Stereolab is a solid surface (SS) horn. Autotech made first SS prototypes. Is GPA 399 Altec 288 replacement?

Attachments

Jacek I don’t know what SS horns means but the Stereo lab are plain round Tractrix horns with truncated profile.

GPA drivers: http://www.greatplainsaudio.com/hf_drivers.html

I bought the 399 but with the lower power aluminum diaphragm, part number 23763, so I got a kind of modern 288 called 399 ;-). The 399 model uses a stronger Pascalite (aluminum diaphragm).

GPA drivers: http://www.greatplainsaudio.com/hf_drivers.html

I bought the 399 but with the lower power aluminum diaphragm, part number 23763, so I got a kind of modern 288 called 399 ;-). The 399 model uses a stronger Pascalite (aluminum diaphragm).

Stereolab is a solid surface (SS) horn. Autotech made first SS prototypes. Is GPA 399 Altec 288 replacement?

Hello Jack,

Here is a link to the 400Hz Stereolab tractrix horn:

SL400 1.4" cf400Hz Spheric Wave Tractrix Horn - STEREO LAB

Best regards from Paris, France

Jean-Michel Le Cléac'h

work in progress ...

An externally hosted image should be here but it was not working when we last tested it.

Sorry the 399 with the lower power diaphragm should have been called a 388 not 399. This is not a regular model but GPA can do it on order.Jacek I don’t know what SS horns means but the Stereo lab are plain round Tractrix horns with truncated profile.

GPA drivers: http://www.greatplainsaudio.com/hf_drivers.html

I bought the 399 but with the lower power aluminum diaphragm, part number 23763, so I got a kind of modern 288 called 399 ;-). The 399 model uses a stronger Pascalite (aluminum )diaphragm.

Thats some really nice engineering on the mount there ..........

Indeed!

GM

Member

Joined 2003

jzagaja please build a reasonably priced neo 555.

jzagaja

Going through the pages looking at all your efforts. Please consider a neo 555 updated to match your horns. It doesn't have to use any patents. Just be roughly inspired by one. The world needs this most I think. I do anyway. Look to goto for inspiration. Why stuff with ferrite drivers or diaphragms for that matter. Use one from another driver that is available and proven. Surely if I can buy a Chinese compression driver off ebay for 30$ why cant A Chinese neo 555 driver be made for say 300$

Dr Geddes

If you are still reading . I know you have probably have forgotten more then I will ever learn. And most likely have better things to do then explaining this to me . So feel free to ignore this question. Or perhaps some one else can answer this question. But if you may. Despite the tests that have been done. I am not still convinced distortion is a non issue. How can 2% plus distortion levels be a non issue? OK maybe a group of guys cant hear it but still I would like to buy a driver that was optimized for lower distortion then that. Perhaps it is not possible with compression driver technology?

I have been in communication with a local driver designer here in Australia that wont even consider compression drivers because of their distortion levels.

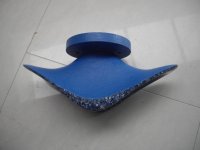

A couple of pictures.

jzagaja

Going through the pages looking at all your efforts. Please consider a neo 555 updated to match your horns. It doesn't have to use any patents. Just be roughly inspired by one. The world needs this most I think. I do anyway. Look to goto for inspiration. Why stuff with ferrite drivers or diaphragms for that matter. Use one from another driver that is available and proven. Surely if I can buy a Chinese compression driver off ebay for 30$ why cant A Chinese neo 555 driver be made for say 300$

Dr Geddes

If you are still reading . I know you have probably have forgotten more then I will ever learn. And most likely have better things to do then explaining this to me . So feel free to ignore this question. Or perhaps some one else can answer this question. But if you may. Despite the tests that have been done. I am not still convinced distortion is a non issue. How can 2% plus distortion levels be a non issue? OK maybe a group of guys cant hear it but still I would like to buy a driver that was optimized for lower distortion then that. Perhaps it is not possible with compression driver technology?

I have been in communication with a local driver designer here in Australia that wont even consider compression drivers because of their distortion levels.

- Home

- Group Buys

- Waveguides and horns