Hi, I originally posted this in another forum, but felt members here may benefit from this also, so I am re-posting some key elements in the processes I used.

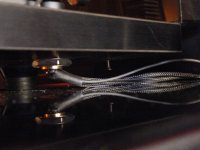

I just rewired my RB300 tonearm, with Isokinetik silver plated wire (Cardas cartridge clips with Mundorf supreme silver lead free solder) : straight loom to the phono preamp..., and finished making a custom 3kg disc to mount the motor from the Rega Planar 3 on. I also dampened the tonearm with 7 expandable earplugs, and put 2 very thin slithers of earplug foam inbetween the spring coils in the weight adjustment part of the tonearm (they ring like a bell), while it was set at 3.5g (maximum-opens the spring up totally) and then set the weight via jewellers scales - leaving the setting at 3.5g.

I have NEVER heard a Rega sound soooooooooOOOOOOO GOOOOOD...!!!

Extra wide soundstage, depth, transparancy, black-silent background, detail, with a laid back clarity...yet so much PUNCH and tight bass....

...and its still in the initial hours of being 'burnt-in'....I cant tear myself away from it.....I also have a ruby bearing in it, and acrylic platter. In the lead base, which I made from a jar stainless lid, I drilled a hole, got a paper-mate biro pen, and took the spring out, cut it in half, and put it in the hole, and used the steel bearing I replaced with the ruby one, for the platter, and used it for a 'thrust bearing' as part of the lead base.....

...man, what a rewarding effort...., some tracks evoked pure emotion....WoW

... I still need to finalise a few minor points...ie: ext-cable clamp, 3 point mini-feet on base etc...,

... that is an 'ancient' Shure M75EJ Type II on there with a near-new Swiss Huco Hyper-elliptical .2 x .7 stylus...The Nagoaka MP-200 is looking like a good cartridge/stylus....for future consideration hmmm

I just rewired my RB300 tonearm, with Isokinetik silver plated wire (Cardas cartridge clips with Mundorf supreme silver lead free solder) : straight loom to the phono preamp..., and finished making a custom 3kg disc to mount the motor from the Rega Planar 3 on. I also dampened the tonearm with 7 expandable earplugs, and put 2 very thin slithers of earplug foam inbetween the spring coils in the weight adjustment part of the tonearm (they ring like a bell), while it was set at 3.5g (maximum-opens the spring up totally) and then set the weight via jewellers scales - leaving the setting at 3.5g.

I have NEVER heard a Rega sound soooooooooOOOOOOO GOOOOOD...!!!

Extra wide soundstage, depth, transparancy, black-silent background, detail, with a laid back clarity...yet so much PUNCH and tight bass....

...and its still in the initial hours of being 'burnt-in'....I cant tear myself away from it.....I also have a ruby bearing in it, and acrylic platter. In the lead base, which I made from a jar stainless lid, I drilled a hole, got a paper-mate biro pen, and took the spring out, cut it in half, and put it in the hole, and used the steel bearing I replaced with the ruby one, for the platter, and used it for a 'thrust bearing' as part of the lead base.....

...man, what a rewarding effort...., some tracks evoked pure emotion....WoW

... I still need to finalise a few minor points...ie: ext-cable clamp, 3 point mini-feet on base etc...,

... that is an 'ancient' Shure M75EJ Type II on there with a near-new Swiss Huco Hyper-elliptical .2 x .7 stylus...The Nagoaka MP-200 is looking like a good cartridge/stylus....for future consideration hmmm

Attachments

Last edited:

j7's confirmation/advice from Audio Origami regarding RB300 mod

...on chatting with j7 from Audio Origami, he confirmed my suspicions about using 'foam spray' in the tonearm, compromising the bearings working properly, and that my foam earplug plan was the most sensible...

...and also commented on concerns I was having about drilling holes in the RB300, as per the Michell tecnoarm. He stated that 'he does not drill the arm tube, as his experiments with an accelerometer showed little or no difference, shifting the ring to a slightly higher frequency when doing so, and that foam was a much better solution for tonearm tube ringing'.

...I found him to be quite a helpful and well-meaning chap...If mods are needed to a tonearm, I would most certainly choose him to do so, for this reason, and the fact that he does not overcharge...and likes what he does..., and his work and advice/confirmations facilitate greater/practical results...

...his 'gold-plated' RB250 tonearms look stunning....

...on chatting with j7 from Audio Origami, he confirmed my suspicions about using 'foam spray' in the tonearm, compromising the bearings working properly, and that my foam earplug plan was the most sensible...

...and also commented on concerns I was having about drilling holes in the RB300, as per the Michell tecnoarm. He stated that 'he does not drill the arm tube, as his experiments with an accelerometer showed little or no difference, shifting the ring to a slightly higher frequency when doing so, and that foam was a much better solution for tonearm tube ringing'.

...I found him to be quite a helpful and well-meaning chap...If mods are needed to a tonearm, I would most certainly choose him to do so, for this reason, and the fact that he does not overcharge...and likes what he does..., and his work and advice/confirmations facilitate greater/practical results...

...his 'gold-plated' RB250 tonearms look stunning....

Motor Isolation

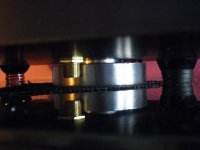

I isolated the motor completely from the plinth, by pouring about 3kg of molten lead into a stainless steel lid, and when cooled, flattened the surface, and bolted the AC motor on the lead base, incorporating a 'built in' thrust bearing situation in the base itself

The leaded base was an idea/thought I had at the time, which occurred when I purchased 2 x slate slabs for a custom Rega Planar 3 I am going to make. Most use the 2nd slab for the motor assembly, however, I don't like the complex look/weight of it all.

One 30mm slate is much more elegant and solid looking. I considered using a 'core drill' to drill out the part for the motor assembly, and have it mounted separately, on the cut-out slate part with a metal (brass?) base glued/attached underneath it.

...With the stock standard Rega Planar 3 I have (purchased from Paul at Classique Sounds Leicester UK (tel 0116 2835821) -- a friendly decent sort of chap), I decided to make the lead base modification...., and ...it works brilliant-ly....

..I do not believe, that much more improvement can be made with regards to motor vibration isolation, unless one went to negligible-effect extremes past that...., for the size of a medium size preserve jar lid, you can fill it with molten lead to near/about 3kg, and it looks great under the TT in brushed stainless steel....If doing a 'thrust bearing' mod, one must ensure that some tacky/sticky grease is in the hole/spring/bearing assembly part, before bolting or screwing the motor onto the base...

THIS IS BETTER THAN ANY TWEAKING WITH DOUBLE SIDED TAPE AND HANGING BANDS/WASHERS ETC...or whatever might be done 'in-situ' on the TT motor housing. Best results are total isolation with only belt connecting motor assembly to platter. You need to ensure that there is at least 2-3mm clearance between the top of the motor assembly and the underside of the plinth. When leveling the plinth, ensure that the motor assembly is equally leveled...and enjoy 😎

I isolated the motor completely from the plinth, by pouring about 3kg of molten lead into a stainless steel lid, and when cooled, flattened the surface, and bolted the AC motor on the lead base, incorporating a 'built in' thrust bearing situation in the base itself

The leaded base was an idea/thought I had at the time, which occurred when I purchased 2 x slate slabs for a custom Rega Planar 3 I am going to make. Most use the 2nd slab for the motor assembly, however, I don't like the complex look/weight of it all.

One 30mm slate is much more elegant and solid looking. I considered using a 'core drill' to drill out the part for the motor assembly, and have it mounted separately, on the cut-out slate part with a metal (brass?) base glued/attached underneath it.

...With the stock standard Rega Planar 3 I have (purchased from Paul at Classique Sounds Leicester UK (tel 0116 2835821) -- a friendly decent sort of chap), I decided to make the lead base modification...., and ...it works brilliant-ly....

..I do not believe, that much more improvement can be made with regards to motor vibration isolation, unless one went to negligible-effect extremes past that...., for the size of a medium size preserve jar lid, you can fill it with molten lead to near/about 3kg, and it looks great under the TT in brushed stainless steel....If doing a 'thrust bearing' mod, one must ensure that some tacky/sticky grease is in the hole/spring/bearing assembly part, before bolting or screwing the motor onto the base...

THIS IS BETTER THAN ANY TWEAKING WITH DOUBLE SIDED TAPE AND HANGING BANDS/WASHERS ETC...or whatever might be done 'in-situ' on the TT motor housing. Best results are total isolation with only belt connecting motor assembly to platter. You need to ensure that there is at least 2-3mm clearance between the top of the motor assembly and the underside of the plinth. When leveling the plinth, ensure that the motor assembly is equally leveled...and enjoy 😎

Attachments

-

Rega lead_cpnnect.jpg691.2 KB · Views: 454

Rega lead_cpnnect.jpg691.2 KB · Views: 454 -

Rega lead_plug.jpg718.9 KB · Views: 506

Rega lead_plug.jpg718.9 KB · Views: 506 -

Rega motor_lead.jpg771.2 KB · Views: 548

Rega motor_lead.jpg771.2 KB · Views: 548 -

Rega base_raw.jpg874.3 KB · Views: 611

Rega base_raw.jpg874.3 KB · Views: 611 -

Rega base_raw_profile.jpg821.7 KB · Views: 1,904

Rega base_raw_profile.jpg821.7 KB · Views: 1,904 -

Rega motor_attach_profile.jpg682.4 KB · Views: 496

Rega motor_attach_profile.jpg682.4 KB · Views: 496 -

Rega motor_attach_top.jpg655.1 KB · Views: 620

Rega motor_attach_top.jpg655.1 KB · Views: 620 -

Rega grease_bearing.jpg787.4 KB · Views: 549

Rega grease_bearing.jpg787.4 KB · Views: 549 -

Rega motor_mesh.jpg826.8 KB · Views: 607

Rega motor_mesh.jpg826.8 KB · Views: 607 -

Rega under_finished.jpg637.6 KB · Views: 615

Rega under_finished.jpg637.6 KB · Views: 615

Last edited:

Final motor modification

I took some of the shrink wrap off to spread the wires from the motor and flatten them glued to the lead base with contact cement. I then cut some Coles rubber mesh to suit the top, so that it does not scratch the plinth (while moving/adjusting the base etc), and just so that it has some aesthetic element to it...I also did the same with the 2 washers/ground bolt head on the bottom of the base...

I then soldered a longer wire and female plug (with shrink tube) to the circuit, ensuring that the circuit is also stuck on with silicone. Silicone is used for the wiring in the plinth cavity in varying places to ensure it will be vibration free.

I proceeded to cut the plastic cover to suit the motor base, and ensure there will be enough clearance so that it does not touch it. I sprayed the interior black, to be consistant with the plinth colour, and placed a piece of foam over the top of the circuit board.

The shaped plastic cover was stuck on with contact cement, and with one screw, and the part where the wire protrudes, was given a dab of silicone as well as that part of the wire; and foam covered as well (including motor wire). The connected wire is allowed to 'hang' slightly away from the plinth, but is foam covered 'just in case' a minor connection with the plinth/cover may occur : -- all to dampen, ensuring zero vibration.

Motor assembly is very easy to detach... and re-attach.... In addition, when the belt gets 'stretched'..., just move the motor back a couple of mm's... 🙂

I took some of the shrink wrap off to spread the wires from the motor and flatten them glued to the lead base with contact cement. I then cut some Coles rubber mesh to suit the top, so that it does not scratch the plinth (while moving/adjusting the base etc), and just so that it has some aesthetic element to it...I also did the same with the 2 washers/ground bolt head on the bottom of the base...

I then soldered a longer wire and female plug (with shrink tube) to the circuit, ensuring that the circuit is also stuck on with silicone. Silicone is used for the wiring in the plinth cavity in varying places to ensure it will be vibration free.

I proceeded to cut the plastic cover to suit the motor base, and ensure there will be enough clearance so that it does not touch it. I sprayed the interior black, to be consistant with the plinth colour, and placed a piece of foam over the top of the circuit board.

The shaped plastic cover was stuck on with contact cement, and with one screw, and the part where the wire protrudes, was given a dab of silicone as well as that part of the wire; and foam covered as well (including motor wire). The connected wire is allowed to 'hang' slightly away from the plinth, but is foam covered 'just in case' a minor connection with the plinth/cover may occur : -- all to dampen, ensuring zero vibration.

Motor assembly is very easy to detach... and re-attach.... In addition, when the belt gets 'stretched'..., just move the motor back a couple of mm's... 🙂

Attachments

Sub-platter mod's

Idea: I have been pondering this issue for a while now..., if 'acrylic' platters make a difference, due to resonant qualities, for the better than glass...(due to ringing effect), then how does putting a metal subplatter on, made of metals that ring more, than resin (ie: aluminium, stainless steel etc) create any improvement???

I am thinking of just filling the resin subplatter with silicone to dampen it...it should work quite well...

I would rather come up with a solution improving the standard --- see if it makes a difference, then....spend $$$ if none can be found...

From what I have seen in other posts/comments on web-sites, the aluminium sub-platters are referred to as 'anti-resonance' ..., with 'anti-resonance patterns'........so, I wonder why??...use a metal that 'resonates' more than plastic/resin/acrylic would??

...so, its simple...I would just get a silcone cannister in a gun/dispenser, and squeeze silicone into the cavities, and get a plastic gyprock (or any flat putty-type blade) and push it into the cavities and flatten evenly at the same time..., until all are even...and let dry...

Action: I just ended up filling the bottom/top halves of the sub-platter with roofing silicone..., believe me, its not for the faint-hearted...It feels 'heavy' and 'well-damped', kind of solid... I just cleaned up the subplatter from extraneous silicone dregs etc...put it on, (with the perfected mod to the motor), and I am amazed that there should be such a difference..., more dynamic, 3D soundstage improvement, clarity, black background, seems more silent..., the 'timbre' of instruments is more evident and has added prescence in the room...., as well as vocals tonal quality...., and overall even 'smoother'.... (did I mention punchier deeper bass??)

I feel like there are people playing musical instruments in my room and singing to me...

...everytime I do something to modify it, my Rega sounds better....

...there is no way, I am going to purchase a 'aluminium subplatter' after this result....hehehe

Idea: I have been pondering this issue for a while now..., if 'acrylic' platters make a difference, due to resonant qualities, for the better than glass...(due to ringing effect), then how does putting a metal subplatter on, made of metals that ring more, than resin (ie: aluminium, stainless steel etc) create any improvement???

I am thinking of just filling the resin subplatter with silicone to dampen it...it should work quite well...

I would rather come up with a solution improving the standard --- see if it makes a difference, then....spend $$$ if none can be found...

From what I have seen in other posts/comments on web-sites, the aluminium sub-platters are referred to as 'anti-resonance' ..., with 'anti-resonance patterns'........so, I wonder why??...use a metal that 'resonates' more than plastic/resin/acrylic would??

...so, its simple...I would just get a silcone cannister in a gun/dispenser, and squeeze silicone into the cavities, and get a plastic gyprock (or any flat putty-type blade) and push it into the cavities and flatten evenly at the same time..., until all are even...and let dry...

Action: I just ended up filling the bottom/top halves of the sub-platter with roofing silicone..., believe me, its not for the faint-hearted...It feels 'heavy' and 'well-damped', kind of solid... I just cleaned up the subplatter from extraneous silicone dregs etc...put it on, (with the perfected mod to the motor), and I am amazed that there should be such a difference..., more dynamic, 3D soundstage improvement, clarity, black background, seems more silent..., the 'timbre' of instruments is more evident and has added prescence in the room...., as well as vocals tonal quality...., and overall even 'smoother'.... (did I mention punchier deeper bass??)

I feel like there are people playing musical instruments in my room and singing to me...

...everytime I do something to modify it, my Rega sounds better....

...there is no way, I am going to purchase a 'aluminium subplatter' after this result....hehehe

Last edited:

...filling stock sub-platter with silicone

I did this modification at my own risk, weighing all the pros and cons...being careful, its quite a messy and tricky job..., but worth it...I reckon... (when done properly and with patience and care)

...I MADE SURE I WASHED IT WITH DETERGENT FIRST then RINSED VERY WELL ... and quickly dried the metal part and shook the rest off and leave to dry..., for best adhesion...

...after injecting silicone in all the pockets, with a spatula or something similar -- the spreading of the injected silicone that now fills all the pockets, was evenly spread.... in a circular motion around the spindle with one corner on the inside plastic lip (underside) and over the outside lip, moving like around a clock face..., ensuring all the silicone is pressed in evenly covering all the sections and evenly weighed, by eye/level...

..for the topside, (after injecting silicone in all the pockets, as also done in the underside), I found the best way was to drag while pushing the silicone down into the pockets from the center to the outside, its kind of tapered from the inside to outside, but that is OK, as the outer lip holds the platter, and the silicone is just 'damping'...., I had to fiddle and muck around a lot, getting it even at times, adding a dab here and there..., and be patient, but its rewarding...Its amazing how much heavier the sub-platter becomes...

...first I did the underside, .... then I put it in something (with a hole in the centre of it) that will hold it LEVEL until it dries..., then did the same for the topside...I waited until it was dry before cleaning/scraping silicone extra on the outside etc, use a plastic ruler first, scraping it off, then a dry 'scotch brite' Coles dishwashing thin ...whatever it is...(actually they are great for cleaning but not scratching too much, as they are rough plastic or something, and not metal) was used to clean the rest off the end of the sub-platter where the belt goes...

...I ensured the silicone was totally dry, before inserting into base..., and added a few extra drops of oil..., enjoy...🙂

I did this modification at my own risk, weighing all the pros and cons...being careful, its quite a messy and tricky job..., but worth it...I reckon... (when done properly and with patience and care)

...I MADE SURE I WASHED IT WITH DETERGENT FIRST then RINSED VERY WELL ... and quickly dried the metal part and shook the rest off and leave to dry..., for best adhesion...

...after injecting silicone in all the pockets, with a spatula or something similar -- the spreading of the injected silicone that now fills all the pockets, was evenly spread.... in a circular motion around the spindle with one corner on the inside plastic lip (underside) and over the outside lip, moving like around a clock face..., ensuring all the silicone is pressed in evenly covering all the sections and evenly weighed, by eye/level...

..for the topside, (after injecting silicone in all the pockets, as also done in the underside), I found the best way was to drag while pushing the silicone down into the pockets from the center to the outside, its kind of tapered from the inside to outside, but that is OK, as the outer lip holds the platter, and the silicone is just 'damping'...., I had to fiddle and muck around a lot, getting it even at times, adding a dab here and there..., and be patient, but its rewarding...Its amazing how much heavier the sub-platter becomes...

...first I did the underside, .... then I put it in something (with a hole in the centre of it) that will hold it LEVEL until it dries..., then did the same for the topside...I waited until it was dry before cleaning/scraping silicone extra on the outside etc, use a plastic ruler first, scraping it off, then a dry 'scotch brite' Coles dishwashing thin ...whatever it is...(actually they are great for cleaning but not scratching too much, as they are rough plastic or something, and not metal) was used to clean the rest off the end of the sub-platter where the belt goes...

...I ensured the silicone was totally dry, before inserting into base..., and added a few extra drops of oil..., enjoy...🙂

Last edited:

...further isolation enhancement

...a further isolation enhancement (assuming one has a solid sound roof/beams), is to have the turntable on a shelf via bracket, (or hanging with heavy weights-maybe?) attached from the ceiling -- or to a solid wall).... WITHOUT the motor assembly..., and THEN have the motor assembly on the standard sound system shelf on the floor...BOTH aligned at the same place, where they should be, but attached/isolated, at the different locations...

...a 'split plinth/motor isolation' AND 'split placement' system ...

...a further isolation enhancement (assuming one has a solid sound roof/beams), is to have the turntable on a shelf via bracket, (or hanging with heavy weights-maybe?) attached from the ceiling -- or to a solid wall).... WITHOUT the motor assembly..., and THEN have the motor assembly on the standard sound system shelf on the floor...BOTH aligned at the same place, where they should be, but attached/isolated, at the different locations...

...a 'split plinth/motor isolation' AND 'split placement' system ...

Well, you obviously are very excited about this (seven posts in less than 90 minutes!) 😀

Thanks for all the photos and ideas - I'm in the process of modding/upgrading my older Planar-2. Right now it has an Origin Live RB250 (just the tail shaft) and my next project will be a heavier platter (I just ordered a bunch of 12" Corian blanks - stole the idea from Planet10's example). I think freshening up the bearing will be the next step after that.

You've added a bunch of weight already - why not build a custom plinth? The Rega construction seems to be based on a lightweight component model to push the resonances up, while you seem to be going the opposite direction with your approach.

Just some thoughts. Thanks again!

-bill

Thanks for all the photos and ideas - I'm in the process of modding/upgrading my older Planar-2. Right now it has an Origin Live RB250 (just the tail shaft) and my next project will be a heavier platter (I just ordered a bunch of 12" Corian blanks - stole the idea from Planet10's example). I think freshening up the bearing will be the next step after that.

You've added a bunch of weight already - why not build a custom plinth? The Rega construction seems to be based on a lightweight component model to push the resonances up, while you seem to be going the opposite direction with your approach.

Just some thoughts. Thanks again!

-bill

that.

You've added a bunch of weight already - why not build a custom plinth? The Rega construction seems to be based on a lightweight component model to push the resonances up, while you seem to be going the opposite direction with your approach.

Just some thoughts. Thanks again!

-bill

I am thinking of building a slate-plinth custom Rega, however, I don't like the cumbersome look of the 'split-plinth' for motor housing practises. That is why I came up with the idea of a seperate (but aesthetic) heavy and compact (easy-to-make-DIY) motor housing. This is what I would use in a custom plinth as well, ... but its also ideally suited I believe, to modding (with care) a standard Rega 3/2 plinth as well... to extract the most out of a Rega..., with minimum cost...🙂

Last edited:

Disclaimer: this thread and subsequent posts outlines procedures that I used for my Rega modification and is for information purposes only. Certain procedures used may require professional assistance and/or advice. Construction of the base in particular should be done by a professional only. It is up to the user to determine safety issues and concerns and research them accordingly. If anyone decides to duplicate any of the procedures listed, they do so entirely at their own risk and volition.

Last edited:

For safety concerns/issues with regards to the use of lead, ...any kind of 'heavy' disk could (and should to avoid using/working with lead without a professional) be possibly used/modified as a alternate base for isolating the motor..., even a modified 'barbell' weight, (maybe one with plastic/rubber casing around it) etc... it does not have to be cast lead... I used lead because it was heaviest with most damping properties and easiest, ...for me...

Last edited:

...when I created my motor isolation base, I found it important when engineering the cavity in the center of it, for the thrust bearing (for spring/bearing), it was important to ensure the base surface was very flat, as I had to bolt down the Rega motor to it quite firmly, to minimize/avoid grease (possibly) finding its way through (This has not been an issue to date).

.., and for a stable coupling of the motor to the base, so that it would sink/transfer the vibrations/energy from the motor to the base...neutralizing them...(and also minimizing motor vibrations going to the belt)

...I upgraded the platter spindle bearing to ruby: the steel bearing I used for the thrust bearing, which was ideal for the intended purpose...

(In using a barbell weight, a seperate Rega motor thrust bearing would need to be fitted onto the motor and the thrust bearing would protrude into the hole in the weight.)

.., and for a stable coupling of the motor to the base, so that it would sink/transfer the vibrations/energy from the motor to the base...neutralizing them...(and also minimizing motor vibrations going to the belt)

...I upgraded the platter spindle bearing to ruby: the steel bearing I used for the thrust bearing, which was ideal for the intended purpose...

(In using a barbell weight, a seperate Rega motor thrust bearing would need to be fitted onto the motor and the thrust bearing would protrude into the hole in the weight.)

Last edited:

I admit, I found original Planar 3 motor rubber suspension quite funky in the beginning. That didn't put me away from trying motor isolation base. It's similar to TigerScents. A heavy (steel, probably) 24mm x 110mm base round tablet was made in a local "garage" for the cost of 8 euros. Drilling and mounting I made myself. And it's the best cost upgrade ratio I've ever spent.

There's increase in clarity at every register. There's more staging, positioning and just simply more information. I highly recommend it for everybody who own Rega Planar TTs.

There's room for improvement. I didn't mount rubber "feets" on the base for decoupling. Not much space left with current Rega feet height. So it's simply base *** to shelf coupling. I didn't drew a core hole for spring and thrust bearing...

There's increase in clarity at every register. There's more staging, positioning and just simply more information. I highly recommend it for everybody who own Rega Planar TTs.

There's room for improvement. I didn't mount rubber "feets" on the base for decoupling. Not much space left with current Rega feet height. So it's simply base *** to shelf coupling. I didn't drew a core hole for spring and thrust bearing...

Attachments

TIGERSCENT..good article and thanks also for the good quantity and quality of the pics too !

I am currently "doing-up" my Rega Planar 3 with the gorgeous RB300 arm.

So far I have replaced the motor mounting rubber "band" pending later change of motor mounting arrangement.

Also I've installed new platter drive belts x2 and DUAL belt pulley and thrust bearing from LPTurntables-Michael Lim. His thrust bearing DOES have a hex screw for adjustment too and is the cheapest thrust bearing around.

The bearing was dry when I got the table and the actual ball had corrosive growth on it so I repolished the ball and renewed the oil and yay!!

Some heatshrink tubing around the perimeter of the sub-platter, actually 2 layers, provided a slowing of platter speed as I dislike the slightly fast rotation on those earlier Regas.

Stock feet have a 3mm wedge of sorbothane under each foot which assisted noisefloor greatly.

2 days ago I rewired the arm with Cardas 33 from Cardas Cart' Clips to a terminal block which has Ultra-low capacitance interconnect leads to rhodium RCA plugs.

I used a Cartridge Vibration Absorbtion device from GoldenAge Audio in Australia which is carbonfibre sandwich material in a 3mm block mounting between cart and headshell, reducing stylus born vibrations transferring to tonearm and this works very well with results evident using the HFNRR test LP. So this has allowed me to use my Shure V15-III with Sas stylus on the medium-mass Rega arm..The V15-III with Sas is very high compliance and was giving resonance issues without the Cart Vibration Absorber thingy...To ensure correct cart VTA for the Shure I needed to install a 3.8mm serrated 3 point spacer from Michael Lim also- about AUD$25.00..This 3.8mm spacer also needed for taller carts such as Ortofons too as I had also tried a Ortofon Salsa MC cart... Then last Friday I received an Acrylic platter mat from JClovesmusic-ebay. Bought from him before. Couldn't see why full platters in acrylic cost so much. I have to say what a surprise after replacing the stock Rega felt with the "XTC" acrylic mat. Quite an improvement sonically and not very expensive at all. So it is all sounding very nice indeed so far..I am waiting on a ceramic ball bearing and lube oil from DuoPhonic UK-ebay to put paid to the bearing & lube operation; also from same supplier a sorbothane motor "shroud" for vibration reduction. After that I may just spring for an answer to the motor mount aspect-either the additional base idea or a heavy motor base like you have done. Trouble is heavy base from o/seas cost heavy postage too !! The additional base for motor mounting from UK about AUD$200.00 inc post or about $170.00 thru an Australian supplier..so bloody exxie... Cheers 4 now all.

I am currently "doing-up" my Rega Planar 3 with the gorgeous RB300 arm.

So far I have replaced the motor mounting rubber "band" pending later change of motor mounting arrangement.

Also I've installed new platter drive belts x2 and DUAL belt pulley and thrust bearing from LPTurntables-Michael Lim. His thrust bearing DOES have a hex screw for adjustment too and is the cheapest thrust bearing around.

The bearing was dry when I got the table and the actual ball had corrosive growth on it so I repolished the ball and renewed the oil and yay!!

Some heatshrink tubing around the perimeter of the sub-platter, actually 2 layers, provided a slowing of platter speed as I dislike the slightly fast rotation on those earlier Regas.

Stock feet have a 3mm wedge of sorbothane under each foot which assisted noisefloor greatly.

2 days ago I rewired the arm with Cardas 33 from Cardas Cart' Clips to a terminal block which has Ultra-low capacitance interconnect leads to rhodium RCA plugs.

I used a Cartridge Vibration Absorbtion device from GoldenAge Audio in Australia which is carbonfibre sandwich material in a 3mm block mounting between cart and headshell, reducing stylus born vibrations transferring to tonearm and this works very well with results evident using the HFNRR test LP. So this has allowed me to use my Shure V15-III with Sas stylus on the medium-mass Rega arm..The V15-III with Sas is very high compliance and was giving resonance issues without the Cart Vibration Absorber thingy...To ensure correct cart VTA for the Shure I needed to install a 3.8mm serrated 3 point spacer from Michael Lim also- about AUD$25.00..This 3.8mm spacer also needed for taller carts such as Ortofons too as I had also tried a Ortofon Salsa MC cart... Then last Friday I received an Acrylic platter mat from JClovesmusic-ebay. Bought from him before. Couldn't see why full platters in acrylic cost so much. I have to say what a surprise after replacing the stock Rega felt with the "XTC" acrylic mat. Quite an improvement sonically and not very expensive at all. So it is all sounding very nice indeed so far..I am waiting on a ceramic ball bearing and lube oil from DuoPhonic UK-ebay to put paid to the bearing & lube operation; also from same supplier a sorbothane motor "shroud" for vibration reduction. After that I may just spring for an answer to the motor mount aspect-either the additional base idea or a heavy motor base like you have done. Trouble is heavy base from o/seas cost heavy postage too !! The additional base for motor mounting from UK about AUD$200.00 inc post or about $170.00 thru an Australian supplier..so bloody exxie... Cheers 4 now all.

Last edited:

I admit, I found original Planar 3 motor rubber suspension quite funky in the beginning. That didn't put me away from trying motor isolation base. It's similar to TigerScents. A heavy (steel, probably) 24mm x 110mm base round tablet was made in a local "garage" for the cost of 8 euros. Drilling and mounting I made myself. And it's the best cost upgrade ratio I've ever spent.

There's increase in clarity at every register. There's more staging, positioning and just simply more information. I highly recommend it for everybody who own Rega Planar TTs.

There's room for improvement. I didn't mount rubber "feets" on the base for decoupling. Not much space left with current Rega feet height. So it's simply base *** to shelf coupling. I didn't drew a core hole for spring and thrust bearing...

...good to see you are enjoying the benefits of this gr8 low-cost upgrade. Keep in mind that lead has less ringing and better damping..., however your mod sounds as though its working for you. If you wish to put some hi-density foam cutouts under the rubber feet AND under the motor base...you will find that height is not an issue and the whole TT with base will be at same level. This will also improve the sonics. Using a gel layer would probably work better than foam ....

Enjoy...🙂

TIGERSCENT..So far I have replaced the motor mounting rubber "band" pending later change of motor mounting arrangement.

...its worth doing...

Couldn't see why full platters in acrylic cost so much. I have to say what a surprise after replacing the stock Rega felt with the "XTC" acrylic mat. Quite an improvement sonically and not very expensive at all. So it is all sounding very nice indeed so far..

I found the acrylic platter is better sounding...I just cut out some rubber mesh that comes in rolls from Coles and it works beautifully...solid tight sound...very cost effective...

..I am waiting on a ceramic ball bearing and lube oil from DuoPhonic UK-ebay to put paid to the bearing & lube operation; also from same supplier a sorbothane motor "shroud" for vibration reduction. After that I may just spring for an answer to the motor mount aspect-either the additional base idea or a heavy motor base like you have done.

I used the ruby ball from them. It works well, the ceramic is apparantly an greater improvement...

...again, the motor-base is worth doing and the best upgrade option that makes a noticable difference... then consider rewiring the arm...all the other options are added tweaks that improve,....additionally..., but these 2 mods make the most dramatic noticable difference...

Cheers...🙂

Digital tachometer arrived and it measures 34.1 rpm. Is there a way to reduce the speed other than adding thickness to subplatter?

Actualy, that's what I did. Without regret until now. Reduced speed to 33.4. Talk about the shift of tone!

I came up with a novel idea. Use a rubber or silicone washer that is totally flat, such as found in plumbing etc, for a nice, snug and flat fit...., however anything similar will do with..., medium density...

Its an idea I came up with to de-couple and dampen the tonearm from resonance from the plinth/platter..., silicone at the right density would be ideal, but this 'K' valve was the best I could come up with at Bunnings this afternoon...

This is 'instead' of the metal washer/spacer that is usually used to raise the height of the tonearm...

'K' is the word !!

I put some Quick Grip contact on one side of the rubber washer VERY EVENLY and thinly; then on the underside of the base of the tonearm after the thread; and then carefully manouvered it along the base thread of the tonearm, and quickly threaded the wiring through the plinth, and pushed it flat and held for about 10 mins.

Then I cut the excess away first with small sharp curved scissors, around the base, and then with a sharp stanley knife. I then cut some gaffa tape and taped the stainless part of the base up, and proceeded with a dremel and small cylindrical sander implement, to even it out nice and round around the base. I then took the tape off and where it was a bit scuffed through some tape I sanded a bit with 240 grit sandpaper so it was all even with the same look.

I proceeded to wrap some silicone gas thread tape around the threaded base part, several times evenly, to further dampen any would-be resonance in that direction...

I then put some contact cement on the underside of the said 'K' washer ONLY, (not too thick as it spreads out past the edges) and pushed it onto the plinth into the hole. I ensured it was straight and then placed a pad on top of the tonearm, and then carefully balanced a 5kg weight on top and and leaving overnight...., to ensure it adheres 'flat' regarding tonearm alignment....

This should further de-couple the arm from the plinth and dampen any vibrations...

One can also add very thin and even silicone or rubber cut to size on top of the sub-platter for further dampening...

Its about 2mm higher, ....at the base of the tonearm, which should be about right, however adding a thin dampening mat on top of the sub-platter, this can be adjusted....

It works rather well, with such a s-i-m-p-l-e modification. There was clearly a distinct improvement in dynamic range, bass response, and clarity accross all registers...I was surprised by the difference...I am re-discovering all my records and they are an increased joy to listen to. Probably should mention that the volume & bass response seems to be much higher. I notice I need to turn it down by about 7 notches. ie: from -11 to -18

Its an idea I came up with to de-couple and dampen the tonearm from resonance from the plinth/platter..., silicone at the right density would be ideal, but this 'K' valve was the best I could come up with at Bunnings this afternoon...

This is 'instead' of the metal washer/spacer that is usually used to raise the height of the tonearm...

'K' is the word !!

I put some Quick Grip contact on one side of the rubber washer VERY EVENLY and thinly; then on the underside of the base of the tonearm after the thread; and then carefully manouvered it along the base thread of the tonearm, and quickly threaded the wiring through the plinth, and pushed it flat and held for about 10 mins.

Then I cut the excess away first with small sharp curved scissors, around the base, and then with a sharp stanley knife. I then cut some gaffa tape and taped the stainless part of the base up, and proceeded with a dremel and small cylindrical sander implement, to even it out nice and round around the base. I then took the tape off and where it was a bit scuffed through some tape I sanded a bit with 240 grit sandpaper so it was all even with the same look.

I proceeded to wrap some silicone gas thread tape around the threaded base part, several times evenly, to further dampen any would-be resonance in that direction...

I then put some contact cement on the underside of the said 'K' washer ONLY, (not too thick as it spreads out past the edges) and pushed it onto the plinth into the hole. I ensured it was straight and then placed a pad on top of the tonearm, and then carefully balanced a 5kg weight on top and and leaving overnight...., to ensure it adheres 'flat' regarding tonearm alignment....

This should further de-couple the arm from the plinth and dampen any vibrations...

One can also add very thin and even silicone or rubber cut to size on top of the sub-platter for further dampening...

Its about 2mm higher, ....at the base of the tonearm, which should be about right, however adding a thin dampening mat on top of the sub-platter, this can be adjusted....

It works rather well, with such a s-i-m-p-l-e modification. There was clearly a distinct improvement in dynamic range, bass response, and clarity accross all registers...I was surprised by the difference...I am re-discovering all my records and they are an increased joy to listen to. Probably should mention that the volume & bass response seems to be much higher. I notice I need to turn it down by about 7 notches. ie: from -11 to -18

Last edited:

- Home

- Source & Line

- Analogue Source

- Rega Planar 3/2 - Significant modifications