Moisture content and stability is dependent on the wood species and age.

Kiln at 12% is probably a sweet-spot for most Mahogany. Air dry is utterly inconsistent unless it's done in very large humidity controlled environment, and it almost never is.

Also be careful with the type of sealer, some are every bit as unstable (for various reasons) as the wood it's supposed to coat.

Kiln at 12% is probably a sweet-spot for most Mahogany. Air dry is utterly inconsistent unless it's done in very large humidity controlled environment, and it almost never is.

Also be careful with the type of sealer, some are every bit as unstable (for various reasons) as the wood it's supposed to coat.

Last edited:

Just searcing bateman´s thread history, must be his stuff

https://www.diyaudio.com/forums/multi-way/323869-achilles-heel-line-arrays.html#post5461878

getting close

https://www.diyaudio.com/forums/multi-way/323869-achilles-heel-line-arrays.html#post5461878

getting close

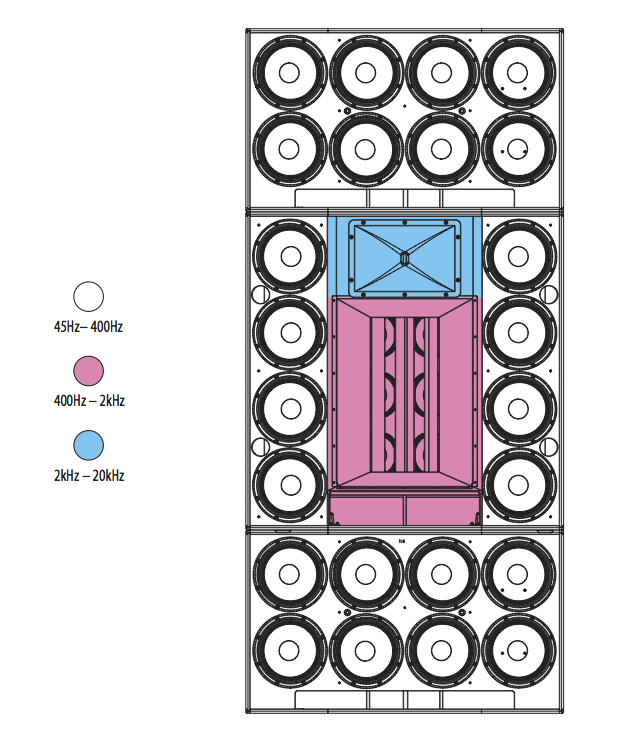

i remember seen thread about matrix speakers, multiple drivers on front. Anyone remembers that thread?

Magico?

Magico?

What would be more relevant would be if they showed how they couple the frame to the panels. I suspect though that this was an earlier design, and that they did NOT do what they should have: which is the equivalent of adding washers. (..look at the "blue stuff" in some of their other newer interior pictures (A3 in particular) which I suspect is a soft silicone.)

I know the baffle width has been discussed but I need a little input. I bought bamboo boards for the baffles and they were listed at 11.5". Seeing other posts about slightly larger baffles being not ideal but 'ok' I went ahead with these. Turns out the boards are actually 11.875" wide.

The reason I purchased these is that I rarely have luck ripping boards true and square and these are perfectly true and square. I'd like to use them as is but wondering if my .875" extra width is going to create an issue. Internal volume will be the same. Same height but slightly shallower and wider.

If its going to cause SQ issues or pull me to far away from the original design I will try to get them cut down. Grrrr....

The reason I purchased these is that I rarely have luck ripping boards true and square and these are perfectly true and square. I'd like to use them as is but wondering if my .875" extra width is going to create an issue. Internal volume will be the same. Same height but slightly shallower and wider.

If its going to cause SQ issues or pull me to far away from the original design I will try to get them cut down. Grrrr....

10mm's either side shouldn't do anything significant for this design, particularly if you do some round-over/chamfer of the edges.

That's good news. I was planning on either a 1/2" roundover or chamfer.

due to high cost on cnc service almost $600 and i'm lucky enough to get an old mahogany log > 1m diameter. with same money, i'm ordering 0.5m3 with 200x35x5cm cut for elsinore, another 3 piece of 200x50x5cm for my audio rack and 1 piece of 200x80x5cm for my dining table.

i just consider my man hour work as $0 for this hobby

looking at the picture sent by wood supplier already teased me

i just consider my man hour work as $0 for this hobby

looking at the picture sent by wood supplier already teased me

Attachments

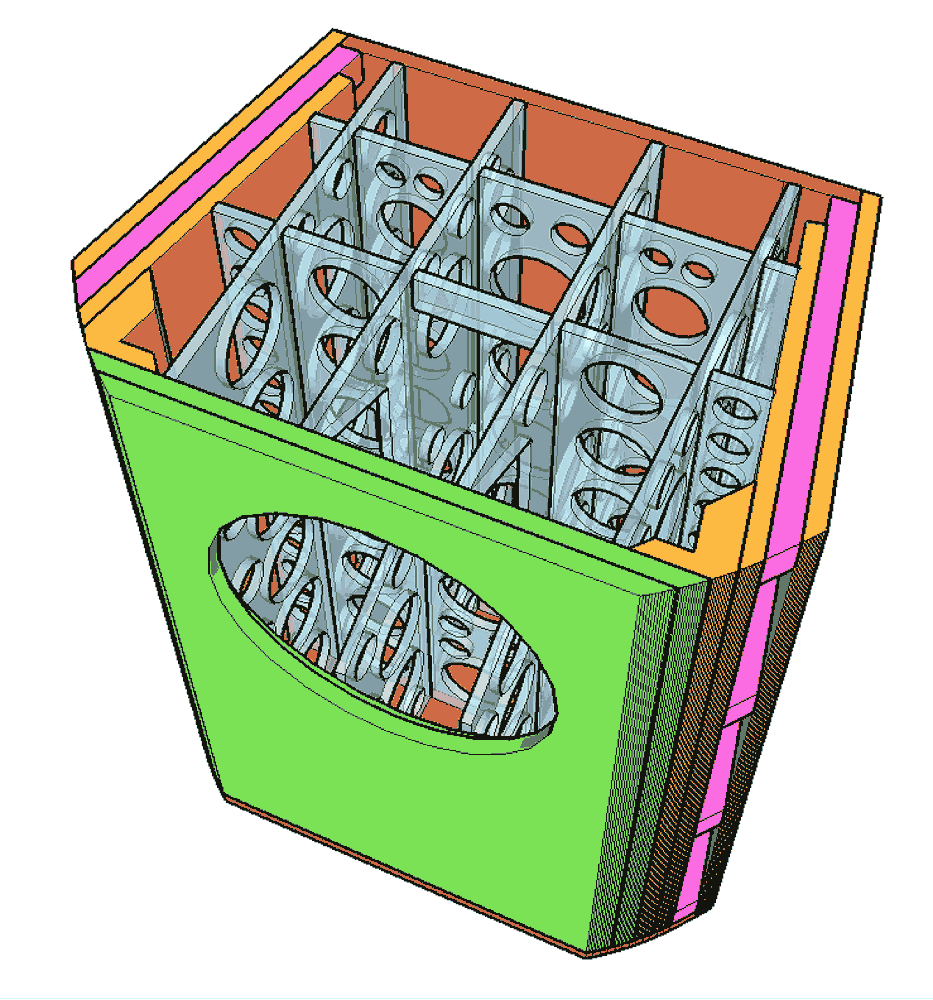

We tend to use a BIG 45° bevel on the inside of the circular cutout if we do a double thick baffle. We rarely do that, instead making the back, the baffle and a full height driver brace from front to back to create a “box section” for greater baffle ridgidity and to share active driver energy to a greater number of panels.

Reminds me, i have been asked, but already intend to do my take on squeezing even more performance out of the Elsinore.

dave

Reminds me, i have been asked, but already intend to do my take on squeezing even more performance out of the Elsinore.

dave

We tend to use a BIG 45° bevel on the inside of the circular cutout if we do a double thick baffle. We rarely do that, instead making the back, the baffle and a full height driver brace from front to back to create a “box section” for greater baffle ridgidity and to share active driver energy to a greater number of panels.

dave

May be I had a longer day than I thought...

Not certain... no strike that, Im pretty positive I don't understand that response...

The sub front panel from Joe's layout has square cutouts.

I believe round cutouts offer more strength.

In area only, the circle cut out is only 1 square inch less than the slightly modified square one. I say modified as I converted the mm to inch (160mm=6.29" and adjusted to 6.25") regardless, Im pretty sure the Romans discovered long ago that force exerts itself around and can carry much more weight than a square... That said, we aren't building aqueducts or bridges but a structure is a structure.

Anyway, that's my argument, and Im hoping to hear opinions on it.

Im sorry If you gave me one, and Im not getting it...

That's great if the force on the bridge is downward. Try ramming it from the side.

if the bridge is already on its side, I will take the pass.

I believe the forces Im thinking about are best tamed by this design.

The largest panel on the elsinore are the sides.

the movement or unwanted vibration of that side panel is limited to 2 directions and the brace as joe designed it I believe is the best way, or at least a fantastic way to keep the loudest movement to a minimum.

I believe if I have read correctly, many are focusing on stiffening the front panel to improve the good stuff. I think a loud side panel is bad stuff.

You fine folks certainly know this speaker much, much much better than me.

That said, I want a box that imparts nothing or is a dead box. I believe some enclosures may prefer certain types of music, and play some better than any other, but that very same speaker sound not nearly as good with other types of music. My taste covers the entire spectrum as far as I can see. Im building these because i believe they may be the very last ones I will ever need.

We tend to use a BIG 45° bevel on the inside of the circular cutout if we do a double thick baffle. We rarely do that, instead making the back, the baffle and a full height driver brace from front to back to create a “box section” for greater baffle ridgidity and to share active driver energy to a greater number of panels.

Reminds me, i have been asked, but already intend to do my take on squeezing even more performance out of the Elsinore.

dave

Waiting patiently.....

Just making sure you saw this pathetic plea.

AFM, I also like a speaker that can sound as good with folk music as it does with metal.

Why do you think of the bridge laying down, are you talking about a horizontal piece with an arch cut into it supporting one line behind the baffle?

Dave was talking about connecting the front and back panels. Some prefer to connect all four.

Why do you think of the bridge laying down, are you talking about a horizontal piece with an arch cut into it supporting one line behind the baffle?

Dave was talking about connecting the front and back panels. Some prefer to connect all four.

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread