According to posts earlier in the thread, no scaling is needed, only less density for stuffing. I'm using the w4-1320sif drivers with decent results, though I wish there was a little more in the 120-600 area especially around 400 HzHow would the dimensions need to be scaled for a 4-inch driver?

Sent from my LG-D801 using Tapatalk

sent from my mobile look-at device

i. Exterior v interior MDF, which should I select ?

ii. Laminated or non-laminated ?

iii. Suede vs matte finish (I'm going for matte)

iv. Class 1 to 4, which one

3. Gonna use silicone sealant and wood glue with wood screws to fasten the box.

Do you guys recommend any particular brand ?

.

i. I went with the only mdf that Home Depot carries

ii. ?

iii. Not sure but after I sanded it with 80grit abranet, it's pretty matte

iv. not sure what class

I used elmers carpenters wood glue. No screws.

Sent from my iPhone using Tapatalk

i. I went with the only mdf that Home Depot carries

ii. ?

iii. Not sure but after I sanded it with 80grit abranet, it's pretty matte

iv. not sure what class

I used elmers carpenters wood glue. No screws.

Sent from my iPhone using Tapatalk

Thanks for the reply !

There are a lot of varieties over here !

You can get upto 50 colour choices with 12 kinds veneers on the sides

I think increase of class ( 1 to 4) means increase in abrasion resistance or something !

The 75mm hole with chamfered edges shown in the drawing are just for indicative purpose ! The 3" TB driver I have doesn't need a 75mm hole.

IIRC, its mounting holes are at 72mm PCD. So, if I had cut a 75mm hole in there, the driver would...

I think you should visit the TB website and take a good look at the dimensions given for the TB W3-1053SC. It's slightly different from what is published in Parts Express or from where you bought those drivers. It'll be better if you can measure the cut-out hole diameter with the driver physically if you have access to a slide caliper gauge.

W3-1053SC - 3" PP Full Range - TB SPEAKER CO., LTD.

You won't have much space to play around with if you don't cut the hole accurately. The driver front frame is quite narrow.

You can use PVA glue like Fevicol SR or similar which is commonly available in India. I've had no problems using this in my builds, and I rarely use screws with my thinner walled speakers!

Try to scallop the inside of the hole and use D or T type inserts with allen head machine screws.

Take care while you're tightening the screws. One slip and its curtains for the driver!

Have you bought your speaker terminals yet? A recessed cup type will be more suitable as you may have to push the speakers up against the wall.

Best of luck with your build.

What kind of sound absorbing material is ideal for 3" driver ?

Glass wool or is there any better material out there ?

You can use polyfill for dampening. You'll get them in the shops that make or sell mattresses and pillows. You should fix some sort of trap like a wide mesh net across the box at 2/3rd length from the top to prevent the stuffing from slipping down.

I hope you're going to paint some primer coat inside, knowing how wet the monsoons can be.

I'll trace the holes and external dimensions from the actual driver onto a paper and transfer it to the panel. So,there won't be any issue.I think you should visit the TB website and take a good look at the dimensions given for the TB W3-1053SC. It's slightly different from what is published in Parts Express or from where you bought those drivers. It'll be better if you can measure the cut-out hole diameter with the driver physically if you have access to a slide caliper gauge.

W3-1053SC - 3" PP Full Range - TB SPEAKER CO., LTD.

You won't have much space to play around with if you don't cut the hole accurately. The driver front frame is quite narrow.

You can use PVA glue like Fevicol SR or similar which is commonly available in India. I've had no problems using this in my builds, and I rarely use screws with my thinner walled speakers!

Try to scallop the inside of the hole and use D or T type inserts with allen head machine screws.

Take care while you're tightening the screws. One slip and its curtains for the driver!

Have you bought your speaker terminals yet? A recessed cup type will be more suitable as you may have to push the speakers up against the wall.

Best of luck with your build.

By the way, thanks for the tips

Appreciate it :thumbsup:

You can use polyfill for dampening. You'll get them in the shops that make or sell mattresses and pillows. You should fix some sort of trap like a wide mesh net across the box at 2/3rd length from the top to prevent the stuffing from slipping down.

I hope you're going to paint some primer coat inside, knowing how wet the monsoons can be.

Ok, I'll try the mattress shops for polyfill.

Regarding primering, a normal oil primer would do, right ?

What about varnish ?

Is the glossy surface formed by vanish, detrimental to the SQ of the speaker ?

Regarding primering, a normal oil primer would do, right ?

What about varnish ?

Is the glossy surface formed by vanish, detrimental to the SQ of the speaker ?

Any oil based wood primer will do. Varnish will not fully prevent moisture absorption. I don't think it will affect SQ although I have not heard of anyone using it for the box interiors. Otherwise why would so many builders use varnish for an exterior finish in solid timber/veneered speakers?

Stay with the primer coat. It'll work better.

Any oil based wood primer will do. Varnish will not fully prevent moisture absorption. I don't think it will affect SQ although I have not heard of anyone using it for the box interiors. Otherwise why would so many builders use varnish for an exterior finish in solid timber/veneered speakers?

Stay with the primer coat. It'll work better.

Ok, noted.

By the way, there is an "exterior grade" MDF available with good resistance to water and other elements with a ~15% increased cost compared to standard MDF.

OK guys, I'm gonna start the build today !

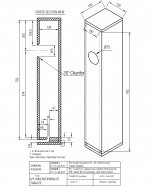

And before I start, I just want to confirm my drawing is correct or not !

Also, would there be any harm if I use "exterior grade" MDF ?

Look, don't worry too much and begin your build. The Tabaqs are a pretty flexible design and tolerant of minor changes so go ahead and start building.

Why would you want to spend extra money on exterior grade MDF? You're going to have some kind of finish on the boxes, aren't you? Whatever that is will come later. Start making sawdust!

All the best.

OK guys, I'm gonna start the build today !

And before I start, I just want to confirm my drawing is correct or not !

Also, would there be any harm if I use "exterior grade" MDF ?

In terms of perfectly following the concept, it's still wrong. In reality.... It's very much close enough.

J.

NOOOOOIn terms of perfectly following the concept, it's still wrong. In reality.... It's very much close enough.

J.

I'll make it anyway

No-one has yet spec'd the parts for the rear "L" of the "reshaped" port - that I am aware.

Need a rear part to the main enclosure floor and a 15x16x10mm part for the "rear port wall".

In my drawing, the port length of the front =Horizontal distance 74mm + vertical distance 23mm = 97mm. In that drawing, the center of the port is placed 59mm from the front panel's inside wall.

If we do a port on the rear wall, the total port length would be

Horizontal distance from center of port to back panel backside 84 + Vertical distance 23 = 107mm.

So, port in the front and the back would have different lengths.

But, if we move the port to the center, then the port path length would be 102mm for front and back, ie., symmetrical !

Would that work ?

In my drawing, the port length of the front =Horizontal distance 74mm + vertical distance 23mm = 97mm. In that drawing, the center of the port is placed 59mm from the front panel's inside wall.

If we do a port on the rear wall, the total port length would be

Horizontal distance from center of port to back panel backside 84 + Vertical distance 23 = 107mm.

So, port in the front and the back would have different lengths.

But, if we move the port to the center, then the port path length would be 102mm for front and back, ie., symmetrical !

Would that work ?

No no no no.... I am not suggesting any changes to the format.

The "blob", rectangle, at the back on the floor of the enclosure. Parts are not defined for this. It could be a block of wood or layers of MDF/wood, or it could be two pieces of MDF at an 90 degree angle . Whatever it is, it's not in the parts list.

Bjørn,

A question here for you.

Do you think that the difficulty eljoantonyn is facing with his box dimensions is primarily arising from the fact that he is using 15 mm thick MDF? It's adding 3 mm to his baffle and also 3 mm to the vent shelf. I had another look at the altered dimensions you posted in Post #1501. It looked fairly straightforward to me.

A question here for you.

Do you think that the difficulty eljoantonyn is facing with his box dimensions is primarily arising from the fact that he is using 15 mm thick MDF? It's adding 3 mm to his baffle and also 3 mm to the vent shelf. I had another look at the altered dimensions you posted in Post #1501. It looked fairly straightforward to me.

There is no port at the back - only at the front.

The revised port is due to the fact that the actual build has a port that is just a little longer than the sim.

The alteration was just to make a port 100% equal to the sim. For 3 inch drivers I would use this outline of the port. Not with 4 inch drivers.

It should be straight forward to make the correct port lenght using material with thicker dimemsions.

Yes the part in the bottom right cornet coould be a piece of wood or several pieces.

Bjørn

Bjørn

The revised port is due to the fact that the actual build has a port that is just a little longer than the sim.

The alteration was just to make a port 100% equal to the sim. For 3 inch drivers I would use this outline of the port. Not with 4 inch drivers.

It should be straight forward to make the correct port lenght using material with thicker dimemsions.

Yes the part in the bottom right cornet coould be a piece of wood or several pieces.

Bjørn

Bjørn

- Home

- Loudspeakers

- Full Range

- TABAQ TL for Tangband