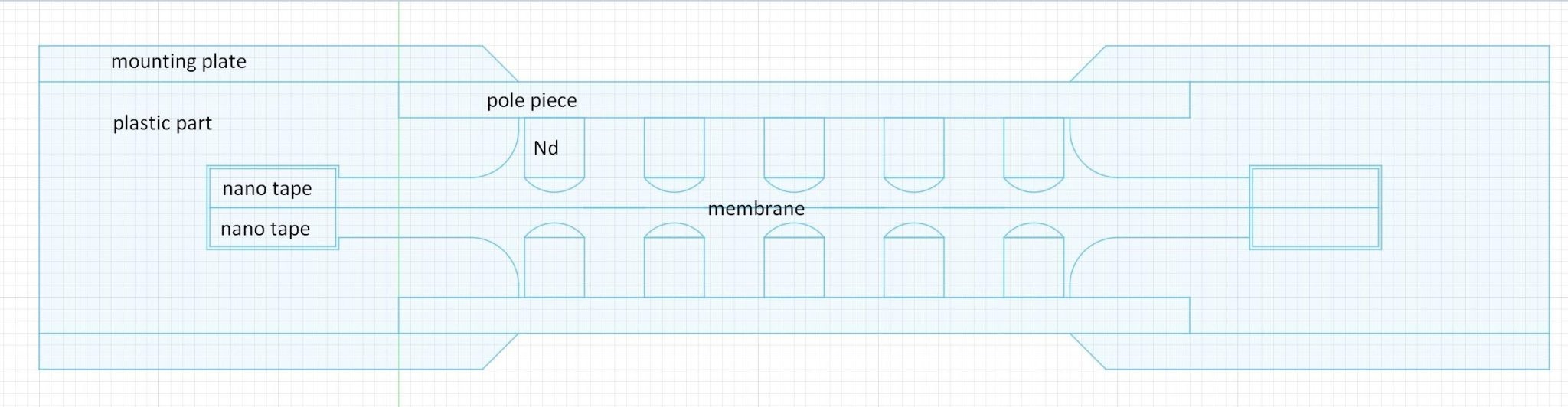

SMAPPP stands for Solhagas's MAgnetic Push Pull Planar.

It'll be a line source 224 cm high; 88 inches for you imperials.

I haven't decided yet if it will be a combined mid and tweeter membrane or seperate membranes.

It will in both cases be one frame with one magnetic structure.

I have a couple of design concerns.

First one is the suspension.

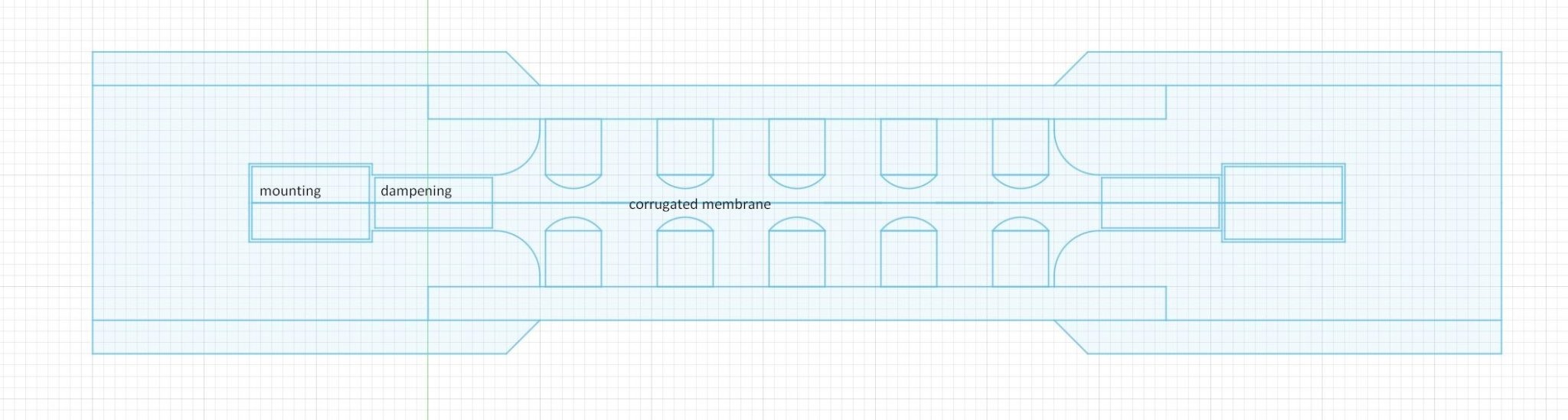

Will it be enough compliance if the membrane is mounted between two 2 millimeter thick nano tape and the distance to the active part of the membrane is 20 millimeters away as depicted below?

It'll be a line source 224 cm high; 88 inches for you imperials.

I haven't decided yet if it will be a combined mid and tweeter membrane or seperate membranes.

It will in both cases be one frame with one magnetic structure.

I have a couple of design concerns.

First one is the suspension.

Will it be enough compliance if the membrane is mounted between two 2 millimeter thick nano tape and the distance to the active part of the membrane is 20 millimeters away as depicted below?

Well, that's my conundrum

I would prefer a flat membrane as it is easier to make and perhaps its tension doesn't detoriate as a corrugated one could.

But I am not sure that I'll get enough compliance; I reckon the needed Xmax is 0.5 mm one way.

Perhaps it will suffice to extend the non aluminium part of the membrane to 30 mm instead of 20? or 40 mm?

Yes, perhaps I need tension on one or two sides and only have the nano tape on one side.

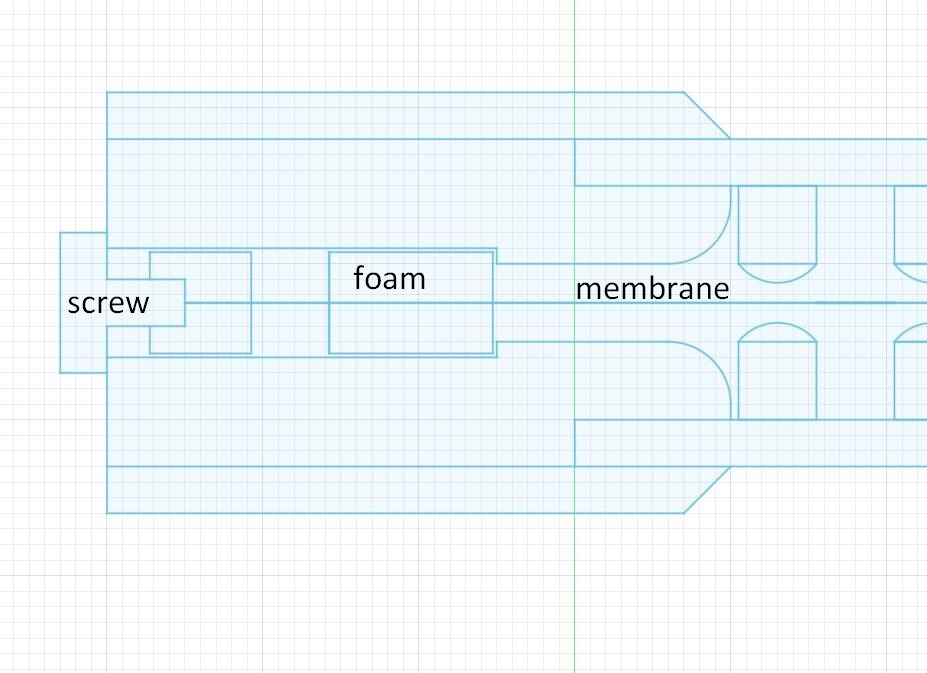

And then use foam as you do instead of using nano tape.

Here's a suggestion:

The membrane can be tensioned by the screw, the plastic part where the membrane is fastened is threaded.

Perhaps the foam isn't even needed?

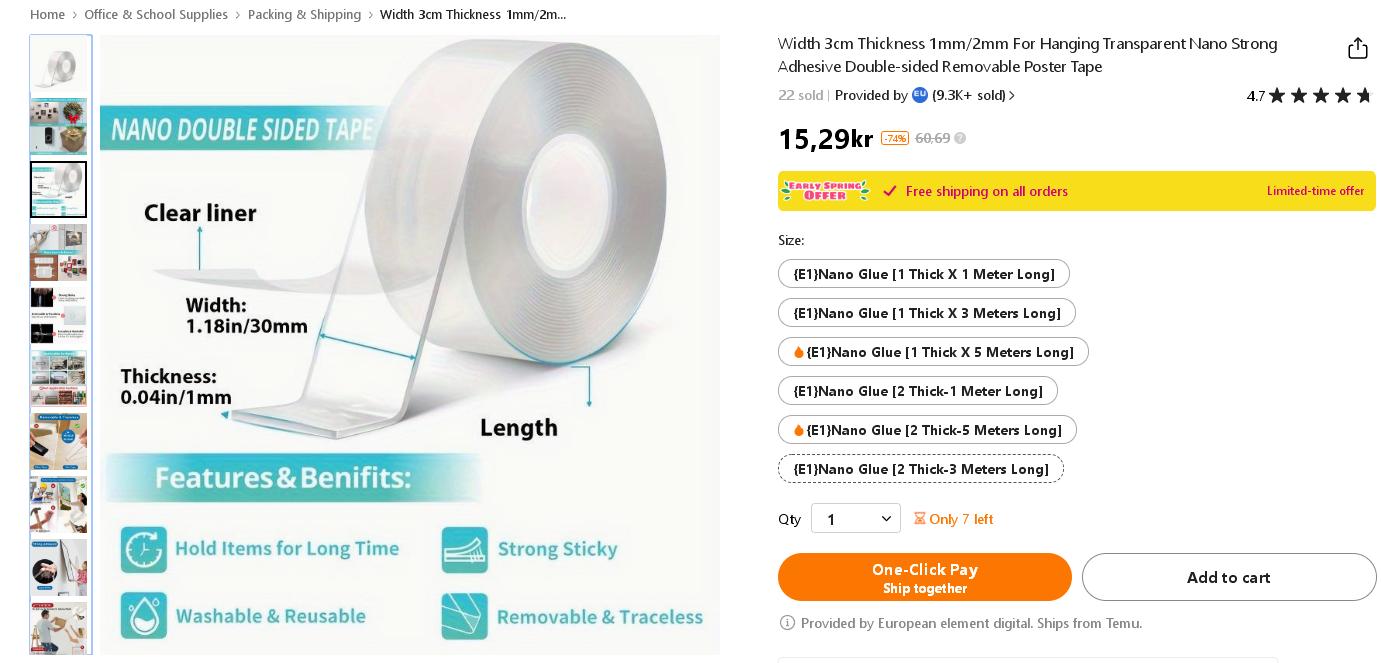

This is nano tape:

It bonds very well to the mylar and adds a little compliance.

I would prefer a flat membrane as it is easier to make and perhaps its tension doesn't detoriate as a corrugated one could.

But I am not sure that I'll get enough compliance; I reckon the needed Xmax is 0.5 mm one way.

Perhaps it will suffice to extend the non aluminium part of the membrane to 30 mm instead of 20? or 40 mm?

Yes, perhaps I need tension on one or two sides and only have the nano tape on one side.

And then use foam as you do instead of using nano tape.

Here's a suggestion:

The membrane can be tensioned by the screw, the plastic part where the membrane is fastened is threaded.

Perhaps the foam isn't even needed?

This is nano tape:

It bonds very well to the mylar and adds a little compliance.

The foam is good thing, because it can damp the transversal and longitudinal resonances.Perhaps the foam isn't even needed?

so active membrane around 40 mm ? then 10mm of mylar without foil on either side ? so with corugation you could achieve a really low res. but mayb thats not what your looking for. 96dB jeees.... should be able to cross lower if you use this kind of heavy crossover  if the stretched mylar allows it

if the stretched mylar allows it

It is 5Alu + 5Mylar + 5Alu + 5Mylar + 5Alu + 5Mylar + 5Alu, so it is a 35 mm active membrane.

But the mylar without foil on each side is much longer than 10 mm, I'd say its about 35 mm on each side of the active membrane.

So I think that will give enough compliance, what do you think?

The crossover is not that heavy, it is just a number to enter in rePhase to make the convolution filters for Roon's DSP.

But the mylar without foil on each side is much longer than 10 mm, I'd say its about 35 mm on each side of the active membrane.

So I think that will give enough compliance, what do you think?

The crossover is not that heavy, it is just a number to enter in rePhase to make the convolution filters for Roon's DSP.

well i dont know i always had bad freq response with stretched mylar with large parts undriven, they will break up and create a peak and a dip. using allot of foam results in a smaller drum partially damped but also makes the resonance go up, because the mylar does not move much there (if all). so you win some and then you lose some. i never directly compared the same area mylar stretched and damped on the sides compared to just a rectangular foil with the same size of foil ( from foam to foam x length) and no foam.

i bet there will be a difference but cant say i tested it (it does work for lower frequencies, since the peak dip is higher up, out of the passband of the driver)

it has been a while since i tried these might need to look at my own video's haha

might need to look at my own video's haha

i bet there will be a difference but cant say i tested it (it does work for lower frequencies, since the peak dip is higher up, out of the passband of the driver)

it has been a while since i tried these

I think, at most of the planars and electrostats must install a lot of damping tools (mesh or fleece behind membrane). But the push-pull NdFeBN magnestic assembly provides a lot of electrical damping at basal resonance (at your plan this is a real scenario), perhaps will be enough take damping material at perimeter of membrane

i meant corugation horizontal over the entire foil. i know this screws up you spacing. corugation vertical like here makes the midle part without any tension or strength. flopping around.

because of the corugation there is no tension side ways. lowering resonance and with the stifness due to corugation you wont have the dip and peak i mentioned . plus your foil width can be kept much smaller. res of the foil in video is 300Hz or something while the foil is 59 mm wide

like this but hen push pul in your case.

because of the corugation there is no tension side ways. lowering resonance and with the stifness due to corugation you wont have the dip and peak i mentioned . plus your foil width can be kept much smaller. res of the foil in video is 300Hz or something while the foil is 59 mm wide

like this but hen push pul in your case.

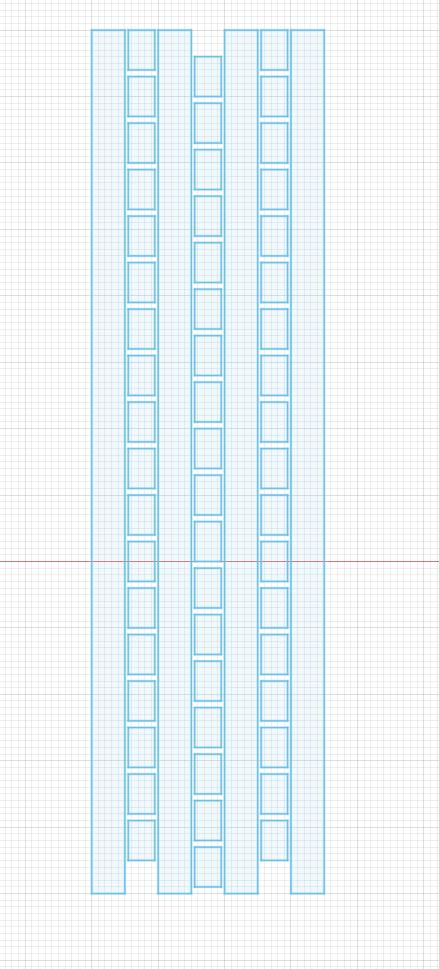

Yes, the horizontal corrugation is one solution to the problem with the passive parts of the membrane not driven.

My problem with that solution is that it is difficult to make a folding jig that long as I want the folds to be permanent, that is baked in an oven.

Also, as you mentioned, the space between the magnets needs to be increased resulting in a weaker magnetic field intensity.

Another potential solution is to reinforce the passive parts with aluminium patches.

Patches as in minimizing any eddy current effects.

I don't know if the extra aluminium patches will provide enough reinforcement and the membrane will for sure be more difficult to make.

The membrane will also be heavier but perhaps the patches doesn't need to be so many and/or large.

My problem with that solution is that it is difficult to make a folding jig that long as I want the folds to be permanent, that is baked in an oven.

Also, as you mentioned, the space between the magnets needs to be increased resulting in a weaker magnetic field intensity.

Another potential solution is to reinforce the passive parts with aluminium patches.

Patches as in minimizing any eddy current effects.

I don't know if the extra aluminium patches will provide enough reinforcement and the membrane will for sure be more difficult to make.

The membrane will also be heavier but perhaps the patches doesn't need to be so many and/or large.

I actually have a 100 mm wide corrugator from back in the day when I built ribbon speakers, but I am concerned about that the corrugation will not stay in shape as the membrane is not baked using a folding tool.

Perhaps it can be baked as it is without a foldingh tool?

I can anyway use 3D printed corrugated mounting to maintain the corrugation and then some foam as dampening:

Perhaps it can be baked as it is without a foldingh tool?

I can anyway use 3D printed corrugated mounting to maintain the corrugation and then some foam as dampening:

The Eddy-current doesn't any wrong effect IMO - perhaps good: better electrical damping at resonance. The membrane moves very small at higher frequency (low speed - low intensity of Eddy-current).Patches as in minimizing any eddy current effects.

with normaly mylar and thick enough alu it wont lose its corugation. if you go thinner then 7-10 micron it might though  i believe its also the ratio mylar+glue thickness vs thickness and softness of the alu. most alufoils i use in larger builds are 15micron , they hold shape fine

i believe its also the ratio mylar+glue thickness vs thickness and softness of the alu. most alufoils i use in larger builds are 15micron , they hold shape fine

Thanks! Then I won't worry about anymore.The Eddy-current doesn't any wrong effect IMO - perhaps good: better electrical damping at resonance. The membrane moves very small at higher frequency (low speed - low intensity of Eddy-current).

- Home

- Loudspeakers

- Planars & Exotics

- Yet another Planar Magnetic Line Source, the SMAPPP