Hello jackinnj, Hello benb,

If I had my way, I would attach the headshell to the tonearm permanently and wire it straight through. When you use an SME type headshell coupling, You introduce three additional joints in the wiring which I don't think is a good thing. I don't think that this type of connector is very good electrically speaking, because the contacts don't provide a wiping action as they mate. They just butt together.

The connectors are on EBAY if you insist.

The Binder people don't make those connectors either.

Sincerely,

Ralf

I'd think a one-piece headshell and arm can achieve better performance.

If I had my way, I would attach the headshell to the tonearm permanently and wire it straight through. When you use an SME type headshell coupling, You introduce three additional joints in the wiring which I don't think is a good thing. I don't think that this type of connector is very good electrically speaking, because the contacts don't provide a wiping action as they mate. They just butt together.

The connectors are on EBAY if you insist.

The Binder people don't make those connectors either.

Sincerely,

Ralf

I now have the tonearm wire, efficient delivery & at a vey reasonable ie sensible Price.

Questions; what is the Best method of using the wire.

It's Silk covered Litz wire

Should I lacquer this wire before Twisting / Braiding

Twisting Or Braiding ?

loose or tight twist / braid ?

Also earthing the arm, is it necessary ?

If so should a Fifth wire be taken to the headshell /cartridge body

or just soldered to the arm tube ?

I'm sure that their have been threads on this subject links to them would be appreciated

Questions; what is the Best method of using the wire.

It's Silk covered Litz wire

Should I lacquer this wire before Twisting / Braiding

Twisting Or Braiding ?

loose or tight twist / braid ?

Also earthing the arm, is it necessary ?

If so should a Fifth wire be taken to the headshell /cartridge body

or just soldered to the arm tube ?

I'm sure that their have been threads on this subject links to them would be appreciated

Last edited:

Hello Jay1234

I think the wires are lacquered underneath the silk. Lacquering them again, (over the silk I assume) would stiffen them.

I think that the lacquer doubles as a flux during soldering. Test a piece.

I think twisting the wires is the accepted method although I braided them in my 1980ies tonearm with no bad effects. If I remember correctly, the length of twist has to do with the wave length of local radio frequency interference. But don't ask me what that is. You don't want the wire to be a receiving antenna for such signals.

When I built my 2012 tonearm, I purchased already twisted 5-conductor wire. I used the fifth wire for grounding wich worked very well. However all the tonearm parts make electrical contact with each other which will change once the various parts are anodized. If there aren't any insulators between the components of your tonearm, it doesn't matter where you attach the ground wire except that it might torque the tonearm if it is attached too far from the pivot.

I hope that I've helped.

Sincerely,

Ralf

Questions; what is the Best method of using the wire.

It's Silk covered Litz wire

Should I lacquer this wire before Twisting / Braiding

Twisting Or Braiding ?

loose or tight twist / braid ?

Also earthing the arm, is it necessary ?

If so should a Fifth wire be taken to the headshell /cartridge body

or just soldered to the arm tube ?

I think the wires are lacquered underneath the silk. Lacquering them again, (over the silk I assume) would stiffen them.

I think that the lacquer doubles as a flux during soldering. Test a piece.

I think twisting the wires is the accepted method although I braided them in my 1980ies tonearm with no bad effects. If I remember correctly, the length of twist has to do with the wave length of local radio frequency interference. But don't ask me what that is. You don't want the wire to be a receiving antenna for such signals.

When I built my 2012 tonearm, I purchased already twisted 5-conductor wire. I used the fifth wire for grounding wich worked very well. However all the tonearm parts make electrical contact with each other which will change once the various parts are anodized. If there aren't any insulators between the components of your tonearm, it doesn't matter where you attach the ground wire except that it might torque the tonearm if it is attached too far from the pivot.

I hope that I've helped.

Sincerely,

Ralf

Joachim I fear that you will have severe problems with the smoothness of the ride, where the magnets meet you will face stops in the motion while the magnets still float. not sure how to overcome this with repelling magnets. I have an idea to order some special shaped magnets 170 mm long, and the opposite 50 mm long, then the bearing can consist of (two) one piece guides and and the traveling sled of (two)others. Even then I fear that the big forces in the bearing will make travel impossible as even the slightest off angle will force the sled to one end. May be a thin mu-metal foil will make it possible to homogenise the neo-field and then with an adjustable chamber (parallel) it can be possible to make a magnet float linear tracker.

I am quite sure that what you have set out to do is not trivial.

Why not use infra red to detect what you need?

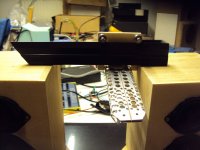

A plug-in �-inch mount headshell for absolutely NO money

An externally hosted image should be here but it was not working when we last tested it.

Joachim -

In your sketch do you have the arm interface on the 2nd layer of the top plinth? Are you trying for a small bit of isolation (as there will be some constrained layer damping between the two sheets of material) between the bearing well and the arm?

In general I like the layout.

Sorry, for getting back deep down in topic. I wonder what kind of layer separates the first and the second layers? I think that would be the same as saying a plinth and an armboard. I'm preparing my Panzer plinth and intending to mount the armboard under the top layer. I wonder if any kind of isolation between the two layers would benefit?

Attachments

I have not seen that before :

Welcome to TTWeights Audio

seems to be that we get more turntables then new genuine analog vinyl.

Welcome to TTWeights Audio

seems to be that we get more turntables then new genuine analog vinyl.

I have not seen that before :

Welcome to TTWeights Audio

seems to be that we get more turntables then new genuine analog vinyl.

Yah, shame huh?

Besides MFSL, who dose good new analog pressings?

Some of that stuff is decent too :

http://217.91.44.153/fmi/iwp/cgi?-db=SCR_Kunden&-loadframes

http://217.91.44.153/fmi/iwp/cgi?-db=SCR_Kunden&-loadframes

Hello Joachim

Thanks for posting that link. Seems to be an interesting website. Later tonight when the house is quiet I'll look at it thoroughly.

Sincerely,

Ralf

I have not seen that before :

Welcome to TTWeights Audio

Thanks for posting that link. Seems to be an interesting website. Later tonight when the house is quiet I'll look at it thoroughly.

Sincerely,

Ralf

Suggestions for Plinth/TT design

Hi all,

I have just gotten some materials, i.e. some Acrylic 600 x 70 x 25 mm

some plywood various sizes 15 mm thick.

I want to use a couple of 300 mm + 9" arms.

I quite like the idea of making pods but finding suitable outer pod vessels is proving difficult.

Any suggestions please

Hi all,

I have just gotten some materials, i.e. some Acrylic 600 x 70 x 25 mm

some plywood various sizes 15 mm thick.

I want to use a couple of 300 mm + 9" arms.

I quite like the idea of making pods but finding suitable outer pod vessels is proving difficult.

Any suggestions please

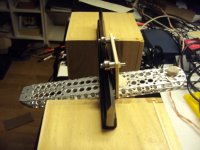

Today i came a big step closer to a functioning DIY tangential arm.

For the moment i gave up on the magnetic floating idea. It is just too difficult and maybe even impossible.

I discussed several possibilities that use ferro fluid with Michael Boresen and Frank Schröder and a captured bearing is an option. The problem is to find materials where the ferro fluid does not stick to or it ends with a dirty mess.

So back to the rollers. On another thread there are some successful builds that use tubes,

mostly from glass. There 4 rollers are needed. The Opus 3 Cantus is an exception. It uses only two rollers but needs a tube that is cut open in the back so the rollers run INSIDE the tube. I like the simplification of using only 2 rollers but i wanted to avoid the tube. Then the idea hit me to use a knife edge instead. First i wanted to use the blade of a cutter knife but Frank Schröder had a better idea. There is a measuring device to check for surface straightness and blemishes that is called " Haarlineal" in German. It is an extremely straight hard metal rod. With this rod and two rollers it can be done easy. I build a fast prototype that is already moving smooth. Dimensions and materials will change and there is more to say about the rollers but i hope that you already get the idea.

For the moment i gave up on the magnetic floating idea. It is just too difficult and maybe even impossible.

I discussed several possibilities that use ferro fluid with Michael Boresen and Frank Schröder and a captured bearing is an option. The problem is to find materials where the ferro fluid does not stick to or it ends with a dirty mess.

So back to the rollers. On another thread there are some successful builds that use tubes,

mostly from glass. There 4 rollers are needed. The Opus 3 Cantus is an exception. It uses only two rollers but needs a tube that is cut open in the back so the rollers run INSIDE the tube. I like the simplification of using only 2 rollers but i wanted to avoid the tube. Then the idea hit me to use a knife edge instead. First i wanted to use the blade of a cutter knife but Frank Schröder had a better idea. There is a measuring device to check for surface straightness and blemishes that is called " Haarlineal" in German. It is an extremely straight hard metal rod. With this rod and two rollers it can be done easy. I build a fast prototype that is already moving smooth. Dimensions and materials will change and there is more to say about the rollers but i hope that you already get the idea.

Attachments

Here is the Opus for comparison :

Atelier 13 - Nashville's New High End Audio Venue

Yes, ask the experts, most of them are open for advice.

Atelier 13 - Nashville's New High End Audio Venue

Yes, ask the experts, most of them are open for advice.

The problem is to find materials where the ferro fluid does not stick to or it ends with a dirty mess.

An externally hosted image should be here but it was not working when we last tested it.

LiquiGlide is a technology platform that allows us to engineer super slippery surfaces for liquids and highly viscous materials such as gels and pastes.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- The Good Turntable