends) but i am willing to spend more to get a enclosure for the aesthetics and convienence.

It seems the Chinese eBay vendors charge a lot more for shipping they used to. I think they also use DHL/FedEx/UPS rather than China Post/EMS, but I don't know that for a fact. That makes them about as expensive as ModuShop and then I'd rather support ModuShop.

Years ago I ordered a pair of BZ4309 for two Modulus-86 builds. They were alright. They look good once assembled and I like that the top and bottom panels sit flush with the top of the heat sinks. But they're not the greatest quality. The parts arrived soaked in cutting fluid. The corner pieces that hold everything together needed de-burring and instead of a counterbore (that's flat on the bottom) they just drilled to a specific depth with a regular drill so I wasn't super confident that the screws would seat properly. Everything came together just fine and both amps are still going, but you can get better chassis quality elsewhere, including with ModuShop.

Tom

Years ago I ordered a pair of BZ4309 for two Modulus-86 builds. They were alright. They look good once assembled and I like that the top and bottom panels sit flush with the top of the heat sinks. But they're not the greatest quality. The parts arrived soaked in cutting fluid. The corner pieces that hold everything together needed de-burring and instead of a counterbore (that's flat on the bottom) they just drilled to a specific depth with a regular drill so I wasn't super confident that the screws would seat properly. Everything came together just fine and both amps are still going, but you can get better chassis quality elsewhere, including with ModuShop.

Tom

peterinhawaii,

2 lower cost options:

https://www.ebay.com.my/itm/196028586625 (approx 111.50 incl shipping)

https://www.ebay.com.my/itm/196029952077 (approx 141.60 incl shipping)

But as Tom already mentioned, maybe check out the Modushop options too.

2 lower cost options:

https://www.ebay.com.my/itm/196028586625 (approx 111.50 incl shipping)

https://www.ebay.com.my/itm/196029952077 (approx 141.60 incl shipping)

But as Tom already mentioned, maybe check out the Modushop options too.

thank you zman01

i started to check into the size for the smaller enclosure(the other one is price competitive with modushop)

threw it all into chatgpt lol. i havent decided yet though. iv seen the posts tom shared with someone fitting it all into smaller enclosures so maybe this was all moot.

#1 Amplifier Audio Shell:

i started to check into the size for the smaller enclosure(the other one is price competitive with modushop)

threw it all into chatgpt lol. i havent decided yet though. iv seen the posts tom shared with someone fitting it all into smaller enclosures so maybe this was all moot.

#1 Amplifier Audio Shell:

- Area = Width x Depth x Internal Height

- Area = 9.84252 inches x 9.84252 inches x 3.14961 inches

- Area ≈ 292.32 cubic inches

- Area = Width x Height x Depth

- Area = 13.07087 inches x 4.60630 inches x 6.10236 inches

- Area ≈ 369.45 cubic inches

- Area = Width x Height x Depth

- Area = 13.07087 inches x 4.60630 inches x 6.10236 inches

- Area ≈ 369.45 cubic inches

peterinhawaii,

Not sure the internal volume is the right way to go.

Think about the layout you are going do, and how will place the PCBs (2 x amplifier PCB, 1 x power supply PCB) and the transformer in the chassis; given the internal length and width of a particular chassis, will you be able to place them on the floor of the chassis without any issues? The chassis should also be tall enough to accommodate the the toroidal transformer and the inside of the chassis lid should not be touching the transformer or any of the mounting hardware. Also see if you can rout the wires in according to best practices.

Also using a SMPS for power makes the build a bit easier, and the SMPS unit usually takes much less space vs the toroidal transformer + power supply PCB; much lighter too.

Not sure the internal volume is the right way to go.

Think about the layout you are going do, and how will place the PCBs (2 x amplifier PCB, 1 x power supply PCB) and the transformer in the chassis; given the internal length and width of a particular chassis, will you be able to place them on the floor of the chassis without any issues? The chassis should also be tall enough to accommodate the the toroidal transformer and the inside of the chassis lid should not be touching the transformer or any of the mounting hardware. Also see if you can rout the wires in according to best practices.

Also using a SMPS for power makes the build a bit easier, and the SMPS unit usually takes much less space vs the toroidal transformer + power supply PCB; much lighter too.

That's certainly one figure of merit (FOM) that one can use. But like any FOM it has its limitations. Unlike cats and peanut butter, the Power-86 and Modulus-86 aren't liquid, however, so it may be more relevant to use the internal X,Y dimensions first and then verifying that there's enough height to accommodate everything.Not sure the internal volume is the right way to go.

For stuff like this I will often draw out the dimensions on a piece of paper and use paper dollies representing the circuit boards (or use the bare circuit boards) to figure out the board locations. More recently I've started drawing shapes in CAD tools, but often the paper+dolly approach is easier and faster.

I think the Quad chassis is tall enough that you can stack two Modulus-86 channels. I'd plan for 6-8 mm from the bottom panel to the bottom of the first board. Then, I think, about 40 mm between boards. Male-female hex standoffs are great for this. McMaster-Carr can be helpful there: www.mcmaster.com

Tom

thank you for the suggestion. I am also checking into the SMPS(i think its $80 and the transformer is $50) but i can save on the size of the chasis going this route. i "feel" like i want the toroidal transformer at the moment(im googling smps vs torodial transformers at the moment) i havent checked the dimensions of the transformer yet either, so much planning lolpeterinhawaii,

Not sure the internal volume is the right way to go.

Think about the layout you are going do, and how will place the PCBs (2 x amplifier PCB, 1 x power supply PCB) and the transformer in the chassis; given the internal length and width of a particular chassis, will you be able to place them on the floor of the chassis without any issues? The chassis should also be tall enough to accommodate the the toroidal transformer and the inside of the chassis lid should not be touching the transformer or any of the mounting hardware. Also see if you can rout the wires in according to best practices.

Also using a SMPS for power makes the build a bit easier, and the SMPS unit usually takes much less space vs the toroidal transformer + power supply PCB; much lighter too.

i havent even begun to think about mounting hardware yetThat's certainly one figure of merit (FOM) that one can use. But like any FOM it has its limitations. Unlike cats and peanut butter, the Power-86 and Modulus-86 aren't liquid, however, so it may be more relevant to use the internal X,Y dimensions first and then verifying that there's enough height to accommodate everything.

For stuff like this I will often draw out the dimensions on a piece of paper and use paper dollies representing the circuit boards (or use the bare circuit boards) to figure out the board locations. More recently I've started drawing shapes in CAD tools, but often the paper+dolly approach is easier and faster.

I think the Quad chassis is tall enough that you can stack two Modulus-86 channels. I'd plan for 6-8 mm from the bottom panel to the bottom of the first board. Then, I think, about 40 mm between boards. Male-female hex standoffs are great for this. McMaster-Carr can be helpful there: www.mcmaster.com

Tom

the quad 405 build here (https://www.diyaudio.com/community/threads/modulus-86-build-thread.267802/post-7059344) i m not sure i can get those heatsink brackets to do a vertical mount like that yet, but I am still looking for best practices for layout designs(like dont mount channels near a transformer or something). i was thinking the transformer on the bottom, the power 86 next to it, and just mount hte modulus 86 directly to the heatsink on the left and right side of the heat sink. (this spreads the heat over the entire heatsink i assume)

or with your suggestion tom(thank you), maybe mount power 86 to the heatsink above the transformer, and the modulus 86 on the right side on top of each other. heat is centered on the modulus 86 side so maybe its less efficient? but i dont know if certain modules should be near another module or not. the smallest enclosures has everything near each other so maybe no big deal? lol

thank you for the suggestion. I am also checking into the SMPS(i think its $80 and the transformer is $50) but i can save on the size of the chasis going this route. i "feel" like i want the toroidal transformer at the moment(im googling smps vs torodial transformers at the moment) i havent checked the dimensions of the transformer yet either, so much planning lol

With the SMPS you will not need the Power-86; so savings will be on both the transformer and the Power-86. It's less revenue for Tom, but he has always encouraged DIYers to build using either of the two options (Thanks Tom).

Last edited:

peterinhawaii,

It's a good practice to keep the transformer and the AC wiring away from the amplifier boards and the signal wires. The AC wiring should be definitely twisted.

It is common to DIY builds wit the transformer towards the front of the case, and the amplifier modules in the center or even towards the rear (if heat is not an issue with placing the output device off-center); that way the input wire and the output (speaker wire) connections can be also kept shorter. It is a good practice to twist the speaker wires.

It's a good practice to keep the transformer and the AC wiring away from the amplifier boards and the signal wires. The AC wiring should be definitely twisted.

It is common to DIY builds wit the transformer towards the front of the case, and the amplifier modules in the center or even towards the rear (if heat is not an issue with placing the output device off-center); that way the input wire and the output (speaker wire) connections can be also kept shorter. It is a good practice to twist the speaker wires.

oh i didnt know you can go with that configuration. i personally wanted to do more soldering but having that power design could significantly change the layout and costs. thank you for sharing that (sorry i dont know why i cant quote your message) @zman01

i cant decide which now lol

i cant decide which now lol

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread