I've epoxied a nut back in and tightened up the fourth bolt. definitely an improvement. Can't find the blu tac so that will have to wait.

Mic position is a bit different, I hadn't realized my mic was flapping around for the previous tests (basically sitting on the sofa rather than sticking straight up in front of it...

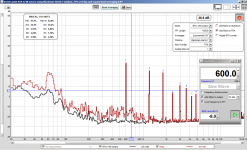

Still to test with the crossover again, I had one measurement where it was showing 2nd harmonic nearly as high as the fundamental Living room has been invaded by Mother in law and Wife as the iphone needed charging and the charger happened to be plugged in in here, so can't blast out any more 600Hz tones for now

Living room has been invaded by Mother in law and Wife as the iphone needed charging and the charger happened to be plugged in in here, so can't blast out any more 600Hz tones for now

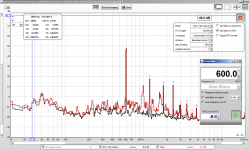

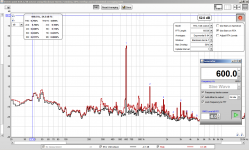

first pic is the damaged one after tightening. 2nd pic the other one for comparison. 3rd pic I went WTF. it is the left unit with crossover. I think I was clipping the preamp input.

Tony

Mic position is a bit different, I hadn't realized my mic was flapping around for the previous tests (basically sitting on the sofa rather than sticking straight up in front of it...

Still to test with the crossover again, I had one measurement where it was showing 2nd harmonic nearly as high as the fundamental

first pic is the damaged one after tightening. 2nd pic the other one for comparison. 3rd pic I went WTF. it is the left unit with crossover. I think I was clipping the preamp input.

Tony

Attachments

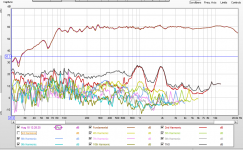

I may have just shifted the problem  Sweep of the left and right speakers in room. quite a difference between the two. I guess I really need to do it outside with both speakers tested in the same position, but it seems my 600 Hz narrow spike has been replaced by two higher and broader ones... and all I've done is tighten up a screw...

Sweep of the left and right speakers in room. quite a difference between the two. I guess I really need to do it outside with both speakers tested in the same position, but it seems my 600 Hz narrow spike has been replaced by two higher and broader ones... and all I've done is tighten up a screw...

Tony.

Tony.

Attachments

Hehe you were spot on. If you don't mind, I'll post that specific comment from the PM

Tony.

Go for it

I may have just shifted the problemSweep of the left and right speakers in room. quite a difference between the two. I guess I really need to do it outside with both speakers tested in the same position, but it seems my 600 Hz narrow spike has been replaced by two higher and broader ones... and all I've done is tighten up a screw...

Tony.

Look at how the second harmonic is defining the issue. That's mechanically, suspension/cone related irregularity. Third also but far less so, looks like he's being taken for a ride.

http://www.diyaudio.com/forums/atta...383103-prize-stupid-act-week-goes-slip_up.jpg

What drivers are these?

Below is a suggestion Mike made via PM before this thread was started, based solely on the original distortion plot.

Mike they are the much maligned Morel MW144's usually criticized for their horrible distortion and terrible motor design Does the second plot of the undamaged speaker indicate this? It looks ok to me, certainly not vanishingly low distortion but seems ok. edit: the tweeters are morel DMS37's

Does the second plot of the undamaged speaker indicate this? It looks ok to me, certainly not vanishingly low distortion but seems ok. edit: the tweeters are morel DMS37's

Note that the spl levels in these plots should be considered relative only. I did not check voltages at the speaker or the distance to the mic, though I'd estimate the distance to mic is probably around 3M. It was pretty loud, way louder than I could have endured without hearing protection on.

To many variables to work out actual level, but I'd say I was pushing a lot more than 1W!! probably more like 20!! I guess if I don't change the settings on the focusrite I could at least work out what voltage I had at the speakers terminals.

Tony.

And indeed one screw was completely loose. Tightening has removed the 600Hz peak almost completely. Unfortunately my damage, or the uneven gluing of the surround (probably both) are still contributing a significant amount of distortion that is not there in the other channel.The ¼ wavelength is roughly equal to the diameter of the driver itself... are they secure to the baffle? One screw needing a little more Oomph might be the cause... still thinking

Mike they are the much maligned Morel MW144's usually criticized for their horrible distortion and terrible motor design

Note that the spl levels in these plots should be considered relative only. I did not check voltages at the speaker or the distance to the mic, though I'd estimate the distance to mic is probably around 3M. It was pretty loud, way louder than I could have endured without hearing protection on.

To many variables to work out actual level, but I'd say I was pushing a lot more than 1W!! probably more like 20!! I guess if I don't change the settings on the focusrite I could at least work out what voltage I had at the speakers terminals.

Tony.

Last edited:

Tony, loosen all screws, reseat them like you would torque head bolts.

Ok you may not know how to build engines, chris cross tightening (1,3,2,4 or 1,4,2,5,3,6) a little at a time til snug. The unbalanced condition may also have warped the frame. This should help in that regard.

Is it possible to remove that "flexible SG" ? Acetone is normally used, but is very reactive to many materials used in speaker construction.

Something like this may help Un-Cure Debonder, 1oz. from Hobby Lobby

Also vinyl conditioner which has Limonene may help. Softens the surround nicely https://en.wikipedia.org/wiki/Limonene

Ok you may not know how to build engines, chris cross tightening (1,3,2,4 or 1,4,2,5,3,6) a little at a time til snug. The unbalanced condition may also have warped the frame. This should help in that regard.

Is it possible to remove that "flexible SG" ? Acetone is normally used, but is very reactive to many materials used in speaker construction.

Something like this may help Un-Cure Debonder, 1oz. from Hobby Lobby

Also vinyl conditioner which has Limonene may help. Softens the surround nicely https://en.wikipedia.org/wiki/Limonene

Last edited:

hehe, know all about head stud tightening  Have rebuilt the engine on my old Morris 1100 a few times! I don't have a low torque torque wrench though, but should be able to torque up gradually without too much problem

Have rebuilt the engine on my old Morris 1100 a few times! I don't have a low torque torque wrench though, but should be able to torque up gradually without too much problem

I was actually thinking about whether there was any way to undo my original repair. I didn't get a good clean fit when I did it. It looks somewhat irregular. I would need to be very careful with the acetone I think, but judicious application with a cotton bud should avoid too many accidents I would hope!

Tony.

I was actually thinking about whether there was any way to undo my original repair. I didn't get a good clean fit when I did it. It looks somewhat irregular. I would need to be very careful with the acetone I think, but judicious application with a cotton bud should avoid too many accidents I would hope!

Tony.

I'd say try something local with Limonene first. This will not damage and may help act like a mold release once penetrated, even if from the edge peeling it back little by little. Perhaps even through the surround. Then acetone applied as you've mentioned albeit cautiously.

When the driver is mounted in the box the distortion is amplified dramatically.

In situations where a surround resonance or magnet-basket resonance is being fed into the enclosure thru the mounting screws, you might consider an isolated type mounting. I have had good luck using rubber well-nuts as shown in Figure 4 of the attachment to solve similar driver vibration problems. You will of course need to use a soft closed cell foam gasket around the basket to ensure no air-leaks while minimizing vibration transfer.

Attachments

None for now, very hectic weekend. I do actually need to replace the gasket though, thought about doing it last weekend but was lazy. I'm using closed cell foam wheather strip at the moment...

Tony.

On small drivers have used glass jar grippy disc's to open them (whatever the heck they're called lol) and are made from neoprene. Get enough of each color or it'll look wonky with the mix match

I did another measurement today, outside of the problematic speaker. Then I decided to put a new neoprene washer on. When I started to tighten (only gently) one of the other bolts started to spin in it's well  Now I'm having difficulty getting it back out again

Now I'm having difficulty getting it back out again

anyway here is the first measurement. I'm going to need to do the epoxy trick on this one too. The original mounting of the nuts was less than durable

Tony.

anyway here is the first measurement. I'm going to need to do the epoxy trick on this one too. The original mounting of the nuts was less than durable

Tony.

Attachments

main problem is I originally used araldite 5 minute epoxy and it does not set rock hard. I have some other stuff that I fixed the other one with which I think should be ok. T-nuts would have been smart but I couldn't source them locally. The other device linked earlier in the thread may be another option.

I persevered and got it out. I'll epoxy back in with the good stuff and hopefully that should be the end of it :rolleys: Part of the issue is that it is in MDF too.

Tony.

I persevered and got it out. I'll epoxy back in with the good stuff and hopefully that should be the end of it :rolleys: Part of the issue is that it is in MDF too.

Tony.

main problem is I originally used araldite 5 minute epoxy and it does not set rock hard. I have some other stuff that I fixed the other one with which I think should be ok. T-nuts would have been smart but I couldn't source them locally. The other device linked earlier in the thread may be another option.

I persevered and got it out. I'll epoxy back in with the good stuff and hopefully that should be the end of it :rolleys: Part of the issue is that it is in MDF too.

Tony.

On the subject of MDF, I've always found it helpful to predrill and then seal with thin super glue. No more tear out.

T-nuts would have been smart but I couldn't source them locally.

I just found a local Sydney source for M5 and M6 T-nuts. Stainless Steel Fasteners, Abrasives, Screws, Wood Fasteners Melbourne, Australia

They have a warehouse in Ermington. I turned up at their door and they sold me 200 of each on the spot.

Graham.

Hi Graham, thanks that's actually really handy! Only problem is I apparently don't know the name to search on! I just browsed through their catalogue but still didn't find any T-nuts, do you have the part number? Good place to go to get cap-head screws too by the looks of things!

Tony.

Tony.

Tony,

They are listed as Tee Nuts on page 20 of the "Hardware" catalogue, together with skein nuts.

I'm not surprised you had trouble finding them. Typical of many local suppliers, this company is pretty useless in terms of making it easy for customers to purchase stuff. When I first called about tee nuts I was told by the office no stock and 1 week to get them in, but I went anyway to buy skein nuts as an alternative, to find out from the warehouse guy (who actually knows the stock range) that tee nuts are all in stock.

I can't remember the exact price, but they were pretty cheap. If you only need a few, and are in northern Sydney, you're welcome to come and grab some (in return for some advice on how to measure speakers)

Graham.

They are listed as Tee Nuts on page 20 of the "Hardware" catalogue, together with skein nuts.

I'm not surprised you had trouble finding them. Typical of many local suppliers, this company is pretty useless in terms of making it easy for customers to purchase stuff. When I first called about tee nuts I was told by the office no stock and 1 week to get them in, but I went anyway to buy skein nuts as an alternative, to find out from the warehouse guy (who actually knows the stock range) that tee nuts are all in stock.

I can't remember the exact price, but they were pretty cheap. If you only need a few, and are in northern Sydney, you're welcome to come and grab some (in return for some advice on how to measure speakers)

Graham.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Tracking down source of distortion peak in my MTM