For this headache, maybe the solution is to simply let it run for a minute or so as a normal track.

-Chris

I wonder if having one cycle say 3dB higher every 1.8sec would be invisible to an analog instrument, we could easily use it as a rotational sync signal in software.

Hi Scott,

I can't say how various instruments would deal with that, but one 3 dB step would likely be tolerated okay. Most lock a PLL to the signal, so the increase should be invisible. The only concern would be an input amplifier overloading depending on how high you take it. You might be further ahead toggling the level by 3 dB.

-Chris

I can't say how various instruments would deal with that, but one 3 dB step would likely be tolerated okay. Most lock a PLL to the signal, so the increase should be invisible. The only concern would be an input amplifier overloading depending on how high you take it. You might be further ahead toggling the level by 3 dB.

-Chris

Sorry not posted on here for a while, mainly because I need a clear run to re-read everything and think about what I might want to do with the record and if the current track list allows it. There are a couple of things it would be useful to measure that I am still wrestling with.

Compliance. Re-reading Walton's book from the 60s he makes some interesting comments about compliance. I'm going to spin off a seperate thread to try and capture all of the discussions we've had on this and maybe start some new ones, but the key is that we need to end up with 3 numbers for compliance Lateral, vertical and +/-45. from any two the third can clearly be calculated. The question I have is whether the subsonic sweeps we have measures everything or if there is something else we can/could measure. I suspect that Software to measure the resonance is where the value is.

Second is phase shift. We have all the calibrated sweeps and spot frequencies so can measure FR and distortion products accurately and repeatably. But will these all the computer to calculate phase shifts, particularly above 15kHz. It's one of those academic interest questions in search for the cantilever resonance. In theory the phase shift will differ between a resonant mode and an electrical filter slope so if we can infer phase in HF roll off then we can get an idea of the cause. With the sweeps we have will there be enough captured to be able to do this (for those versed in the art sorry for the dumb question, but Signal processing stuff always takes me a while to get my head around). I suppose the question is, do we need a slower 10kHz to 30kHz sweep to get enough samples to be able to do level/phase plots or are we good to go? I get scared when I see a 20Hz-30kHz sweep in 15 seconds, but I know a computer works fast so might not care and 60-90 sweeps may only be useful so fleshies can keep up!

Thirdly we have FR vs radius. The measurements that Hifichoice in UK do on cartridges suggests that FR is different inner grooves to outer. I have no reason to suspect this is not the case with some stylus profiles, but the presented data could be explained by other reasons so would be nice to be able to test. It would be good to have one of the sweeps from the outer tracks repeated in the middle and on the inside. I do need to mull a bit more about ideal locations and if we need to take into account the normal alignments for those of us without linear trackers. I'll get back on that part.

And finally (for now) bedding in track. locked groove with some modulation to linish up the diamond and get the suspension bedded in. There is no evidence that bedding in helps (other than some ortofon DJ cartridges), and I do already have a locked pink noise groove on my cardas sweep record so happy to be shouted down on this.

And one question, that I can't find the answer to (as in probably missed the post). We only have 100Hz square wave, not 1kHz. Was there a good reason for this?

Bill

Compliance. Re-reading Walton's book from the 60s he makes some interesting comments about compliance. I'm going to spin off a seperate thread to try and capture all of the discussions we've had on this and maybe start some new ones, but the key is that we need to end up with 3 numbers for compliance Lateral, vertical and +/-45. from any two the third can clearly be calculated. The question I have is whether the subsonic sweeps we have measures everything or if there is something else we can/could measure. I suspect that Software to measure the resonance is where the value is.

Second is phase shift. We have all the calibrated sweeps and spot frequencies so can measure FR and distortion products accurately and repeatably. But will these all the computer to calculate phase shifts, particularly above 15kHz. It's one of those academic interest questions in search for the cantilever resonance. In theory the phase shift will differ between a resonant mode and an electrical filter slope so if we can infer phase in HF roll off then we can get an idea of the cause. With the sweeps we have will there be enough captured to be able to do this (for those versed in the art sorry for the dumb question, but Signal processing stuff always takes me a while to get my head around). I suppose the question is, do we need a slower 10kHz to 30kHz sweep to get enough samples to be able to do level/phase plots or are we good to go? I get scared when I see a 20Hz-30kHz sweep in 15 seconds, but I know a computer works fast so might not care and 60-90 sweeps may only be useful so fleshies can keep up!

Thirdly we have FR vs radius. The measurements that Hifichoice in UK do on cartridges suggests that FR is different inner grooves to outer. I have no reason to suspect this is not the case with some stylus profiles, but the presented data could be explained by other reasons so would be nice to be able to test. It would be good to have one of the sweeps from the outer tracks repeated in the middle and on the inside. I do need to mull a bit more about ideal locations and if we need to take into account the normal alignments for those of us without linear trackers. I'll get back on that part.

