I see now that it was the ND105 that was tested and it worked fine. I am a rookie at this and am torn between a 3 inch for highs vs 4 inch for lows. Guess I have to make a decision and just build something.

Thanks for the input. I will play around with WinISD and see what comes up.

Thanks for the input. I will play around with WinISD and see what comes up.

TABAQS for my sister.

Thanks again Bjorn. My plans for TABAQS have been put on hold. My access to a table saw and other equipment has changed as I may be changing schools in the summer.

Was able to get these finished these for my sister, before the change.

TangBands that were on clearance from PE.

JHutka

Thanks again Bjorn. My plans for TABAQS have been put on hold. My access to a table saw and other equipment has changed as I may be changing schools in the summer.

Was able to get these finished these for my sister, before the change.

TangBands that were on clearance from PE.

JHutka

Attachments

TABAQS for my sister.

Thanks again Bjorn. My plans for TABAQS have been put on hold. My access to a table saw and other equipment has changed as I may be changing schools in the summer.

Was able to get these finished these for my sister, before the change.

TangBands that were on clearance from PE.

JHutka

Thanks again Bjorn. My plans for TABAQS have been put on hold. My access to a table saw and other equipment has changed as I may be changing schools in the summer.

Was able to get these finished these for my sister, before the change.

TangBands that were on clearance from PE.

JHutka

I built a micro Tabaqube with a 36 in pathlength (4 x 9 in) and 4 square inch cross sectional area to use with a 1 in driver from a small MP3 speaker/player. These player I have utilizes an LM4871 3-watt (mono) amplifier and also contains a microSD mp3 player, a rechargeable Li-ion battery, and a 3.5mm jack for connecting your external sound source (iPod). I wanted to make it small and portable, and I wanted to make fast and cheap. So I ended up using the foamcore paper board (poster backing) as the speaker housing material. You can make this in a hour with just an X-Acto knife, a ruler, and a hot melt glue gun. Anyhow, I made each quadrant have a 2 in x 2 in cross section, and there are 6 turns to the TABAQ - basically it looks like the 3d transparent drawing from my earlier post for the TABAQUBE but looks stretched out since the footprint is only 4 in x 4 in instead of 9.5 in x 9.5 in. I stuffed it pretty tightly with polyster fill from an old pillow per Bjohanessen's recommendation of about 2/3 the length from the closed end. I put some wire inside before sealing the unit off with glue on the top lid. For the vent dimensions, I was not sure how big to make it because this is so far from the parameters of the original TABAQ, so I made provisions for having an adjustable slot width by adding more foamcore inserts to tune the sound.

For the mp3 player, do a search for "hamburger mp3 player". I found one for about $9 and they have quite an amazingly powerful sound for how small they are. However, the bass is really non-existent as you would imagine for a speaker without a real enclosure. The bass could really be improved from the standpoint of an mp3 speaker with full-range sound which is why I took on this project. I took the hamburger player apart and separated the speaker and trimmed off some excess plastic and mounted that on the front with hot melt glue. Then I hot melt glued the back half of the hamburger on the back of the micro Tabaqube so that the 3.5 mm jack could go to the top where my iPOD nano would sit. The electronics half of the hamburger is really impressive for what can be done with $9. There is the microSD card slot, the mp3 player IC, the 3 watt amp, Li-ion battery pack, charging circuit, LED's and track and volume controls, and mini USB charging jack.

So how does it sound? Very nice for something that costs less than $10 and weighs less than 5 ozs including speaker cabinet! The bass is now present in good quantities, whereas it was completely missing before. The player is actually too loud to comfortably listen to if it is on your desk at full volume - I turn it down to maybe 60%. It sounds better than most portable mp3 players I have heard in the $30 to $50 price range, albeit, it is only mono. But that is OK as I use it mostly for background music while doing stuff around the house. It was a lot of fun to build and I am a true believer in DIY mass loaded transmission lines to make speakers full and rich.

Thank you to Bjohanessen for inspiring me to do this! Now that I have done it in foamboard, I have a good idea what I need to do to make the wooden cabinets for my Vifa TC9D's when they show up. I will make a stereo side-by-side TABAQ powered by a TA2020 amp. Although, I am also tempted to make a picture stereo transmission line, maybe I need to order more drivers???

Regards,

xrk971

Photos show the Tabaqube internal baffles, assembled with stuffing, 1 in driver on front, the electronics on back, and with an iPOD nano which fits perfectly on the top.

hey man, not to be obtuse, but could you post plans for this? i have a very similar mp3 player and i would love to try this design.

Micro Tabaqube for 1 in driver

Here is the plan for the micro 1 in driver Tabaqube. There is no simulation here so YMMV. Add VERY LIGHT (circa 2 to 3 grams of polyfill teased out to form a soft loose amount in the first 18 in of the line) stuffing to the first half of the transmission line. Too much and there will be no bass response. You will have to manually adjust the vent gap by adding or removing little slices of foam core until it sounds good. I would have modeled it if I had T/S params for the driver.

Here is the plan for the micro 1 in driver Tabaqube. There is no simulation here so YMMV. Add VERY LIGHT (circa 2 to 3 grams of polyfill teased out to form a soft loose amount in the first 18 in of the line) stuffing to the first half of the transmission line. Too much and there will be no bass response. You will have to manually adjust the vent gap by adding or removing little slices of foam core until it sounds good. I would have modeled it if I had T/S params for the driver.

Attachments

Here is the plan for the micro 1 in driver Tabaqube. There is no simulation here so YMMV. Add VERY LIGHT (circa 2 to 3 grams of polyfill teased out to form a soft loose amount in the first 18 in of the line) stuffing to the first half of the transmission line. Too much and there will be no bass response. You will have to manually adjust the vent gap by adding or removing little slices of foam core until it sounds good. I would have modeled it if I had T/S params for the driver.

I made it prior to your reply, and now i think i have too much stuffing in it. hopefully it won't react too badly to me opening it back up....

I did the same thing. Cut a small window with razor and pull out excess stuffing. Reseal with hot melt.

I made mine using gel-type CA glue, it has awesome sealing abilities and has almost no deflection due to drying very, very hard. The enclosure makes my little Brookstone speaker a real performer and I'm pretty satisfied with the current amount of filling. I experimented with adding a wider horn mouth and I seem to have gained some bass.

If anyone cares, heres the speaker I used: Pop-Up Mini Speaker with FM Tuner at Brookstone?Buy Now!

Next up is making a test enclosure for the 35mm Foster drivers out of an old eMac I ran into... I would love to find more data on them to make a somewhat calculated design instead of just building something and hoping it works.

I have a similar problem with a Tabaq (3W-871) i built, it sounds a little flat. Could be something with the stuffing or with that it isn't airtight. Would it be better with a different speaker, say W3-1878?

I put the stuffing around the wall, should i fill it up instead (this is my first build so a friend who helped me said it would be enough)?

I haven't tried any real sealant but used glue to attach the sides to eachother, but maybe this isn't enough?

I really want this to work as it should, i got my wife interested in the project so she made the covering to the speakers ->

I put the stuffing around the wall, should i fill it up instead (this is my first build so a friend who helped me said it would be enough)?

I haven't tried any real sealant but used glue to attach the sides to eachother, but maybe this isn't enough?

I really want this to work as it should, i got my wife interested in the project so she made the covering to the speakers ->

An externally hosted image should be here but it was not working when we last tested it.

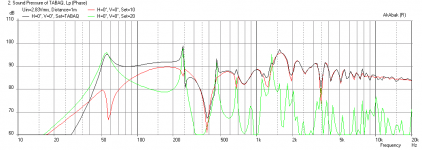

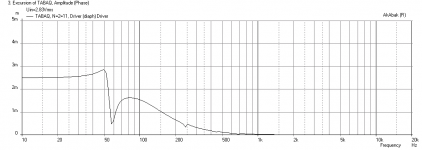

The W3-871 sims pretty well in a Tabaq. As you can see, it should reach 55

Hz. However, the max displacement of 0.5 mm may cause problems as about 1.5 mm is needed to reach 80 Hz at 1 watt. Maybe this is cause of why it sounds flat? Max excursion is being reached? Try another W3 driver with higher xmax if you have one. The Vifa Tc9fd has xmax of 2.5 mm and can be swapped out with bigger cutout.

Hz. However, the max displacement of 0.5 mm may cause problems as about 1.5 mm is needed to reach 80 Hz at 1 watt. Maybe this is cause of why it sounds flat? Max excursion is being reached? Try another W3 driver with higher xmax if you have one. The Vifa Tc9fd has xmax of 2.5 mm and can be swapped out with bigger cutout.

Attachments

- Home

- Loudspeakers

- Full Range

- TABAQ TL for Tangband