It seems to be a lot of controversy around proper tapping techniques. People use all sort of different methods and I spend 3 days arguing with another member what is the best way to do this simple task.

So I'm saying once again: cordless drill gun with a clutch is definitely the easiest and fastest way to tap. Trust me, I do it almost every day.

My favourite gun for that purpose is Bosch. It has more finese than Makita and deWalt is good only for heavy construction work. The clutch is set to 5 on a scale of 24. I mount the tap and put some lubricant to the tip. I'm using that lubricant, but any oil is good and I even had good results with WD40.

So I'm saying once again: cordless drill gun with a clutch is definitely the easiest and fastest way to tap. Trust me, I do it almost every day.

My favourite gun for that purpose is Bosch. It has more finese than Makita and deWalt is good only for heavy construction work. The clutch is set to 5 on a scale of 24. I mount the tap and put some lubricant to the tip. I'm using that lubricant, but any oil is good and I even had good results with WD40.

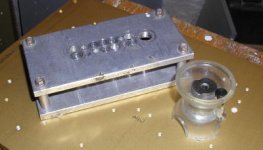

Attachments

For the demonstration purpose I mounted the 1/4" aluminum piece in a vice, but usually I hold it by hand. I'm tapping with 8-32 tap and the hole is 9/64". I run the tap and approx. halfway the clutch engages. I put the drill in reverse, clean the tap and go again. This time it goes through completely. Whole procedure took less than 10 seconds. Don't tell me you can do it faster by hand or Tapmatic. Also using drill gun has this advantage that it's much easier to align the tap straight and holding it that way while tapping (comparing to doing it by hand).

Attachments

I also tapped 4-40 size thread. The hole is 3/32". This time the tap went through in a first run. 2 seconds maximum and it's done. While doing it this way it's impossible to break the tap. The only possibility it may happen is either dull tap or very hard material. Some aluminum alloys are easier to machine than others.

Attachments

Also using drill gun has this advantage that it's much easier to align the tap straight and holding it that way while tapping

And that would be a Dewalt scre gun, wouldn't it Peter?

Anthony

Peter,

I'm not sure that drill tapping is good for 3mm or less. (even a hand job is difficult without breaking the tap).

If you use duraluminium I believe that is easier to tap, but with softer aluminium ( like the one on some heatsinks) the tap sometimes become stuck, since the dust doens't come out from the other side. In these cases I prefer to not to use oil, to clean the thread easier.

In copper, I allways use oil. In the tapping process for my aleph 5 amp (almost done!) I broke two 3mm taps in 12 holes.

copper is very difficult to tap in 3mm because it gets stuck very easy, especialy in the first tap turns.

I'm not sure that drill tapping is good for 3mm or less. (even a hand job is difficult without breaking the tap).

If you use duraluminium I believe that is easier to tap, but with softer aluminium ( like the one on some heatsinks) the tap sometimes become stuck, since the dust doens't come out from the other side. In these cases I prefer to not to use oil, to clean the thread easier.

In copper, I allways use oil. In the tapping process for my aleph 5 amp (almost done!) I broke two 3mm taps in 12 holes.

copper is very difficult to tap in 3mm because it gets stuck very easy, especialy in the first tap turns.

Using drill gun is always better than hand. Just adjust the clutch properly. Through all my work I broke a tap only once.

The hardest part is to start the thread, because when doing it by hand, rotating the tap and keeping it straight at the same time is very difficult. The drill gun eliminates that problem.

I don't really like 3mm thread, because it's too fine. I prefer 6-32, but I imagine that obtaining proper fasteners in Europe might be problematic.

Remember also, that most of the taps you see are machine taps and supposed to be used in Tapmatic sort of heads. For hand tapping, proper tap sets come with 3 taps per set. One is used for starting thread and it has has the grooves starting very slowly, far from a tip and they are not deep. Second one is intermediate and the last one is a finishing tap, which makes final thread. You can usually omit the second one and use only the other two. When you have access to such tools using taps and doing it by hand is also very easy and it is impossible to break anything.

I recommend to use oil all the time. If I don't have oil I use saliva and it works too.

The pic shows what I was talking about. Both taps are M3. The top one is for starting a thread, it goes very nicely into a hole (which should be 2.5mm) and it's very easy to keep it straight. The second one is to finish what first one started.

The hardest part is to start the thread, because when doing it by hand, rotating the tap and keeping it straight at the same time is very difficult. The drill gun eliminates that problem.

I don't really like 3mm thread, because it's too fine. I prefer 6-32, but I imagine that obtaining proper fasteners in Europe might be problematic.

Remember also, that most of the taps you see are machine taps and supposed to be used in Tapmatic sort of heads. For hand tapping, proper tap sets come with 3 taps per set. One is used for starting thread and it has has the grooves starting very slowly, far from a tip and they are not deep. Second one is intermediate and the last one is a finishing tap, which makes final thread. You can usually omit the second one and use only the other two. When you have access to such tools using taps and doing it by hand is also very easy and it is impossible to break anything.

I recommend to use oil all the time. If I don't have oil I use saliva and it works too.

The pic shows what I was talking about. Both taps are M3. The top one is for starting a thread, it goes very nicely into a hole (which should be 2.5mm) and it's very easy to keep it straight. The second one is to finish what first one started.

Attachments

Peter:

I use manual tapping tools, even with my B&D cordless drill

the tap I broke was allways the first one.

If I start with the 3rd one (only works in very soft aluminium) the taps doesn't get stuck as the first one.

Also I bought two kind of taps one with 3 cutting edges(my favourite) and other with 4 cutting edges. the last is stronger, but the final result is worst.

I use manual tapping tools, even with my B&D cordless drill

the tap I broke was allways the first one.

If I start with the 3rd one (only works in very soft aluminium) the taps doesn't get stuck as the first one.

Also I bought two kind of taps one with 3 cutting edges(my favourite) and other with 4 cutting edges. the last is stronger, but the final result is worst.

How to tap with drill press?

Peter,

Thanks a lot for all the illustrations, it is a great help.

After reading a lot of threads I picked up a router and a drill press. I did not buy a saw as I can use router to cut wood (and I am not planning to cut a lot of it anyway) - still learning how to use it properly, getting better though. I bought a drill press instead of a portable drill as I read that it gives better accuracy and control. I was going to practice drilling and tapping on scrap aluminum this weekend. But till reading these posts I did not realize that you would need a clutch for tapping

So, is there a clutch that you can attach to the drill press? Or some other technique can be used. I don't think I want a drill press if I cannot use it for tapping as well. I guess I can make some of drill guides as shown above before returning it

Peter,

Thanks a lot for all the illustrations, it is a great help.

After reading a lot of threads I picked up a router and a drill press. I did not buy a saw as I can use router to cut wood (and I am not planning to cut a lot of it anyway) - still learning how to use it properly, getting better though. I bought a drill press instead of a portable drill as I read that it gives better accuracy and control. I was going to practice drilling and tapping on scrap aluminum this weekend. But till reading these posts I did not realize that you would need a clutch for tapping

So, is there a clutch that you can attach to the drill press? Or some other technique can be used. I don't think I want a drill press if I cannot use it for tapping as well. I guess I can make some of drill guides as shown above before returning it

For m3 I use 2.5 mm drill bits.

I must say my only break taps occured with m3. all other sizes were fine and oil is needed. maybe I must buy better m3 taps.

I must say that I got better threads with dry tapping m3 in alutronic heatsinks. the oil joined up the dust and damaged the thread. without oil I could make 20mm depth threads with cleaning just two times.

In copper (or iron) tapping without oil is impossible to me.

I must say my only break taps occured with m3. all other sizes were fine and oil is needed. maybe I must buy better m3 taps.

I must say that I got better threads with dry tapping m3 in alutronic heatsinks. the oil joined up the dust and damaged the thread. without oil I could make 20mm depth threads with cleaning just two times.

In copper (or iron) tapping without oil is impossible to me.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Useful tools and techniques