Joe & Co.:

I'm new to building speakers but have been approached by a friend with access to a professional woodworking shop that will build enclosures for us at a very attractive price. We are focused on the Elsinore, in part because of the detailed information available and the knowledge of its fan base. One of the unknowns we are currently wrestling with is whether the waveguides for the Elsinore Mark VI version are commercially available or must be assembled (and if so, from what). Frankly, I have no idea what it takes to construct a waveguide or the skills and equipment needed to make them properly. What's the story?

Thanks,

Scott

You can email Joel, he had a local company to produce them on a CNC and maybe he still offer them for Elsinore builders

http://www.diyaudio.com/forums/multi-way/97043-elsinore-project-thread-81.html#post2531238

Mk6 Treble element wave guide molds almost ready

Finally i found the lathe i have been looking for during more than a year. After a busy weekend the molds are finally ready for finishing. The size is adapted to the Mk6 version of the speaker (same diameter as the mid/base = 172 mm). which mean that me myself and my friend will have to redo our recessment in our not yet ready Mk5 version speaker pairs......

Finally i found the lathe i have been looking for during more than a year. After a busy weekend the molds are finally ready for finishing. The size is adapted to the Mk6 version of the speaker (same diameter as the mid/base = 172 mm). which mean that me myself and my friend will have to redo our recessment in our not yet ready Mk5 version speaker pairs......

Attachments

SRMcGee, I got the waveguides for mine 3d printed. Just gave the design to some guy who drew it up on cad and fabricated them for me. Overall cost was $50. It will need some sanding afterwards as the edges will not be smooth to begin with.

Could you post a pic of the waveguides done on the 3D printer. I occasionally do freelance work for a company which has several 3D printers in use. I had planned to show them the dimensions next time I was working for them and ask the question but I haven't been back there recently. What 3D drawing software did you use and would it be possible to get a copy of the drawing file? I think the 3D printing process would be the most efficient way of accurately making the waveguides and the printers are dropping in price all the time.

Cheers.

Waveguide photo is attached. No idea what software he used, nor do I have the file. All I know is that he drea a 2d cross section and rotated it to make it 3d and circular

Thanks for the pics of the printed waveguides. How hard was it to get a smooth finish on them? Any chance of a pic of the finished result? I imagine quite a bit of sanding etc to get an acceptable result. I've worked with printed objects in a completely unrelated field but the finish straight out of the printer is quite rough but I've never needed to sand one to a smooth finish. I do however think this method is the way to go.

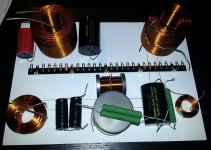

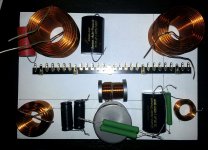

Attached (I hope) is a pic of my xover for MK V as it is at present. I've modified it quite a bit from it's original form. (It's a bit untidy now) I originally had all the inductors lying flat but realized I was breaking the law with regard to inductor crosstalk so I re orientated them to reduce this possible effect. Also I replaced the the 2 MFD Cap in series with the tweeter with two 1MFD Jantzen Superior Z caps which are much larger than the Solen SCR cap they replaced. (A vast improvement ). Since only values have changed from MK V to MK VI the layout is still relevent. When I get some time I will redo the PCB and tidy everything up but functionally they're fine as they are. The PCB fits snugly into a diecast box obtained from RS components.Also being bit of a novice it'll give me some help

Attachments

Last edited:

You can play with the coils placement, but it looks already good.

Maybe put the two corner bottom coils on their side.

Here's a nice article about coils placement.

Maybe put the two corner bottom coils on their side.

Here's a nice article about coils placement.

Last edited:

Insulation

Hi,

I have been trolling the polymax website, and it looks like their insulation batts are now 100% polyester not the wool blend as specified on Joe's website.

Can someone please confirm this, and let me know if polymax still has a wool blend product? Otherwise what alternative products and stuffing densitys has everyone used?

Thx,

Steve

Hi,

I have been trolling the polymax website, and it looks like their insulation batts are now 100% polyester not the wool blend as specified on Joe's website.

Can someone please confirm this, and let me know if polymax still has a wool blend product? Otherwise what alternative products and stuffing densitys has everyone used?

Thx,

Steve

Hi,

I have been trolling the polymax website, and it looks like their insulation batts are now 100% polyester not the wool blend as specified on Joe's website.

Can someone please confirm this, and let me know if polymax still has a wool blend product? Otherwise what alternative products and stuffing densitys has everyone used?

Thx,

Steve

you can use any other insulation equivalent, don't worry too much about it

e.g. bradford, pink batts etc.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread