Explain this please

-Justin

When the stylus loses contact with the groove wall, it comes crashing back down. It's the crash that digs into the groove wall and lifts a little 'flap' similar to when you cut yourself. Any material that gets in there cannot be cleaned out. That losing contact is the dreaded mis-tracking. When I worked at the stereo stores back in the '70s, the mantra was get the best (lowest tracking force) cartridge you could afford and run it at the TOP end of the manufacturers range. If they said 3/4 to 1.5, run at 1.5.

Higher tracking force cartridges have heaver styli and the only way to keep it in contact at all times is to stiffen the mechanical support in the stylus and raise the tracking force. The more expensive cartridges used lower mass (more fragile) styli. Shure and others used nude mount diamonds in the high end styli. The less expensive used an aluminum stud with the diamond bonded (glued) to it and the assembly pressed into the cantilever. On their real high end the cantilever was telescoped to have low mass at the stylus and more strength at the rubber flex point. They also claimed a laminated magnet. Then the assembly is tuned, in the V15 type V that was around 33KHz.

The mis-tracking damage is visible as white streaks. The only cure is to replace the disc and use better gear next time.

G²

<snip>

It would be interesting to see whether the technique works well for the garden variety tweaker..

Based on observation of the current stylus deflection of my ZU, it appears exceedingly unlikely that I could get Bear's technique to work with my cartridge. Deflection at 2.55gms (recommended range 2.3 - 2.7gms based on ambient temperature) is only half what I would expect based on Bear's approach.

I feel a lot more comfortable recommending people set their tracking force using a reasonably accurate gauge. I have an inexpensive Chinese made gauge, it tares at 5gms and you zero it before taring/measuring. I have measured 1 - 2gm weights and it is reasonably accurate. (Since I don't know the exact precision of the weights I can't get more specific.) The gauge cost $38 on eBay recently.

Kevin,

You may be misinterpreting somewhat.

The idea is NOT to get a deflection equal to 1/2 way into the housing.

The idea is to get a deflection equal to 1/2 of the linear deflection of the cantilever.

One way to get a feel for this is to try looking at a number of cartridges, up close and well lit as they are lowered onto the record surface. You will start to see a trend, and have a gestalt understanding.

More to the point, if you look down the bore, along the cantilever, and into that little hole in the body of the cartridge, you'll also find that most often the ideal deflection puts the cantilever dead bang in the middle of that hole...

I'd bet that at your recommended tracking force, the ZU's (a modified body Dennon) cantilever will be pretty darn close to being dead center in that hole...

One reason that I do it this way is that the actual weight is less important than having the cartridge operating in its linear range. I prefer to do that empirically, and this works for me in most cases. And anyhow one often needs to slightly adjust the tracking force if you get very into the setup...

Either way is fine, but if you don't have a gauge handy, this will work once you can "see" it.

------------------------------------------------

Another poster talked about:

Regarding the ultra low tracking force of some MM carts, like the Empire... there are issues with light tracking forces. This presumes a low mass arm with very very good anti-skate compensation, and a TT that is almost perfectly set up in all regards... most arms and TTs won't do this very well... I also have issues with the way they sound. Why the MMs tend to sound different is somewhat unclear, and I don't have a good answer. I'm not adverse to MMs, just haven't heard any that are as "good" to listen to as some MCs...

Now, on the topic of MCs... I don't know which MCs have a tipped up HF response. Mine do not. There is a supplier in the Mid Hudson Valley of NY whose products do seem to all have a HF tip up... but that's not a cartridge from a major manufacturer.

Manufacturers like Ortophon for example show a dead flat freq response. My Koetsu is also pretty darn flat as well... we could go down the list... is that due to a deliberate inductive rolloff of a cantilever resonance? If so, I'd be all "ears" on this topic and would like to see some data and test information that supports this idea...

_-_-bear

You may be misinterpreting somewhat.

