Hi Pete, thanks for reading!

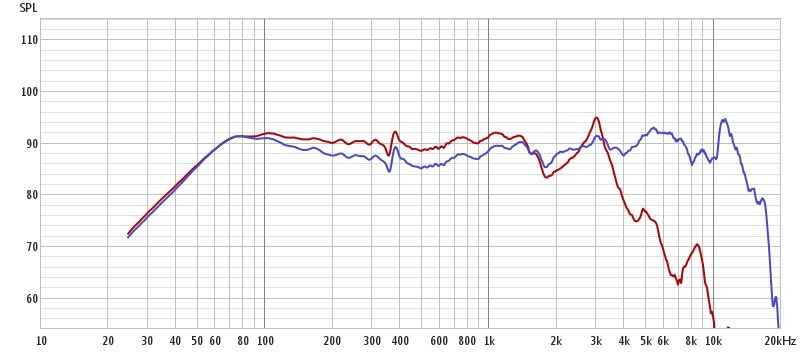

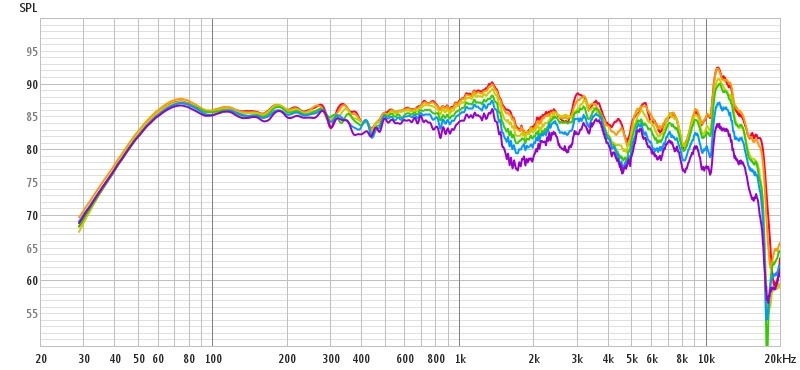

Here are the actual measurements from REW...

Red is driver alone, blue is whole system including wf / XO / twt. This is constant box, measurement environment, drive level.

unlikely to have anything to do with the crossover, more likely either box too small, box tuning too high, or rooom acoustics

Here are the actual measurements from REW...

Red is driver alone, blue is whole system including wf / XO / twt. This is constant box, measurement environment, drive level.

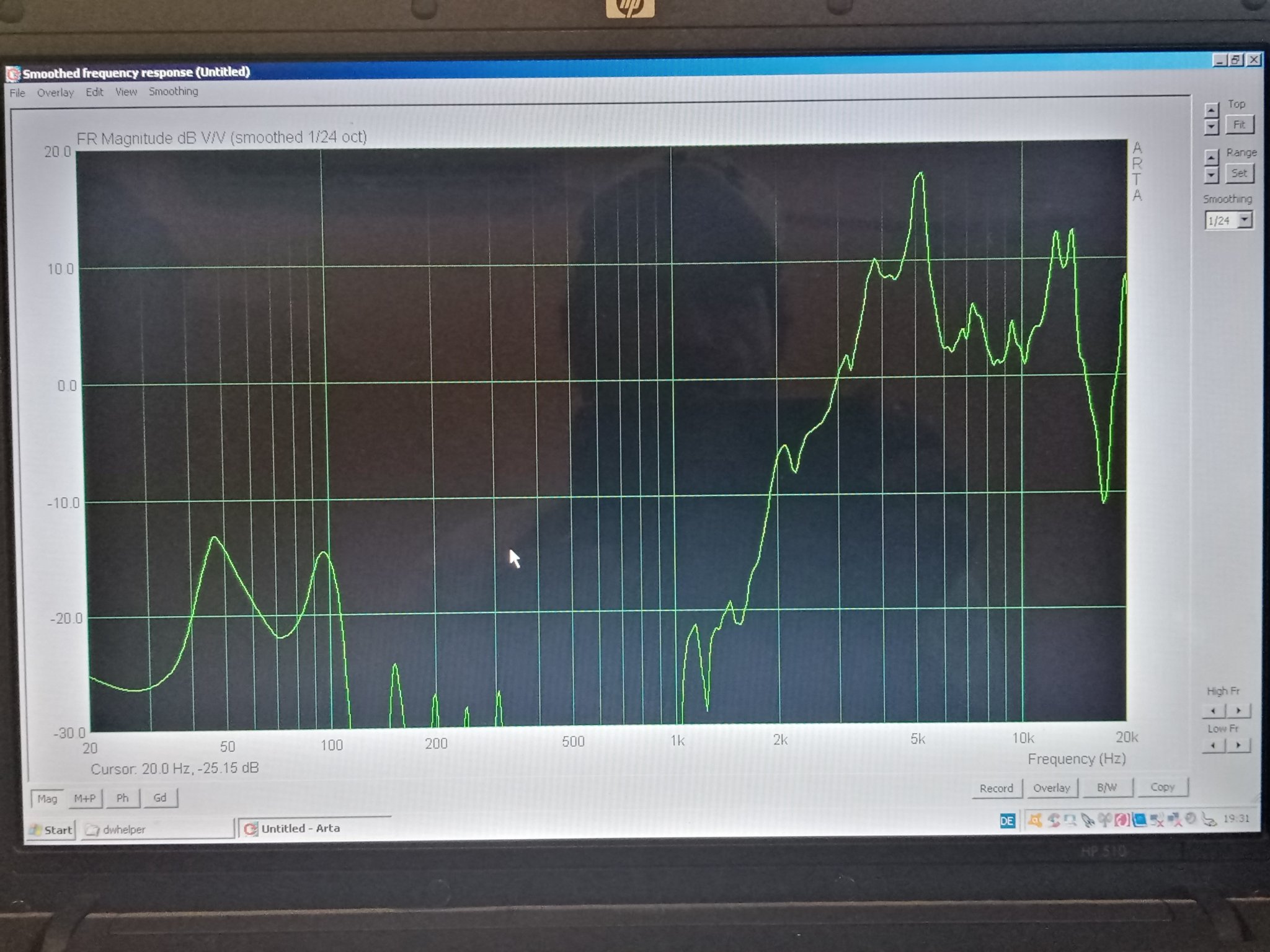

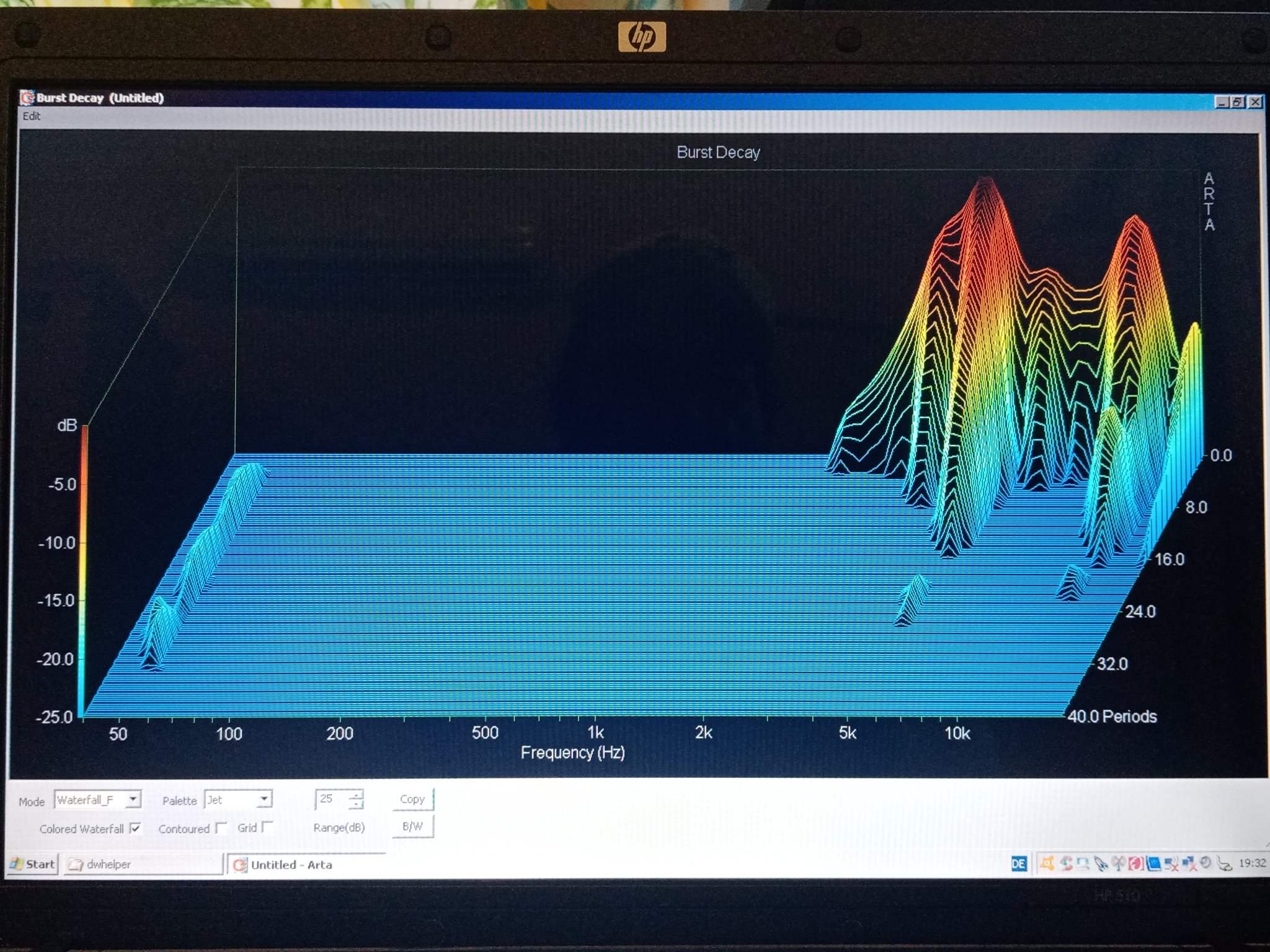

Here are some wrap up measurements for XO4 on this project. I've been enjoying listening to this speaker, I don't think the piezos sound terrible at all. The woofer is actually the THD limitation in this case. Here, check this out.

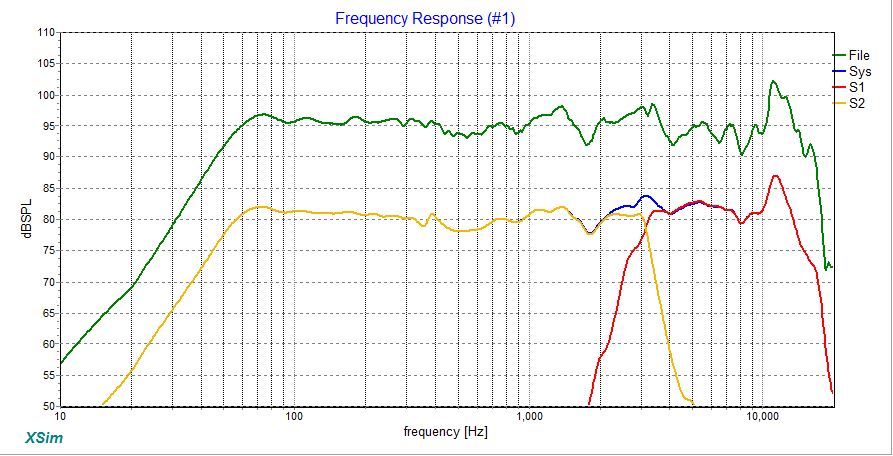

This is the measured output, vs the simulation. Things show up a little bit differently I presume because the confirmation measurement (green) and the measurements that fed the simulation were different sessions and I didn't manage to set everything up identically.

I'm taking ground-planes in my driveway, and angling my speaker down to point the listening axis at the mic. I've been shimming up the back of the speaker with scrap wood, but I think I'll have to make some sort of repeatable / adjustable incline platform to up my measurement game. Has anyone seen examples of others making something like this? Looking for ideas.

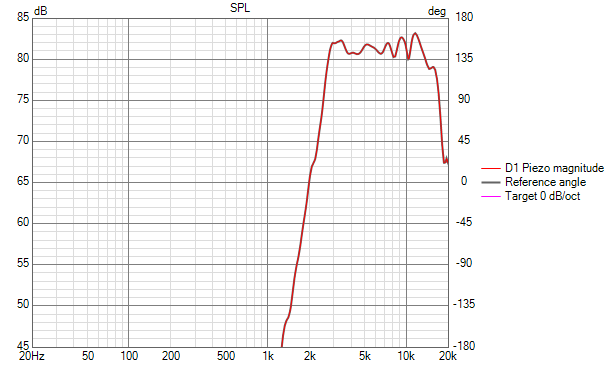

But the result is as expected. Tamed the LF boom, little peaks at 1500 and 3k. Tweeter resonance up at 11k -ish. The 3k prominence could have been dealt with maybe if I had re-done the woofer LP, but I didn't want to buy a new inductor for it. I didn't worry about the 11k peak, I figured it would be narrow dispersion, but some other measurements showed it wasn't, so maybe I should have dealt with that. I don't hear it in listening, maybe my ears are old, but I also think there's not really a lot of content above 10k.

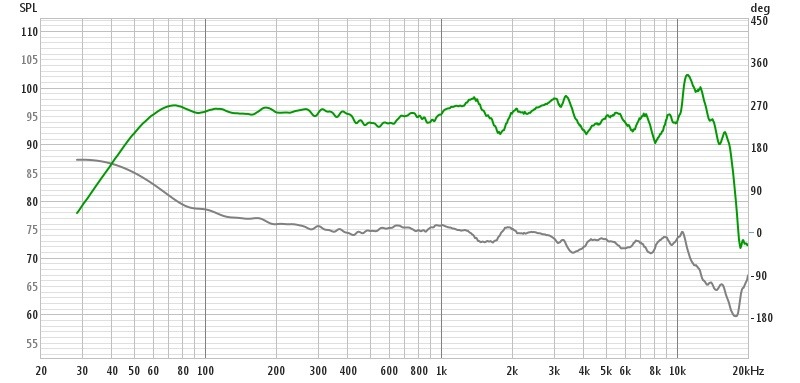

Minimum phase (grey above) looks better than I expected. I think I have the piezo reversed and was expecting to see the phase flip somewhere but I guess not?

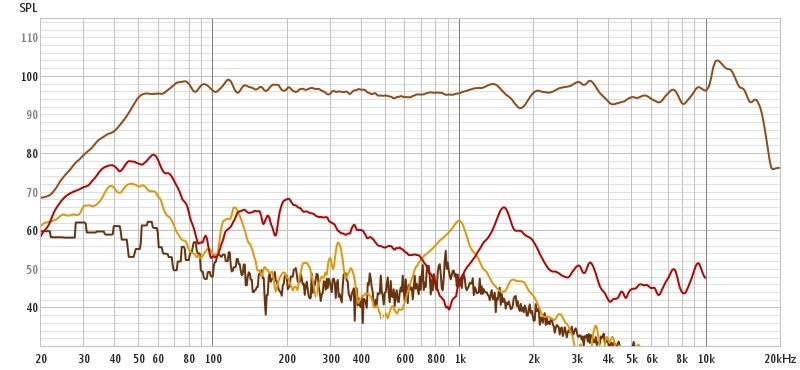

Here's distortion, I see the graph key wasn't included in the image export. Red is H2, yellow is H3, brown is noise floor. REW has more harmonics, but I have turned them off as they are below the noise floor (does that mean they're invalid? Or is there some means of determining what's going on down there?*). From the woofer-only (no XO) measurement in post 21 or 19, you can see the woofer has a resonance at 3kHz, so 3rd harmonic of 1k and 2nd harmonic of 1.5k makes sense. But the distortion in the piezo range is 50-ish dB down and H2 dominant so the THD of the Piezo seems fine to me.

* If the noise floor is tilting down (typical) then maybe you could see some THD below noise floor b/c the noise floor at the harmonic is lower than the noise floor at the fundamental?

This is FR off axis, going 0-10-20-30-40-50 degrees. Not bad, I think! But 11k wasn't just a narrow dispersion thing.

As I said, I've been enjoying listening to these. It might be because they're fairly nice, but it also might be because I've got them set up on the coffee table, so I'm listening pretty close (just under 5 ft) and they're far from the walls, so I'm getting a lot of direct sound and less room sound.

This is the measured output, vs the simulation. Things show up a little bit differently I presume because the confirmation measurement (green) and the measurements that fed the simulation were different sessions and I didn't manage to set everything up identically.

I'm taking ground-planes in my driveway, and angling my speaker down to point the listening axis at the mic. I've been shimming up the back of the speaker with scrap wood, but I think I'll have to make some sort of repeatable / adjustable incline platform to up my measurement game. Has anyone seen examples of others making something like this? Looking for ideas.

But the result is as expected. Tamed the LF boom, little peaks at 1500 and 3k. Tweeter resonance up at 11k -ish. The 3k prominence could have been dealt with maybe if I had re-done the woofer LP, but I didn't want to buy a new inductor for it. I didn't worry about the 11k peak, I figured it would be narrow dispersion, but some other measurements showed it wasn't, so maybe I should have dealt with that. I don't hear it in listening, maybe my ears are old, but I also think there's not really a lot of content above 10k.

Minimum phase (grey above) looks better than I expected. I think I have the piezo reversed and was expecting to see the phase flip somewhere but I guess not?

Here's distortion, I see the graph key wasn't included in the image export. Red is H2, yellow is H3, brown is noise floor. REW has more harmonics, but I have turned them off as they are below the noise floor (does that mean they're invalid? Or is there some means of determining what's going on down there?*). From the woofer-only (no XO) measurement in post 21 or 19, you can see the woofer has a resonance at 3kHz, so 3rd harmonic of 1k and 2nd harmonic of 1.5k makes sense. But the distortion in the piezo range is 50-ish dB down and H2 dominant so the THD of the Piezo seems fine to me.

* If the noise floor is tilting down (typical) then maybe you could see some THD below noise floor b/c the noise floor at the harmonic is lower than the noise floor at the fundamental?

This is FR off axis, going 0-10-20-30-40-50 degrees. Not bad, I think! But 11k wasn't just a narrow dispersion thing.

As I said, I've been enjoying listening to these. It might be because they're fairly nice, but it also might be because I've got them set up on the coffee table, so I'm listening pretty close (just under 5 ft) and they're far from the walls, so I'm getting a lot of direct sound and less room sound.

So here are my closing thoughts:

- Piezos can sound fine. Rule of thumb + instinct are a start, but better I think is to measure and simulate. Getting good measurements is easier said than done, of course.

- My lot had fair variation, so I would think twice about following a project without being able to make my own measurements. I was right at the bottom of their reach at about 3k, if you are able to cross higher you might see less variation around the high Q bump at the bottom of their range.

- Build quality is very low (on my lot, at least). But piezos are cheap and simple. They are easy to work on! This is DIY, so that's a feature not a bug. Troubleshoot your units for air leaks, add damping material, mod the diaphragm, damp the horn. Maybe a bigger rear chamber? Maybe 3d print a new horn or phase plug? I'd love to see some piezo mod projects. They're so cheap, it would be easy to participate. I'd get more into some of the horn + phase plug discussion if the barrier to entry was lower.

- This project was based off the 1016 style, rectangular 2x5 type. The back assembly of that seems to match the round 1005 type. It unscrews and the horn + phase plug comes off on one side, with the diaphragm and rear chamber on the other. I think the slightly larger 1025 type (3x7 inch) disassembles more completely and I bet it would be easier to work on.

- The info I had seen about the 1016 style said good down to 3k - 3.5k, and that seems about right. I see the 1025 says 1.8 kHz and the screw-on 1188 style says to 800 Hz. (parts express piezo pages) I wonder if that's legit?

- High impedance in the device leads to XO parts choices. Capacitors are small, that's nice. But the inductor is big, and that's a bummer. That L2 in my XO design (see post 19) is 6.8 mH. PE had a close-out inductor in that value so it didn't sting too much. But there's hardly any power going through it. Is there some other class of inductors that would be a better choice - smaller power, more DCR prob ok, lower price? What would one look for? You could put a big resistor in parallel with the Piezo and use more traditional XO thinking, but maybe there's a benefit to be had here?

- Piezos can sound fine. Rule of thumb + instinct are a start, but better I think is to measure and simulate. Getting good measurements is easier said than done, of course.

- My lot had fair variation, so I would think twice about following a project without being able to make my own measurements. I was right at the bottom of their reach at about 3k, if you are able to cross higher you might see less variation around the high Q bump at the bottom of their range.

- Build quality is very low (on my lot, at least). But piezos are cheap and simple. They are easy to work on! This is DIY, so that's a feature not a bug. Troubleshoot your units for air leaks, add damping material, mod the diaphragm, damp the horn. Maybe a bigger rear chamber? Maybe 3d print a new horn or phase plug? I'd love to see some piezo mod projects. They're so cheap, it would be easy to participate. I'd get more into some of the horn + phase plug discussion if the barrier to entry was lower.

- This project was based off the 1016 style, rectangular 2x5 type. The back assembly of that seems to match the round 1005 type. It unscrews and the horn + phase plug comes off on one side, with the diaphragm and rear chamber on the other. I think the slightly larger 1025 type (3x7 inch) disassembles more completely and I bet it would be easier to work on.

- The info I had seen about the 1016 style said good down to 3k - 3.5k, and that seems about right. I see the 1025 says 1.8 kHz and the screw-on 1188 style says to 800 Hz. (parts express piezo pages) I wonder if that's legit?

- High impedance in the device leads to XO parts choices. Capacitors are small, that's nice. But the inductor is big, and that's a bummer. That L2 in my XO design (see post 19) is 6.8 mH. PE had a close-out inductor in that value so it didn't sting too much. But there's hardly any power going through it. Is there some other class of inductors that would be a better choice - smaller power, more DCR prob ok, lower price? What would one look for? You could put a big resistor in parallel with the Piezo and use more traditional XO thinking, but maybe there's a benefit to be had here?

I use piezos for years, the "good old ones" from Monacor(?), type PHM8.19 (8x19cm).

They got their own enclosure, filled with sand to kill the plastic horn's resonances, and also a simple crossover, see below.

In front of them I mounted something which was called 'sound distributor lens' back than.

They sound fine. Listeners who doesn't know don't recognize them as piezos.

They got their own enclosure, filled with sand to kill the plastic horn's resonances, and also a simple crossover, see below.

In front of them I mounted something which was called 'sound distributor lens' back than.

They sound fine. Listeners who doesn't know don't recognize them as piezos.

Hey, that's a neat idea!They got their own enclosure, filled with sand to kill the plastic horn's resonances

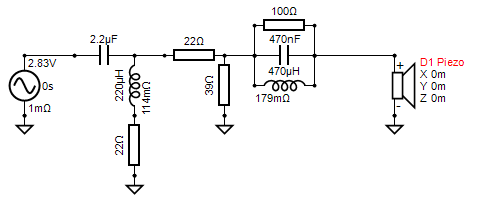

It doesn't have to be big, if you include series resistor with the inductor. That "dumping" resistor is crucial (6.8 ohms here), see my "ultimate" crossover for Motorola KSN 1005A:But the inductor is big, and that's a bummer. That L2 in my XO design (see post 19) is 6.8 mH.

https://www.diyaudio.com/community/threads/to-piezo-or-not-to-piezo.310934/page-2#post-5162616

Blue: Motorola KSN 1005A

Green: with "ultimate crossover"

Last edited:

Filter for "1016" piezo, with supplied REW measurements. Woofer SPL at 1m/1w is not taken in consideration, nor the phase relationship:

Take notice of the importance of the "dumping" resistor (22 ohm here, in series with 0.22 mH), which allows much smaller values of the inductor.

Take notice of the importance of the "dumping" resistor (22 ohm here, in series with 0.22 mH), which allows much smaller values of the inductor.

Last edited:

Sonce, that looks like a good result! I'll play with that topology in simulation to understand better.

Alternatively, I was thinking maybe of something like this:

https://www.digikey.com/en/products/detail/bourns-inc/RLB1314-682KL/2561403

$0.62 each, 6.8 mH, qty 1, 120 mA rating and 9.4 ohm DCR. In my existing XO, with 20 Vrms out of the amp it looks like only 80 ma (or so? so low that its hard to see in XSim) in the inductor. Not appropriate for traditional XO duty, but I wonder if I could get away with using such a part here? Is there some aspect I'm not aware of that makes it inappropriate for audio duty?

Alternatively, I was thinking maybe of something like this:

https://www.digikey.com/en/products/detail/bourns-inc/RLB1314-682KL/2561403

$0.62 each, 6.8 mH, qty 1, 120 mA rating and 9.4 ohm DCR. In my existing XO, with 20 Vrms out of the amp it looks like only 80 ma (or so? so low that its hard to see in XSim) in the inductor. Not appropriate for traditional XO duty, but I wonder if I could get away with using such a part here? Is there some aspect I'm not aware of that makes it inappropriate for audio duty?

I am preparing a pair for indirect sound so frequency response is not critical.

Thin metal foil does not change the frequency response but I do that to all drivers I use (see thread "How to make a diy sandwich loudspeaker cone" here in the forum)

Added 100 ohms from plus to minus and tried 0.26uF and 0.039uF in line.

Raw driver no crossover

Thin metal foil does not change the frequency response but I do that to all drivers I use (see thread "How to make a diy sandwich loudspeaker cone" here in the forum)

Added 100 ohms from plus to minus and tried 0.26uF and 0.039uF in line.

Raw driver no crossover

In some low-cost applications I was using very similar inductors, but with much smaller inductance (0,33 mH or so). Smaller inductance values use the same ferite core and have the same price, but they can witstand much higher amperage - between 0.75 and 0.9 A!Alternatively, I was thinking maybe of something like this:

https://www.digikey.com/en/products/detail/bourns-inc/RLB1314-682KL/2561403

$0.62 each, 6.8 mH, qty 1, 120 mA rating and 9.4 ohm DCR.

So perhaps it is core saturation which is the limiting factor? I wonder if there is a slightly larger ferrite core version available...Smaller inductance values use the same ferite core and have the same price, but they can witstand much higher amperage - between 0.75 and 0.9 A!

It looks like your pair resonates higher than mine, 5k rather than 3. I wonder, is it a property of the diaphragm? The piezo element? The rear chamber? The horn? I suggest a bit of poly fluff around the back of the diaphragm, see my posts 2 and 4 in this thread. Cheap piezos seem to me like fertile ground for these sorts of mods, inexpensive to try lots of iterations and learn what is actually helpful, and I think maybe the very cost sensitive construction leaves performance on the table for DIY greedy boyz to snatch up.I am preparing a pair for indirect sound so frequency response is not critical.

@AdamThorne

In former times I used to dampen the back side and even putting a second layer of alu foil on the backside.

You have to unsolder the wiring for that gently putting the paper cone up/out without deforming it.

Today I do not proceed this time investment which certainly would help the sound.

Maybe drilling holes into the back chamber for accessing it for damping is an easier process.

In another project I realized a 12db filter taming the lower resonance even better.

The measurement assisted XOs for piezos in this thread are impressively well made and it shows that time alignment can be better than with traditional tweeters not showing steps or turnovers in phase we usually see(!)

If everything is carefully designed.

What I like most with piezos that if filtered properly at least with minimal crossover of 6db they lose their nervous sound everyone experiences with the raw drivers.

Piezos add an attack in transients to the sound which I find difficult to realize with traditional tweeters.

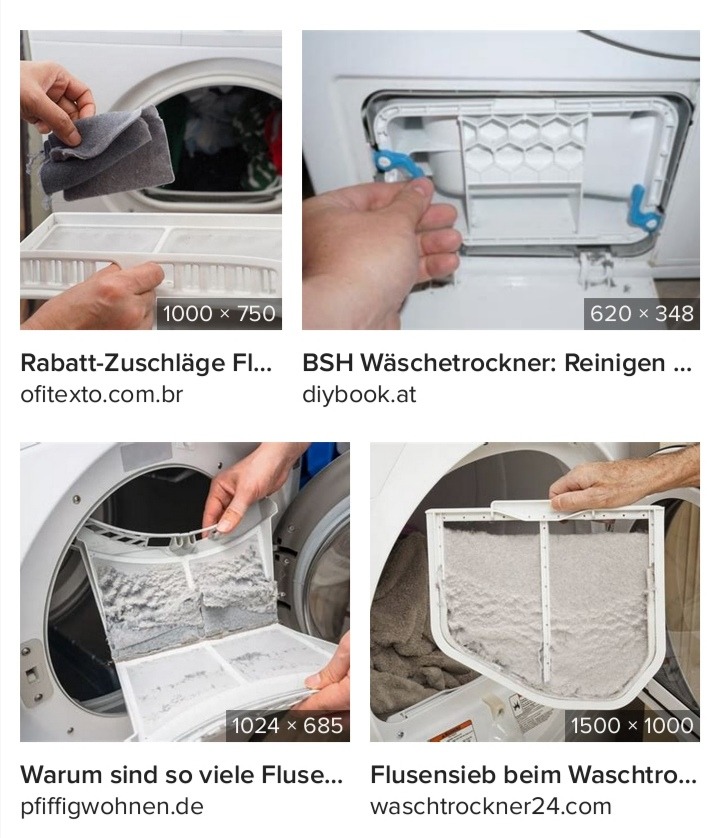

For damping the cavity I used the fine damping material found for free in drying machines for clothes.

In former times I used to dampen the back side and even putting a second layer of alu foil on the backside.

You have to unsolder the wiring for that gently putting the paper cone up/out without deforming it.

Today I do not proceed this time investment which certainly would help the sound.

Maybe drilling holes into the back chamber for accessing it for damping is an easier process.

In another project I realized a 12db filter taming the lower resonance even better.

The measurement assisted XOs for piezos in this thread are impressively well made and it shows that time alignment can be better than with traditional tweeters not showing steps or turnovers in phase we usually see(!)

If everything is carefully designed.

What I like most with piezos that if filtered properly at least with minimal crossover of 6db they lose their nervous sound everyone experiences with the raw drivers.

Piezos add an attack in transients to the sound which I find difficult to realize with traditional tweeters.

For damping the cavity I used the fine damping material found for free in drying machines for clothes.

@AdamThorne

It must be stated here that the mods you mention (damping cone and chamber) in post 2+4 means a lot for the sound although through the measurement you see only slight changes.

Modge podge or alu mod I practice sonically does more than measurements would suggest.

Even adding a rubber damper to the Piezo like in the early Motorola piezos is worth a try.

In the beginning of the production of Piezo tweeters industry was struggling to get most out of these.

And as usually only DIY mods can reach this level of implementation care or even surpass it.

It must be stated here that the mods you mention (damping cone and chamber) in post 2+4 means a lot for the sound although through the measurement you see only slight changes.

Modge podge or alu mod I practice sonically does more than measurements would suggest.

Even adding a rubber damper to the Piezo like in the early Motorola piezos is worth a try.

In the beginning of the production of Piezo tweeters industry was struggling to get most out of these.

And as usually only DIY mods can reach this level of implementation care or even surpass it.

- Home

- Loudspeakers

- Multi-Way

- Trying to get the best out of cheapo piezos