In that case, where is offset angle? It looks like 90 degree to me.

Point B does NOT pivot and is at a fixed angle therefore point B is the offset angle. If there's no offset, it would be straight from point A to point C, which is the effective length. Again, it's not that different from a Dynavector arm, except it has a much shorter arm for vertical movement. If the arm is tangential, BCD would always be a right triangle. It is not.

Gus' arm adds unnecessary mass and geometric confusion to a conventional pivot arm but if it sounds good to him then that's all that matters. He can of course alter it or align it differently to see if there's further improvement.

Point B does NOT pivot and is at a fixed angle therefore point B is the offset angle. If there's no offset, it would be straight from point A to point C, which is the effective length. Again, it's not that different from a Dynavector arm, except it has a much shorter arm for vertical movement. If the arm is tangential, BCD would always be a right triangle. It is not.

Gus' arm adds unnecessary mass and geometric confusion to a conventional pivot arm but if it sounds good to him then that's all that matters. He can of course alter it or align it differently to see if there's further improvement.

I do intend to make some changes. This was always just an experiment. The other two conventional arms both perform better than expected, especially the 12".

The whole point of knocking up the test record player is so that I can mess about without doing any damage to the good decks.

As an aside, the test deck is a bitsa. The platter and bearing is from an AR EB101 and the motor from an old Dual. The pulley was miles too small. As I don't have a metal working lathe, it was necessary innovate!! The shaft on the motor is the same size as the axles on slot racers so I used a wheel which has a strong grub screw fixing, stuck a couple of thick brass washers onto the wheel, stuck it on the drill press and used a file to shape the pulley!! The strobe disk shows that it is dead to speed, the dots staying still with no movement at all. Quite impressed with myself

I do intend to make some changes. This was always just an experiment. .... Quite impressed with myself

I'm just an armchair theorist but you're the fearless experimenter and I admire that and you should be impressed by yourself. Have fun!

PS, don't forget to update with any changes, especially if you decide to add an extra pivot to turn it into a "Birch" arm.

Point B does NOT pivot and is at a fixed angle therefore point B is the offset angle. If there's no offset, it would be straight from point A to point C, which is the effective length. Again, it's not that different from a Dynavector arm, except it has a much shorter arm for vertical movement. If the arm is tangential, BCD would always be a right triangle. It is not.

Gus' arm adds unnecessary mass and geometric confusion to a conventional pivot arm but if it sounds good to him then that's all that matters. He can of course alter it or align it differently to see if there's further improvement.

Yes. You are right. I understand it now.

I'm just an armchair theorist but you're the fearless experimenter and I admire that and you should be impressed by yourself. Have fun!

PS, don't forget to update with any changes, especially if you decide to add an extra pivot to turn it into a "Birch" arm.

I'm a bit confused about the Birch arm. Surely if there are two pivots, there would be no control over how the arm behaves. The present pivot would have little or no force applied as the one under the arm would move about or perhaps, even pull the whole shebang forward without moving across the record at all. I need to have a look a the Birch in order to understand.

Well, good though it sounded, the 90 degree arm wasn't better than my 12" so it's been modified.

It now represents my take on the Dynovector arm. Much simplified of course. The mastic around the wires is drying right now but tomorrow I will wire it up and we will see what we will hear.

Just the one horizontal pivot so I still need the big weight to even the load on the bearing. A simple rod stops the small arm from dropping too far. manual for the mo but I reckon I can figure out a lift of some kind.

Should I keep posting this sort of stuff here or should I go back to my other thread?

It now represents my take on the Dynovector arm. Much simplified of course. The mastic around the wires is drying right now but tomorrow I will wire it up and we will see what we will hear.

Just the one horizontal pivot so I still need the big weight to even the load on the bearing. A simple rod stops the small arm from dropping too far. manual for the mo but I reckon I can figure out a lift of some kind.

Should I keep posting this sort of stuff here or should I go back to my other thread?

