Patrick,

You mention, over in "that other thread", that you couldn't export a Hornresp design to Akabak because of a decreasing area section. You probably have a version of Hornresp earlier than 23.20. I identified the problem and suggested a fix a few months ago, and David implemented the fix shortly afterwards.

(I tried to post in "that" thread, but my diymobileaudio user account is borked - I lost the confirmation email when I opened the account and I'm permanently in "voyer" (sic) mode. I've asked for it to be fixed, but no response.)

Peter,

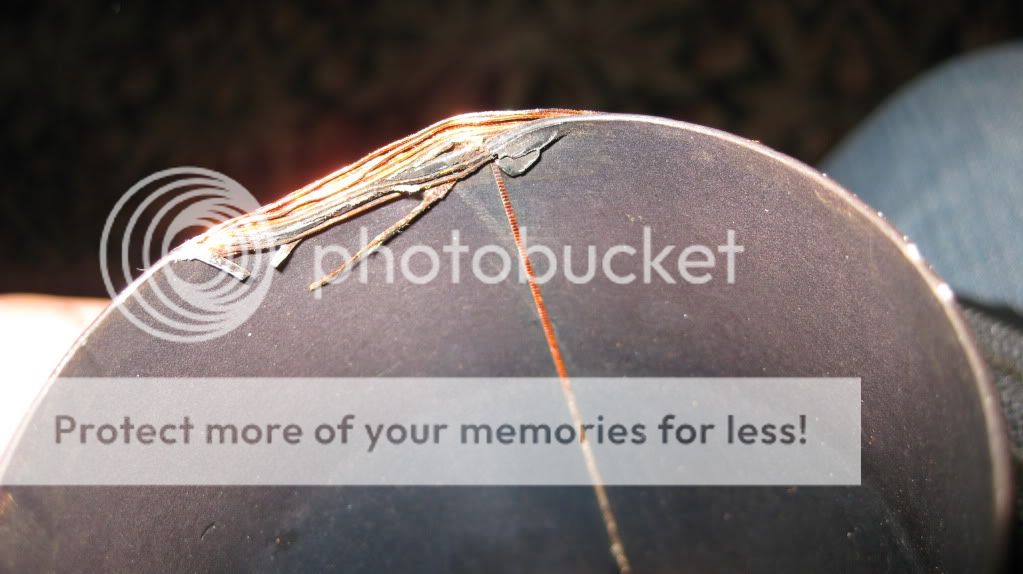

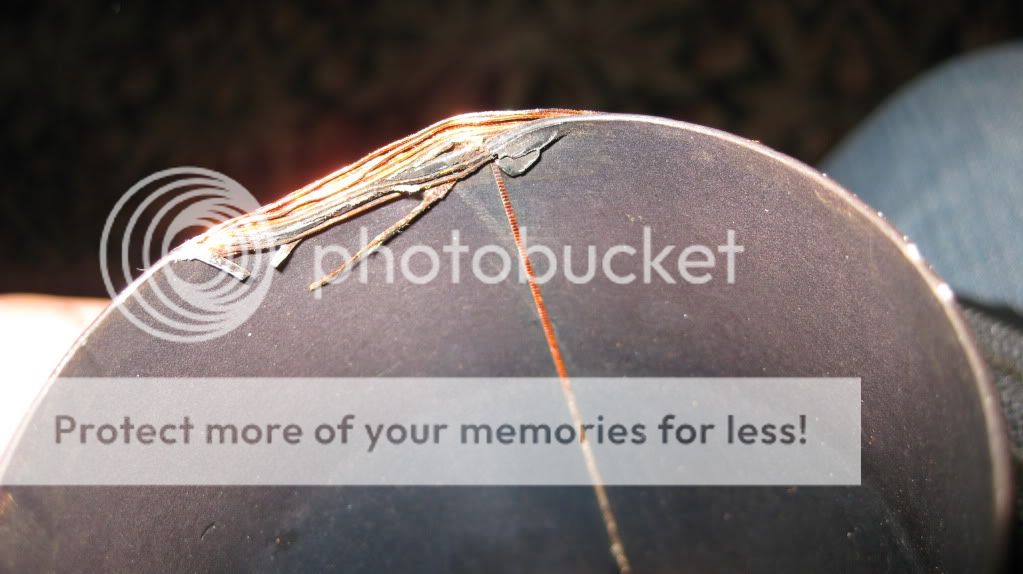

I was just looking at the photos you posted (on the other forum). There's a set of impact marks on the edge of the pole piece, and I doubt that they were caused by the voice coil. Note that I'm not suggesting that you put them there. They could equally have been there since manufacture. They just look funny, is all.

As for the event itself, well, **it happens. Lambros clearly understands that. It's not like you set out to deliberately blow it up - or went out to club baby seals to death with it.

You mention, over in "that other thread", that you couldn't export a Hornresp design to Akabak because of a decreasing area section. You probably have a version of Hornresp earlier than 23.20. I identified the problem and suggested a fix a few months ago, and David implemented the fix shortly afterwards.

(I tried to post in "that" thread, but my diymobileaudio user account is borked - I lost the confirmation email when I opened the account and I'm permanently in "voyer" (sic) mode. I've asked for it to be fixed, but no response.)

Peter,

I was just looking at the photos you posted (on the other forum). There's a set of impact marks on the edge of the pole piece, and I doubt that they were caused by the voice coil. Note that I'm not suggesting that you put them there. They could equally have been there since manufacture. They just look funny, is all.

As for the event itself, well, **it happens. Lambros clearly understands that. It's not like you set out to deliberately blow it up - or went out to club baby seals to death with it.

Hello Don 🙂

my name is Brian / I noticed the marks on the pole piece as well and it looks as if the piece had been dropped / no way for me to have made that on the pole piece / it was that way when i opened it up to investigate / i would not have been able to strike it without scaring the top plate as well !!! it came that wat built ! im sure of it / but weather it is the murder weapon or not is susspect...????

my name is Brian / I noticed the marks on the pole piece as well and it looks as if the piece had been dropped / no way for me to have made that on the pole piece / it was that way when i opened it up to investigate / i would not have been able to strike it without scaring the top plate as well !!! it came that wat built ! im sure of it / but weather it is the murder weapon or not is susspect...????

An externally hosted image should be here but it was not working when we last tested it.

Brian,

Sorry about the name mixup, it's something I do a lot... I even forgot my wife's name once. I went to introduce her to a friend, and my mind went blank... that was 15 years ago. I've never been allowed to forget the event, or her name, since.

The mark looks a little like it's been smoothed down with emery paper, which implies it happened during manufacture. I tried to figure out what caused the coil damage, but there are too many variables. One explanation consistent with the visible damage is that there was an obstruction at the bottom of the gap such as a piece of swarf or a piece chipped off one of the magnets, unlikely as it may seem.

Anyway, Lambro is the best person to perform the post mortem. What we can do is learn from it. With Patrick's excellent explanation of why we need subsonic filters, and the dramatic evidence of what happens if we don't use one, I'm convinced.

It's like trying to convince people to bolt their boxes securely into their vehicles. You can point out the dangers until you're blue in the face, but they aren't going to bother until they see someone who's been crushed by a loose sub box.

How to secure a sub enclosure - rec.audio.car | Google Groups

Sorry about the name mixup, it's something I do a lot... I even forgot my wife's name once. I went to introduce her to a friend, and my mind went blank... that was 15 years ago. I've never been allowed to forget the event, or her name, since.

The mark looks a little like it's been smoothed down with emery paper, which implies it happened during manufacture. I tried to figure out what caused the coil damage, but there are too many variables. One explanation consistent with the visible damage is that there was an obstruction at the bottom of the gap such as a piece of swarf or a piece chipped off one of the magnets, unlikely as it may seem.

Anyway, Lambro is the best person to perform the post mortem. What we can do is learn from it. With Patrick's excellent explanation of why we need subsonic filters, and the dramatic evidence of what happens if we don't use one, I'm convinced.

It's like trying to convince people to bolt their boxes securely into their vehicles. You can point out the dangers until you're blue in the face, but they aren't going to bother until they see someone who's been crushed by a loose sub box.

How to secure a sub enclosure - rec.audio.car | Google Groups

Hi davygrvy,

Hornresp calculates normal SPL response using a constant input voltage Eg. Maximum SPL response is calculated using a constant input power Pmax (except when the Xmax limit is reached at any frequency).

David, Why are you using constant power? I can't seem to wrap my head around the info the graph is presenting. If you had used constant voltage calculated from the rated impedance for a given power, I could understand the data presented in a more useful manner as all power amps are constant voltage devices unless you're using some silly feedback-less tube amp that has a damping factor much less than 1. Only then does power come closer to constant.

Maybe it shows the limits of possible EQ correction, yet a maximum output voltage the power amp has to provide is not part of the data given and would still require an outside calculation given the impedance data set.

As I said in my previous message, it is important to understand the difference between input power and input voltage 🙂

I do, thank you. And I'm glad you gave me a confirm HR isn't presenting what I want to see.

It's like trying to convince people to bolt their boxes securely into their vehicles. You can point out the dangers until you're blue in the face, but they aren't going to bother until they see someone who's been crushed by a loose sub box.

[start-threadjack]

LOL - I didn't need much convincing. In my previous car, the box was secured by four bolts to the front, and screwed down in the back. It met its end in a head-on collision with a tree - Brian Steele's Photos - P5182 | Facebook. The box didn't budge. Lost the subs though - basket and magnet structure look fine, but the subs start to whine after they see power for awhile.

In my current car, the sub is in the spare tire well, and bolted down using the same bolt that used to keep the tire in place. To be honest I'm more concerned about a rear-end collision shearing the top off and sending it through the back seat, so I may implement something different in a year or so.

[end-threadjack]

Hi davygrvy,

A loudspeaker drive unit fails for two main reasons - excess power (heat) or excess diaphragm displacement. The Maximum SPL chart displayed in Hornresp is the standard accepted method for showing the SPL performance envelope of a driver, given these two limiting failure conditions.

As far as explaining the information that the graph is presenting, I can’t do any better than to repeat the Maximum SPL description given in the Hornresp Help file:

"Displays the maximum sound pressure level in decibels that can be achieved at 1 metre without exceeding the rated thermal limited electrical input power Pmax or the diaphragm linear mean-to-peak displacement limit Xmax, versus frequency in hertz."

Doesn’t using the Calculate Parameter tool to find the value of Eg required for a given input power and load impedance, and then looking at the normal SPL chart, give you what you want? Am I missing something here?

Hopefully by now, you would agree that it should be 🙂.

The power rating of a constant voltage amplifier based on some nominal stated load impedance is a virtually meaningless parameter when it comes to considering the performance of a drive unit which has a frequency-dependent electrical impedance that at some frequencies is quite different to the nominal constant load resistance used to rate the amplifier. Note that Re is not a good indicator of the impedance of a driver, as it applies at 0 hertz (dc) only.

Note also that in these considerations, it is the power performance of the drive unit that is of interest (as given by Pmax) and not the power rating of the amplifier.

Kind regards,

David

Why are you using constant power? I can't seem to wrap my head around the info the graph is presenting.

A loudspeaker drive unit fails for two main reasons - excess power (heat) or excess diaphragm displacement. The Maximum SPL chart displayed in Hornresp is the standard accepted method for showing the SPL performance envelope of a driver, given these two limiting failure conditions.

As far as explaining the information that the graph is presenting, I can’t do any better than to repeat the Maximum SPL description given in the Hornresp Help file:

"Displays the maximum sound pressure level in decibels that can be achieved at 1 metre without exceeding the rated thermal limited electrical input power Pmax or the diaphragm linear mean-to-peak displacement limit Xmax, versus frequency in hertz."

If you had used constant voltage calculated from the rated impedance for a given power, I could understand the data presented in a more useful manner.

Doesn’t using the Calculate Parameter tool to find the value of Eg required for a given input power and load impedance, and then looking at the normal SPL chart, give you what you want? Am I missing something here?

Yet a maximum output voltage the power amp has to provide is not part of the data given.

Hopefully by now, you would agree that it should be 🙂.

The power rating of a constant voltage amplifier based on some nominal stated load impedance is a virtually meaningless parameter when it comes to considering the performance of a drive unit which has a frequency-dependent electrical impedance that at some frequencies is quite different to the nominal constant load resistance used to rate the amplifier. Note that Re is not a good indicator of the impedance of a driver, as it applies at 0 hertz (dc) only.

Note also that in these considerations, it is the power performance of the drive unit that is of interest (as given by Pmax) and not the power rating of the amplifier.

Kind regards,

David

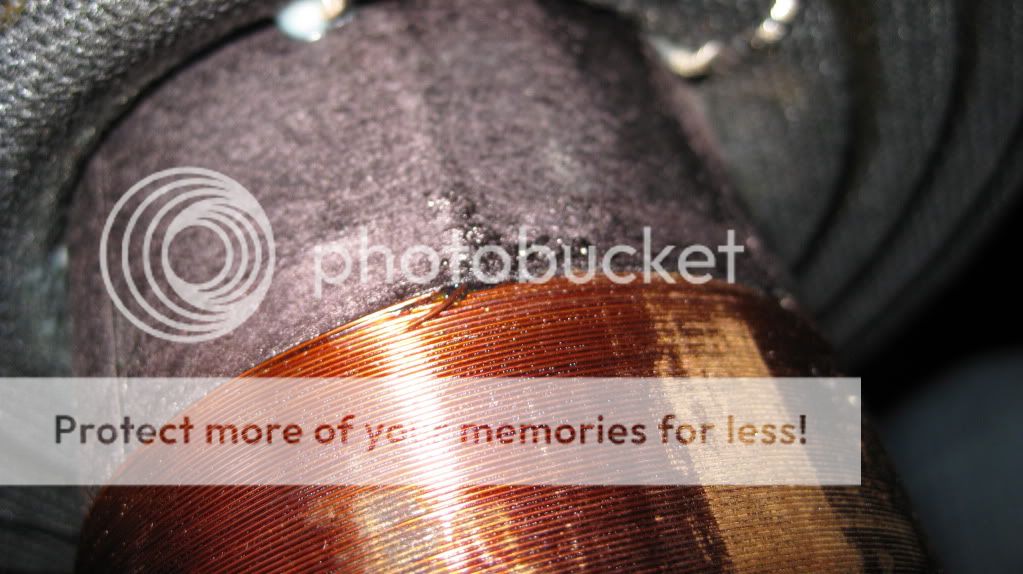

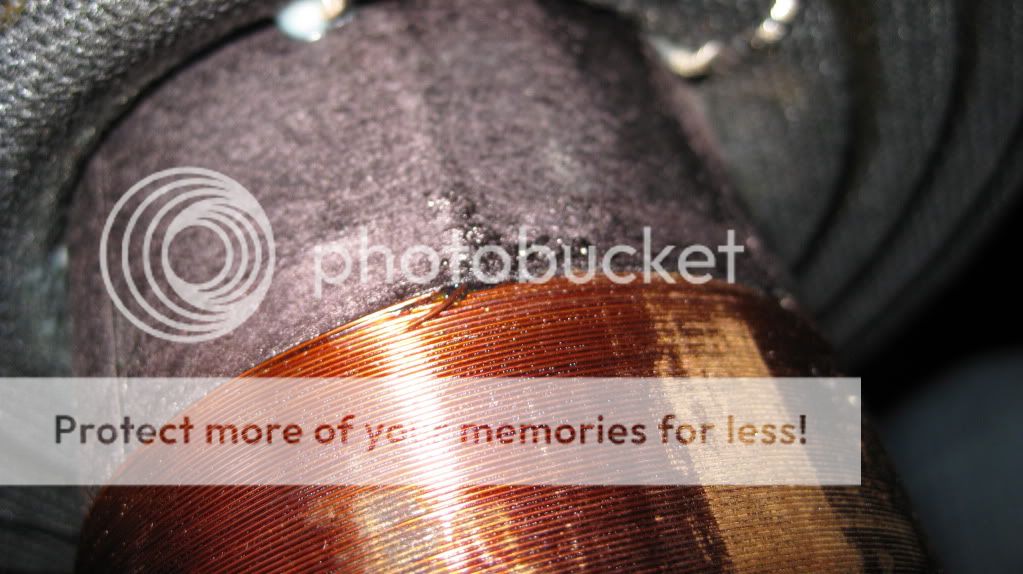

The middle photo on post #22 tells a story.

It looks like the cone left the gap on the TOP side, then slammed into the pole piece on its way back into the gap.

I had this happen many years ago on a 15. When it hung up on top it eventually overheated and burst into flame. A fire extinguisher was needed at the school dance where this happened. The janitor ruined the good woofer too. Fortunately there were still six 15s in three other double 15 cabinets that were OK.

It looks like the cone left the gap on the TOP side, then slammed into the pole piece on its way back into the gap.

I had this happen many years ago on a 15. When it hung up on top it eventually overheated and burst into flame. A fire extinguisher was needed at the school dance where this happened. The janitor ruined the good woofer too. Fortunately there were still six 15s in three other double 15 cabinets that were OK.

The power rating of a constant voltage amplifier based on some nominal stated load impedance is a virtually meaningless parameter when it comes to considering the performance of a drive unit which has a frequency-dependent electrical impedance that at some frequencies is quite different to the nominal constant load resistance used to rate the amplifier. Note that Re is not a good indicator of the impedance of a driver, as it applies at 0 hertz (dc) only.

Note also that in these considerations, it is the power performance of the drive unit that is of interest (as given by Pmax) and not the power rating of the amplifier.

Kind regards,

David

When you calculate the dissipated power do you use just the power dissipated in the voice coil (i^2 * Re) or power dissipated in the whole system (i^2 * real(Z))? I think a power efficiency figure which is a ratio of acoustic output to voice coil dissipated power would be the most reasonable given that it is the voice coil heating which is limiting our power handling.

I think Hornresp shows the amount of energy that the speaker draws. (the energy of the added resistance is not included as it could just as well be emulated)

It also shows the efficiency of which the system converts the drawn energy to sound, both in % and watts.

Just calculate what the dissipated energy would be.

Doing W = V^2 / R on exported data to get power comes out different then sample tool so I might be missing something or doing it wrong.

David will probably straighten it out.

A voltage graph for the max spl tool would be nice though, but sampling it works ok if you know there to start looking.

an optional wattage graph for SPL would also be nice, might remove some confusion in regards to power vs voltage.

Although adding a second unit to the graph might be bad. How about a popup window?

It also shows the efficiency of which the system converts the drawn energy to sound, both in % and watts.

Just calculate what the dissipated energy would be.

Doing W = V^2 / R on exported data to get power comes out different then sample tool so I might be missing something or doing it wrong.

David will probably straighten it out.

A voltage graph for the max spl tool would be nice though, but sampling it works ok if you know there to start looking.

an optional wattage graph for SPL would also be nice, might remove some confusion in regards to power vs voltage.

Although adding a second unit to the graph might be bad. How about a popup window?

The middle photo on post #22 tells a story.

It looks like the cone left the gap on the TOP side, then slammed into the pole piece on its way back into the gap.

Ding, ding, ding... we have a winner. Also, if the woofer is run so that it very nearly jumps the gap you can get a rubbing that tends to look like "emery paper" was used.

LB, I know that you got beat up on the other site and it is certainly not my intention to do so here... I have two sons that both have several thousand watt systems in their vehicles and have seen this failure more than once (this ignores the time I spent as an installer). Overexcursion is hard to predict because it is very dependent on the box design and implementation. The sims can predict one thing but performance is usually quite different. This happens for a variety of reasons including difference in speaker parameters, leaks in the box, aerodynamics associated with the loading of the driver to the enclosure (assuming something other than a sealed enclosure) or loading of the driver to the environment (e.g. corner loading).

The bright side of this is you are not out of pocket any $ and I'm sure that you are learning a great deal.

Doesn’t using the Calculate Parameter tool to find the value of Eg required for a given input power and load impedance, and then looking at the normal SPL chart, give you what you want? Am I missing something here?

What it doesn't do is combine an Xmax and Pe limit together. I'll try to throw together an example gnuplot script to show you what I mean.

The middle photo on post #22 tells a story.

It looks like the cone left the gap on the TOP side, then slammed into the pole piece on its way back into the gap.

This is what I suggested as well, on the other forum.

Hi breez,

In Hornresp, by definition:

The electrical input power is the power delivered to the whole loudspeaker system (Rg is not part of the loudspeaker system).

The acoustical output power is the sound power radiated by the loudspeaker.

The difference between the input and output powers represents internal system losses - mostly due to voice coil resistance Re, but a small amount due to suspension resistance Rms.

I have no plans at this stage to change the Hornresp Maximum SPL tool or associated Sample outputs. The power efficiency figure you are seeking can of course be readily calculated (near enough) from existing Sample outputs, as follows:

Efficiency (as a percentage) = (AcousticalOutput / (InputPower - AcousticalOutput)) * 100

Kind regards,

David

When you calculate the dissipated power do you use just the power dissipated in the voice coil (i^2 * Re) or power dissipated in the whole system (i^2 * real(Z))?

In Hornresp, by definition:

The electrical input power is the power delivered to the whole loudspeaker system (Rg is not part of the loudspeaker system).

The acoustical output power is the sound power radiated by the loudspeaker.

The difference between the input and output powers represents internal system losses - mostly due to voice coil resistance Re, but a small amount due to suspension resistance Rms.

I think a power efficiency figure which is a ratio of acoustic output to voice coil dissipated power would be the most reasonable given that it is the voice coil heating which is limiting our power handling.

I have no plans at this stage to change the Hornresp Maximum SPL tool or associated Sample outputs. The power efficiency figure you are seeking can of course be readily calculated (near enough) from existing Sample outputs, as follows:

Efficiency (as a percentage) = (AcousticalOutput / (InputPower - AcousticalOutput)) * 100

Kind regards,

David

Hi David_Web,

Electrical input power is calculated as follows:

Pe = I ^ 2 * Ret watts

where

I = Eg / (((Rg + Ret) ^ 2 + Xet ^ 2) ^ 0.5) amps

(Ret and Xet are the real and imaginary components respectively, of the total system impedance)

Sorry, it's not going to happen 🙂.

Kind regards,

David

Doing W = V^2 / R on exported data to get power comes out different then sample tool so I might be missing something or doing it wrong.

Electrical input power is calculated as follows:

Pe = I ^ 2 * Ret watts

where

I = Eg / (((Rg + Ret) ^ 2 + Xet ^ 2) ^ 0.5) amps

(Ret and Xet are the real and imaginary components respectively, of the total system impedance)

A voltage graph for the max spl tool would be nice though, but sampling it works ok if you know there to start looking.

an optional wattage graph for SPL would also be nice, might remove some confusion in regards to power vs voltage.

Although adding a second unit to the graph might be bad. How about a popup window?

Sorry, it's not going to happen 🙂.

Kind regards,

David

Someone mentioned "dynamic offset" of drivers and that it could be caused by subsonic content or clipping amplifiers.

Now there is the bad news: Dynamic offset can also happen through some "pneumatic rectification" effect (don't know what it is correctly called like) caused by the non-equal flow resistance of the vents for air flowing in and air flowing out. My gut feeling tells me that the effect is strongest where the port should actually reduce cone displacement: At resonance !

Regards

Charles

Now there is the bad news: Dynamic offset can also happen through some "pneumatic rectification" effect (don't know what it is correctly called like) caused by the non-equal flow resistance of the vents for air flowing in and air flowing out. My gut feeling tells me that the effect is strongest where the port should actually reduce cone displacement: At resonance !

Regards

Charles

was it high passed? A pa style tapped horn without a high pass, is like a duck in a shooting gallery...

What about the new DTS-10, is that a PA Style tapped horn?

I do not read anywhere anyone needing a high pass on that considering it goes down to 10Hz.

What about the new DTS-10, is that a PA Style tapped horn?

I do not read anywhere anyone needing a high pass on that considering it goes down to 10Hz.

ok... you got me there 🙂

I was referring to a 40hz TH like what was designed in this case, as I associate PA with 40hz for lowest note, and HT with 20hz or under for lowest note. (I can hear the dnb folks screaming about that... but hey, 40hz is my opinion on PA.)

It was possibly a 28hz dnb note that killed this driver...

I guess I should be more careful on my words in the future.

No no, it was fine...Im very curious about it that is all and wanted to know if it was a general case.

What I see in these pictures is a piece-of-junk car audio driver with many design compromises, it's intended to be used only in sealed boxes. A vented box with a single big port in one corner could have produced exactly the same result.

Excursion capability is high, power handling is high, but the design is extremely weak when it comes to handle the cone tilt resulting from uneven acoustical load around the cone and high excursion. That's what produced the rubbing of the voice coil against the pole piece. The driver is not intended to work against a hard and uneven air load (the scenario in most horns).

To make it worse, the spider is very far from the pole piece, so any minor cone tilt results in great deviation of the voice coil from the center. The donut style rubber surround makes it even worse because it does not provide any cone centering effect either.

Such a driver would require at least a symmetrical taped horn or symmetrical ports in a vented box. Anyway, a dual spider driver, or any driver with the spider closer to the pole piece, or just any driver with a cloth surround would be much more reliable in such a tapped horn (for example, almost all pro-audio subs).

Furthermore, one layer of the voice coil got almost completely unwrapped but there are no signs of darkening, so heat was not involved at all. I think it was just due to the lack of quality and quantity in the enamel used to put the magnet wire together and/or improper curing.

Low cost Chinese car-audio subs? No thanks 😀

Excursion capability is high, power handling is high, but the design is extremely weak when it comes to handle the cone tilt resulting from uneven acoustical load around the cone and high excursion. That's what produced the rubbing of the voice coil against the pole piece. The driver is not intended to work against a hard and uneven air load (the scenario in most horns).

To make it worse, the spider is very far from the pole piece, so any minor cone tilt results in great deviation of the voice coil from the center. The donut style rubber surround makes it even worse because it does not provide any cone centering effect either.

Such a driver would require at least a symmetrical taped horn or symmetrical ports in a vented box. Anyway, a dual spider driver, or any driver with the spider closer to the pole piece, or just any driver with a cloth surround would be much more reliable in such a tapped horn (for example, almost all pro-audio subs).

Furthermore, one layer of the voice coil got almost completely unwrapped but there are no signs of darkening, so heat was not involved at all. I think it was just due to the lack of quality and quantity in the enamel used to put the magnet wire together and/or improper curing.

Low cost Chinese car-audio subs? No thanks 😀

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Tapped Horns - Simulation VS Reality