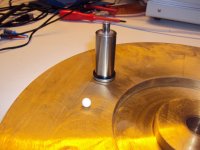

Here is the brass platter. It is 320mm in diameter and 40mm high.

This is not your wimpy aluminum, it weights a considerable 24kG.

When i stroke it there is only a very high pitched ping. I think that will go away ones it sits on the bearing and has a record mat. The mat could be made from POm or even PEAK but that is very expensive.

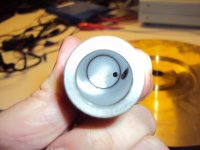

You also see the inverted bearing i used. It had a ceramic ball on a ceramic mirror and oil.

Ultimately it was too week and the platter was not turning any more.

This is not your wimpy aluminum, it weights a considerable 24kG.

When i stroke it there is only a very high pitched ping. I think that will go away ones it sits on the bearing and has a record mat. The mat could be made from POm or even PEAK but that is very expensive.

You also see the inverted bearing i used. It had a ceramic ball on a ceramic mirror and oil.

Ultimately it was too week and the platter was not turning any more.

Attachments

Hi,

When I had my 6kg platter with ceramic ball resting on a ceramic bearing run in, I measured the dip the ball had formed and calulated the pressure per area. Did it repeatedly, because I thought of a calculating failure first. The result was a presure of 3tons per cm2!! Interpolating to Your 24kg platter I'd expect a pressure of 10-12tons per cm2.

I doubt that any bearing would last long under these conditions. The bearing will run dry regardless of how much oil or grease you put in. I'm no mechanic but I'd assume that a hard-hard bearing combination won't suffice here and that a hard-soft combination of ball and mirror is preferrable for heavy platters.

jauu

Calvin

When I had my 6kg platter with ceramic ball resting on a ceramic bearing run in, I measured the dip the ball had formed and calulated the pressure per area. Did it repeatedly, because I thought of a calculating failure first. The result was a presure of 3tons per cm2!! Interpolating to Your 24kg platter I'd expect a pressure of 10-12tons per cm2.

I doubt that any bearing would last long under these conditions. The bearing will run dry regardless of how much oil or grease you put in. I'm no mechanic but I'd assume that a hard-hard bearing combination won't suffice here and that a hard-soft combination of ball and mirror is preferrable for heavy platters.

jauu

Calvin

I don't know if any of you have ever seen one of those large round stones, over 2 meters in diameter round that you can rotate with a finger are done. A very thin film of water is injected under the stone in a matching base and this floats the globe and allows for it to rotate with little energy. The pumps that are used a low pressure and when you look at the surface area that the film supports it will support a very high weight. This could be a way to support the platter with a simple pump and an oil bath and eliminate any frictional forces.

spinning stone balls,spinning granite marble stone sandstone ball spheres globes balls - YouTube

spinning stone balls,spinning granite marble stone sandstone ball spheres globes balls - YouTube

Just a hole and a glass plate like the Forsell that has a heavy platter too.

An aquarium pump is enough for this.

Yes,

With a aquarium pump "Rena air 600" only for max platter 2,5kg ....

And, better with multiple air nozzles ...

With 0.5bar it's possible to float a 16kg platter ....

With 0.5bar its possible to carry 5 meter water column, so with a platter area of app 1/10 sq-m you can carry 500 Kg at 0.5 bar. The pressure for lifting a 26 kg TT platter with air very very low, as the pressure works on a quite big surface.but you cant have any wobble or vertical misalignment at all in your bearing, I have built many TT-this way A very very good bearing, but you need some kind of brush (carbon, copper or) to get rid of the static charge build up.

And one thing to consider is that Air flow is noisy too...and so is the pump

I really like the MAG-lev with attraction, there i believe you can get both the uniform bearing-force reduction and the ability to lead away record-groove vibrations. By inserting iron disks in the bearing you can null the flux variations of the neo, and at the same time place them under a iron shield as to prevent any rotational flux reaching the cartridge.

Anyone here with machining capabilities willing to give this a go, then I'll make the machine drawings and do the math, maybe we could make it a group buy item..??

And one thing to consider is that Air flow is noisy too...and so is the pump

I really like the MAG-lev with attraction, there i believe you can get both the uniform bearing-force reduction and the ability to lead away record-groove vibrations. By inserting iron disks in the bearing you can null the flux variations of the neo, and at the same time place them under a iron shield as to prevent any rotational flux reaching the cartridge.

Anyone here with machining capabilities willing to give this a go, then I'll make the machine drawings and do the math, maybe we could make it a group buy item..??

Last edited:

MiiB,

Without seeing your drawing of the air bearing it sounds like you are calculating using the entire surface area of the platter as the bearing surface. In Joachim's instance the bottom of the platter is not flat but machined for the bearing assembly and has a large recess cut into the surface. I look forward to your drawings to see how you propose to accomplish this. I know we can just raise the air pressure to increase the force over a smaller area but wonder about the noise of the pump. Another question I have for anyone is the air pump itself. Wouldn't most of these pumps have a pulsating output, in a fish tank who cars if the air stream is continuous or pulsed, but for work in an airbearing I would think you would need a pulse-less air supply to not have the same problem of motion as the effect of an unevenly charged magnetic surface on two repelling magnets?

Without seeing your drawing of the air bearing it sounds like you are calculating using the entire surface area of the platter as the bearing surface. In Joachim's instance the bottom of the platter is not flat but machined for the bearing assembly and has a large recess cut into the surface. I look forward to your drawings to see how you propose to accomplish this. I know we can just raise the air pressure to increase the force over a smaller area but wonder about the noise of the pump. Another question I have for anyone is the air pump itself. Wouldn't most of these pumps have a pulsating output, in a fish tank who cars if the air stream is continuous or pulsed, but for work in an airbearing I would think you would need a pulse-less air supply to not have the same problem of motion as the effect of an unevenly charged magnetic surface on two repelling magnets?

Pulses can be tuned out by surge tanks made out of 3" or more in Dia. black PVC pipe and filled with polyester stuffing. 12" to 18" in length and multiple tanks in line work since this is easy to accomplish

I have made an 8" Dia air bearing with a 13 pound acrylic/ lead platter that uses less than 1 PSI to float it. You want the least amount of air pressure and no more or less than necessary to keep it quiet.

I can post Dimensions if you want when I get back home.

Regards

David

I have made an 8" Dia air bearing with a 13 pound acrylic/ lead platter that uses less than 1 PSI to float it. You want the least amount of air pressure and no more or less than necessary to keep it quiet.

I can post Dimensions if you want when I get back home.

Regards

David

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- The Good Turntable