You are right, the tubes are 2 generations behind, maybe 3. I had an idea, when I suddenly owned a lot of very, very expensive tubes.Hybrid technology is very good sometimes ,not everything needs to be in clear rules ,when you are DIY something. You may get best of each type of technology then and combine that .Simplicity of opamps circuits , their speed , and combine with retro tubes style and high voltages .For me tubes are associated with something retro , like b/w tv we had in 80's or very old radios with vinyl on top ...

I think it would be easier to use non-tube based driver for GU's ,but thats are your choices and challenges .

Company Reichelt suddenly sold a very large assortment, probably a whole stock from an eliminated company. And they really had no idea, what matching prices would look like.

I immediately bought, what I was able to pay.

GU50 was 12 € - incredible. Today, I ordered the last tubes somewhere else, because somebody gave them a hint or two. But I got anything for good prices!

I plan to build anything on one large epoxy PCB, copper on both sides and to put that on top of a solid frame. All tubes, caps through holes, to see them and they dissipate thei heat. I have all ceramic sockets. Inside, lower side of the PCB, components will have a conventional wiring (except the semiconductor PCB).

Because the inner side will be copper plated too, it will be easy to make a solid wiring.

A bunch of toroids with 900VA input total will fit inside, nonvisible. They may reside on a steel plate, which is mounted to the frame by joints on the rear, so I can open that. For sure, I will need a forced ventilation for at least 250 W heat. So a blower will put the inside under some low pressure, while all tubes sockets will have extra borings around, to cool their glass frames a bit and avoid overheating.

The EC120 cores might get a clear epoxy resin, finally. Not decided, yet. It is difficult to make them pretty. Metal covers are forbidden because of eddy currents and I feel proud to show these 'small' transformers - the only true innovation.

Large, heavy, energy waste and - cool 😎

Regarding feedback processing, I initially started with a complex situation: When PWM is 'silence', 50/50% then there is no need for any magnetic discharge. But with lower frequencies, higher amplitude, it is required. What is the effect of it's execution?

Amplitude at speaker will be lowered.

Theoretically, there exists a solution for a continous compensation of lowered amplitude by insertion of magnetic discharge.

Problem is, to create a linear energy discharge mechanism. It allways will have quantum steps, when it starts.

Why? Because the power circuit must travel full swing, until discharge starts happening.

Very complex, to find a no-nonlinear solution. So I decided, to execute the stable timing, fully linear amplitude proportion.

Selection of frequencies for triangle and magnetic discharge just have 2 concerns:

1st is: not recognizable, easy to solve.

2nd is: because of mixing at output, they need to be different in frequencies at an interference, which is not recognizable too. Greetings from Fourier...

Today, I got my second set of 4 GU50s - cool, my second channel!

Amplitude at speaker will be lowered.

Theoretically, there exists a solution for a continous compensation of lowered amplitude by insertion of magnetic discharge.

Problem is, to create a linear energy discharge mechanism. It allways will have quantum steps, when it starts.

Why? Because the power circuit must travel full swing, until discharge starts happening.

Very complex, to find a no-nonlinear solution. So I decided, to execute the stable timing, fully linear amplitude proportion.

Selection of frequencies for triangle and magnetic discharge just have 2 concerns:

1st is: not recognizable, easy to solve.

2nd is: because of mixing at output, they need to be different in frequencies at an interference, which is not recognizable too. Greetings from Fourier...

Today, I got my second set of 4 GU50s - cool, my second channel!

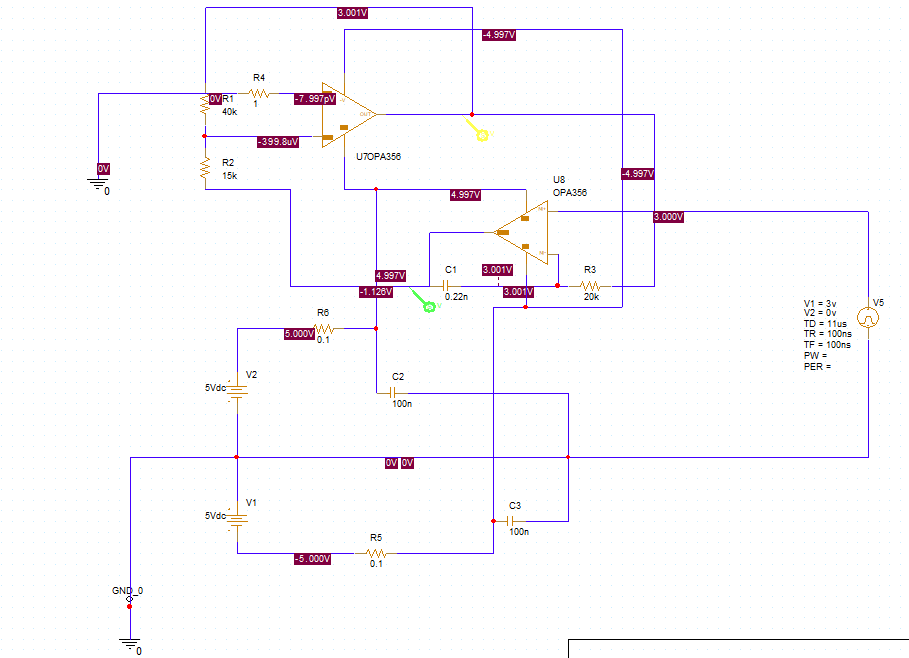

Today I finalzzed simulation for the signal generator. I selected opamps and made experiments with the dimensioning. The result was good.

The circuit is here:

You can ignore the red bias points. The circuit, as is, runs at near 200 kHz and generates a 50%/50% duty cycle triangle of 2 Vpp and a square wave with 5V/-5Vpp suare wave with a rising time of 28 nsec - Not too bad! The amps are cheap. The circuit has two big advantages:

On the right side is a voltage input named V5. If I apply a DC voltage there, I can shift the duty cycle, while keeping frequency and voltage swing.

This is, what I need for the discharge timing.

If I make the resistor R3 adjustable, I can tune the frequency, without impact to the output voltage. Of course, that resistor already needs to have low parasitics.

With the symmetric duty cycle, I can attach the next stage, which does AF / RF comparison, generates PWM and drives the first PCC89.

With the nonsymmetric duty cycle, the same circuit can be attached to the magnetic discharge circuit.

I was astonished about the quality of the triangle. Very linear ramps, no noise,

Notice, there are 2 of these circuits, running with different fequencies, more then 40 kHz diferent frequencies.

The circuit is here:

You can ignore the red bias points. The circuit, as is, runs at near 200 kHz and generates a 50%/50% duty cycle triangle of 2 Vpp and a square wave with 5V/-5Vpp suare wave with a rising time of 28 nsec - Not too bad! The amps are cheap. The circuit has two big advantages:

On the right side is a voltage input named V5. If I apply a DC voltage there, I can shift the duty cycle, while keeping frequency and voltage swing.

This is, what I need for the discharge timing.

If I make the resistor R3 adjustable, I can tune the frequency, without impact to the output voltage. Of course, that resistor already needs to have low parasitics.

With the symmetric duty cycle, I can attach the next stage, which does AF / RF comparison, generates PWM and drives the first PCC89.

With the nonsymmetric duty cycle, the same circuit can be attached to the magnetic discharge circuit.

I was astonished about the quality of the triangle. Very linear ramps, no noise,

Notice, there are 2 of these circuits, running with different fequencies, more then 40 kHz diferent frequencies.

You have found nice opamp , interesting how it would perform in my current amplifier . Earlier have found wideband opamps ,high-speed ,but their inputs were not symetrical . Negative input was for low impedance like 50 ohm feedback ,so not a choice for audio .

I would reduce R3 few times and increase C1 ,to lower parasitic effects like pcb capacitance . High resistance on high frequencies not perform as expected in my experience .

I would reduce R3 few times and increase C1 ,to lower parasitic effects like pcb capacitance . High resistance on high frequencies not perform as expected in my experience .

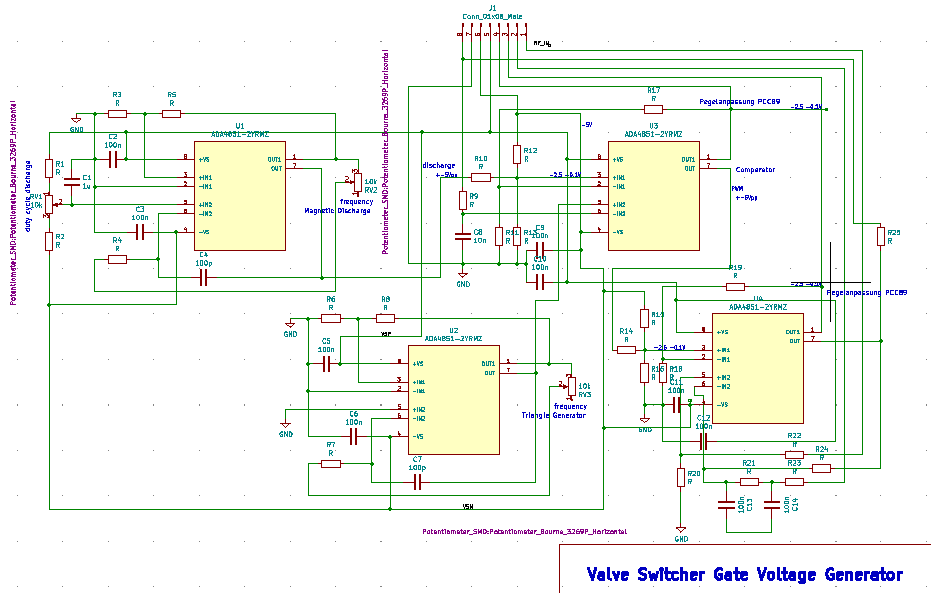

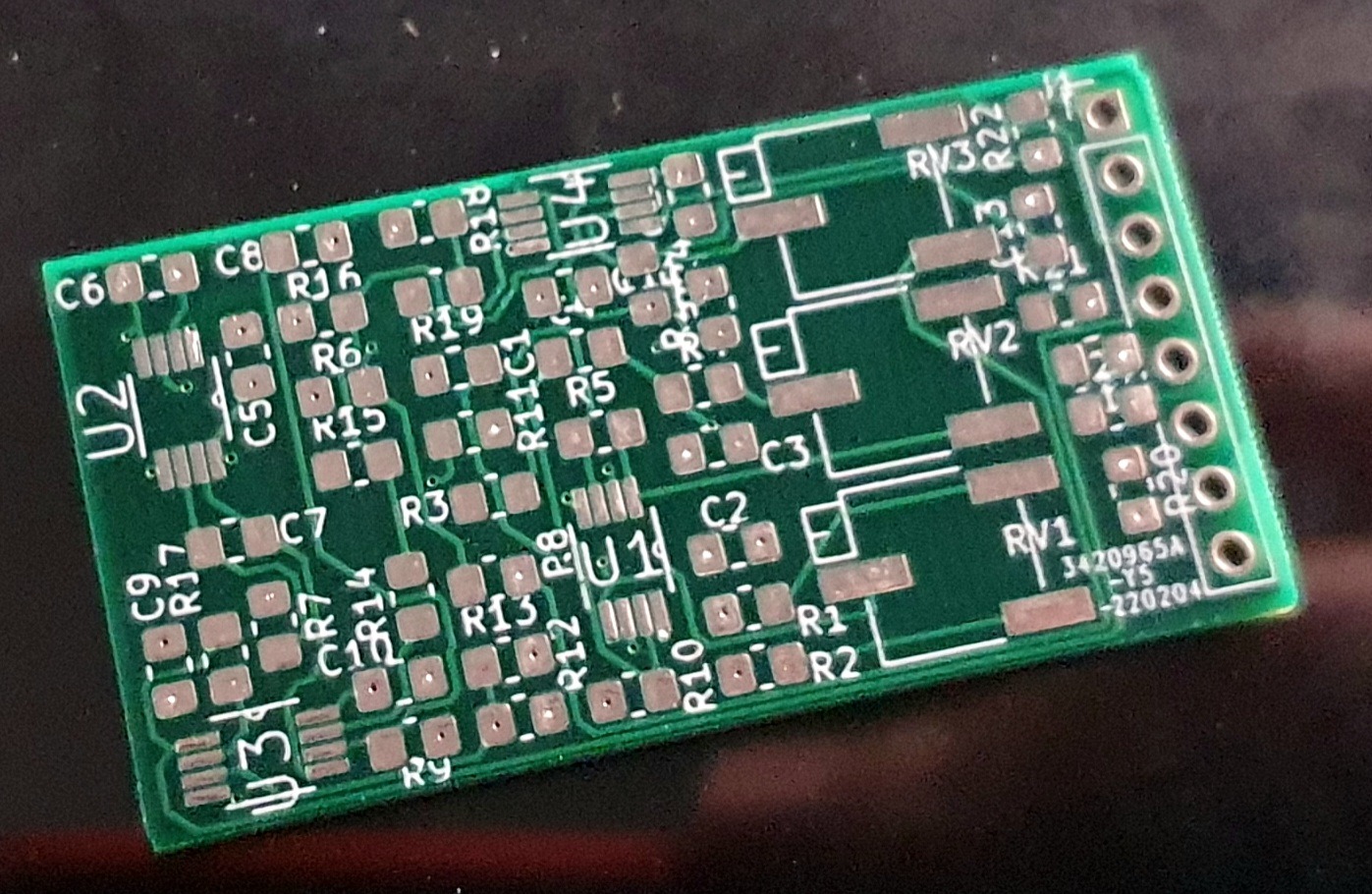

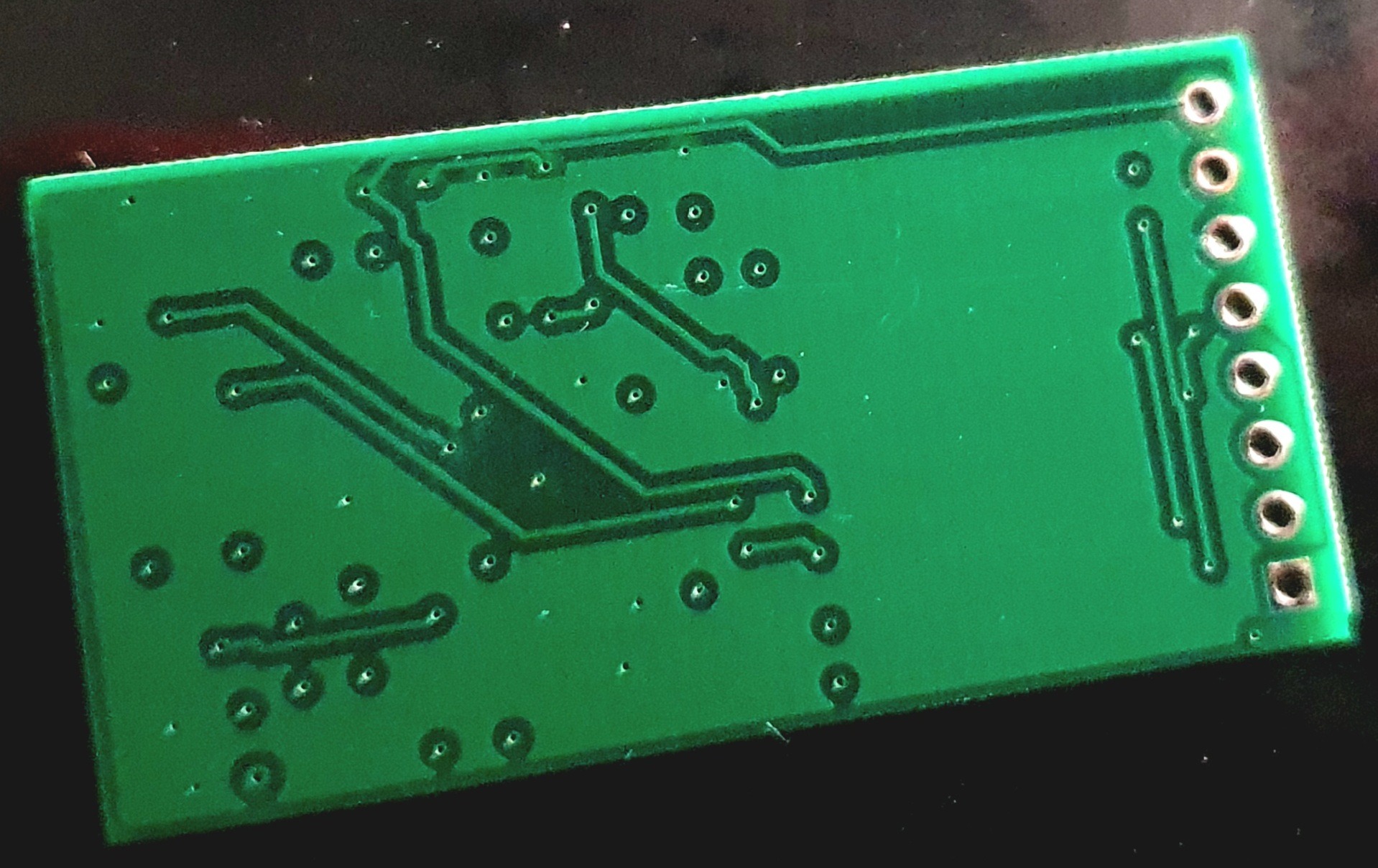

I made the CAD work for a print of the SMD components. It also incorporates the feedback path. Dimensioninng is not finished, but most important parts are simulated.

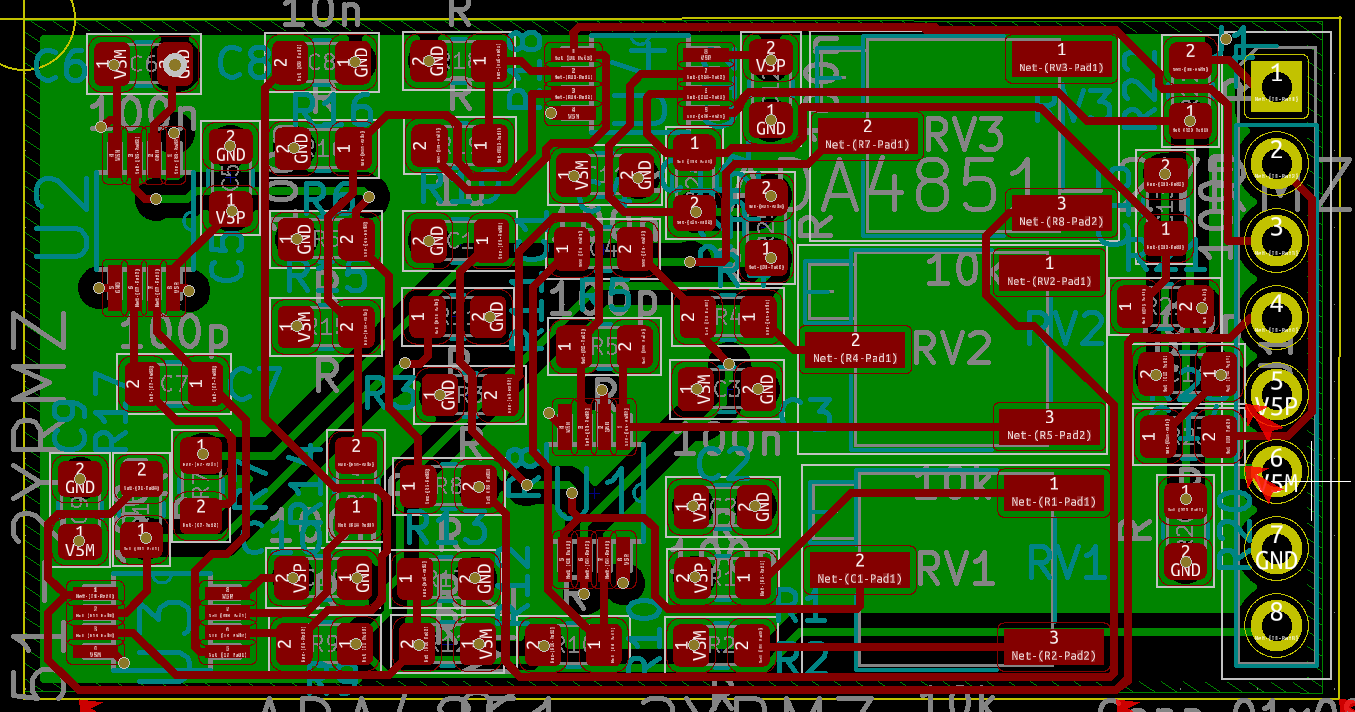

I also designed the PCB.

It might not be optimal, or fully correct, but all components are 0805, so I can correct, what is wrong.

It is a 4 Layer board. Front is components (red), second is GND, third is plus 5V and rear side is -5V (green)

I also designed the PCB.

It might not be optimal, or fully correct, but all components are 0805, so I can correct, what is wrong.

It is a 4 Layer board. Front is components (red), second is GND, third is plus 5V and rear side is -5V (green)

Nice work . 4 layers can't be self made , so you have to order it somewhere ,and what if it would not work properly ?

I think more practical would be real tests with tubes ,transformer ,pwm first . Thats the power part . If it works , then move to driver ,if all ok ,then to oscilator , input part ,feedback . Or maybe you already performed some testing ? What if tubes would radiate so much RF , that it would disturb all other parts operation ? You would then design that differently ,knowing that . Maybe not 4 layers needed ,but metal box for everything ,even tubes should be invisible from outside ,any hole will radiate a lot . This maybe comparable to microwave oven ,~1000w ~3kv ,there are only small holes in door glass to prevent RF coming out . But in this case this will be lower frequency and harder to shield i think .

I think more practical would be real tests with tubes ,transformer ,pwm first . Thats the power part . If it works , then move to driver ,if all ok ,then to oscilator , input part ,feedback . Or maybe you already performed some testing ? What if tubes would radiate so much RF , that it would disturb all other parts operation ? You would then design that differently ,knowing that . Maybe not 4 layers needed ,but metal box for everything ,even tubes should be invisible from outside ,any hole will radiate a lot . This maybe comparable to microwave oven ,~1000w ~3kv ,there are only small holes in door glass to prevent RF coming out . But in this case this will be lower frequency and harder to shield i think .

I have simulated, the CAD design is checked.Nice work . 4 layers can't be self made , so you have to order it somewhere ,and what if it would not work properly ?

I place that order along with another. That limits cost.

I used 0805 size, manual assemby is easy.

If I need to make cuts or wires then these will be on outer sides.

For testing the transformer and GU50 parts, I immediatly need proper signals for driving gate 1. Of course, I will not start with 500V anode power. One GU50 is first step, then the counterpart GU50, then rising to 500V and finally all 4.I think more practical would be real tests with tubes ,transformer ,pwm first . Thats the power part . If it works , then move to driver ,if all ok ,then to oscilator , input part ,feedback .

If the transformer roughly matches all steps, the entire loop with feedback.

The transformer will be calculated, then a single wire layer will be measured, then another layer, measured.

If it is not optimal, it will not be unusable.

The design is mechanically easy to do:Or maybe you already performed some testing ? What if tubes would radiate so much RF , that it would disturb all other parts operation ? You would then design that differently ,knowing that . Maybe not 4 layers needed ,but metal box for everything ,even tubes should be invisible from outside ,any hole will radiate a lot .

I bought PCB material and will make boxes, soldered.

A cage of copper will cover the whole.

The copper on my PCB material will convert almost all to eddy currents. The top cover of copper is meshed or with lots of holes.This maybe comparable to microwave oven ,~1000w ~3kv ,there are only small holes in door glass to prevent RF coming out . But in this case this will be lower frequency and harder to shield i think .

All copper surfaces will get chemical nickel. finish.

Last edited:

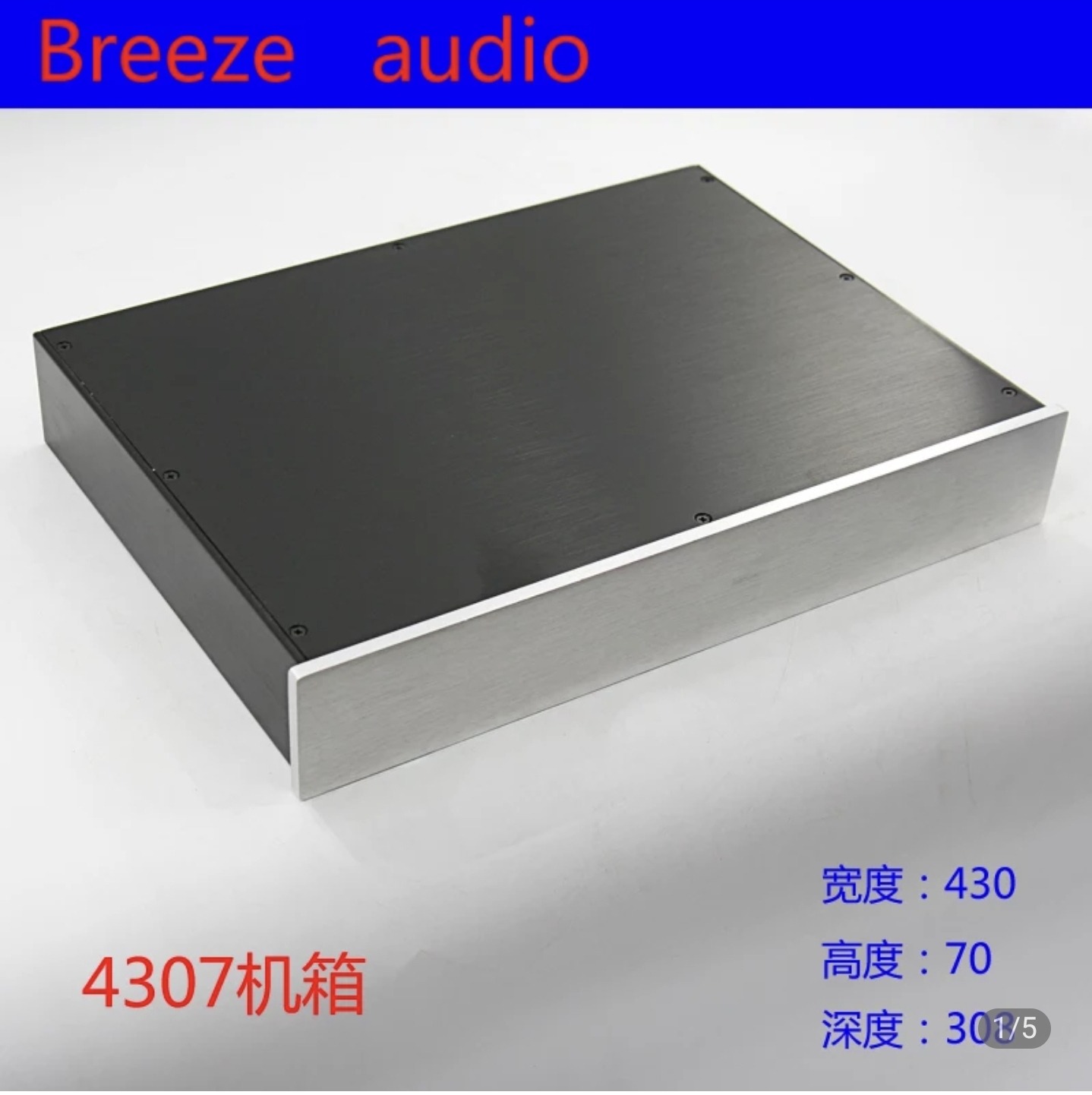

I bought 2 cases, each 70 mm high, 430mm wide, 300mm deep. They shall be stacked and be the housing for the whole bunch of tubes and their interconnections in the upper case, while the lower case will be the housing of the ring transformers for power and a small silent blower.

The cases will have a set of joints on the rear,in order to enable opening and working on the interior.

The top plate will be exchanged against PCB material, where the outside will get chemical nickel and chrome finish. No connections, wiring visible.

You see a black anodized top plate, that will be omitted. The interior of the upper case will get RF shield and some vertical PCB sheets to build boxes, where necessary, for RF and mechanical stability.

Most probably, the top plate will be double, in order to distribute the airflow and hide GND signal solderings, the ceramic sockets and their skrews.

The surface will carry GND and can be used to mount the shielding top RF cage.

The joints will be at the rear, cables will pass there through a PCB plate with many holes at the bottom of the upper case and the cables will get ferrite chokes.

I bought these:

The cases will have a set of joints on the rear,in order to enable opening and working on the interior.

The top plate will be exchanged against PCB material, where the outside will get chemical nickel and chrome finish. No connections, wiring visible.

You see a black anodized top plate, that will be omitted. The interior of the upper case will get RF shield and some vertical PCB sheets to build boxes, where necessary, for RF and mechanical stability.

Most probably, the top plate will be double, in order to distribute the airflow and hide GND signal solderings, the ceramic sockets and their skrews.

The surface will carry GND and can be used to mount the shielding top RF cage.

The joints will be at the rear, cables will pass there through a PCB plate with many holes at the bottom of the upper case and the cables will get ferrite chokes.

I bought these:

Today, I received 5 PCBs for the combined

Analog to PWM, PWM triangle generator, magnetic discharge oscillator, feedback processor - hence, all opamp based, integrated circuits on one PCB.

It is driving the PCC89 UHF triodes, which are the gate drivers for GU50 RF tubes.

The circuit is the one above.

The board has the size of a bigger postage stamp, so it can be hidden behind anything. It can be glued to a surface after successful test.

The connections are on one side, complete, as the circuit schematics indicate.

All components are placed topside, including 3 variable, precision resistors, trimmers. These have multiple turns and hence, no danger to be misadjusted or damaged.

When somebody is interested in getting a PCB, write me.

When somebody is interested in getting a PCB, write me.

I will do the PCB completion and test within next weeks and will report my level of success.

Greetings,

Joachim

Analog to PWM, PWM triangle generator, magnetic discharge oscillator, feedback processor - hence, all opamp based, integrated circuits on one PCB.

It is driving the PCC89 UHF triodes, which are the gate drivers for GU50 RF tubes.

The circuit is the one above.

The board has the size of a bigger postage stamp, so it can be hidden behind anything. It can be glued to a surface after successful test.

The connections are on one side, complete, as the circuit schematics indicate.

All components are placed topside, including 3 variable, precision resistors, trimmers. These have multiple turns and hence, no danger to be misadjusted or damaged.

I will do the PCB completion and test within next weeks and will report my level of success.

Greetings,

Joachim

Last edited:

Hi,

I needed to suspend the project temporarily.

I collected all the material, made a PCB for the triangle and comparator units.

My father went into medical desaster, finally died.

So, this project went out of track.

I still want to do this funny project, because I suddenly got lots of highest quality RF tubes and want to see, if this works at all.

It is not intended as being duplicated, because the material is a huge money value in this case.

Give me a year, then I will restart and we will see, what the results will be.

I will not take this into my own grave

Greetings and have fun with your own projects,

Joachim

I needed to suspend the project temporarily.

I collected all the material, made a PCB for the triangle and comparator units.

My father went into medical desaster, finally died.

So, this project went out of track.

I still want to do this funny project, because I suddenly got lots of highest quality RF tubes and want to see, if this works at all.

It is not intended as being duplicated, because the material is a huge money value in this case.

Give me a year, then I will restart and we will see, what the results will be.

I will not take this into my own grave

Greetings and have fun with your own projects,

Joachim

- Home

- Amplifiers

- Class D

- tubes in Class D?