Computer Modelled Results:

That will be the result with details supplied so far.

OPTIONAL - PLEASE READ AND DECIDE:

IF a Zobel Network made from 10R Resistor and 0.68uF, it will look like this.

Note the flatter HF Impedance (Z) and Electrical Phase.

Later I would like users to test this optional extra. Note that it is no affect on the Frequency Response with Voltage type amps and very neglible with non-Voltage amps.

Yet it sonic influence is something I'd like an opinion about. It shuld not be a hard test and we can share its influence.

OPTIONAL CROSSOVER PARTS LIST

2 x 10R 5W min

2 x 0.68uF Film Cap - Use Good Quality

Again re-iterating what I said above, that 2.2uF High Quality cap going to the Tweeter, while I have specified that value, I would also like to try 2uF and live with it for a little while before making final comment. So If I change that valuie, hope you don't hold that against me, but I will advice what I do.

I think I have now passed on all the Crossover details I have now.

Now have to wait for Steve to come back with final Waveguides for distribution. These will be measured up and possibly posted (Steve will have final say).

In the meantime, if any questions to be asked, fire away.

Cheers, Joe R.

That will be the result with details supplied so far.

OPTIONAL - PLEASE READ AND DECIDE:

IF a Zobel Network made from 10R Resistor and 0.68uF, it will look like this.

Note the flatter HF Impedance (Z) and Electrical Phase.

Later I would like users to test this optional extra. Note that it is no affect on the Frequency Response with Voltage type amps and very neglible with non-Voltage amps.

Yet it sonic influence is something I'd like an opinion about. It shuld not be a hard test and we can share its influence.

OPTIONAL CROSSOVER PARTS LIST

2 x 10R 5W min

2 x 0.68uF Film Cap - Use Good Quality

Again re-iterating what I said above, that 2.2uF High Quality cap going to the Tweeter, while I have specified that value, I would also like to try 2uF and live with it for a little while before making final comment. So If I change that valuie, hope you don't hold that against me, but I will advice what I do.

I think I have now passed on all the Crossover details I have now.

Now have to wait for Steve to come back with final Waveguides for distribution. These will be measured up and possibly posted (Steve will have final say).

In the meantime, if any questions to be asked, fire away.

Cheers, Joe R.

Last edited:

Hi Joe,

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

Hi Joe,

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

Hi Joe,

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

Is the waveguide will look something like the peerless india large faceplate?

Shallow Waveguide (Buyouts) - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathe.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Thank For all your work and your knowledge sharing.

Hi jbarb i,ll have a go at answering some of your questions.

I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

I am having the same problem at the moment. I made the boxes when it was 45oc and we hadn,t had rain for nearly two years as soon i finished applying the 2pak primer it has rained ever day the joins have swelled 0.2mm doesn,t sound like much but looks terrible.

doesn,t sound like much but looks terrible.

At least it wasn,t the finish coat.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

I don,t think it matters its just the lower the DCR the higher the cost for minamal gain.

You can go lower if you like but don,t exceed Joes Max values.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

White paint = Positive terminal.

You can check with a 1.5v battery and some wire. Cone moves forward slightly with correct phase. Just tap the terminals quickly.

Cheers Paul

I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box.

I am having the same problem at the moment. I made the boxes when it was 45oc and we hadn,t had rain for nearly two years as soon i finished applying the 2pak primer it has rained ever day the joins have swelled 0.2mm

doesn,t sound like much but looks terrible.

doesn,t sound like much but looks terrible.At least it wasn,t the finish coat.

Is it possible to choose a better value for L1 than 1 Ohm? And let L3 1 Ohm max?

As 1.8 mH 0.43R for L1 (M-L140-180 for ex.) and 1.8mH 0,7R for L3 (M-L100-180 for ex.)?

I have often heard it's better to have a DCR as low as possible for Bass speaker, but I don’t know exactly what that change. I don’t want to sabotage your good work with my mistakes.

I don,t think it matters its just the lower the DCR the higher the cost for minamal gain.

You can go lower if you like but don,t exceed Joes Max values.

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

White paint = Positive terminal.

You can check with a 1.5v battery and some wire. Cone moves forward slightly with correct phase. Just tap the terminals quickly.

Cheers Paul

POSSIBLE AMENDMENT TO CROSSOVER:

I am currently listening with 2.0uF instead of the earlier mentioned 2.2uF.

I have a feeling that this may well be where I will stay personally.

I have amended the crossover in Post #677 but NOT in the Parts List Post #678

I can't edit that post, but the graphic in #677 comes off my webserver and that is why I was able to change it.

As I stated earlier, this value can be tweaked up or down 10% - so if you want to try 1.8uF, 2.0uF and 2.2uF - that would be fine, just make sure you tell us your experience.

As mentioned earlier, mabe get some 2.0uF and also 0.22uF to add for trial. But the difference is fairly subtle and yet may be important to the individual.

But make it 2.0uF official.

Cheers, Joe R.

I am currently listening with 2.0uF instead of the earlier mentioned 2.2uF.

I have a feeling that this may well be where I will stay personally.

I have amended the crossover in Post #677 but NOT in the Parts List Post #678

I can't edit that post, but the graphic in #677 comes off my webserver and that is why I was able to change it.

As I stated earlier, this value can be tweaked up or down 10% - so if you want to try 1.8uF, 2.0uF and 2.2uF - that would be fine, just make sure you tell us your experience.

As mentioned earlier, mabe get some 2.0uF and also 0.22uF to add for trial. But the difference is fairly subtle and yet may be important to the individual.

But make it 2.0uF official.

Cheers, Joe R.

Hi Joe,

I hope you can send the waveguide in France .. I started building the Elsinore for several months now, but I have not yet been completed yet. I want to finish them with white lacquer (like piano). not an easy finish with MDF. The MDF has a tendency to swell with moisture, I fixed by painting the inside of the box...

Maybe I could ask a friend to do it for me with the dimensions and a CNC lathep...

Is it possible to choose a better value for L1 than 1 Ohm? ...

I have often heard it's better to have a DCR as low as possible for Bass speaker...

The Peerless tweeter, there is a touch of white paint on a stud, but I do not know if it's for negative or positive. Does someone can give me an answer?

Yes, getting that glossy finish in MDF is a LOT of work.

The Waveguide will fit into the exact space, the cavity, that the felt is currently fitted. They will be made of MDF and it will be up to you what finish they are. More instructions to come including photos.

If we end up publishing the Waveguide dimensions a CNC machine would be handy. But I need to consult Steve.

The DCR, DC Resistance, is the recommended maximum, so lesser value is good. But low DCR is also expensive, the values I have given means that it shouldn't be hard to get good chokes at your own budget.

Yes, that white dot is positive, others use red and not sure why they didn't likewise.

Cheers, Joe

Hi jbarb i,ll have a go at answering some of your questions.

Cheers Paul

Just noticed you had already done all the work and gave the same answers.

Yeah, I use the battery trick all the time too. Especially after wiring up the box to the terminals.

Cheers, Joe R.

Thank you Joe, and spoonted,

I'll get back to finishing actively the boxes and looking for the inductors and capacitors.

Waiting for pictures of your job Joe ;-)

Spoonted, maybe try to block humidity by painting the inside of the boxes if you don't want to be always bothered.

I'll get back to finishing actively the boxes and looking for the inductors and capacitors.

Waiting for pictures of your job Joe ;-)

Spoonted, maybe try to block humidity by painting the inside of the boxes if you don't want to be always bothered.

Joe, if this new waveguide tucks into the chamfer on the tweeter face plate, how tolerant is it going to be to tweeter misalignment in the recess? Even a millimeter out might cause problems, or is there a gap around the outside of the waveguide which can be caulked or filled etc?

Joe, if this new waveguide tucks into the chamfer on the tweeter face plate, how tolerant is it going to be to tweeter misalignment in the recess? Even a millimeter out might cause problems, or is there a gap around the outside of the waveguide which can be caulked or filled etc?

I tried to send you an email a little while ago and it bounced, changed email address or just a gremlin?

Yes, the Waveguide will have a couple of 'features' that will all be revealed. At the throat of the Waveguide Steve puts in a little lip to fill in some of the bevelled edge of the face plate of the tweeter. At the rear of the Waveguide there will be a round indent where it meets up with the face plate of the tweeter, this means that they won't actually touch and can deal with tweeters that are not perfectly flush mounted inside the box's cavity.

Also the Waveguide will be slightly smaller than the cavity height and width. About 1.5mm gap around the edge. This will give some latitude, but as you say, the tweeter needs to be close to dead centre inside the cavity.

What, even allowing for the Waveguide having a bit of room to move, that the throat of the Waveguide will not line up with the tweeter properly, or that the Waveguide looks skewed (visually not acceptable), then there is only one solution, that is to remount the tweeter.

But the good thing is this, any repair work will be hidden by the Waveguide. So the rebating (routing) to make the tweeter flush mounted, if there is a gap to due more routing, it will not be seen. Also the tweeter should possibly be rotated and new fresh mounting holes, as there may only be mm in it and the existing holes now make it more difficult.

Of course, all above mainly applies to those who have already mounted the tweeter, or upgrading, and not starting from fresh.

As soon as I get the first batch of Waveguides from Steve I will post pictures etc and that will help illustrate much of the above. Steve is making 10 pairs to start with.

Cheers, Joe

BUMP

Hey North Americans,

I know there are more of you Elsinore builders out there. Please post or send me PM if you are interested in a group buy of the upcoming Mk 5 wave guide.

So far there are 4 that registered interest - if we could gain a few more we will move to the GB forum

Thanks,

Francois

Count me in as well. I'm very interested in getting a set of the waveguides.

NA GB for waveguides

With BHD as a new group buyer we now have a total of 6. (Johngalt47, I got you previously)

Joe,

How do we get in touch with the guide maker. We probably need to know the cost and shipping before we could place a firm order. I originally anticipated injection molded plastic - wave guides made of plywood/chipboard may be expensive to ship to NA.

Thanks,

Francois

With BHD as a new group buyer we now have a total of 6. (Johngalt47, I got you previously)

Joe,

How do we get in touch with the guide maker. We probably need to know the cost and shipping before we could place a firm order. I originally anticipated injection molded plastic - wave guides made of plywood/chipboard may be expensive to ship to NA.

Thanks,

Francois

With BHD as a new group buyer we now have a total of 6. (Johngalt47, I got you previously)

Joe,

How do we get in touch with the guide maker....

Thanks,

Francois

Steve is known as greenpea, so he is contactable.

But they will be ordered from me as he would rather me field all extraneous inquiries etc.

As for group buy, that is defintely something we can arrange, and Steve will be in the loop as he knows what going on here on the thread.

Cheers, Joe R.

Hi Guys

Steve and I had a good discussion and we have made some decisions you guys might be interested in.

Yes, we will publish details if you wish to make your own, but as Steve can testify, they are not exactly easy to make and he makes them by hand without using a CNC machine.

Here is the problem:

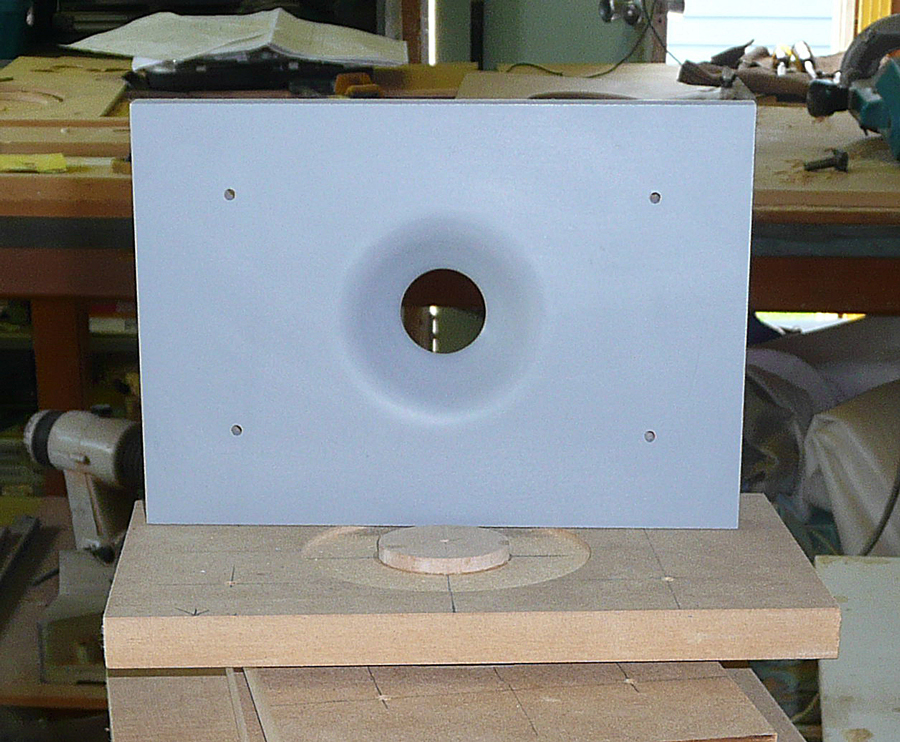

This creates a gap when the conical waveguide is fitted:

Steve says that is the single greatest and most time consuming aspect of make the Waveguide.

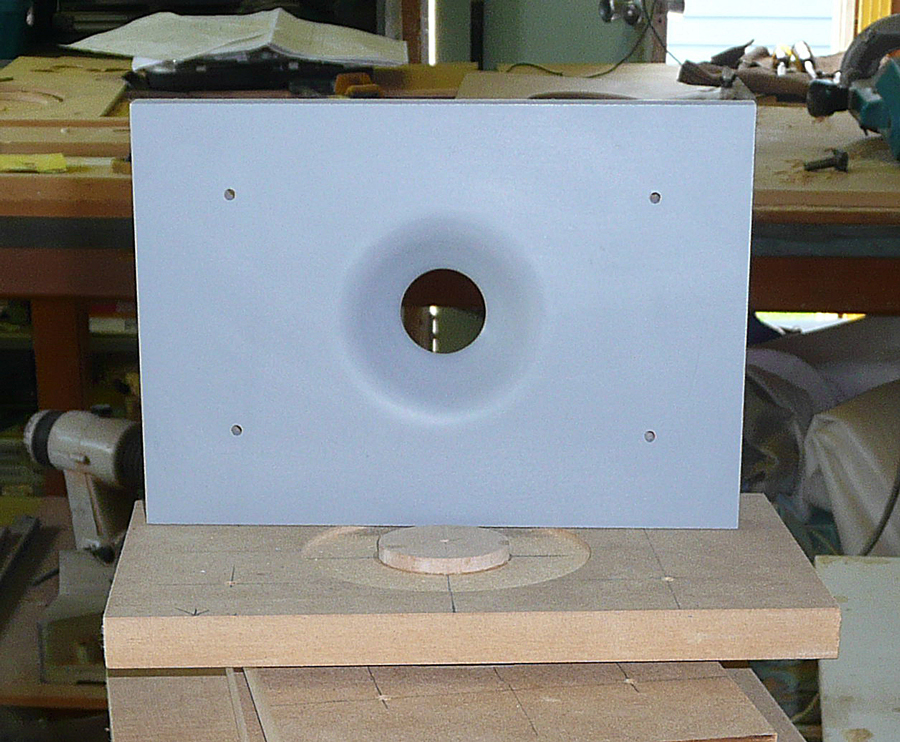

Here is a few photos he sent and I cropped and resized, sharpened a bit:

BATCH:

The Waveguide will come with an undercoat. This will protect the MDF from absorbing moisture until you get it. It is suggested you get a spray can Black Enamel - I can get for $5 up the road from here (alternative colour you like). I suggest Satin or Semi-Gloss as the most practicable - flat looks just too flat and glossy shows up the tiniest imperfections.

CLOSEUP - FRONT:

The cavity the Waveguide fits into is 230mm by 160mm, so the Waveguide is designed to fit into that cavity with about 1mm to 1.5mm gap. We are aiming at near 1.5mm, but with a coat or two will be slightly less.

Of course one can carefully trim the edges to give a bit more movement, but it is really more of a matter of getting the Tweeter to line up with the throat of the Waveguide. If you have to move the tweeter, the good thing is that any imperfection is covered up when the Waveguide is in place:

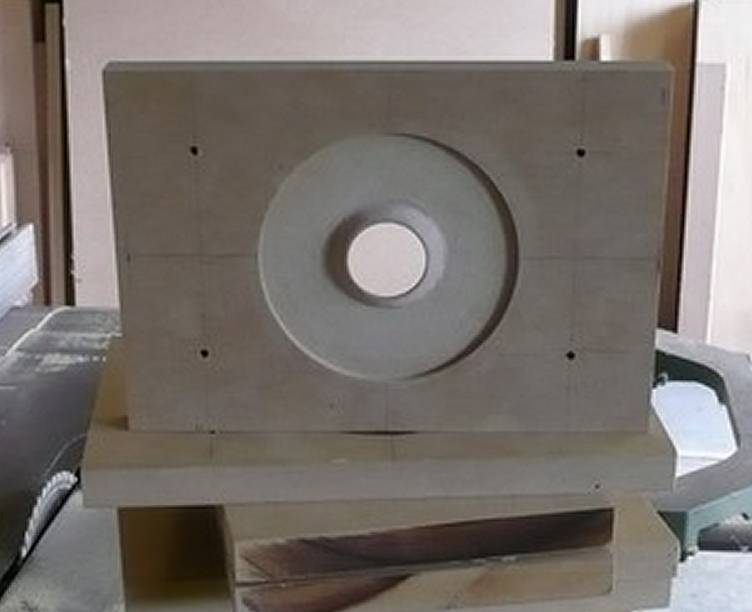

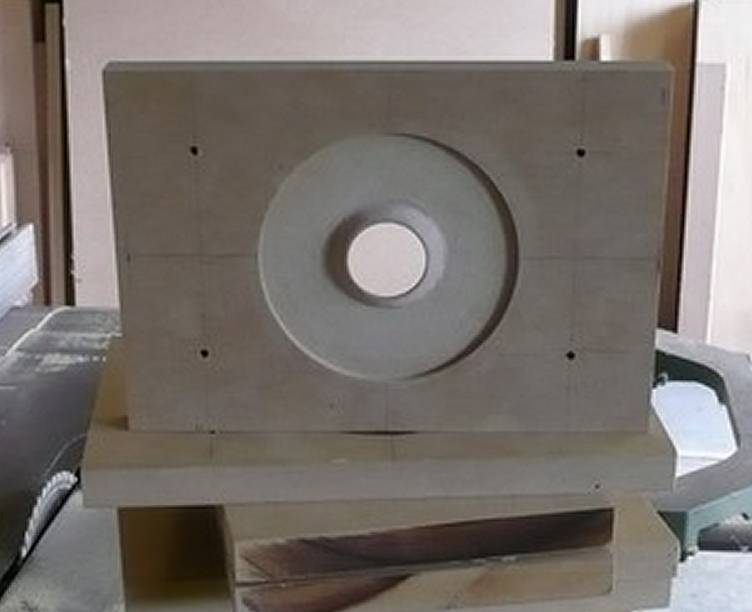

REAR:

CLOSEUP - REAR:

This rear part of the Waveguide is clearly the most tricky part.

When I get the first batch from Steve I will measure it up and prepare drawings with dimensions, so if you feel that you are up to making them yourselves, then there will not be an objection when we get to the price.

