Hi there,

Great work! There are a couple of other things I recommend looking at.

First is the motor PSU. The motor power supply in the Rega is about as basic as you get but they actually use the same motor as the Linn LP12 and a number of other similar turntables. The upshot is that any supply designed for the LP12 will work on the Rega!

There are several DIY designs you could build, you can build a clone of the Naim Armageddon and I have a clone of the Norton Air Power here. These will work fine on your Rega and improve the timing and refinement as well as giving you a bit more detail.

The other thing you want to do is remove the paint on the arm. Johnny, Audio Origami, can do this to very high standard but you can do it yourself quite easily. It opens up the sound, makes it more airy.

By the way, removing the paint is the only modification that Roy Gandi actually approves of! The paint was never part of the original design. Rega could add damping to the arm tube if they wanted to, but they don't, and I agree with them.

Great work! There are a couple of other things I recommend looking at.

First is the motor PSU. The motor power supply in the Rega is about as basic as you get but they actually use the same motor as the Linn LP12 and a number of other similar turntables. The upshot is that any supply designed for the LP12 will work on the Rega!

There are several DIY designs you could build, you can build a clone of the Naim Armageddon and I have a clone of the Norton Air Power here. These will work fine on your Rega and improve the timing and refinement as well as giving you a bit more detail.

The other thing you want to do is remove the paint on the arm. Johnny, Audio Origami, can do this to very high standard but you can do it yourself quite easily. It opens up the sound, makes it more airy.

By the way, removing the paint is the only modification that Roy Gandi actually approves of! The paint was never part of the original design. Rega could add damping to the arm tube if they wanted to, but they don't, and I agree with them.

Hi there,

Great work! There are a couple of other things I recommend looking at.

First is the motor PSU. The motor power supply in the Rega is about as basic as you get but they actually use the same motor as the Linn LP12 and a number of other similar turntables. The upshot is that any supply designed for the LP12 will work on the Rega!

There are several DIY designs you could build, you can build a clone of the Naim Armageddon and I have a clone of the Norton Air Power here. These will work fine on your Rega and improve the timing and refinement as well as giving you a bit more detail.

The other thing you want to do is remove the paint on the arm. Johnny, Audio Origami, can do this to very high standard but you can do it yourself quite easily. It opens up the sound, makes it more airy.

By the way, removing the paint is the only modification that Roy Gandi actually approves of! The paint was never part of the original design. Rega could add damping to the arm tube if they wanted to, but they don't, and I agree with them.

Hey yes: I was considering building a PSU..., which one works best in your opinion - and do you have links to schematics?

I spoke with Johnny about the RB300. He actually uses tonearm damping though, and the damping I did on my arm worked quite well.., I didnt think removing the paint would have a noticable enough effect. I may consider it with my RB250.

Cheers

Last edited:

Hey yes: I was considering building a PSU..., which one works best in your opinion - and do you have links to schematics?

Yes, here you go: LINK

Off hand I don't know where you'd get the plans for the Geddon but I'm sure they're out there. They are both quite simple devices.

As to which is best, well I doubt there is much in it. They are very similar. Few people have done fair comparisons of both but at the time some people who had felt the Air Power was the better of the two. And better than the other LP12 supplies that were available. But like I say, I think that any differences between the two will be very small.

I spoke with Johnny about the RB300. He actually uses tonearm damping though, and the damping I did on my arm worked quite well..,

Yes, maybe it does. I guess it depends on what you are trying to achieve. Some resonances/colourations are noticeable and distracting, like the upper-mid ringing on the Linn Ittok, but I never felt the Rega arms had any such issues. I think they are pretty neutral and if anything a bit bland. I didn't want to kill the sound any more, I wanted to open it up.

I didn't think removing the paint would have a noticeable enough effect.

When Rega designed the arm the whole one-piece casting thing was revolutionary. When it came to finishing the arm to a commercially acceptable standard they found that casting quality was too variable to allow the tube to be left bare. The only cost-effective solution was to paint the tube but the paint does damp the tube and add weight. Eventually Rega managed to refine the casting process and select the cleanest tubes for their best arm. What is the difference between the RB1000 and the cheaper arms? Lack of paint! Yes, of course there are other differences too if the paint helped, or if it made no difference, the RB1000 would be painted.

Having stripped two RB300s I can tell you it is worth doing. I'd say the difference is at least as big as a rewire.

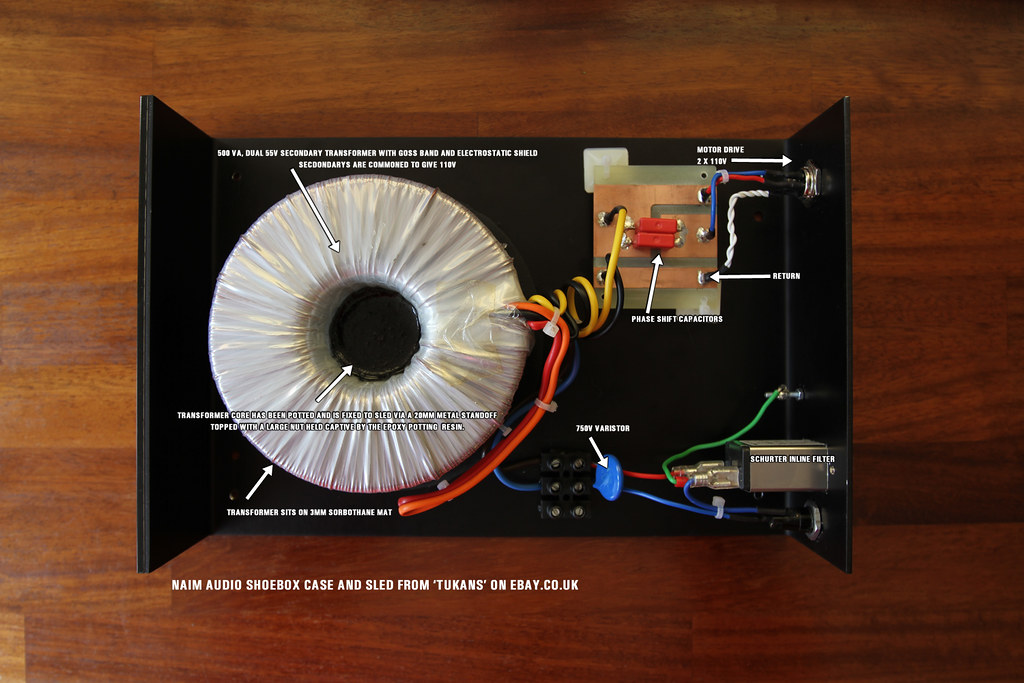

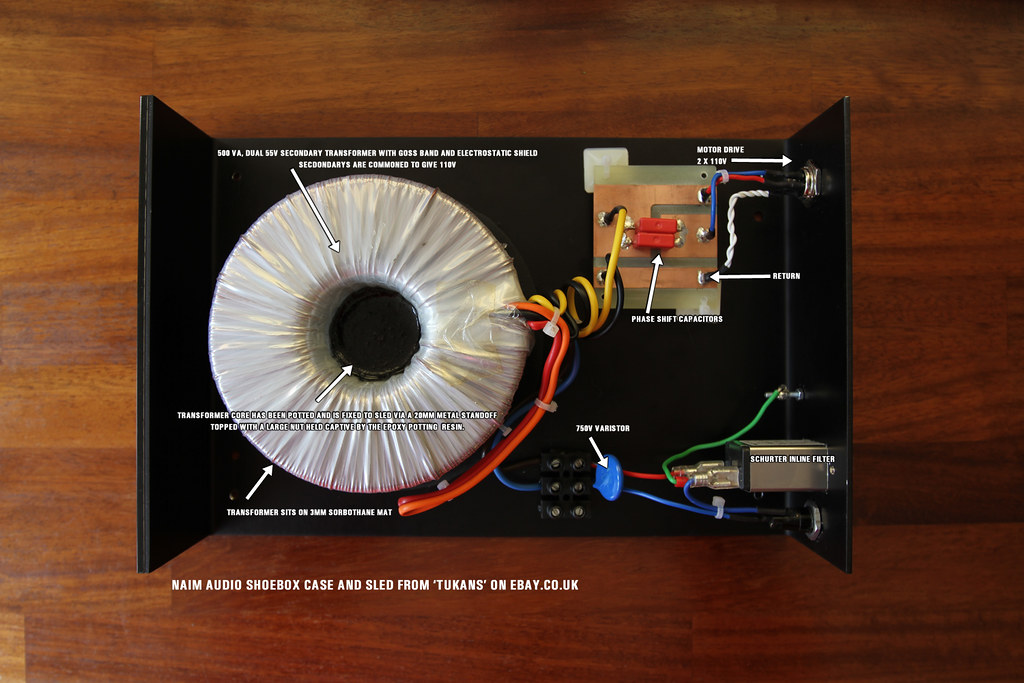

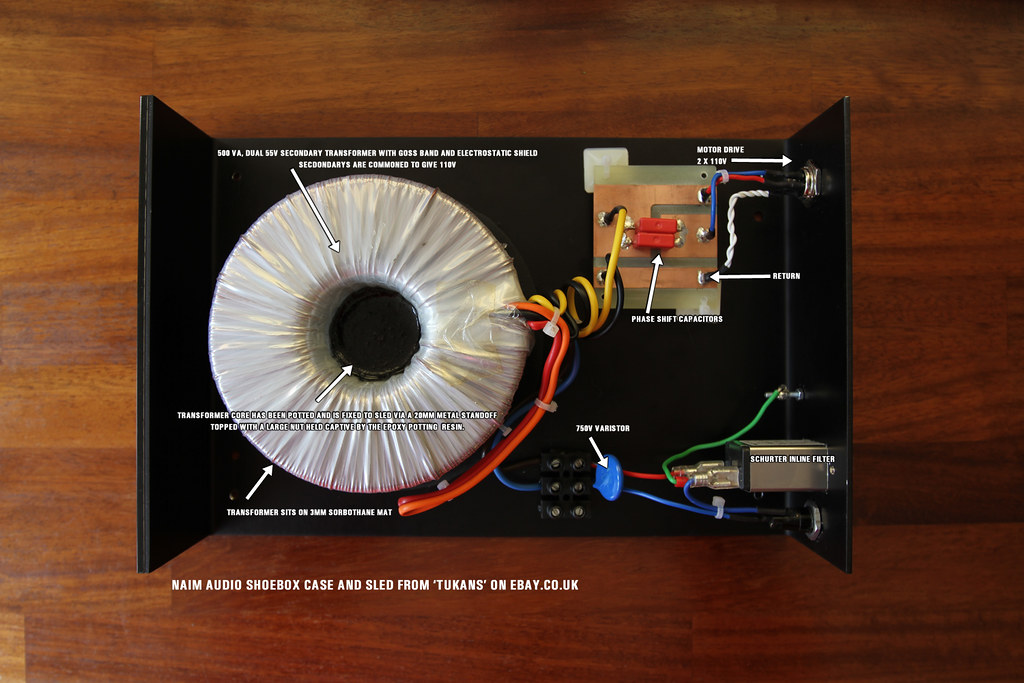

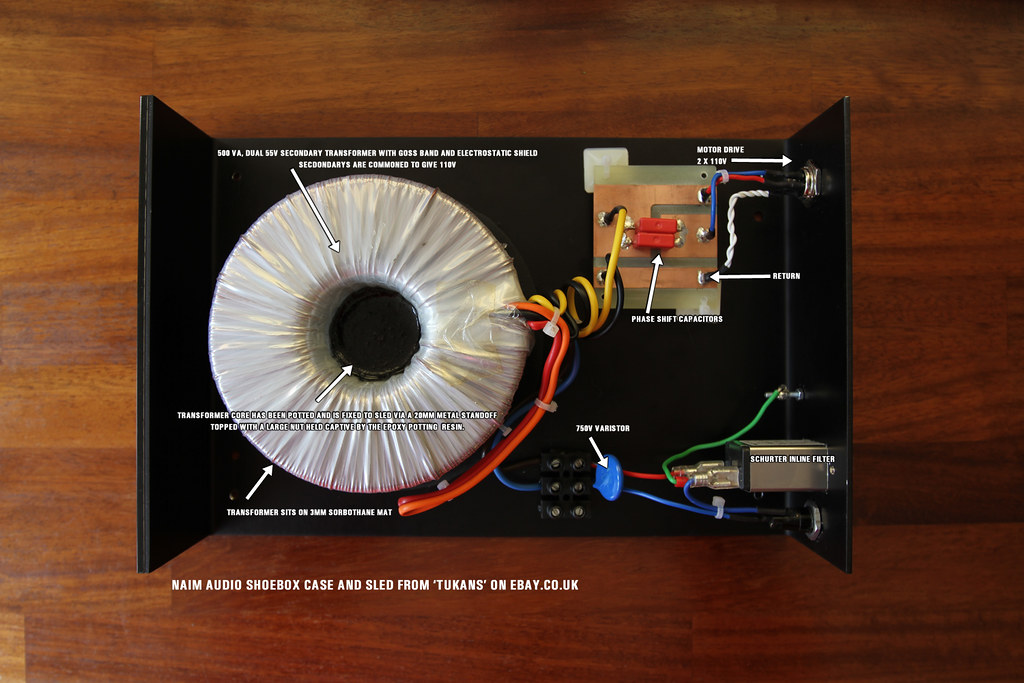

Rega have used 24v (currently) and 120v motors. So make sure if considering a Geddon you use the correct transformer for your needs. Here's my LP motor Geddon used on my Kuzma.

Yes, here you go: LINK

Off hand I don't know where you'd get the plans for the Geddon but I'm sure they're out there. They are both quite simple devices.

As to which is best, well I doubt there is much in it. They are very similar. Few people have done fair comparisons of both but at the time some people who had felt the Air Power was the better of the two. And better than the other LP12 supplies that were available. But like I say, I think that any differences between the two will be very small.

Is there a design that allows for 33/45 speed changes?

Yes, maybe it does. I guess it depends on what you are trying to achieve. Some resonances/colourations are noticeable and distracting, like the upper-mid ringing on the Linn Ittok, but I never felt the Rega arms had any such issues. I think they are pretty neutral and if anything a bit bland. I didn't want to kill the sound any more, I wanted to open it up.

hmmmm, I havent found it an issue - sounds 'smoother' with detail if anything to me...

Having stripped two RB300s I can tell you it is worth doing. I'd say the difference is at least as big as a rewire.

...OK..., now you have me thinking..., so - if you put clear laquer on the arm, after stripping it, then you have the same situation, and if you leave it, it goes dull and oxidises, also giving a similar situation....

...I was thinking of sandblasting it, but its just the finish I am concerned about...., since I have already rewired my RB300 and dont want to send it away...

...but might get Johnnie from AO to gold plate my RB250 arm now, since you mention it....

Last edited:

Rega have used 24v (currently) and 120v motors. So make sure if considering a Geddon you use the correct transformer for your needs. Here's my LP motor Geddon used on my Kuzma.

...I like the simple compact design - I would use the same case...if you can still get it, ... where did you get the transformer from? I have 240v here, and the motor is the 120vAC with modified circuit for 240v.....

...I guess I could dispense with the modified circuit and use a 240primary/120secondary....

Last edited:

The Norton Air-Power looks like it might work best...; anyone done a comparision with Norton and Geddon??

Last edited:

Is there a design that allows for 33/45 speed changes?[quote/]

No, not that I know of. There might be I guess but I've never heard of it.

hmmmm, I havent found it an issue - sounds 'smoother' with detail if anything to me...

It's all a matter of taste. Right now I'm using a step-up transformer I put together for my Denon DL-103 cartridge. In many ways it sounds wonderful. It sound more organic, tuneful, detailed, etc but I probably won't be keeping it in my system. While so much about what it does is good it also robs music of 'bite'. Music that should sound frenetic and edgy sounds 'nice'. So 'smoother' isn't always a good thing.

If you put clear laquer on the arm, after stripping it, then you have the same situation

Yes.

and if you leave it, it goes dull and oxidises

It depends. If you polish the tube yourself my hand you're unlikely to get it as clean and shiny as Johnny can get it and it does dull a bit over time. Not to the extent that it's going to significantly alter the sound though. If it's very highly polished it tarnishes much less.

...I was thinking of sandblasting it...but might get Johnnie to gold plate it....

Any surface treatment you do to the tube will sound different. A gold-plated tube will not sound the same as a stripped one and a bead-blasted one will sound different again. Johnny is probably the best person to ask about the differences, he's heard them, I haven't.

I chose to strip the tube because I knew that Rega approve of that. Lots of people are quick to say 'Oh Rega got this or that wrong' but I think they're better designers than that. Many of the mods that people do to these arms were rejected by Rega for a reason. They might give you one thing at the cost of something else or unbalance the sound. I think it's funny that so many people say that the RB250 is better than the RB300, rubbish! If the configuration of the RB250 was better why would Rega only use it fort their cheapest arm? Would that not be really stupid?

I think it's funny that so many people say that the RB250 is better than the RB300, rubbish! If the configuration of the RB250 was better why would Rega only use it fort their cheapest arm? Would that not be really stupid?

The additional features on the RB300 arm, such as spring assembly for adjustment replaces one side with no bearings, so that the RB300 only has one side with bearings - the RB250 does not have this useless feature, and has 2 bearings instead, giving greater alignment and stability. In addition the spring 'rings like a bell' on the RB300 if you tap it. I had to dampen it and render it unusable.

The wiring is worse on the RB250, and the counterweight is abominably worse. So the cost of producing the RB300 arm is greater, and has added features, with a much better (once tungsten) counterweight; and is therefore put on Regas better turntables with regards to the RB250. However, the RB250 is a more solid and stable performer due to its precise simplicity - IF one changes the counterweight and rewires it (added cost: ie Michell tecnoweight etc).

I dont believe Rega makes all thier decisions based on 'idealism', but some are simply more effective economic measures, and some things - well, just dont work as well, ie: motor needs greater isolation and arm needs decoupling (this is where the music starts sounding more 'live'), not in line with some of Regas statements. What I did I found works. 🙂

Last edited:

That the RB300 only has one side with bearings

That's a popular misconception. The RB300 has two bearings, just like the RB250, and the bearing spindle is supported at both sides, just like the RB250. It's just that the dial-side bearing support is removable on the RB300.

I don't believe Rega makes all thier decisions based on 'idealism', but some are simply more effective economic measures

Maybe, but why then would they use a configuration that was less stable and less effective on their more costly arms when they have a better option that costs less? How does that make sense?

Just as you're looking beyond the surface and considering Rega's motives one has to consider the motives of those who say the RB250 configuration is better. Can that be taken at face value?

Everyone who sells modified Rega arms uses the RB250 configuration and insists that it's better. Why? Did they choose it simply because it is better, as they would have you beleive? Not really. Firstly, it's all they can get! Rega have always supplied RB250-type arms and parts to other companies for modification and resale. For most of their history Rega have refused to supply any of their better arms for this purpose. The modders have used the RB250 because Rega won't give them anything else. Which is fair enough, it's their investment and they can protect it if they want.

Also, if you've ever taken these arms apart you'll know that it's a lot easier to work on an RB250 than an RB300. After-market companies use these arms because it's easy to do some simple work on an already great product and claim credit for the whole thing.

It's the same with dynamic verses static balancing. I don't think that either is inherently wrong, they both have advantages and disadvantages, but most small manufacturers and modders prefer static-balance because it's much simpler to make and to deal with. But of course they're not going to say that are they? No. Every one of them will say that they choose things because they are better, not because they make life easier and are cheaper to make.

Like I say, it's not fair to call into question the motives of Rega while ignoring the motives of the modders. Personally, I think Rega have done all the hard work and understand these arms better than a lot of people give them credit for.

That's a popular misconception. The RB300 has two bearings, just like the RB250, and the bearing spindle is supported at both sides, just like the RB250. It's just that the dial-side bearing support is removable on the RB300.

I should have said that on the RB300 the vertical bearings are only supported on one side of the arm, and supported by the spring assembly on the other, which is a lot sloppier than the RB250...The RB250 is a lot more stable and superior on that regard, as bearings on both sides are secured on each side.

Maybe, but why then would they use a configuration that was less stable and less effective on their more costly arms when they have a better option that costs less? How does that make sense?

So that they could add an extra feature ie: the spring loaded VTF adjustment assembly (which 'rings like a bell' and adds distortion). Its just adding 'bells (forgive the pun) and whistles', with no real practical value...for the discerning audiophile who uses more precise measuring instruments.

I still like the RB300 arm, and have one and use it (modified) and am quite happy with it, but on inspecting the RB250, I believe it will be even better just considering the greater bearing housing stability.... 🙂

Rega have used 24v (currently) and 120v motors. So make sure if considering a Geddon you use the correct transformer for your needs. Here's my LP motor Geddon used on my Kuzma.

I could easily make the Norton AirPower with 2 x 60/80v transformers @ 500VA each, or the Geddon with 1 x 1000 VA tranformer with 55vx2 secondaries..., at a similar price-point...

Which would work best? would there be a major difference?

I was previously thinking of just getting some copper or nickel plaited braiding, and putting shielding on a power cord and shrink tube over that; and earthing it...at some stage. I wonder if that might create a 'good enough' improvement???

Last edited:

I should have said that on the RB300 the vertical bearings are only supported on one side of the arm

No, they're not. The removable plate on the dial side of the bearing boss supports the bearing shaft, just like the fixed side supports the other. What do you think the big nut in the middle does? I'm not saying that it's structurally better than the RB250 but it's not significantly worse either.

Also consider that for a few quid extra, at used prices, you're also getting a stainless steel pillar (brass on the RB250), a stainless steel counter-weight stub (plastic on the RB250) and, if you buy an early one, a tungsten counterweight (mild steel on the RB250). Someone said the cable is better too but I don't know that it is.

Like I said, I've tried disabling the spring tracking force and balancing the arm statically. I can't hear any significant difference. In stock form the RB300 is a good bit better than the RB250. The arm accounted for most of the sonic difference between the Planar 2 and three. The only other difference between the two decks was a couple of millimetres extra thickness on the plinth!

So you buy your RB250 and you need to spend how much just to get it up to the spec of the RB300? Fair enough if you want to mod the arm anyway and yes, of course it will sound better than an RB300 once you've rewired it, fitted a new stub and counterweight, stripped the tube etc but so it should as it will also have cost you a lot more!

I was previously thinking of just getting some copper or nickel plaited braiding, and putting shielding on a power cord and shrink tube over that; and earthing it...at some stage. I wonder if that might create a 'good enough' improvement???

Why would it? I'd be very surprised if it did anything at all.

No, they're not. The removable plate on the dial side of the bearing boss supports the bearing shaft, just like the fixed side supports the other. What do you think the big nut in the middle does? I'm not saying that it's structurally better than the RB250 but it's not significantly worse either.

Also consider that for a few quid extra, at used prices, you're also getting a stainless steel pillar (brass on the RB250), a stainless steel counter-weight stub (plastic on the RB250) and, if you buy an early one, a tungsten counterweight (mild steel on the RB250). Someone said the cable is better too but I don't know that it is.

Like I said, I've tried disabling the spring tracking force and balancing the arm statically. I can't hear any significant difference. In stock form the RB300 is a good bit better than the RB250. The arm accounted for most of the sonic difference between the Planar 2 and three. The only other difference between the two decks was a couple of millimetres extra thickness on the plinth!

So you buy your RB250 and you need to spend how much just to get it up to the spec of the RB300? Fair enough if you want to mod the arm anyway and yes, of course it will sound better than an RB300 once you've rewired it, fitted a new stub and counterweight, stripped the tube etc but so it should as it will also have cost you a lot more!

Well, I took the thing apart - so I know; and clearly it is only supported securely on one side. The spring-loaded side is not a secure support in comparison, but is surprisingly basic and and nowhere near as secure as the RB250..., however it is also a commonly known fact stated in a number of reputable sources ie:

"Unlike the RB250, the RB300's vertical bearings are supported on just one side of the bearing housing to make room for the VTF adjuster on the opposite side. External wiring is slightly higher quality than that on the RB250. Internal wiring is identical." A Guide to Rega Tonearms | From RB250 to Michell TecnoArms | Vinyl Engine

In addition, one needs to properly 'dampen' the spring to stop it from ringing..., for if one taps on the RB300 with the stub against ones ear, one can hear it 'ring'. Setting it to 3 is not enough and does not stop the ringing. All these mods add up and make towards a better sounding tonearm once done.

I pointed out in a previous post that the counterweight and wiring was better on the RB300, but once changed on the RB250, it was structurally superior and is most likely to have a better sound. In any case, I would advise changing the wiring on either arm, so its a moot point to the DIY'er. If dampening the arm, you need a heavier weight anyway to being it closer to the pivot point - which is advisable; and the Michell tecnoweight is a good option.

Last edited:

Why would it? I'd be very surprised if it did anything at all.

Countering induced RF interference which may affect on some level the smoother possible running of the motor.

Used a fair bit in HiFi. Do a google search on it.

It may make a difference to some degree on a TT - with regards to the motor; and it may not. Just an idea...

Last edited:

"Unlike the RB250, the RB300's vertical bearings are supported on just one side of the bearing housing to make room for the VTF adjuster on the opposite side."

I have lost count of the number of times that I've seen this said despite knowing for a fact that it's wrong. I took the trouble of asking Paul Darwin at Rega to clarify. Here is what he said:

"I can state categorically that ALL Rega arms are supported on two sides, confusion may come in because of the spring tracking but it is still supported on both sides."

ALL Rega arms have two bearings for horizontal movement and ALL Rega arms support the bearing shaft at both sides. I can't reach the whole internet but I hope that at least on this forum people can get this simple fact right at last.

Tiger, IME you can shield the power cable all you like the improvement will be the absolute square root of SFA. If you want to improve on a simple phase shift capacitor network then a big traffo to clean higher mains frequency harmonics is a good way to do it. I'm not a fan of different voltages on different phases. All you are doing is weakening the drive torque of the motor at half of the poles, much better to use the correct phase cap values so that the drive isn't skewed, hint 0.22uf isn't the right value, and as motor windings vary it can be off by more than 10% and that's a difference you can feel in the palm of your hand.

I use the big traffo because that's what measured best looking at a series of Fm speed demodulations of test tones played via my deck. I do use very thick 'oil' in my deck which adds considerable drag, collapses the magnetic field in the motor and all but eliminates cogging artefacts in the process. You do trade a tiny bit of belt slippage and slow down if you go too viscous, but find the right value and it's all positives. (I'm not sure what 'oil' you could use on the Rega bearing that would add viscous drag, I use an LP12 bearing which has air bleed holes so is ideal for purpose.

I use the big traffo because that's what measured best looking at a series of Fm speed demodulations of test tones played via my deck. I do use very thick 'oil' in my deck which adds considerable drag, collapses the magnetic field in the motor and all but eliminates cogging artefacts in the process. You do trade a tiny bit of belt slippage and slow down if you go too viscous, but find the right value and it's all positives. (I'm not sure what 'oil' you could use on the Rega bearing that would add viscous drag, I use an LP12 bearing which has air bleed holes so is ideal for purpose.

I have lost count of the number of times that I've seen this said despite knowing for a fact that it's wrong. I took the trouble of asking Paul Darwin at Rega to clarify. Here is what he said:

"I can state categorically that ALL Rega arms are supported on two sides, confusion may come in because of the spring tracking but it is still supported on both sides."

ALL Rega arms have two bearings for horizontal movement and ALL Rega arms support the bearing shaft at both sides. I can't reach the whole internet but I hope that at least on this forum people can get this simple fact right at last.

Have you taken one apart? I can tell you that the support is not of the same standard on the spring assembly side, and one gets a strong impression there is only one bearing. Even though there are two, the secure and proper support for them is only on one side. The other sides support is nowhere near as secure nor precise and therefore not as stable as the RB250

Yeah, I was thinking the shielded cable would be most effective with regards to electronics....Tiger, IME you can shield the power cable all you like the improvement will be the absolute square root of SFA. If you want to improve on a simple phase shift capacitor network then a big traffo to clean higher mains frequency harmonics is a good way to do it. I'm not a fan of different voltages on different phases. All you are doing is weakening the drive torque of the motor at half of the poles, much better to use the correct phase cap values so that the drive isn't skewed, hint 0.22uf isn't the right value, and as motor windings vary it can be off by more than 10% and that's a difference you can feel in the palm of your hand.

I use the big traffo because that's what measured best looking at a series of Fm speed demodulations of test tones played via my deck. I do use very thick 'oil' in my deck which adds considerable drag, collapses the magnetic field in the motor and all but eliminates cogging artefacts in the process. You do trade a tiny bit of belt slippage and slow down if you go too viscous, but find the right value and it's all positives. (I'm not sure what 'oil' you could use on the Rega bearing that would add viscous drag, I use an LP12 bearing which has air bleed holes so is ideal for purpose.

Are you suggesting that the 'Geddon' single transformer as a 'large one' of about 1000 VA is preferrable to the Norton Air Power which uses 2 of differing voltages each 500 VA?

...and what would the more correct capacitor value be instead of 0.22uf ???

...also, on your 'Geddon', what values are the 'phase shift capacitors'? and what is the 'return' part of the ciruit - it must be the earth or ground wire ?

Last edited:

Have you taken one apart?

Yes.

one gets a strong impression there is only one bearing. Even though there are two

Brilliant mate, really :0)

Look, you can think what you want. I know how the arms are constructed and I gave you a quote from Rega telling you how they are constructed. I could explain it at length but that would just come across as patronising, and I really can't be bothered.

- Home

- Source & Line

- Analogue Source

- Rega Planar 3/2 - Significant modifications