An externally hosted image should be here but it was not working when we last tested it.

Should I keep posting this sort of stuff here or should I go back to my other thread?

I don't mind and I'm pretty sure others don't mind either. I enjoy it.

virtual pivot

This thread just simmers for a while then boils over. It's really good to see new guys and projects.

When I first started to work out a working Birch Thales arm I wondered if some sort of pantograph arrangement set at the pivot might work. I finally got around to testing that and it does. The dual pivot arms create a virtual control point and just eyeballing the swing arm tracks tangentially quite accurately. The arm swings smoothly and easily even with cheap bearings.

Next I need to get a real swing arm with vertical bearings built.

This thread just simmers for a while then boils over. It's really good to see new guys and projects.

When I first started to work out a working Birch Thales arm I wondered if some sort of pantograph arrangement set at the pivot might work. I finally got around to testing that and it does. The dual pivot arms create a virtual control point and just eyeballing the swing arm tracks tangentially quite accurately. The arm swings smoothly and easily even with cheap bearings.

Next I need to get a real swing arm with vertical bearings built.

Attachments

OK, now to answer/follow up on some previous posts.

bgruhn: Hi Bill, my apologies for taking so long to reply. I read multiple recommendations for the ADC, particularly the XLM, so when I had a chance to get one reasonably, I jumped. It's a very nice cart. I designed that arm specifically for high compliance light VTF carts and it works well with the ADC and Shure M91.

gus3049: Welcome to the madness. I liked the arms you posted in the other thread and here. A zen teacher named D.T. Suzuki wrote that a beginner has some advantages because of not knowing what can't be done. You're off to a good start. If you dig back through this thread, there's a wealth of information about the Birch Thales geometry including Mark Kelly's posts on the math and how to make a drawing starting at #210. Super10018's otherwise excellent drawing in #874 leaves out two absolutely critical components. There has to be a control pivot at the point where to dotted lines converge and a connection between that point and the pivot arm. Without that control, no force is applied is applied at B so the pivot arm will not rotate.

super10018: DD has answered most of your points about pivot LTs, but let me add a couple. For instance, mechanical advantage is in their favor, the arm doesn't always hang over the platter, vertical bearings can be better placed, and neutral balance is easier to achieve. Ultimately, I think the best reason to build a pivot LT is just for the hell of it. There are inherent tracking inaccuracies, as Jonathon Carr, 2wice, and I have reported, but they can be minimized. There is skating, but, again, that can be dealt with. They do have to be designed and built with some precision, but going by the very nice work you did on your own LT, you shouldn't have a problem.

bgruhn: Hi Bill, my apologies for taking so long to reply. I read multiple recommendations for the ADC, particularly the XLM, so when I had a chance to get one reasonably, I jumped. It's a very nice cart. I designed that arm specifically for high compliance light VTF carts and it works well with the ADC and Shure M91.

gus3049: Welcome to the madness. I liked the arms you posted in the other thread and here. A zen teacher named D.T. Suzuki wrote that a beginner has some advantages because of not knowing what can't be done. You're off to a good start. If you dig back through this thread, there's a wealth of information about the Birch Thales geometry including Mark Kelly's posts on the math and how to make a drawing starting at #210. Super10018's otherwise excellent drawing in #874 leaves out two absolutely critical components. There has to be a control pivot at the point where to dotted lines converge and a connection between that point and the pivot arm. Without that control, no force is applied is applied at B so the pivot arm will not rotate.

super10018: DD has answered most of your points about pivot LTs, but let me add a couple. For instance, mechanical advantage is in their favor, the arm doesn't always hang over the platter, vertical bearings can be better placed, and neutral balance is easier to achieve. Ultimately, I think the best reason to build a pivot LT is just for the hell of it. There are inherent tracking inaccuracies, as Jonathon Carr, 2wice, and I have reported, but they can be minimized. There is skating, but, again, that can be dealt with. They do have to be designed and built with some precision, but going by the very nice work you did on your own LT, you shouldn't have a problem.

gus3049: Welcome to the madness. I liked the arms you posted in the other thread and here. A zen teacher named D.T. Suzuki wrote that a beginner has some advantages because of not knowing what can't be done. You're off to a good start. If you dig back through this thread, there's a wealth of information about the Birch Thales geometry including Mark Kelly's posts on the math and how to make a drawing starting at #210. Super10018's otherwise excellent drawing in #874 leaves out two absolutely critical components. There has to be a control pivot at the point where to dotted lines converge and a connection between that point and the pivot arm. Without that control, no force is applied is applied at B so the pivot arm will not rotate.

Hi,

Thanks for the additional info, it makes more sense now. Jumping in has been a feature of my life. I made my first guitar without having any knowledge of how it should be done but there are features of that first instrument that I still use. I only learned how to do it properly at college in my fifties but it is surprising how much you learn just by trying stuff.

The Dynovector type arm is now playing and sounds very good, much better than my previous effort which I guess is not too surprising, given the geometry. I like the idea of the short arm. It feels like it should be better resonance wise and certainly sounds very even. It has bought a lot of detail to the fore whereas the Rega tends to smooth things out a little.

Mind you, I would find it hard to choose between this one and my bog standard 12". Given the simplicity, I think I'll stick to the 12" on my main deck.

I can't wait to get the linear tracker back from my brother in law. It's a problem trying to develop something when we are in two different countries. We have to post it back and forth for testing and development purposes. If it all works out I will post it on my other thread as it certainly isn't a tangential pivot arm!!

Ultimately, I think the best reason to build a pivot LT is just for the hell of it.

That's the spirit!

When I first started to work out a working Birch Thales arm I wondered if some sort of pantograph arrangement set at the pivot might work. I finally got around to testing that and it does. The dual pivot arms create a virtual control point and just eyeballing the swing arm tracks tangentially quite accurately. The arm swings smoothly and easily even with cheap bearings.

Next I need to get a real swing arm with vertical bearings built.

That's the idea I've been toying with, a parallelogram or 4 pivot point horizontal frame that holds the vertical arm without magnet nor "tail rod." Thanks for confirming that it works! Can't wait for more updates. Thanks Doug!

Last edited:

Ralf,

Thank you.

I don't deal well with math, either. As I get deeper into arm design, I really regret that. My approach is pretty blunt, a lot of cut and try.

When I was doing the first two arms, I sometimes drew pivot circles for different length swing arms on the same drawing. The circles appeared to parallel each other and that seemed to be inherent in the logic of Thales circles. As I told DD, I'd been playing with the pantograph possibility for a while and decided to at least build a model, which was rickety affair, but showed the idea had promise.

With the Birch Thales, the length of the swing arm determines the pivot arm length and vice versa. The dual pivot means the initial choice of one or the other can be pretty arbitrary because a major problem with longer swings arms has been eliminated, but Jonathon Carr's tables seem to establish that there are specific swing/pivot ratios that result in the least tracking error. Mark Kelly found the same thing, I believe.

I think the dual pivot might be arranged so that the outside rear pivot bearing follows an ellipse, which would mean even more accurate tracking, but that brings me back to math, again, alas.

Thank you.

I don't deal well with math, either. As I get deeper into arm design, I really regret that. My approach is pretty blunt, a lot of cut and try.

When I was doing the first two arms, I sometimes drew pivot circles for different length swing arms on the same drawing. The circles appeared to parallel each other and that seemed to be inherent in the logic of Thales circles. As I told DD, I'd been playing with the pantograph possibility for a while and decided to at least build a model, which was rickety affair, but showed the idea had promise.

With the Birch Thales, the length of the swing arm determines the pivot arm length and vice versa. The dual pivot means the initial choice of one or the other can be pretty arbitrary because a major problem with longer swings arms has been eliminated, but Jonathon Carr's tables seem to establish that there are specific swing/pivot ratios that result in the least tracking error. Mark Kelly found the same thing, I believe.