And finally (for now) bedding in track. locked groove with some modulation to linish up the diamond and get the suspension bedded in. There is no evidence that bedding in helps (other than some ortofon DJ cartridges), and I do already have a locked pink noise groove on my cardas sweep record so happy to be shouted down on this.

And one question, that I can't find the answer to (as in probably missed the post). We only have 100Hz square wave, not 1kHz. Was there a good reason for this?

Bill

And one other thing. The vertical/lateral tracking tests are the tracks most likely to get damaged by mistracking. If we have space should we repeat these so there is a backup in case . This is more worry than anything else. A mistracking stylus can cause damage, but in the 21st century is this an issue compared to the cartridges of the early 60s?

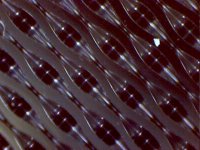

To revisit an old photo. I never noticed the slight errors in this photo of one of the tracking torture tests in the CBS STR series. The frequencies work out to exactly interleave in the ideal so the large modulation does not impinge on adjacent tracks. If you look carefully the alignment varies revolution to revolution. We should be able to estimate the lathe variations from this information.

Attachments

The main stumbling blocks to getting what we want cut are the cutter head and the cutting engineer. A few have looked at the track list and declined to be involved, and other have said things like "that'll never cut." We don't yet have precise info on what can be cut, or what a certain engineer is willing to try.

We have to remember that this LP has to be cut, and that cutting has its faults and limitations.

We have to remember that this LP has to be cut, and that cutting has its faults and limitations.

I used to keep a file at work ITYS.....I Told You So. It was fairly full and handy for ready access...... other have said things like "that'll never cut."

If you look back at my posts and comments on track lists, you'll see both comments as to why those tracks won't cut (or play!) and suggested corrections to fix.

I don't see how (or why) one would take on a venture of this nature without first understanding the physical meaning of programme material as applied to groove-shape, and the physical limits of cutting and playback.............

There should be nothing in the test record that doesn't crop up in normal programme material, so if you get it right it should just cut. When it's right you won't be asking for anything special...............We have to remember that this LP has to be cut, and that cutting has its faults and limitations.

Just tell them it's post-punk Stockhausen, not a test record

You need to provide a post production master and the mastering engineer needs to trust you enough not to compress, limit, eq or otherwise fiddle. A set reference level is then all you need.

LD

Last edited:

No need for "I told you so." That does not advance the project, which is a group efffort. Most of the signals were put on the list by requests seen in this thread - the idea being that we discuss with the cutting engineers what they think is possible, and what changes need to be made so that they can cut it. Some requests were rejected out of hand, because we already knew they could not be cut; E.G, sweeps to 50K.

Since we don't exactly know what the limitations of the cutter heads are, we need to have a dialog with the mastering house to find out. Unfortunately they do not provide a list of precise cutting specifications that we can stay within. We are slowly teasing out that list by having engineers look at our track list. It's not the most efficient way of getting there, but it's all we have at the moment.

Since we don't exactly know what the limitations of the cutter heads are, we need to have a dialog with the mastering house to find out. Unfortunately they do not provide a list of precise cutting specifications that we can stay within. We are slowly teasing out that list by having engineers look at our track list. It's not the most efficient way of getting there, but it's all we have at the moment.

Then, respectfully, you don't understand what the limiting factor is. In fact that isn't frequency. And 50K is cuttable at the right (low) level so long as curvature remains within limits. All one needs to do is select the right level for the test tone. Curvature equates to acceleration, and there's both a playback and cutting limit at about 2000G or so which is easy to avoid. At no point did I propose anything which wasn't cuttable and playable, quite the opposite. About 1000G is what I worked to, and no problems getting 50KHz at a low level to meet that.Some requests were rejected out of hand, because we already knew they could not be cut; E.G, sweeps to 50K.

If the mastering equipment has a primitive audioband bandwidth eq hard roll-off at say 20K, that would need to be disabled, of course.

How do we think the quad carrier ever worked...................?

But we know, from experience, absolute playback limits in terms of displacement, groove angle and curvature. And we know playback is the limiting factor because those limits are hit in normal programme material. Then we don't need to know cutter limits, we just need to stick within the envelope of normal playback limits......................Since we don't exactly know what the limitations of the cutter heads are, we need to have a dialog with the mastering house to find out.

It's pointless cutting anything that isn't playable, right ?

One needs to think of it physically, as maximum displacement, groove angle, and curvature. And devise tests which stay within playable limits. It's not difficult, really..........

I have presented corrections, and put forward definitions for tracks which stay within playable (and therefore cuttable) limits. Sometimes near the limit of course. Biff, out they went.......It's not the most efficient way of getting there, but it's all we have at the moment.

Perhaps my posts weren't ever understood, but I think that's an issue with some members not grasping the primitives of vinyl mechanics rather than their content. It's necessary to understand the physics of playback to devise sensible tests. All my opinion, of course.

LD

Last edited:

Perhaps my posts weren't ever understood, but I think that's an issue with some members not grasping the primitives of vinyl mechanics rather than their content. It's necessary to understand the physics of playback to devise sensible tests. All my opinion, of course.

LD

It's sad for me that this keeps coming up but I did say from day one we will be herding cats. There is a reality that the membership at large here varies a lot and many would just like a chance to have all the basic setup and TT speed tracks in one place for <$15.

You can probably count folks that want to revisit fundamental research on vinyl reproduction on one hand. Personally I have always loved measuring things that have not been measured before and am willing to help out solely for the intellectual exercise.

OK, then YOU find a mastering house that will agree to do it.Then, respectfully, you don't understand what the limiting factor is. In fact that isn't frequency. And 50K is cuttable at the right (low) level so long as curvature remains within limits.

As Scott says, it's cat herding. Track list by committee. Some folks just want a good, solid test LP that is affordable, other people want new groundbreaking signals to dig deep into the unlit corners of vinyl. This LP can end up being a mix of both.

I'll agree with you on that. Just make sure the tracks are expected to be reasonably tracked with the average cartridge. It seems pointless to cut a track that only a select few cartridges will track without damaging the LP. If you do that, make certain those tracks are called out with a warning.

I don't think useful data can be generated from a mistracking cartridge other than "it can't track this level".

After this project, you know what we really could use? A defects CD for alignment of CD players.

-Chris

I don't think useful data can be generated from a mistracking cartridge other than "it can't track this level".

After this project, you know what we really could use? A defects CD for alignment of CD players.

-Chris

other people want new groundbreaking signals to dig deep into the unlit corners of vinyl.

On that point if there actually was any money in uncovering some new facet of vinyl reproduction the $500 to do it all for yourself would be a very small startup cost.

Don't know if this has been mentioned yet, I might have missed it?

All In One Cartridge Setup Software & Test LPs

A Scientific & Repeatable Method To Calibrate:

Speed, Wow & Flutter, Azimuth, VTA, VTF, Anti-skating, Loading, Gain, Vibrations & Resonance Frequencies.

AU$989!!

All In One Cartridge Setup Software & Test LPs

A Scientific & Repeatable Method To Calibrate:

Speed, Wow & Flutter, Azimuth, VTA, VTF, Anti-skating, Loading, Gain, Vibrations & Resonance Frequencies.

AU$989!!

On that point if there actually was any money in uncovering some new facet of vinyl reproduction the $500 to do it all for yourself would be a very small startup cost.

It wouldn't get you a ferrari! But actually for me the challenge of getting a group of people together to do it is actually more fun.

Dr Fiekert has made a steady income stream from his record even with it's issues. I suspect not a good income though.

If I were capable of doing it myself I'd probably find a hifi mag that would publish some articles on the science and test methodology as that would cover the cutting costs. But without all the analysis software it would be no use and that is a big undertaking which I can't do. So on balance, although we are herding cats it will eventually come out with the best thing. IMO.

Oh dear, seems the healthy lack of trust in this venture isn't buried too far below the surface then......On that point if there actually was any money in uncovering some new facet of vinyl reproduction the $500 to do it all for yourself would be a very small startup cost.

Making money from vinyl technology isn't, and never has been, my motivation. Philanthropy, interest and seeing how far one can take playback performance from such an insanely simple idea as the phonograph is all that ever motivated me.

Including the tracks I suggested is absolutely not for personal financial gain. I'd have thought you'd get the pursuit of technical interest bit, and it would be right up your street, Scott. Whereas producing a basic setup record for the people, whilst laudable, wasn't........?

Actually, there's space for both ends of the technical spectrum on the same record, and if there was half a quantum of trust we might move forward..........

LD

Some requests were rejected out of hand, because we already knew they could not be cut; E.G, sweeps to 50K.

Then, respectfully, you don't understand what the limiting factor is. In fact that isn't frequency. And 50K is cuttable at the right (low) level so long as curvature remains within limits.

Folks let's try and keep the misunderstanding to a minimum. These cuts exist on the CBS Labs disks (500-50k constant velocity, no RIAA). Lucky, we are simply not having any luck in getting one of the bargain services to agree to do this. Maybe giving them a copy to examine would help. I don't think doing this is a switch of a couple of levers, I'm still assuming this requires taking a system off line and going in and making modifications and undoing them after. AFAIK no one has nixed anything "out of hand" without getting input from prospective vendors.

I figure the same issue clouds the hole centering (intervention in the standard flow means $$). BTW is there an additional issue around centering both sides at once?

Oh dear, seems the healthy lack of trust in this venture isn't buried too far below the surface then......

I was referring to the IP discussions that I hope have been dropped. I don't see how trust enters into it except between us and prospective vendors, "Take off all your safeties and we promise our signals will not break anything."

If we had a vendor that said I like your project just ask me what you want me to do and I'll make sure it all works we would not be having any of these discussions.

- Home

- Source & Line

- Analogue Source

- Test LP group buy