Sorry, I wouldn't even want to do that!

For me, the reason I say it's too big has to do with vertical spacing, I have no problem with that empty horizontal part. It's there on the amplifier tag as well...

It's all about the spacing for me. I've made many small tweaks before being happy with this tag. Must have tried 30 different fonts etc.

At least 10 of those were unfit to use for printing.

Ah well, it's all very personal I assume. I'm pretty happy with how the amp turned out...

Even the size of the logo compared to the space above and around it matters to me.

This is just my personal taste, for me it is in balance this way.

I'd fuss over where to place a button like no one else! I've always been that way.

For me, the reason I say it's too big has to do with vertical spacing, I have no problem with that empty horizontal part. It's there on the amplifier tag as well...

It's all about the spacing for me. I've made many small tweaks before being happy with this tag. Must have tried 30 different fonts etc.

At least 10 of those were unfit to use for printing.

Ah well, it's all very personal I assume. I'm pretty happy with how the amp turned out...

Even the size of the logo compared to the space above and around it matters to me.

This is just my personal taste, for me it is in balance this way.

I'd fuss over where to place a button like no one else! I've always been that way.

Attachments

I can see your automotive passion reflected in these designs.

Your inspiration was helpful, there, it's finished!

(just kidding

Attachments

TOSLINK is 135Mbit/s (135MHz) so I don’t think it will be very susceptible to artifacts or interference due to fiber material or jacket material - basically it’s a light pipe for 650nm LED not a single mode optical fiber with a laser diode. It’s tough durable interference free stuff for audio frequencies. I don’t think you will detect a difference between plastic or glass, or metal or plastic jacks (except for durability).

I don’t think you answered my earlier question about regular XLR cable with balanced driver and balanced receiver? Proven low noise is noisy environments for long runs in pro audio applications.

Commercially available receivers and senders like TORX 147 et al are 10-15 mbps. Thats it I'm afraid. Probably the actual fiber can send more but alas...

I use them to move my DACs close to the speakers. My DACs (2, one L, one R) has re-clcoking so jitter is of no concern. I feel confident that the BER is sufficiently low. The isolation is what I'm also after except being able to reduce the length of the analog path.

//

Last edited:

I already have a mission to build this stacked plywood cabinet for Elsinore, I have ordered 5mm alum as my template copying someone else idea. I wont use steel ll rod, but i thinking about using dowels on each layer.

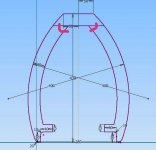

as attached picture, the template I order will remove the orange line and add green one. then I will add separate baffle just like SF Amati Homage (i really olve it craftmanship), no vinyl cover just exposed plywood

will i avoid any crack with using dowels? anyone had tested the same?

as attached picture, the template I order will remove the orange line and add green one. then I will add separate baffle just like SF Amati Homage (i really olve it craftmanship), no vinyl cover just exposed plywood

will i avoid any crack with using dowels? anyone had tested the same?

Attachments

I'd leave that green line open. That way you can get more shapes out of a single sheet of ply by inter-locking them. That's how I saved wood. There's plenty of room to attach the baffle to. No need for a closed front. Use a couple of layers as braces too.

The Elsinore? Cool project. I've been silently following that one for quite a while.

I hope the dowels will work out for you. I know of at least one other ply laminate construction that cracked:

http://www.diyaudio.com/forums/full-range/167744-fe168e-sigma-teardrop-enclosure-17.html#post4118349

That one did not have any steel rods at all. He went on to fix it with fiberglass, similar to my solution (epoxy and fiberglass matt for me).

Love the look of that Sonus Faber enclosure though, should look good filled with the Elsinore gear.

You may be able to add a coat of fiberglass + matt and still keep the wood look. Look up how they coat boats that way. I had thought about doing that myself. The fiberglass matt will be completely clear and transparent. I'd think about adding a few flexible seams in there though. The force of expanding wood can be quite severe.

The Elsinore? Cool project. I've been silently following that one for quite a while.

I hope the dowels will work out for you. I know of at least one other ply laminate construction that cracked:

http://www.diyaudio.com/forums/full-range/167744-fe168e-sigma-teardrop-enclosure-17.html#post4118349

That one did not have any steel rods at all. He went on to fix it with fiberglass, similar to my solution (epoxy and fiberglass matt for me).

Love the look of that Sonus Faber enclosure though, should look good filled with the Elsinore gear.

You may be able to add a coat of fiberglass + matt and still keep the wood look. Look up how they coat boats that way. I had thought about doing that myself. The fiberglass matt will be completely clear and transparent. I'd think about adding a few flexible seams in there though. The force of expanding wood can be quite severe.

If You decide not to use these logos on the speakers, they could be made into some pretty hip earnings for your misses. Maybe too heavy, but good promotion for your business if You ever decide to go that route.

Took them off yesterday. The arrays look prettier without them. I'll make a list of people that want these earrings, anyone want to sign up?

@wesayso

I'm worried about now whether to proceed or not on stacked ply, but it think it's worth to try considering that i will need around 2-3 sheets of ply. the cost is not too much, but assembling time which must be sacrified.

or maybe using solidwood 2"x4" like this is also doable

I'm worried about now whether to proceed or not on stacked ply, but it think it's worth to try considering that i will need around 2-3 sheets of ply. the cost is not too much, but assembling time which must be sacrified.

or maybe using solidwood 2"x4" like this is also doable

Attachments

From the start I had planned to cover the stacks with fiberglass matt. Until I saw the base wood after sanding. I just had to try to keep that look but it didn't work out.

But my stack was 2 m 25 cm(!)

Eventually you'll have to decide for yourself, no one can give you any guarantees.

But my stack was 2 m 25 cm(!)

Eventually you'll have to decide for yourself, no one can give you any guarantees.

I just ordered the template from my friend who has cnc machine and usually received speaker cabinet order. but hey what is the fun if he is the one who build it

the template is from mdf then I'll go to metal shop to cut 6mm metal sheet based on this template. to avoid any crack, the side box thickness is set to 40mm. From all builds that I found on other threads, the template is usually jointed together between left and right side. But i separate them to reduce wasted plywood and also to copy SF amati homage design with solid wood on the backside.

the middle template is for the bracing, while the big one will be the base guide.

I'm still in the waiting list for meranti marine plywood 18mm, because the factory has minimum order for 30 sheets, while I only have budget for 8 sheets. this is my only hope for the plywood which is void free and strong enough used on the sea boat

I'll start another thread build later, but for sure I'll need your advices

the template is from mdf then I'll go to metal shop to cut 6mm metal sheet based on this template. to avoid any crack, the side box thickness is set to 40mm. From all builds that I found on other threads, the template is usually jointed together between left and right side. But i separate them to reduce wasted plywood and also to copy SF amati homage design with solid wood on the backside.

the middle template is for the bracing, while the big one will be the base guide.

I'm still in the waiting list for meranti marine plywood 18mm, because the factory has minimum order for 30 sheets, while I only have budget for 8 sheets. this is my only hope for the plywood which is void free and strong enough used on the sea boat

I'll start another thread build later, but for sure I'll need your advices

Attachments

Last edited:

Are you going to use a seal between the solid wood back and the ply sides?

As they are different materials I'd expect the largest difference in expansion/contraction right there (just as between my Aluminium baffle and enclosure).

I do hope you will succeed. I think it remains a good idea to have build in layers that can deal with the expanding/contracting wood. What that layer should be is a valid question though. It would be an elastic rubber every x number of layers. In such a case steel rods throughout would still make sense (to me).

I don't regret using the rods, as that is what kept the enclosures in one piece. A next time I'd add (insert) flexible layers from the get go but still use those rods.

As they are different materials I'd expect the largest difference in expansion/contraction right there (just as between my Aluminium baffle and enclosure).

I do hope you will succeed. I think it remains a good idea to have build in layers that can deal with the expanding/contracting wood. What that layer should be is a valid question though. It would be an elastic rubber every x number of layers. In such a case steel rods throughout would still make sense (to me).

I don't regret using the rods, as that is what kept the enclosures in one piece. A next time I'd add (insert) flexible layers from the get go but still use those rods.

I got myself in trouble with my new amplifier. As the RCA-outs were a bit smaller than usual I wanted to replace them. After swapping them out and sorting some wires I fired the amplifier up again only to find out I had no sound coming from the left channel  .

.

Quite frankly, I was terrified I had broken something. I took some time off to let it sink in and to contact koldby. After careful analysis, things started to point to the protection relays on the left side not working as it should.

Together with koldby we went trough the schematics and PCB (koldby had already discovered the schematics had an error in it) and koldby suggested some changes of components.

Yesterday I was able to put things right again, swapped out both the relays and a resistor on each channel and I am happy to say everything is up and running again.

Quite frankly, I was terrified I had broken something. I took some time off to let it sink in and to contact koldby. After careful analysis, things started to point to the protection relays on the left side not working as it should.

Together with koldby we went trough the schematics and PCB (koldby had already discovered the schematics had an error in it) and koldby suggested some changes of components.

Yesterday I was able to put things right again, swapped out both the relays and a resistor on each channel and I am happy to say everything is up and running again.

wesayso,

Good to know that nothing was "broken" and the amp is in working order again.

It was quite a relief to have it purring again on all 24 cylinders.

Agree and like happy endings...

Wish I could let you hear the bass part... it isn't lacking.

Even better with that big Telos amp on it. Makes me wonder why I need subwoofers...

I faintly recall: headroom... but sometimes I think I'm just crazy

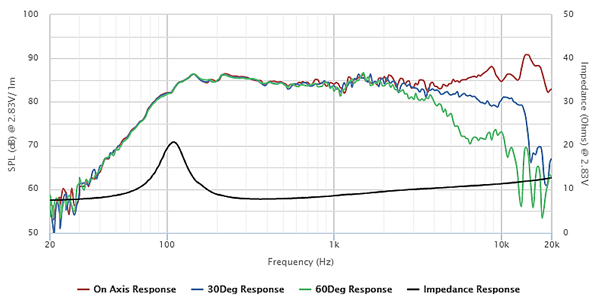

Please can you help me understand how you get such great bass from such a little driver?

Is this your driver

https://www.parts-express.com/pedocs/specs/264-1062--tymphany-tc9fd18-08-spec-sheet.pdf

with a 30dB drop off at 20Hz?

Do you just equalise +30dB to compensate?

Please can you help me understand how you get such great bass from such a little driver?...

As long as we indoor its very seldom except in very large rooms we need any drivers that reach linear down to 20Hz or so, see below red curve how my room can behave in a free Jeff Bagby spreadsheet. Think what wesayso have done is get speakers to cooperate with rooms reverse curve and in my opinion gives a natural low end as it sounds into some head phones, not that its easy to setup and find out but when done it works great for all music.

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- The making of: The Two Towers (a 25 driver Full Range line array)