I think the dual pivot might be arranged so that the outside rear pivot bearing follows an ellipse, which would mean even more accurate tracking, but that brings me back to math, again, alas.

Last edited:

I don't know if you realize it or not but your dual pivot tonearm is a brilliant idea.

Mathematics not being my strong side, I wonder what mathematical method may help in determining the optimum locations of all the pivots?

Sincerely,

Ralf

Goes for me too. This is by far my favorite thread on diyaudio, and though I myself have not contributed a lot, there are always loads of good ideas.

Doug's dual pivot contribution is awesome, and I can't imagine why I havent seen this on paper or in real life before.

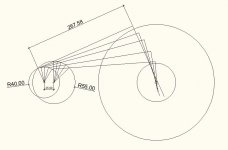

This is what I have come up with after 30 minutes on Autocad:

This is done by trial and error, but hopefully there could be some basic math at the bottom of this.

Steen

Attachments

Doug,

I am not going to argue which arm has the favor mechanically here. To my experience, linear arm can easily outperform pivot arm.

Your experiment is excellent! However, I am not sure why it needs a guide mechanism. The guide mechanism you have adds one more contact point. It means adding more friction. What it needs may be just something like anti-skating device to add a inward force. This force can be added on magnetically or mechanically.

I am not going to argue which arm has the favor mechanically here. To my experience, linear arm can easily outperform pivot arm.

Your experiment is excellent! However, I am not sure why it needs a guide mechanism. The guide mechanism you have adds one more contact point. It means adding more friction. What it needs may be just something like anti-skating device to add a inward force. This force can be added on magnetically or mechanically.

Steen,

Thanks for posting the CAD drawing. I can't do that, either. I have to draw everything with a T square, a compass, and in pencil. Your 30 minutes have you headed in the right direction. Replicating the original Birch drawing in CAD might be a good idea and I suggest checking Jonathon Carr's posts about the importance of null points. I know, bunch of damned numbers, but it's worth it. I don't quite understand why this idea hasn't surfaced before because it's strongly implied in the Birch drawing - just kinda sitting there. With any luck, there isn't some snag I'm just not aware of yet.

super10018,

You've built a couple of very good parallel LTs. At the very least build a model of the arm mechanism you are suggesting. The construction is well within your abilities and it may prove to be an interesting and valuable new track (sorry, couldn't resist). Right now, though, you are arguing from an untested hypothesis.

Thanks for posting the CAD drawing. I can't do that, either. I have to draw everything with a T square, a compass, and in pencil. Your 30 minutes have you headed in the right direction. Replicating the original Birch drawing in CAD might be a good idea and I suggest checking Jonathon Carr's posts about the importance of null points. I know, bunch of damned numbers, but it's worth it. I don't quite understand why this idea hasn't surfaced before because it's strongly implied in the Birch drawing - just kinda sitting there. With any luck, there isn't some snag I'm just not aware of yet.

super10018,

The point you consistently miss is that this is a linear tracking arm.To my experience, linear arm can easily outperform pivot arm.

Thank you.Your experiment is excellent!

Because it won't work without one.However, I am not sure why it needs a guide mechanism.

What you are proposing is just the same devil in a different dress.What it needs may be just something like anti-skating device to add a inward force. This force can be added on magnetically or mechanically.

You've built a couple of very good parallel LTs. At the very least build a model of the arm mechanism you are suggesting. The construction is well within your abilities and it may prove to be an interesting and valuable new track (sorry, couldn't resist). Right now, though, you are arguing from an untested hypothesis.

Last edited:

The construction is well within your abilities and it may prove to be an interesting and valuable new track (sorry, couldn't resist). Right now, though, you are arguing from an untested hypothesis.

You are 100% correct. I am going to do some experiments to see if it works without a guide mechanism.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms