Thanks for the details, Grey. I went back through and re-read the thread.

would it be possible to make a heat exchanger out of many sections of copper tubing? I was thinking of using 1/2" copper water pipe in 1-2 foot lengths (in a back/forth setup, to increase the area).

Steve

would it be possible to make a heat exchanger out of many sections of copper tubing? I was thinking of using 1/2" copper water pipe in 1-2 foot lengths (in a back/forth setup, to increase the area).

Steve

GRollins, I did read all the thread before I posted the first post.

My Technics amp is Class-H and the fan isn't loud or noisy because the speed is controlled by temperature. There are fans that are very quiet 19 adB and they can move around 20 CFM.

How are you going to cool off other components on the PCB board. Someone posted that are going to output over 7000 watts. Why not get more efficient speaker drivers?

My suggest to HFE was an alternative and a better one for massive cooling. All the components will get cooling because the whole PCB board is submerged under a liquid acting like a heatsink. Super or clustered computers will also benefit from this substance.

My Technics amp is Class-H and the fan isn't loud or noisy because the speed is controlled by temperature. There are fans that are very quiet 19 adB and they can move around 20 CFM.

How are you going to cool off other components on the PCB board. Someone posted that are going to output over 7000 watts. Why not get more efficient speaker drivers?

My suggest to HFE was an alternative and a better one for massive cooling. All the components will get cooling because the whole PCB board is submerged under a liquid acting like a heatsink. Super or clustered computers will also benefit from this substance.

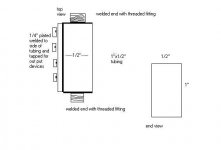

heres another idea for a heat exchancher that you could build out of rectangular aluminum tubing. this is a crude drawing that i did in windows paint but it gives the general idea. the tubing is cheap but you'll need to have a little welding done with a mig or tig.

Attachments

Mike,

I started with rectangular aluminum but wasn't happy with the results I was getting. Plus, a propane torch is all you need to solder copper pipe. That's cheaper and easier to handle than a welding rig.

To my eyes, copper looks sexier than aluminum anyway. I polished it, then shot it with ordinary spray-can lacquer so that I don't have to keep going back and polishing it.

In addition, I believe copper is a better conductor of heat than aluminum.

For the Alephs, I set up two banks of six (using 8" long pieces of Cu bar, spacing the output devices 1" apart), then set them parallel to each other about 6" apart--wide enough to put the front end board between them. Then I used a T and two 90 degree elbows at each end to supply and remove water.

This gives a rectangle something like this. Ignore the periods--they're just there to keep the diagram from collapsing. If I can find someone who's got a digital camera or a scanner or something, I'll take pictures and post them.

.|-------| (bank of output devices)

-............- (water inlet and outlet on opposite ends)

.|-------| (bank of output devices)

To attach the vinyl tubing, I soldered on pipe thread fittings, and screwed in barbed brass nipples on each end.

Grey

I started with rectangular aluminum but wasn't happy with the results I was getting. Plus, a propane torch is all you need to solder copper pipe. That's cheaper and easier to handle than a welding rig.

To my eyes, copper looks sexier than aluminum anyway. I polished it, then shot it with ordinary spray-can lacquer so that I don't have to keep going back and polishing it.

In addition, I believe copper is a better conductor of heat than aluminum.

For the Alephs, I set up two banks of six (using 8" long pieces of Cu bar, spacing the output devices 1" apart), then set them parallel to each other about 6" apart--wide enough to put the front end board between them. Then I used a T and two 90 degree elbows at each end to supply and remove water.

This gives a rectangle something like this. Ignore the periods--they're just there to keep the diagram from collapsing. If I can find someone who's got a digital camera or a scanner or something, I'll take pictures and post them.

.|-------| (bank of output devices)

-............- (water inlet and outlet on opposite ends)

.|-------| (bank of output devices)

To attach the vinyl tubing, I soldered on pipe thread fittings, and screwed in barbed brass nipples on each end.

Grey

For my aluminum blocks, I just used epoxy to put the plates and fittings on the ends. For the Leach amp, I just put thermal grease between the tubes and heatsink and screwed it down.

Electro, I'm the guy with the 7200W amp. You wonder why I don't just use more efficient speakers? The answer is- I AM. I'll be putting that 7200W into at least 8 Audiobahn ALUM12X subs which are rated 1kW and 96.4dB@1W@1m. With it I'll be using an 1800W amp with 6 EV 10" mid-woofers (99db@1W@1m), and an 800W amp (my Leach amps) with 8 horns (106dB@1W@1m). It'll be loud! (well, about 146dB peak, if I remember correctly). Anyway, the submersion idea would work great, but It would require the use of some rare and expensive liquid, and the power, input, and output leads would need to be sealed, and servicing it would be a bitch. I suppose it would be a little like working on an oil-filled transformer. I'll just be using ordinary heatsinks for the drivers transistors, etc.

(well, about 146dB peak, if I remember correctly). Anyway, the submersion idea would work great, but It would require the use of some rare and expensive liquid, and the power, input, and output leads would need to be sealed, and servicing it would be a bitch. I suppose it would be a little like working on an oil-filled transformer. I'll just be using ordinary heatsinks for the drivers transistors, etc.

Also, my pump and fan won't come on until the temp. reaches maybe 75 or 80deg.C or so. All the noise it makes won't be much compared to the rest of the sound system, so it should be fine.

P.S. Grey, I'd love to see pictures of your work!

Here's an updated picture of my Leach amp heatsink:

Electro, I'm the guy with the 7200W amp. You wonder why I don't just use more efficient speakers? The answer is- I AM. I'll be putting that 7200W into at least 8 Audiobahn ALUM12X subs which are rated 1kW and 96.4dB@1W@1m. With it I'll be using an 1800W amp with 6 EV 10" mid-woofers (99db@1W@1m), and an 800W amp (my Leach amps) with 8 horns (106dB@1W@1m). It'll be loud!

Also, my pump and fan won't come on until the temp. reaches maybe 75 or 80deg.C or so. All the noise it makes won't be much compared to the rest of the sound system, so it should be fine.

P.S. Grey, I'd love to see pictures of your work!

Here's an updated picture of my Leach amp heatsink:

Attachments

a few ideas

I like your water cooling idea and i think for big amps it is reasonable. I know a few things about it from overclocking computers, 1st thier is no need to use braided hose, instead I would go with beverage tubing that you can get at home depot for cheap, it has a metal braid in it and stands up to high heat (like 300F) and it also comes in lots of different sizes. 2nd if you haven't thought about it yet car transmision radiators (even a small engine radiator) make good heat exchangers also you can get them in nice polished aluminum or even chrome, remember to use distiled water thou and have a few fans blowing thou them. 3rd your pump is way small, you'd be better off lookin into a ehiem pump from your local fish/pet store, they last long and the smallest are like 250 gph with a small footprint also they are pretty quiet.

I like your water cooling idea and i think for big amps it is reasonable. I know a few things about it from overclocking computers, 1st thier is no need to use braided hose, instead I would go with beverage tubing that you can get at home depot for cheap, it has a metal braid in it and stands up to high heat (like 300F) and it also comes in lots of different sizes. 2nd if you haven't thought about it yet car transmision radiators (even a small engine radiator) make good heat exchangers also you can get them in nice polished aluminum or even chrome, remember to use distiled water thou and have a few fans blowing thou them. 3rd your pump is way small, you'd be better off lookin into a ehiem pump from your local fish/pet store, they last long and the smallest are like 250 gph with a small footprint also they are pretty quiet.

The thing that seems to have escaped some people is that this isn't a thought experiment...it's a working system.

The system (pump and all) I have is sufficient so far to cool two pairs of Aleph 2s. That's roughly 600W of power dissipation. I have not yet had to go to forced air cooling through the heat exchanger; passive, convective air flow through the heat exchanger is sufficient. I've got the heat exchanger sitting on a couple of scraps of 2x4, so it's spaced 1 1/2" off of a concrete floor. If I manage to hook another amp or two into this system and finally overrun the dissipation capabilities, I'll space it further off the floor. If that doesn't work, I'll go to forced air through the heat exchanger--I've already got a fan on hand that will be perfect for the job. Eventually, I will part with some money and buy a new pump so that I can put this one back in my brewing system where it belongs.

But for the time being, it's doing a great job and the price was right.

Grey

The system (pump and all) I have is sufficient so far to cool two pairs of Aleph 2s. That's roughly 600W of power dissipation. I have not yet had to go to forced air cooling through the heat exchanger; passive, convective air flow through the heat exchanger is sufficient. I've got the heat exchanger sitting on a couple of scraps of 2x4, so it's spaced 1 1/2" off of a concrete floor. If I manage to hook another amp or two into this system and finally overrun the dissipation capabilities, I'll space it further off the floor. If that doesn't work, I'll go to forced air through the heat exchanger--I've already got a fan on hand that will be perfect for the job. Eventually, I will part with some money and buy a new pump so that I can put this one back in my brewing system where it belongs.

But for the time being, it's doing a great job and the price was right.

Grey

Water Cooling

Folks,

There has been a huge amount of thought go into the cooling issues here. It naturally involves pumps, heat exchangers, fans, level monitors (not mentioned yet, I've noticed, but important!), and tubing. All great stuff.

However, what about a total loss system?

How much water is needed, I hear you scoff!

Actually, not much. Consider the math.

Let's look at Grey's system. It dissipates 600W. I will use metrics, sadly, because that's my grounding and I've forgotten all that BTU and Fahrenheit stuff.

600W is 600 joules per second, by definition. According to Monsieur Calorie, there are 4.2 joules per calorie, which is the heat content of 1 degree C per cc of water. So, we need to dissipate 143 calories per second.

Each cc of water will raise its temperature 1C for each calorie dissipated. With 143ccs per second of flow, this would give us just a 1C rise in temperature, assuming even heat distribution of course.

Let's shoot for a 15C temperature rise in the water temperature. This will mean the junction temperature could be held easily to 20C over that, and as we see later, that's still real cool. In turn this means 142/15 ccs per second, which is 9.52 ccs/second, or 572ccs per minute. In turn, this is 34.3 litres per hour, which is 9.05 US gallons per hour. Not too much, a lot less than a shower, and eminently affordable, particularly given the excesses of our obsession............. (grin!!)

Since the water running through the arteries of our amp is from a tap, then it will have come through underground pipes. This is a great heatsink; mostly it will be at least 10C cooler than ambient air temperature. So, after passing though our heatsink, it will be just 5C over ambient, which is actually a mere 9 degrees F warmer! So if the junction temperature is 20C over that (a very pessimistic assessment, BTW), it is still only 25C over ambient! (This is 45F over ambient) Wow!

For complete safety, you will need the following: A solenoid controlled tap - use one from a dishwasher at the local refuse depot; a temperature cutout mounted on the hottest part of the amp, say one of the output devices. (these are made for guitar amps, cost about $US3, and can be had in a selection of temperature thresholds); and lastly, a flow restrictor, which needs only to be a nicely adjustable ball **** with some sort of vernier gauge on it. You could even use a metal or plastic tube with a restrictor, and set it up so that it NEVER closes right off.

Now, this total loss system is highly portable, since there are no pumps. It should be treated the same way as your boat's outboard motor, and ocassionally flushed out with cleanser. You can even fit it with a small temperature gauge, heck, cars have them....

This system would be just wonderful for hot climates, with large, thirsty gardens.

Cheers,

Hugh

www.printedelectronics.com

Folks,

There has been a huge amount of thought go into the cooling issues here. It naturally involves pumps, heat exchangers, fans, level monitors (not mentioned yet, I've noticed, but important!), and tubing. All great stuff.

However, what about a total loss system?

How much water is needed, I hear you scoff!

Actually, not much. Consider the math.

Let's look at Grey's system. It dissipates 600W. I will use metrics, sadly, because that's my grounding and I've forgotten all that BTU and Fahrenheit stuff.

600W is 600 joules per second, by definition. According to Monsieur Calorie, there are 4.2 joules per calorie, which is the heat content of 1 degree C per cc of water. So, we need to dissipate 143 calories per second.

Each cc of water will raise its temperature 1C for each calorie dissipated. With 143ccs per second of flow, this would give us just a 1C rise in temperature, assuming even heat distribution of course.

Let's shoot for a 15C temperature rise in the water temperature. This will mean the junction temperature could be held easily to 20C over that, and as we see later, that's still real cool. In turn this means 142/15 ccs per second, which is 9.52 ccs/second, or 572ccs per minute. In turn, this is 34.3 litres per hour, which is 9.05 US gallons per hour. Not too much, a lot less than a shower, and eminently affordable, particularly given the excesses of our obsession............. (grin!!)

Since the water running through the arteries of our amp is from a tap, then it will have come through underground pipes. This is a great heatsink; mostly it will be at least 10C cooler than ambient air temperature. So, after passing though our heatsink, it will be just 5C over ambient, which is actually a mere 9 degrees F warmer! So if the junction temperature is 20C over that (a very pessimistic assessment, BTW), it is still only 25C over ambient! (This is 45F over ambient) Wow!

For complete safety, you will need the following: A solenoid controlled tap - use one from a dishwasher at the local refuse depot; a temperature cutout mounted on the hottest part of the amp, say one of the output devices. (these are made for guitar amps, cost about $US3, and can be had in a selection of temperature thresholds); and lastly, a flow restrictor, which needs only to be a nicely adjustable ball **** with some sort of vernier gauge on it. You could even use a metal or plastic tube with a restrictor, and set it up so that it NEVER closes right off.

Now, this total loss system is highly portable, since there are no pumps. It should be treated the same way as your boat's outboard motor, and ocassionally flushed out with cleanser. You can even fit it with a small temperature gauge, heck, cars have them....

This system would be just wonderful for hot climates, with large, thirsty gardens.

Cheers,

Hugh

www.printedelectronics.com

And I have a thirsty garden...

I haven't measured the temperature of my tap water, but underground temperatures (think of caves) tend to stabilize around 50-55 F, roughly 10 C. I don't have my physics texts with me, but Hugh's math looks right. It would be even cooler than I'm getting now, with less plumbing.

However, for the nonce, my system is closed, although I reserve the right to change things on a whim. Perhaps if/when this drought ends, I'll consider dumping the water outside, but at the moment, I'd be afraid of drawing down the water table to the point where my pump can't supply water any longer.

Something that I had considered, and something which should appeal to those who consider themselves "green," is to cycle the heat through the water heater, thus reducing the number of times the heater elements have to run to keep the water warm for your showers etc. Just think of it as an indoors version of those solar collectors that you see on peoples' roofs to boost the water temperature.

Something for those who seem to feel that 600W is a <i>huge</i> amount of heat: 600W is only about half a hair dryer. Don't hold your hand in front of it...try to heat a room with it. It will work, but only if it's not too cold outside. A single pair of Aleph 2s only put out about the equivalent of three light bulbs. One of the factors I considered when I was starting this whole shebang was the fact that I've got a 1000W room heater--just one of those little cubes that secretaries put under their desks to keep their tootsies warm--in my office/sound room, and it takes forever to warm up the room.

Yes, it's a lot of heat if it's all concentrated in one place, but the entire idea of a heatsink, whether air or water-cooled, is to spread that heat around. Just don't get intimidated by the numbers.

Grey

I haven't measured the temperature of my tap water, but underground temperatures (think of caves) tend to stabilize around 50-55 F, roughly 10 C. I don't have my physics texts with me, but Hugh's math looks right. It would be even cooler than I'm getting now, with less plumbing.

However, for the nonce, my system is closed, although I reserve the right to change things on a whim. Perhaps if/when this drought ends, I'll consider dumping the water outside, but at the moment, I'd be afraid of drawing down the water table to the point where my pump can't supply water any longer.

Something that I had considered, and something which should appeal to those who consider themselves "green," is to cycle the heat through the water heater, thus reducing the number of times the heater elements have to run to keep the water warm for your showers etc. Just think of it as an indoors version of those solar collectors that you see on peoples' roofs to boost the water temperature.

Something for those who seem to feel that 600W is a <i>huge</i> amount of heat: 600W is only about half a hair dryer. Don't hold your hand in front of it...try to heat a room with it. It will work, but only if it's not too cold outside. A single pair of Aleph 2s only put out about the equivalent of three light bulbs. One of the factors I considered when I was starting this whole shebang was the fact that I've got a 1000W room heater--just one of those little cubes that secretaries put under their desks to keep their tootsies warm--in my office/sound room, and it takes forever to warm up the room.

Yes, it's a lot of heat if it's all concentrated in one place, but the entire idea of a heatsink, whether air or water-cooled, is to spread that heat around. Just don't get intimidated by the numbers.

Grey

Youngin, I AM using a small car engine radiator, and the pump and fan from it as well, as I have stated several times earlier. But mine is old and ugly, not all chrome plated and stuff. Did you read the thread? Grey is right about some people not seeming to understand that we have actually done this with great success. After putting nearly 900W of heat into my cooler for about an hour and a half, the temperature of the block barely rose a measurable amount.

Some of those electric baseboard room heaters have the element inside a sealed waterfilled tube with lots of fins on it. It appears that it couldbe cut open on the ends, the element removed, and hoses attached. Slightly Harder to find or more expensive perhaps are the hot water baseboard radiators which have replaced the old cast iron freestanding kind. They are actually made for circulating hot water though, which would make using them a no brainer. They look like the electric baseboard heaters.

There are also cast iron european radiators with beautiful stove enamel finishes- look like a flat panel with pipes coming out. VERY

expensive, and probably don't have the surface area of those baseboard ones.

There are also cast iron european radiators with beautiful stove enamel finishes- look like a flat panel with pipes coming out. VERY

expensive, and probably don't have the surface area of those baseboard ones.

I don't know, I kinda like the idea of the old cast iron radiators. I imagine you could pick them up cheaply. You might just start a rage among the interior decorator crowd for amp-heated housing.

"Say, Jonathan, is that what I think it is?"

"Why yes, Buffy, that's the latest Aleph technology, eco-conscious heating system. I just had it installed last week."

"Why, Jonathan, it's beautiful. I'll have to have that installed in <i>my</i> condominium."

"And it sounds good, too..."

Grey

"Say, Jonathan, is that what I think it is?"

"Why yes, Buffy, that's the latest Aleph technology, eco-conscious heating system. I just had it installed last week."

"Why, Jonathan, it's beautiful. I'll have to have that installed in <i>my</i> condominium."

"And it sounds good, too..."

Grey

San Francisco-a great place for Class A amps

Hey! I thought of that too. Maybe excellent for SAF.

I figured the surface area is a bit small, They ARE pretty big ....maybe they would work......

Also, someone is sure to point out here that they should be called "convectors" 'cause, like heatsinks, they lose most heat by convection

Hey! I thought of that too. Maybe excellent for SAF.

I figured the surface area is a bit small, They ARE pretty big ....maybe they would work......

Also, someone is sure to point out here that they should be called "convectors" 'cause, like heatsinks, they lose most heat by convection

Yeah, I also thought of the possibility of using one of those old cast iron gas radiators when I saw one in a junkyard as I was looking for a heater core to use as a radiator in my Leach amp. Too big for my purposes now, but they'd look great and would probably work quite well to, and no fan.

I tried to find out more about Greys water cooled system and searched for it in the internet. I am especially interested in a picture because it is unlikely to find the same system here in Germany. Finally I found the site http://www.colemanac.com/.

I've sent the question below to their support email address.

Here is teir answer and my Email:

From: "Consumer Relations UPG" <upg.consumer.relations@york.com>

Subject: RE: Technical data for heat pump COLEMAN 6904-502

Date: Mon, 6 Jan 2003 15:37:06 -0600

Peter, I spoke with our technical people and we are having trouble locating

any information on a 6904-502. Is there any other information you can supply

us with that could help us identify this unit, ie mobile home, residential,

RV etc.

Thank You

UPG Consumer Relations

-----Original Message-----

Sent: Friday, January 03, 2003 9:50 PM

To: upg.consumer.relations@york.com

Subject: Technical data for heat pump COLEMAN 6904-502

Dear ladies and gentlemen,

could you please be so kind and send me a disciption / technical data for

the

heat pump COLEMAN 6904-502? The heat sink of an old heat pump was used in an

experiment for effective cooling of an amplifier and worked very well. But

the technical data (especially the thermal resistance) is not available

which

would be very helpful to verify the results.

Thank you very much in advance.

Best regards

Peter Roehl

(Remark: Address upg.consumer.relations@york.com found on site http://www.colemanac.com/)

Grey, do you have more information?

I've sent the question below to their support email address.

Here is teir answer and my Email:

From: "Consumer Relations UPG" <upg.consumer.relations@york.com>

Subject: RE: Technical data for heat pump COLEMAN 6904-502

Date: Mon, 6 Jan 2003 15:37:06 -0600

Peter, I spoke with our technical people and we are having trouble locating

any information on a 6904-502. Is there any other information you can supply

us with that could help us identify this unit, ie mobile home, residential,

RV etc.

Thank You

UPG Consumer Relations

-----Original Message-----

Sent: Friday, January 03, 2003 9:50 PM

To: upg.consumer.relations@york.com

Subject: Technical data for heat pump COLEMAN 6904-502

Dear ladies and gentlemen,

could you please be so kind and send me a disciption / technical data for

the

heat pump COLEMAN 6904-502? The heat sink of an old heat pump was used in an

experiment for effective cooling of an amplifier and worked very well. But

the technical data (especially the thermal resistance) is not available

which

would be very helpful to verify the results.

Thank you very much in advance.

Best regards

Peter Roehl

(Remark: Address upg.consumer.relations@york.com found on site http://www.colemanac.com/)

Grey, do you have more information?

Afraid not. It came from a home unit, but I don't remember what brand offhand. One of the kids was carrying a digital camera around the other day. Maybe I can con them into taking a picture of the thing.

I don't think it's going to be all that critical what kind of heat exchanger you get. Homes require a great deal more heat than an amplifier puts out, so most anything out of a domestic heat pump is going to be vastly overrated for stereo use. I'm running two pairs of Aleph 2s on one system (about 1200W total heat dissipation) and without even using forced air through the heat exchanger I can still hold my finger directly on the output devices forever.

Someone had a junked heat pump out by the road the other day, but it was gone by the time I had a chance to stop and look it over.

If all else fails, use a car radiator.

Grey

I don't think it's going to be all that critical what kind of heat exchanger you get. Homes require a great deal more heat than an amplifier puts out, so most anything out of a domestic heat pump is going to be vastly overrated for stereo use. I'm running two pairs of Aleph 2s on one system (about 1200W total heat dissipation) and without even using forced air through the heat exchanger I can still hold my finger directly on the output devices forever.

Someone had a junked heat pump out by the road the other day, but it was gone by the time I had a chance to stop and look it over.

If all else fails, use a car radiator.

Grey

Just came across this thread.

Very Interesting, as ive done lots of water cooling of PCs.

Here is an example:

I made all of the copper piping/exchangers made in that pic.

One problem i can see you having is with mains-hum.

If you try and build this into a small case, the pump will create quite a strong mains freq hum in your amp. This will be from the impellor magnet and its driving electromagnet. It will have to be well megneticly shielded.

Also, pumps CANNOT be trusted. Come up with a way to monitor water flow and shut the amp down if it stops.

Theres a better idea then a car radiator, is a car's heater-core (as us PC water coolers call it).

Its the radiator used in the dash to heat up cabin air from engine coolant heat.

They are very small, and very efficient with good designs.

The one i use in my PC is 200x200x50mm with the entry/exit on one end with 16mm (ID) copper pipe.

Very Interesting, as ive done lots of water cooling of PCs.

Here is an example:

An externally hosted image should be here but it was not working when we last tested it.

I made all of the copper piping/exchangers made in that pic.

One problem i can see you having is with mains-hum.

If you try and build this into a small case, the pump will create quite a strong mains freq hum in your amp. This will be from the impellor magnet and its driving electromagnet. It will have to be well megneticly shielded.

Also, pumps CANNOT be trusted. Come up with a way to monitor water flow and shut the amp down if it stops.

Theres a better idea then a car radiator, is a car's heater-core (as us PC water coolers call it).

Its the radiator used in the dash to heat up cabin air from engine coolant heat.

They are very small, and very efficient with good designs.

The one i use in my PC is 200x200x50mm with the entry/exit on one end with 16mm (ID) copper pipe.

At least in my case, the pump and heat exchanger are in another room. That's one of the glories of water-cooled stuff--you can dump the heat somewhere else.

Car heater cores are cute, but can't dissipate the heat that a larger heat exchanger can. Of course, if you're running smaller (or fewer) circuits than I am, you may not need that much. I've always wanted to do a Mini-A with a heat exchanger about the size of a paperback book. Not for any real reason...just because it'd be cute.

Grey

Car heater cores are cute, but can't dissipate the heat that a larger heat exchanger can. Of course, if you're running smaller (or fewer) circuits than I am, you may not need that much. I've always wanted to do a Mini-A with a heat exchanger about the size of a paperback book. Not for any real reason...just because it'd be cute.

Grey

I read earlier in the thread that you didn't have any milling equipment, Grey. I am in Charlotte and have a small mill and various other metal working tools. If you need to do an upgrade to this or some other system, I'd be glad to machine some stuff for you if needed and the drive is short, so I could even run it by. OK, maybe that last part is just a cry to hear what an Aleph really sounds like. . .

Seriously, though, if you're interested, send me an e-mail or something.

S.

Seriously, though, if you're interested, send me an e-mail or something.

S.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Water cooled audio circuitry