I have just installed my boards into the old carcass of my monoblock amps. I just "tacked" in the power connections etc for the moment because I will build a new chassis for the amps and use them with DPS 500 power supplies I have ordered from AP. They work but I have the mother of all hums, likely ground loop induced which I will need to play with to fix.

In relation to that, where are people grounding their amps to the chassis? I have run a ground wire from the high current power ground input to chassis. Another alternative would be from the centre of the off board filter caps. I might need to experiment with lifting the board from chassis ground with a low ohm resistor too. Time to get out the clip leads.

Finally thanks to Owen for all the hardwork, and the great boards.

Rob.

Rob,

Some photos could be very helpful. It could be a combination of a) ground current-induced voltages across ground conductors and b) some loop enclosing too much geometric area that is having currents induced in it by some AC magnetic field.

For the chassis connection, it seems like just after the last reservoir caps would be better than between them.

Tom

All exposed conductive external parts must be connected to Chassis.

That Chassis must have a direct connection to PE.

There in lies the requirement for everything to be connected to PE, not directly but connected.

A solitary screw head on the outside of a plastic case, even underneath, is a conductive external part.

That screw must be connected to Chassis and thence to PE.

A screw head buried deep inside an insulating pocket, with a plastic cover preventing children tampering, is not exposed and thus does not need to be connected to Chassis.

That Chassis must have a direct connection to PE.

There in lies the requirement for everything to be connected to PE, not directly but connected.

A solitary screw head on the outside of a plastic case, even underneath, is a conductive external part.

That screw must be connected to Chassis and thence to PE.

A screw head buried deep inside an insulating pocket, with a plastic cover preventing children tampering, is not exposed and thus does not need to be connected to Chassis.

All exposed conductive external parts must be connected to Chassis.

That Chassis must have a direct connection to PE.

There in lies the requirement for everything to be connected to PE, not directly but connected.

A solitary screw head on the outside of a plastic case, even underneath, is a conductive external part.

That screw must be connected to Chassis and thence to PE.

A screw head buried deep inside an insulating pocket, with a plastic cover preventing children tampering, is not exposed and thus does not need to be connected to Chassis.

This is absolutely not true... there is no legal or safety requirement to tie any part of the chassis to earth either here in NA or in EU.

If there was, then two prong appliances would be illegal, but they're not.

All the products from Paradigm/Anthem were always two-terminal plug and never used any form of chassis ground. This was a very intentional (and costly) design decision, but they stuck with it.

The difference is in the creepage and clearance requirements from mains to chassis. If you have an earthed chassis, the creepage and clearance is greatly reduced (no need for triple insulation or 6mm global clearance live to isolated).

If you have a floating chassis, the C&C requirements are much more strict.

You really should read through the codes before lambasting other users on here when they haven't done anything wrong.

Regards,

Owen

why are you connecting chassis to anything but safety ground and perhaps any AC line filter components?

ahh you havent received DPS500 yet?

Yes still waiting for the DPS-500. The setup I have now is a hack to see if the board worked, it did, albeit with lots and I mean LOTS of hum. The grounding is conventional, ie PG to chassis and I have experimented with lifting safety ground, without success but there are wires from the filter caps wires not twisted etc as they will be when the amp is properly built. That said, when the input is grounded the AC on the speaker terminals is unmeasurable, at least with a DMM.

This seems to indicate a loop but I haven't tracked it down yet.

Thanks all for the input.

I also forgot to say that I wanted to get the amps running in rough form pending the new parts arriving so that, amongst other things, I could assess suitable heatsink size.

The existing amps have Conrad 100mm x 300mm heatsinks which have a thermal resistance of C/W .32 for a 80C rise. I have at least succeeded in determining that this size is adequate for running the amps at circa 360ma bias, but I wouldn't want to run them much higher than that. I was going to build my own amp case again but have decided to go easy on myself , so I just ordered a case from Silicon Ray with circa 150mm x 300mm heatsinks so that I can run 600ma bias comfortably.

The existing amps have Conrad 100mm x 300mm heatsinks which have a thermal resistance of C/W .32 for a 80C rise. I have at least succeeded in determining that this size is adequate for running the amps at circa 360ma bias, but I wouldn't want to run them much higher than that. I was going to build my own amp case again but have decided to go easy on myself , so I just ordered a case from Silicon Ray with circa 150mm x 300mm heatsinks so that I can run 600ma bias comfortably.

Owen, any thoughts on using the new quad die Semelab laterals with the wire? thought I might give them a go for the subs.

Robert, do remember that the DPS supplies will not start up into 600mA you will need to sequence it so they start into lower bias, say 150-200, then increase to 600mA. do you have any actual data on the siliconray heatsinks that makes you comfortable in almost doubling the bias for only 50mm extra height and no extra length?

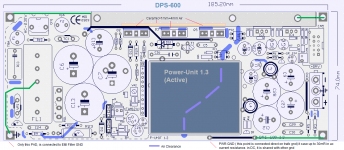

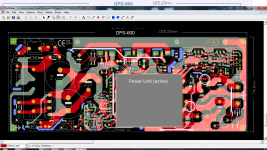

with the DPS500 and 600 the recommended format is to connect the supplies together through the standoff hole marked with a GND symbol (which is tied to the AC line filter components) and then to Safety ground, no other connection to ground. the supplies are CE qualified with this set up in mind.

Robert, do remember that the DPS supplies will not start up into 600mA you will need to sequence it so they start into lower bias, say 150-200, then increase to 600mA. do you have any actual data on the siliconray heatsinks that makes you comfortable in almost doubling the bias for only 50mm extra height and no extra length?

with the DPS500 and 600 the recommended format is to connect the supplies together through the standoff hole marked with a GND symbol (which is tied to the AC line filter components) and then to Safety ground, no other connection to ground. the supplies are CE qualified with this set up in mind.

Nowt so flash as actual data from Silicon Ray I am afraid. My reasoning is- I could I think run the amps on the existing heatsinks at 600ma, but I would not be comfortable running them at that temperature.

I am or will be running +-50v high current/60v low current rails

The existing heatsinks are attached to a wooden box via angled aluminium extrusions, the Silicon Ray chassis will be all aluminium.

The silicon ray heatsinks look to be the equivalent of the conrad 30-150, same fin depth and material thickness from what I can see.

I was hoping the DPS 500 may let me get away with a higher bias on startup than the 600 and let me avoid sequencing... time will tell.

In your implementation do you ground the amp module to the case at all?

I am or will be running +-50v high current/60v low current rails

The existing heatsinks are attached to a wooden box via angled aluminium extrusions, the Silicon Ray chassis will be all aluminium.

The silicon ray heatsinks look to be the equivalent of the conrad 30-150, same fin depth and material thickness from what I can see.

I was hoping the DPS 500 may let me get away with a higher bias on startup than the 600 and let me avoid sequencing... time will tell.

In your implementation do you ground the amp module to the case at all?

I had similar problem with my AC coupled SE amps when using a screw with too large head. Screwhead touched input cap.They work but I have the mother of all hums.

Other than that, i didn't notice any hum or other strange behavior, no difference how grounding was wired.

Amp does not have safety grounding because original amp didn't. It has double isolated transformer.

wb Margus

no need for grounding the amp to an external ground, just the GND screw term on the DPS power supply. here is the recommendation from Roberto. note the GND screw term on the corner, it connects to the AC line filter, that is connected directly to safety ground and thats it, the power supplies are double insulated afaik.

Note the CE mark too, so this isnt some whacky/risky audiophile grounding setup, rather the way it should be and given the amp topology, no need to have shield ground or safety ground anywhere near the amp side power supply, or signal ground. power ground (which is separate, on the clean side of the power supply, becomes the speaker return directly in Roberto's schematic, but it can just as easily just connect the ground on the amp board as speaker return. Try both, I intend to.

as for starting into 600mA, nope its not going to work any better on the dps500, it has the same auxiliary regulator section as the 600, so you will need to stick to 350-400mA, or install smart bias switching, hochopeper and I came up with an optically isolated switching scheme that can be manual, or connected to a controller for automatically handing it,

Note the CE mark too, so this isnt some whacky/risky audiophile grounding setup, rather the way it should be and given the amp topology, no need to have shield ground or safety ground anywhere near the amp side power supply, or signal ground. power ground (which is separate, on the clean side of the power supply, becomes the speaker return directly in Roberto's schematic, but it can just as easily just connect the ground on the amp board as speaker return. Try both, I intend to.

as for starting into 600mA, nope its not going to work any better on the dps500, it has the same auxiliary regulator section as the 600, so you will need to stick to 350-400mA, or install smart bias switching, hochopeper and I came up with an optically isolated switching scheme that can be manual, or connected to a controller for automatically handing it,

Attachments

Last edited:

AndrewT may not be 100% right but I think you are 100% wrong.This is absolutely not true... there is no legal or safety requirement to tie any part of the chassis to earth either here in NA or in EU.

Regards,

Owen

From the Ontario (Canada) Electrical Safety Code 2012:

Equipment bonding

10-400 Fixed equipment, general

Exposed, non-current-carrying metal parts of fixed equipment shall be bonded to ground if the equipment is

(a) supplied by means of metal-enclosed wiring;

(b) supplied by means of wiring that contains a bonding conductor;

(c) located in a wet location and is not isolated;

(d) located within reach of a person who can make contact with any grounded surface or object;

(e) located within reach of a person standing on the ground;

(f) in a hazardous location;

(g) in electrical contact with metal, metal foil, or metal lath; or

(h) to operate with any terminal at more than 150 volts-to-ground, except for

(i) enclosures for switches or circuit breakers that are accessible to qualified persons only;

(ii) metal frames of electrically heated devices that have been exempted in accordance with Rule 2-030

and are permanently and effectively insulated from ground; and

(iii) transformers mounted on wooden poles at a height of more than 2.5 m above grade level, provided

that the installation is in compliance with the requirements of the supply authority.

Unless you misspoke, I cannot see in any way that you are not making a completely false statement.

Andrew maybe you misunderstood where the resistor is going?No No No !!!.I might need to experiment with lifting the board from chassis ground with a low ohm resistor

The CE marked Amplifier I helped develop used a 100 Ohm with a small capacitor, maybe 22n, across it to lift the centre tap and earth star from the mains earthed chassis.

The 1993 Meridian amps I have separate the centre tap from chassis via a capacitor, 0.1u I think.

The Hi-Fi we're talking about is not fixed equipment. Portable.Equipment bonding

10-400 Fixed equipment, general

Last edited:

The 1993 Meridian amps I have separate the centre tap from chassis via a capacitor, 0.1u I think.The Hi-Fi we're talking about is not fixed equipment. Portable.

Correct... it has its own subsection in the code.

AndrewT may not be 100% right but I think you are 100% wrong.

From the Ontario (Canada) Electrical Safety Code 2012:

Equipment bonding

10-400 Fixed equipment, general

Exposed, non-current-carrying metal parts of fixed equipment shall be bonded to ground if the equipment is

(a) supplied by means of metal-enclosed wiring;

(b) supplied by means of wiring that contains a bonding conductor;

(c) located in a wet location and is not isolated;

(d) located within reach of a person who can make contact with any grounded surface or object;

(e) located within reach of a person standing on the ground;

(f) in a hazardous location;

(g) in electrical contact with metal, metal foil, or metal lath; or

(h) to operate with any terminal at more than 150 volts-to-ground, except for

(i) enclosures for switches or circuit breakers that are accessible to qualified persons only;

(ii) metal frames of electrically heated devices that have been exempted in accordance with Rule 2-030

and are permanently and effectively insulated from ground; and

(iii) transformers mounted on wooden poles at a height of more than 2.5 m above grade level, provided

that the installation is in compliance with the requirements of the supply authority.

Unless you misspoke, I cannot see in any way that you are not making a completely false statement.

I've highlighted the relevant section above... There is no need to supply a ground to any audio equipment, period.

If the equipment does indeed have a three terminal power connector (implying an earth connection) then it may fall under some of the above rules, but there is no hard requirement to have any earth connection at all on consumer electronics goods.

I'm not going to argue against the idea that it's good practice to tie the chassis and everything near it to earth, but it's not a legal requirement, and it's not dangerous in any way to deviate from that if you know what you're doing.

In addition to the above, tying the chassis and all other metal protrusions to earth may protect you from accidental electrocution, but it won't protect against burning your house down. Designing and building your own equipment carries with it a large risk if you don't know what you're doing, and don't take the time to learn how to design safely.

Here's the standard you need:

http://ulstandardsinfonet.ul.com/scopes/60065.html

Regards,

Owen

Last edited:

Thank you for the correction. It seems as though the OESC actually does not mandate the grounding of metal-enclosure audio equipment, at least as far as I can see.The Hi-Fi we're talking about is not fixed equipment. Portable.

ClassI equipment

We are not allowed to attempt to build any ClassII equipment. Otherwise known as "Double Insulated".

All the mains powered equipment that we build is ClassI. These must all use the PE connection to blow the mains Fuse.

If the PE is not used then the Fuse will not blow and can leave the equipment Live.

This would be dangerous.

I say again:

We as untrained, unsupervised amateurs cannot build ClassII equipment. ClassII production and test standards are way above what is required for ClassI.

I twice gave a similar answer days ago, but both were censored.

As a result others are now compelled to argue with OPC's wrong information.

We are not allowed to attempt to build any ClassII equipment. Otherwise known as "Double Insulated".

All the mains powered equipment that we build is ClassI. These must all use the PE connection to blow the mains Fuse.

If the PE is not used then the Fuse will not blow and can leave the equipment Live.

This would be dangerous.

I say again:

We as untrained, unsupervised amateurs cannot build ClassII equipment. ClassII production and test standards are way above what is required for ClassI.

I twice gave a similar answer days ago, but both were censored.

As a result others are now compelled to argue with OPC's wrong information.

Andrew you need to quote the regulations, page, paragraph, etc.. It's hearsay otherwise. And the whole subject has occurred due to your misunderstanding of what someone said about the centre tap and earth star being separated from the chassis earth.

Maybe things have changed in the last fifteen years but we didn't have to get our products certified as compliant, we just complied with the regulations and put the CE mark. If someone complained to Trading Standards then they may test the product and if found to be non-compliant, require it to removed from sale until the regulatory deviation is put right.

Obviously if for personal use then your concern is over litigation from a friend or relative who got a shock from your faulty equipment in your home or that you lent to them. Would the state be bothered to sue you over such a thing? Only if your acquaintance referred the matter to the Police service or CPS?

Why not? Some people do know what they doing, are trained, don't need to be supervised!! If it's worrying you that someone might litigate against your non-compliant home built apparatus then make sure it complies and get it tested and certified.We as untrained, unsupervised amateurs cannot build ClassII equipment.

Maybe things have changed in the last fifteen years but we didn't have to get our products certified as compliant, we just complied with the regulations and put the CE mark. If someone complained to Trading Standards then they may test the product and if found to be non-compliant, require it to removed from sale until the regulatory deviation is put right.

Obviously if for personal use then your concern is over litigation from a friend or relative who got a shock from your faulty equipment in your home or that you lent to them. Would the state be bothered to sue you over such a thing? Only if your acquaintance referred the matter to the Police service or CPS?

Last edited:

Andrew,

Assuming you are correct, which is not the case, explain how you handle the following:

- Loudspeaker binding posts on an amplifier

- XLR output from a preamp

Both of the above are exposed metal parts which cannot be bonded to earth while maintaining even basic functionality.

It's not about bonding everything to earth, it's about isolation between primary (live) side and secondary safe side.

Regards,

Owen

Assuming you are correct, which is not the case, explain how you handle the following:

- Loudspeaker binding posts on an amplifier

- XLR output from a preamp

Both of the above are exposed metal parts which cannot be bonded to earth while maintaining even basic functionality.

It's not about bonding everything to earth, it's about isolation between primary (live) side and secondary safe side.

Regards,

Owen

- Home

- Amplifiers

- Solid State

- "The Wire AMP" Class A/AB Power Amplifier based on the LME49830 with Lateral Mosfets