The idea is NOT to get a deflection equal to 1/2 way into the housing.

The idea is to get a deflection equal to 1/2 of the linear deflection of the cantilever.

One way to get a feel for this is to try looking at a number of cartridges, up close and well lit as they are lowered onto the record surface. You will start to see a trend, and have a gestalt understanding.

More to the point, if you look down the bore, along the cantilever, and into that little hole in the body of the cartridge, you'll also find that most often the ideal deflection puts the cantilever dead bang in the middle of that hole...

I'd bet that at your recommended tracking force, the ZU's (a modified body Dennon) cantilever will be pretty darn close to being dead center in that hole...

One reason that I do it this way is that the actual weight is less important than having the cartridge operating in its linear range. I prefer to do that empirically, and this works for me in most cases. And anyhow one often needs to slightly adjust the tracking force if you get very into the setup...

Either way is fine, but if you don't have a gauge handy, this will work once you can "see" it.

------------------------------------------------

Another poster talked about:

Regarding the ultra low tracking force of some MM carts, like the Empire... there are issues with light tracking forces. This presumes a low mass arm with very very good anti-skate compensation, and a TT that is almost perfectly set up in all regards... most arms and TTs won't do this very well... I also have issues with the way they sound. Why the MMs tend to sound different is somewhat unclear, and I don't have a good answer. I'm not adverse to MMs, just haven't heard any that are as "good" to listen to as some MCs...

Now, on the topic of MCs... I don't know which MCs have a tipped up HF response. Mine do not. There is a supplier in the Mid Hudson Valley of NY whose products do seem to all have a HF tip up... but that's not a cartridge from a major manufacturer.

Manufacturers like Ortophon for example show a dead flat freq response. My Koetsu is also pretty darn flat as well... we could go down the list... is that due to a deliberate inductive rolloff of a cantilever resonance? If so, I'd be all "ears" on this topic and would like to see some data and test information that supports this idea...

_-_-bear

Hi,

For a well designed cartridge is fairly obvious (I guess this comes with

experience) when the tracking force in the right range. Any mismatching

though of arm mass to compliance will greatly confuse matters and never

be a happy combination.

At the correct tracking force stylus rake angle should be correct.

Simple fact is, mistracking due to low tracking force (or a worn stylus) will

and does cause far more record damage than any alleged stylus wear.

Actual record wear comes a very distant third as an issue IMO.

The above IMO is the major cause of record damage. The second

causes degradation, but not damage as such, this is playing dusty

records without cleaning them properly.

Small dust particles are impacted into the groove by the stylus,

even if subsequently removed by cleaning the impression remains.

I've found religious use of a carbon fibre brush (nothing else will

do, the last thing you want is a "velvet" pad that only traps

visible dust) to be very effective.

rgds, sreten.

For a well designed cartridge is fairly obvious (I guess this comes with

experience) when the tracking force in the right range. Any mismatching

though of arm mass to compliance will greatly confuse matters and never

be a happy combination.

At the correct tracking force stylus rake angle should be correct.

Simple fact is, mistracking due to low tracking force (or a worn stylus) will

and does cause far more record damage than any alleged stylus wear.

Actual record wear comes a very distant third as an issue IMO.

The above IMO is the major cause of record damage. The second

causes degradation, but not damage as such, this is playing dusty

records without cleaning them properly.

Small dust particles are impacted into the groove by the stylus,

even if subsequently removed by cleaning the impression remains.

I've found religious use of a carbon fibre brush (nothing else will

do, the last thing you want is a "velvet" pad that only traps

visible dust) to be very effective.

rgds, sreten.

Close & Way Heavy

The Akai was pretty close to what the markings on the counterweight show. The Deccollaro, on the other hand, was, as I expected after rigging an Electro-Voice model 26 cartridge in its arm, far too heavy. The Deccollaro came in, after adjustment, at about 5.2 grams. That record player, with its .7mil diamond needle, is pretty easy on the records, and plays 78's and other records that are too rough for the Akai.

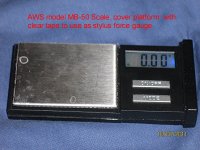

Hi Guys, I finally got one of these tiny digital gram-scales and covered the platform with clear packing tape to make a killer tracking force scale for just USD 13.

The Akai was pretty close to what the markings on the counterweight show. The Deccollaro, on the other hand, was, as I expected after rigging an Electro-Voice model 26 cartridge in its arm, far too heavy. The Deccollaro came in, after adjustment, at about 5.2 grams. That record player, with its .7mil diamond needle, is pretty easy on the records, and plays 78's and other records that are too rough for the Akai.

Attachments

Hi Guys, I finally got one of these tiny digital gram-scales and covered the platform with clear packing tape to make a killer tracking force scale for just USD 13.

Very nice idea!

Thanks

Thanks for the kind words, Sir. What intrigued me most about using this model scale is that it's only 1.7" wide and especially well suited for my purpose. It even has a tare function that "zero's out" the few hundreths of a gram that the tape weighs.

Very nice idea!

Thanks for the kind words, Sir. What intrigued me most about using this model scale is that it's only 1.7" wide and especially well suited for my purpose. It even has a tare function that "zero's out" the few hundreths of a gram that the tape weighs.

Nice!

Nice!!! I'll see if they'll start a sales commission account to pay me from. $$$$

It's on my shopping list for this afternoon.

Nice!!! I'll see if they'll start a sales commission account to pay me from. $$$$

Even better:

Digital Precision Scale with Leather Case (5g Max / 0.01g Resolution) - Free Shipping - DealExtreme

(watch out for some of the other scales that have iron-base, unusable with MC-pickups(unless you stack a 1/2" plastic-something ontop...))

Arne K

(sorry for ruining your business-opportunity...)

Digital Precision Scale with Leather Case (5g Max / 0.01g Resolution) - Free Shipping - DealExtreme

(watch out for some of the other scales that have iron-base, unusable with MC-pickups(unless you stack a 1/2" plastic-something ontop...))

Arne K

(sorry for ruining your business-opportunity...)

No Problem

No problem. I don't think they'd pay me any way.. Mine, with its 50 gram limit, suits my purposes because the precision scale's 5 gram limit wouldn't have let me do my ceramic cartridge.

Even better:

Digital Precision Scale with Leather Case (5g Max / 0.01g Resolution) - Free Shipping - DealExtreme

(watch out for some of the other scales that have iron-base, unusable with MC-pickups(unless you stack a 1/2" plastic-something ontop...))

Arne K

(sorry for ruining your business-opportunity...)

No problem. I don't think they'd pay me any way.. Mine, with its 50 gram limit, suits my purposes because the precision scale's 5 gram limit wouldn't have let me do my ceramic cartridge.

50 gram scale...

I bought one a few years ago. 50 grams, .01 gram accuracy. It can do carats , etc so jeweler's "precision". Biggest hassle is devising a way to read the weight when at record level. One thing of note: if a calibration weight is not included get one. These scales need to be periodically calibrated to ensure accurate readings. I use water measured in a 10 cc hypodermic needle (less the needle). Good enough for my insulin, good enough to precisely measure water.

, etc so jeweler's "precision". Biggest hassle is devising a way to read the weight when at record level. One thing of note: if a calibration weight is not included get one. These scales need to be periodically calibrated to ensure accurate readings. I use water measured in a 10 cc hypodermic needle (less the needle). Good enough for my insulin, good enough to precisely measure water.

The 5 gram scales look very much like some VTF gauges sold by some of the record retailers.

I bought one a few years ago. 50 grams, .01 gram accuracy. It can do carats

The 5 gram scales look very much like some VTF gauges sold by some of the record retailers.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Tracking force of cartridges