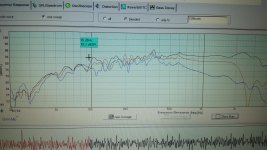

Looks promising so far..

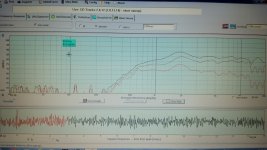

Thanks, I'm actually a little surprised at how flat it gets in the sim. Playing with crossing at 1.8k in the sim, things are looking promising. So far... 2nd order electrical mid and 3rd tweeter are where they like to be, but that's using that Pyle horn laying on the cabinet like it is so I know the response will change once I change that. Hoping to try to smooth the breakup above 8k by modifying the horn a tad, but I'm not really sure how much of that I'd hear anyhow so maybe it isn't a huge deal.

Tonight I'm going to cut that woofer cabinet down and put dual, flared 4" round ports in the front. Once that's done, I'll figure out just exactly how I want to move forward with this horn. I'm considering modifying the Pyle horn to make the front as wide as the woofer cabinet, I'll maybe use fiberglass for that. But who knows, I'm sure I'll change my mind again and go back to the original idea of building one

Last edited:

You might consider buying a molded SEOS horn from The SEOS? Project DIY Sound Group (they're relatively inexpensive) to see if you like the sound of it, and then cutting it in half and using it as a pattern to build the final product in wood.

I'm going to glue up some boards tonight and try to make my first prototype horn. I have the measurements from the Pyle PH612 constant radiation horn that I posted a picture of, now I want to build one that's fairly radically different and see what changes in the measurements. But I'm hoping some here can answer some questions first...

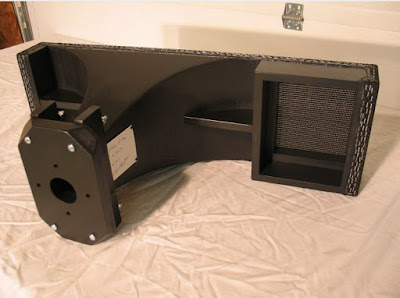

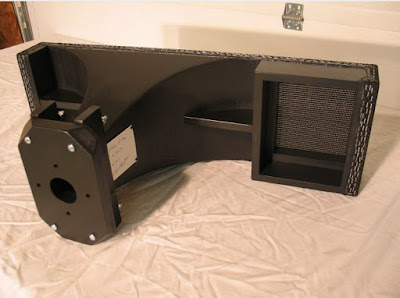

This is the horn I'm trying to copy (to the best of my ability, with no dimensions, just a picture)...

Front view of the same horn...

And this is what I have so far. I know the horn above^^ has a 2" wide, square throat where the compression tweeter threads on. So my plan is to do a 2" x 2" ID throat entry, with a 14" wide x 4.5" tall exit (14" wide is basically where the edge of the horn's exit transitions to flat on the front baffle). The curves I drew in front of the larger horn transition are the Pyle's horn transitions to scale; the darker, larger curves I drew are what I came up with trying to mimic the one above. The one I drew is 10" deep, I don't know how deep the black one in the pic above is...

That said, I have 3 questions for any of you that have done this before...

1. Any advice on how to slope the top and bottom of this? Should I start with a mellow transition from the 2" throat entry that gets steeper as it reaches the 4.5" wide exit? Or, should I maintain a more consistent transition (like the wooden one in my pic above)?

2. Is this too big? Am I going to have time alignment issues because that tweeter is so far behind the midrange? (Should I make it shallower and less wide?)

2. If you had to guess, how would you say this will change the measurements from what I posted above using the Pyle horn?? I know what I'm doing completely changes the tuning compared to the Pyle horn, but I'm curious how and that's why I'm doing it, I'm hoping to compare and try to learn something.

This is the horn I'm trying to copy (to the best of my ability, with no dimensions, just a picture)...

Front view of the same horn...

And this is what I have so far. I know the horn above^^ has a 2" wide, square throat where the compression tweeter threads on. So my plan is to do a 2" x 2" ID throat entry, with a 14" wide x 4.5" tall exit (14" wide is basically where the edge of the horn's exit transitions to flat on the front baffle). The curves I drew in front of the larger horn transition are the Pyle's horn transitions to scale; the darker, larger curves I drew are what I came up with trying to mimic the one above. The one I drew is 10" deep, I don't know how deep the black one in the pic above is...

That said, I have 3 questions for any of you that have done this before...

1. Any advice on how to slope the top and bottom of this? Should I start with a mellow transition from the 2" throat entry that gets steeper as it reaches the 4.5" wide exit? Or, should I maintain a more consistent transition (like the wooden one in my pic above)?

2. Is this too big? Am I going to have time alignment issues because that tweeter is so far behind the midrange? (Should I make it shallower and less wide?)

2. If you had to guess, how would you say this will change the measurements from what I posted above using the Pyle horn?? I know what I'm doing completely changes the tuning compared to the Pyle horn, but I'm curious how and that's why I'm doing it, I'm hoping to compare and try to learn something.

Last edited:

Update...

I figured out the horn I was mimicking is for a 2" compression midrange (I'm learning ), so I'm not sure how much that would effect the high frequency if I made it a 2" throat and used my 1" compression tweeter in it, but I decided to scrap that plan for now anyhow. I haven't totally given up on it, I actually already glued up some wood to make one, but I started a different plan that I'll finish first...

), so I'm not sure how much that would effect the high frequency if I made it a 2" throat and used my 1" compression tweeter in it, but I decided to scrap that plan for now anyhow. I haven't totally given up on it, I actually already glued up some wood to make one, but I started a different plan that I'll finish first...

I decided to just use the Pyle lens I had, but I'm modifying it aesthetically so it blends better with my build. This is a daunting task, and I'm glad to finally be done with the fiberglass. Now I need to smooth everything out with bondo. I've done quite a bit of body work, I used to work for a body shop. Here's what I've done so far...

I've just been making this up as I go along, and this is what I started with. I used polyurethane construction adhesive and screws to mount the lens to a piece of 3/4" MDF that I routed out so the lens sits flush...

I then coated the face and edges with fiberglass. I could've just used bondo, but I didn't want to chance the seam between the plastic lens and the MDF telegraphing through the paint later...

I wasn't a fan of how the top and bottom looked, the face was too wide above and below the horn's mouth...

So I ripped that down, then recoated the edges with more fiberglass. Ripping through the screws I used to mount the lens to the MDF was not a good time (note to self, sharpen that saw blade)...

After grinding/sanding that, I then coated it in bondo and sanded it...

I still have a ways to go. I need to come up with a good way to sand the whole top all at once so I can keep a smooth, flat face. Then, sanding the contours around the horn's exit where it meets the face is going to be tough to get consistent.

A pic of the edge, where I still need quite a bit of filler...

I figured out the horn I was mimicking is for a 2" compression midrange (I'm learning

I decided to just use the Pyle lens I had, but I'm modifying it aesthetically so it blends better with my build. This is a daunting task, and I'm glad to finally be done with the fiberglass. Now I need to smooth everything out with bondo. I've done quite a bit of body work, I used to work for a body shop. Here's what I've done so far...

I've just been making this up as I go along, and this is what I started with. I used polyurethane construction adhesive and screws to mount the lens to a piece of 3/4" MDF that I routed out so the lens sits flush...

I then coated the face and edges with fiberglass. I could've just used bondo, but I didn't want to chance the seam between the plastic lens and the MDF telegraphing through the paint later...

I wasn't a fan of how the top and bottom looked, the face was too wide above and below the horn's mouth...

So I ripped that down, then recoated the edges with more fiberglass. Ripping through the screws I used to mount the lens to the MDF was not a good time (note to self, sharpen that saw blade)...

After grinding/sanding that, I then coated it in bondo and sanded it...

I still have a ways to go. I need to come up with a good way to sand the whole top all at once so I can keep a smooth, flat face. Then, sanding the contours around the horn's exit where it meets the face is going to be tough to get consistent.

A pic of the edge, where I still need quite a bit of filler...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Want to build high frequency horns, help please!