PRICE:

Well, again we discussed it at length. When Steve decided he was going to make them he did not realise that it was going to be just that bit more harder top make. I have also insisted that he must be recompensed and he could not be expected to do it for nothing.

Again, on that basis we decided to publish the Waveguides dimensions, you can always try to do it for yourself.

As we are in Australia and that Air Postage to other parts of the world is rather expensive and the weight is over 1Kg - look like $45 covers to anywhere on the globe including Europe and US.

We also discussed making the price per pair the same for everybody, but I think that a $10 premium will be added to overseas buyers, but that hardly pays for the extra. But everybody will still pay near the same price.

Australia Wide: AUD $130

Outside Australia & Air Postage: AUD $140

If you wish to pay via PayPal, the 3.5% fee will be absorbed.

Of course Group Buys will be negotiated with Steve - at this stage have not yet decided on any details. But if they are all sent to the same address, say in the US, then the saving on Air freight alone will help.

OK, over to you guys. Steve should finish the first batch during this week. It looks like he will need to do another fairly soon after that?

Cheers, Joe R.

Final Pic - Prototype:

Make sure to click on it - it looks squat on my monitor:

Steve and I had a good discussion and we have made some decisions you guys might be interested in.

Yes, we will publish details if you wish to make your own, but as Steve can testify, they are not exactly easy to make and he makes them by hand without using a CNC machine.

Here is the problem:

An externally hosted image should be here but it was not working when we last tested it.

This creates a gap when the conical waveguide is fitted:

Steve says that is the single greatest and most time consuming aspect of make the Waveguide.

Here is a few photos he sent and I cropped and resized, sharpened a bit:

BATCH:

The Waveguide will come with an undercoat. This will protect the MDF from absorbing moisture until you get it. It is suggested you get a spray can Black Enamel - I can get for $5 up the road from here (alternative colour you like). I suggest Satin or Semi-Gloss as the most practicable - flat looks just too flat and glossy shows up the tiniest imperfections.

CLOSEUP - FRONT:

The cavity the Waveguide fits into is 230mm by 160mm, so the Waveguide is designed to fit into that cavity with about 1mm to 1.5mm gap. We are aiming at near 1.5mm, but with a coat or two will be slightly less.

Of course one can carefully trim the edges to give a bit more movement, but it is really more of a matter of getting the Tweeter to line up with the throat of the Waveguide. If you have to move the tweeter, the good thing is that any imperfection is covered up when the Waveguide is in place:

REAR:

An externally hosted image should be here but it was not working when we last tested it.

CLOSEUP - REAR:

This rear part of the Waveguide is clearly the most tricky part.

When I get the first batch from Steve I will measure it up and prepare drawings with dimensions, so if you feel that you are up to making them yourselves, then there will not be an objection when we get to the price.

PRICE:

Well, again we discussed it at length. When Steve decided he was going to make them he did not realise that it was going to be just that bit more harder top make. I have also insisted that he must be recompensed and he could not be expected to do it for nothing.

Again, on that basis we decided to publish the Waveguides dimensions, you can always try to do it for yourself.

As we are in Australia and that Air Postage to other parts of the world is rather expensive and the weight is over 1Kg - look like $45 covers to anywhere on the globe including Europe and US.

We also discussed making the price per pair the same for everybody, but I think that a $10 premium will be added to overseas buyers, but that hardly pays for the extra. But everybody will still pay near the same price.

Australia Wide: AUD $130

Outside Australia & Air Postage: AUD $140

If you wish to pay via PayPal, the 3.5% fee will be absorbed.

Of course Group Buys will be negotiated with Steve - at this stage have not yet decided on any details. But if they are all sent to the same address, say in the US, then the saving on Air freight alone will help.

OK, over to you guys. Steve should finish the first batch during this week. It looks like he will need to do another fairly soon after that?

Cheers, Joe R.

Final Pic - Prototype:

Make sure to click on it - it looks squat on my monitor:

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread