The 6MDN44's were what I had on hand and since they are 96.5dB sensitive, you don't need 4 of them. Just one or two can work depending on sensitivity of your CD. They work surprisingly well open backed (no rear chamber) and can take quite a bit of power. They also reach lower than the M10's allowing you to xo to a woofer below 200Hz rather than 400Hz. If you do it right, a bass horn sub can handle 30Hz to 200Hz easily and you keep a two-way horn that is simple.

midrange choices

I can't really criticize your choice of midrange as I seriously considered the M10 myself before others demonstrated that a 2-way design would be sufficient. In some ways, a 3-way does it better but with more cost/complexity - another amp and DSP channel for an active solution in addition to the drivers.

I think I can identify the compromises that go with the M10 vs the Faital 3FE25 or the Dayton ND91. All these drivers may be OK but which one is best? The latter two can reach all the way down to 200 Hz in the horn in a corner or perhaps 275 Hz in free space. The Dayton has >2x the excursion as the Faital but the Faital appears to be cleaner up top than either the Dayton or the Faital. I distrust the Visaton on power handling as its rated only at 800 Hz++. My simulation (I forget where I got the T/S params as they aren't in the data sheet) shows low efficiency and limited maximum SPL compared to the alternatives.

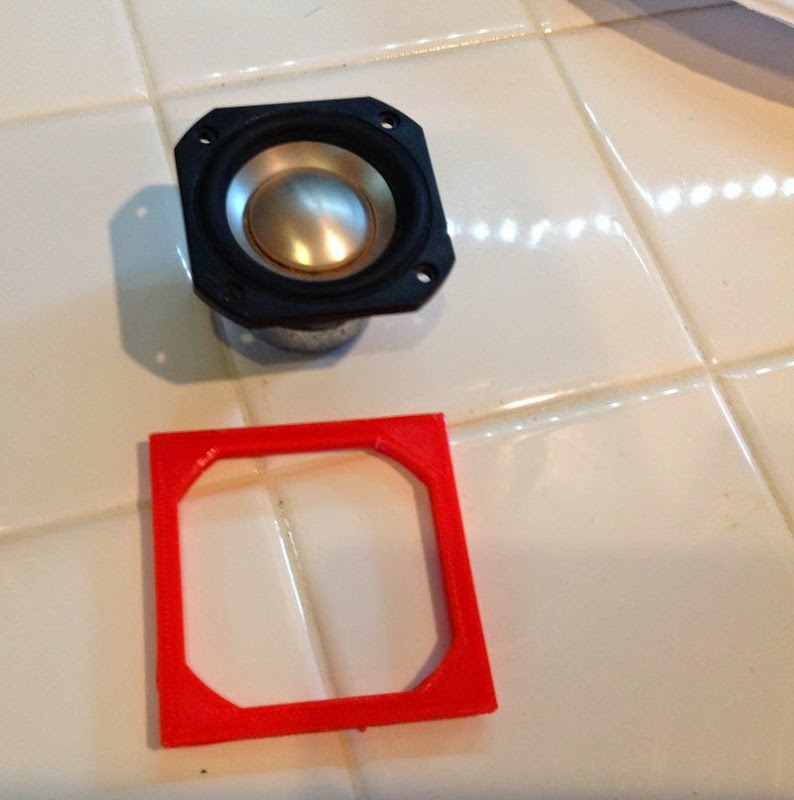

Before I switched to a 2-way, I was leaning towards the 4FE35 because I wanted its extra bass extension. I have one of those in hand and its seems that it would be trivial to seal it with a strip of plastic wrapped around the frame or a plastic cap fabbed with a 3D printer. The 3FE25 appears to be built the same way I hesitate to recommend the 4FE because its sims show more sensitivity to rear chamber volume and Vtc. Dealing with that could be a lot more work for another 50 or 75 Hz extension.

Looking at my M10 sims in HR, I see a sharp roll off below 400 Hz for the M10. I think this may be problematic as Tom Danley has recommended generous overlap between drivers multiple times. That is certainly necessary for a passive crossover with its attendant low slopes. I'm not sure how hard a requirement it is if you are going active. I suspect its helps with the synergizing.

In many ways choosing a driver is a self fulfilling prophecy. You make your choice and then do what you need to do to make your choice work. I think you should take a look at your choice on the bench before finalizing the horn design. I regret not having done that myself on my own design.

Jack

I can't really criticize your choice of midrange as I seriously considered the M10 myself before others demonstrated that a 2-way design would be sufficient. In some ways, a 3-way does it better but with more cost/complexity - another amp and DSP channel for an active solution in addition to the drivers.

I think I can identify the compromises that go with the M10 vs the Faital 3FE25 or the Dayton ND91. All these drivers may be OK but which one is best? The latter two can reach all the way down to 200 Hz in the horn in a corner or perhaps 275 Hz in free space. The Dayton has >2x the excursion as the Faital but the Faital appears to be cleaner up top than either the Dayton or the Faital. I distrust the Visaton on power handling as its rated only at 800 Hz++. My simulation (I forget where I got the T/S params as they aren't in the data sheet) shows low efficiency and limited maximum SPL compared to the alternatives.

Before I switched to a 2-way, I was leaning towards the 4FE35 because I wanted its extra bass extension. I have one of those in hand and its seems that it would be trivial to seal it with a strip of plastic wrapped around the frame or a plastic cap fabbed with a 3D printer. The 3FE25 appears to be built the same way I hesitate to recommend the 4FE because its sims show more sensitivity to rear chamber volume and Vtc. Dealing with that could be a lot more work for another 50 or 75 Hz extension.

Looking at my M10 sims in HR, I see a sharp roll off below 400 Hz for the M10. I think this may be problematic as Tom Danley has recommended generous overlap between drivers multiple times. That is certainly necessary for a passive crossover with its attendant low slopes. I'm not sure how hard a requirement it is if you are going active. I suspect its helps with the synergizing.

In many ways choosing a driver is a self fulfilling prophecy. You make your choice and then do what you need to do to make your choice work. I think you should take a look at your choice on the bench before finalizing the horn design. I regret not having done that myself on my own design.

Jack

This would be a real game changer for car audio, if you made everything half the size.

When I put some Unity horns up on the dash of my car, I was able to get the footprint down to about the size of a football. But if you 3D printed it, you could probably shrink that down to about the size of a baseball. You would have to use a conventional tweeter, but that works fine as long as you don't need to get louder than about 110dB.

So basically you'd have a 3D printed Synergy Horn with a neodymium ring radiator tweeter, and four 2" midranges. It would be the size of a baseball. It would have four 2" woofers and about 110dB of output.

while my local maker space has a ~$26k Shopbot, there are cheaper benchtop types, finished or kitswhat "hobby gantry routers" do you think would be up to the task and what would they cost?

CNC Machines | Rockler Woodworking & Hardware

https://www.buildyourcnc.com/blackfoot48v40.aspx

the trick is that you only have to relief carve single thickness plywood sheets, say 3/4" and can then stack and glue with CNC cut registration features if you like

still looking for free/cheap sw chain for the 3D design and CAM

@cookiemonster77 Excellent work!

Regarding 3D printed vs CNC; there should be multiple benefits to 3D printing that would be more difficult with CNC. Small radiused edges on non-symmetric mid entry holes. Elliptic (or more non-traditional e.g. JBL M2) horn cross-section. To be fair, most anything _could_ be fabbed with a CNC router, it is just liable to take more assembly / post-processing and or more advanced tool paths, tool changes, etc. for some of the more interesting options.

Another interesting 3D printed possibility is a custom form factor. Someone might print a triangular rear for a corner soffit mount. Someone else might be restricted to speakers that fit in an odd shaped living room niche. PB could print one that snugs up externally and feathers out internally to the windshield of his specific vehicle.

For those worried about either having to use a large amount of plastic or risk wall resonance, the horn sides can be printed double walled with access points to pour in sand (or sand+glue or cement or ...).

A really useful resource for the hobbyist would be a parametric OpenSCAD script that would take number of drivers, crossover frequency, horn profile, etc and generate a printable model. Potentially the model would have recesses in which to insert plywood. The CD to horn transition and mid-injection holes would be printed, then for material cost reasons, the horn would be extended to full size with sheet/board material.

Regarding 3D printed vs CNC; there should be multiple benefits to 3D printing that would be more difficult with CNC. Small radiused edges on non-symmetric mid entry holes. Elliptic (or more non-traditional e.g. JBL M2) horn cross-section. To be fair, most anything _could_ be fabbed with a CNC router, it is just liable to take more assembly / post-processing and or more advanced tool paths, tool changes, etc. for some of the more interesting options.

Another interesting 3D printed possibility is a custom form factor. Someone might print a triangular rear for a corner soffit mount. Someone else might be restricted to speakers that fit in an odd shaped living room niche. PB could print one that snugs up externally and feathers out internally to the windshield of his specific vehicle.

For those worried about either having to use a large amount of plastic or risk wall resonance, the horn sides can be printed double walled with access points to pour in sand (or sand+glue or cement or ...).

A really useful resource for the hobbyist would be a parametric OpenSCAD script that would take number of drivers, crossover frequency, horn profile, etc and generate a printable model. Potentially the model would have recesses in which to insert plywood. The CD to horn transition and mid-injection holes would be printed, then for material cost reasons, the horn would be extended to full size with sheet/board material.

@xrk971 & nc535: Thanks for the tips on alternative midranges! Do you have akabak-compatible data already set up? (thiele small (preferably extended, so we get the rising impedance up high)? If you have the ability to measure the cone profile too I would be most grateful!  (see below for why cone profile is more useful than a simple volume-under-the-cone number).

(see below for why cone profile is more useful than a simple volume-under-the-cone number).

@winslow: It seems I posted the wrong picture re excursion earlier. Here it is, for the M10 mids as simulated:

So it does seem like 400Hz is the magic number for the M10 mids. These are peak numbers (so are the SPL numbers). VACS shows peak, not RMS unless you adjust each chart. But they are based on 2.83VRMS figures.

I do think the horn is not loading the driver anymore at that point. The sims were done with a 300x300mm "main flare". I think I can stretch the whole horn to be 600x600, which gives 520Hz pattern control according to Bill Waslo´s spreadsheet.

I am wondering whether 60x60 is too narrow. Perhaps 90x90 is a better option? For a 60x60 cube pattern control should end at 400Hz.

In this case, a two-way could make sense, if I could get a two-way to cover the entire range down to 400Hz, or would it be best with woofers in the horn to cover the transition to omni?

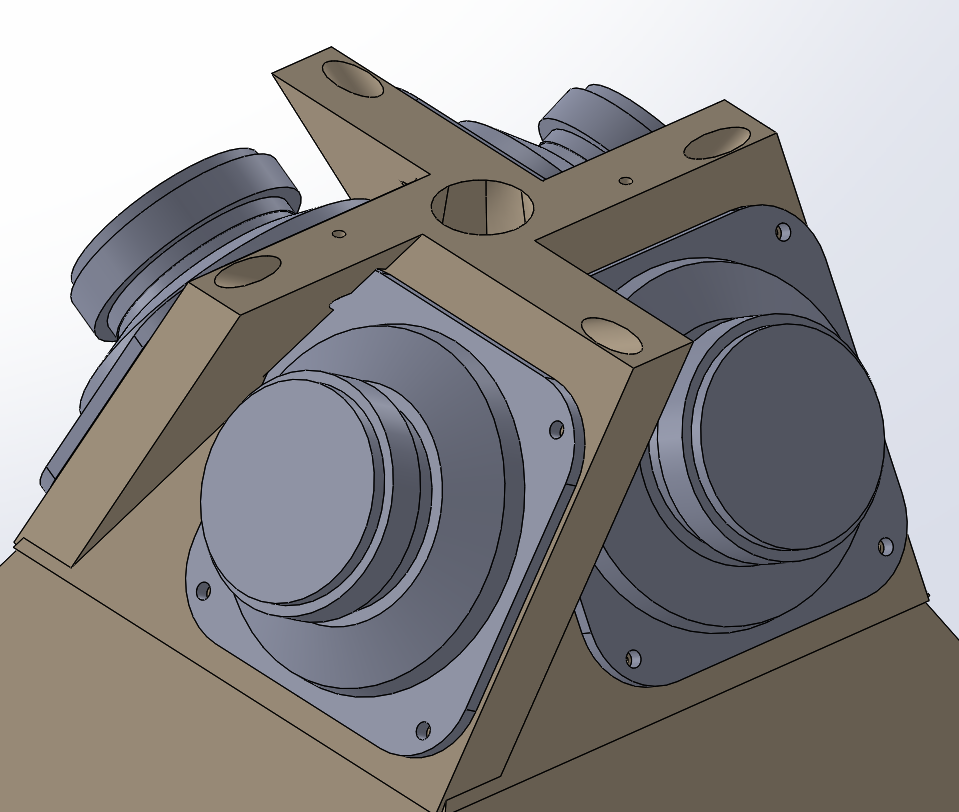

@fudce: Good input on methods of printing! Sounds like a good idea to print hollow and fill with something dead. Related to your post, it seems 3D printing could make for tight coupling of drivers, even if they need to be farther apart due to their size. Here´s a quick mockup of what I have in mind:

Knowing the cone geometry of the midrange driver would allow simming this assymetrical entry in ABEC in BEM, to see how the offset hole would change the frequency response.

Of course, phase plugs could be added here.

@patrick: Glad you liked the idea - I read most of your posts as they are very inspirational.

It´s been a busy few days, so not much progress to report. Next step is to try with the alternative drivers. When modelling in ABEC, once something happens in the BEM domain, changes are slow because it has to re-solve. I think I might make a LEM-only variant, similar to Akabak, and do the initial sims there, transferring part of it over to BEM once I´m reasonably happy with the sims.

@winslow: It seems I posted the wrong picture re excursion earlier. Here it is, for the M10 mids as simulated:

So it does seem like 400Hz is the magic number for the M10 mids. These are peak numbers (so are the SPL numbers). VACS shows peak, not RMS unless you adjust each chart. But they are based on 2.83VRMS figures.

I do think the horn is not loading the driver anymore at that point. The sims were done with a 300x300mm "main flare". I think I can stretch the whole horn to be 600x600, which gives 520Hz pattern control according to Bill Waslo´s spreadsheet.

I am wondering whether 60x60 is too narrow. Perhaps 90x90 is a better option? For a 60x60 cube pattern control should end at 400Hz.

In this case, a two-way could make sense, if I could get a two-way to cover the entire range down to 400Hz, or would it be best with woofers in the horn to cover the transition to omni?

@fudce: Good input on methods of printing! Sounds like a good idea to print hollow and fill with something dead. Related to your post, it seems 3D printing could make for tight coupling of drivers, even if they need to be farther apart due to their size. Here´s a quick mockup of what I have in mind:

Knowing the cone geometry of the midrange driver would allow simming this assymetrical entry in ABEC in BEM, to see how the offset hole would change the frequency response.

Of course, phase plugs could be added here.

@patrick: Glad you liked the idea - I read most of your posts as they are very inspirational.

It´s been a busy few days, so not much progress to report. Next step is to try with the alternative drivers. When modelling in ABEC, once something happens in the BEM domain, changes are slow because it has to re-solve. I think I might make a LEM-only variant, similar to Akabak, and do the initial sims there, transferring part of it over to BEM once I´m reasonably happy with the sims.

Attachments

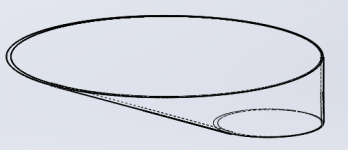

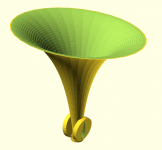

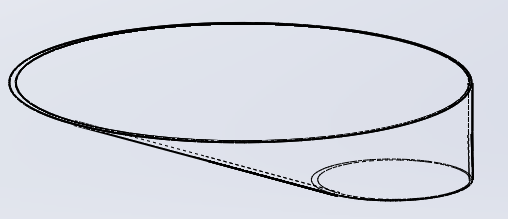

To illustrate some of my thoughts, here is what should be a tractrix expansion (expansion code borrowed from Lukas Süss aka mechadense via Thingiverse), elliptical horn with teardrop mid entry holes. 6.5" mid mounting plates. 1" CD with 2 bolt sized CD mounting plate.

The code originally was for a circular tractrix horn, I scaled to an ellipse by stretching subsequent layers farther and farther on one axis. I don't actually know whether this destroys the tractrixness of the expansion. I'm hoping it just creates a lower frequency curve, which is part of the point, so all should be well. Fair warning though .

.

The code originally was for a circular tractrix horn, I scaled to an ellipse by stretching subsequent layers farther and farther on one axis. I don't actually know whether this destroys the tractrixness of the expansion. I'm hoping it just creates a lower frequency curve, which is part of the point, so all should be well. Fair warning though

Attachments

I can't really criticize your choice of midrange as I seriously considered the M10 myself before others demonstrated that a 2-way design would be sufficient. In some ways, a 3-way does it better but with more cost/complexity - another amp and DSP channel for an active solution in addition to the drivers.

I think I can identify the compromises that go with the M10 vs the Faital 3FE25 or the Dayton ND91. All these drivers may be OK but which one is best? The latter two can reach all the way down to 200 Hz in the horn in a corner or perhaps 275 Hz in free space. The Dayton has >2x the excursion as the Faital but the Faital appears to be cleaner up top than either the Dayton or the Faital. I distrust the Visaton on power handling as its rated only at 800 Hz++. My simulation (I forget where I got the T/S params as they aren't in the data sheet) shows low efficiency and limited maximum SPL compared to the alternatives.

Before I switched to a 2-way, I was leaning towards the 4FE35 because I wanted its extra bass extension. I have one of those in hand and its seems that it would be trivial to seal it with a strip of plastic wrapped around the frame or a plastic cap fabbed with a 3D printer. The 3FE25 appears to be built the same way I hesitate to recommend the 4FE because its sims show more sensitivity to rear chamber volume and Vtc. Dealing with that could be a lot more work for another 50 or 75 Hz extension.

Looking at my M10 sims in HR, I see a sharp roll off below 400 Hz for the M10. I think this may be problematic as Tom Danley has recommended generous overlap between drivers multiple times. That is certainly necessary for a passive crossover with its attendant low slopes. I'm not sure how hard a requirement it is if you are going active. I suspect its helps with the synergizing.

In many ways choosing a driver is a self fulfilling prophecy. You make your choice and then do what you need to do to make your choice work. I think you should take a look at your choice on the bench before finalizing the horn design. I regret not having done that myself on my own design.

Jack

Dayton nd91 is a great driver. Check out some of my projects. The faital is alright. The Dayton works better. More displacement and sounds cleaner.

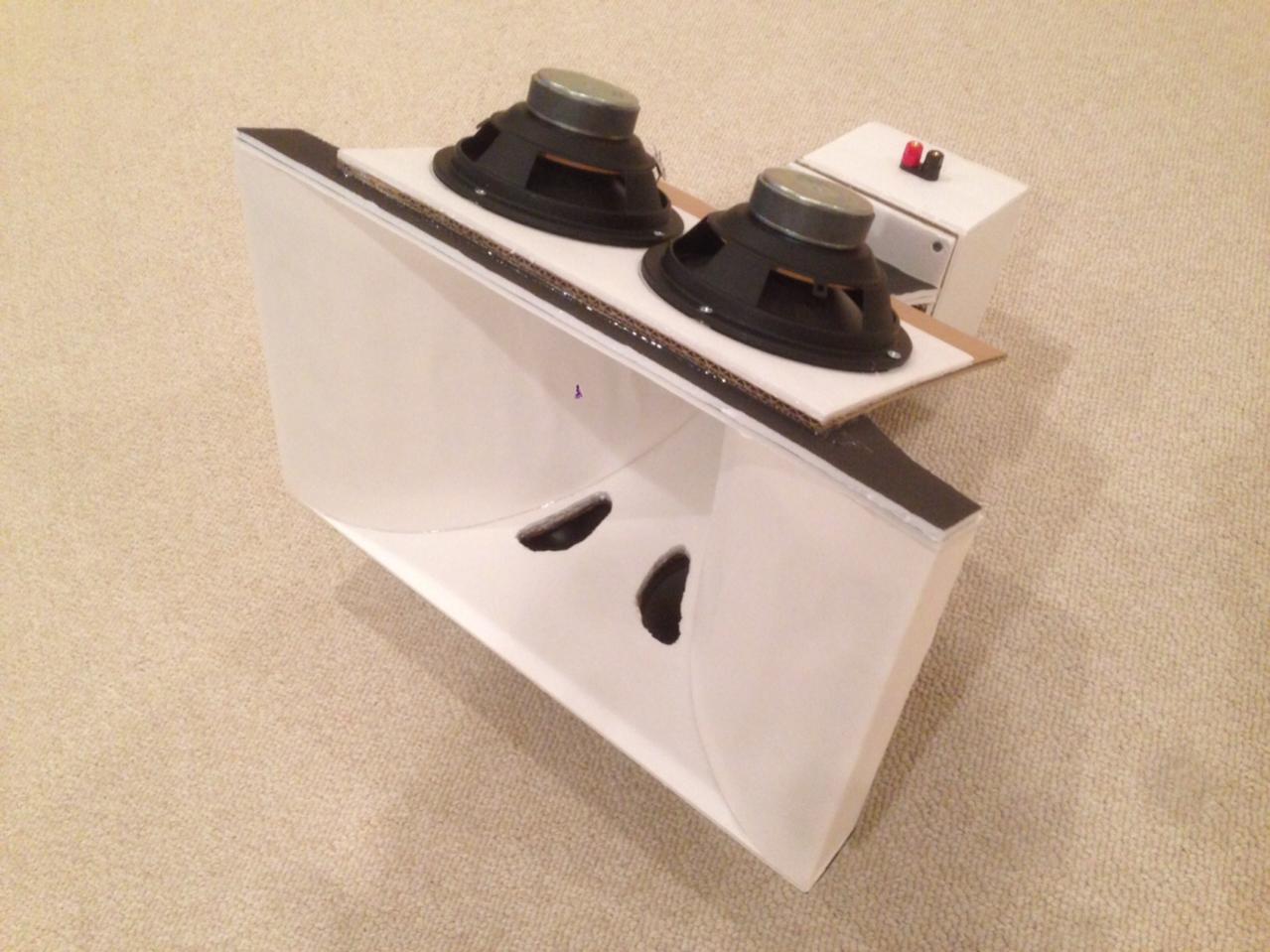

Here are the beginnings of a 3D printed synergy horn, using the buyout version of the Peerless 830970

I'm using a "Printrbot Simple", which sells for $599 at Amazon

Nice! Going to miss your hack sawed OSB/fiberglass and duct taped speakers.

Last edited:

To illustrate some of my thoughts, here is what should be a tractrix expansion (expansion code borrowed from Lukas Süss aka mechadense via Thingiverse), elliptical horn with teardrop mid entry holes. 6.5" mid mounting plates. 1" CD with 2 bolt sized CD mounting plate.

The code originally was for a circular tractrix horn, I scaled to an ellipse by stretching subsequent layers farther and farther on one axis. I don't actually know whether this destroys the tractrixness of the expansion. I'm hoping it just creates a lower frequency curve, which is part of the point, so all should be well. Fair warning though.

A tractrix sounds great in a synergy. I built one with a full range driver as the tweeter and they sound fantastic. One of the best sounding speakers I have ever heard. You can use Ed Forker's (volvotreter) spreadsheet to calculate the profile. Here is more details of the Trynergy http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy.html

Last edited:

Nice! i need to get one of these printers I suppose. Happy with the Printrbot?

Sent from my iPhone using Tapatalk

Actually I came close to throwing it out the window yesterday.

Sure, I could've returned it to Amazon.

But have you ever worked on something for three hours straight, and every time you try to make it better you wind up making it worse? And then you realize that there would be nothing more satisfying than throwing it out the window and watching it explode?

Yeah, that was my experience with the Printrbot.

An externally hosted image should be here but it was not working when we last tested it.

If doing 3d printing - quality of the machine is important it is a mechanical device with lots of moving parts and wear and tear and tolerances matter. You may need to spend upwards of $2k for a quality machine that won't make you want to go postal.

Remember when good laser printers cost $1500?

Here is one I am thinking of getting. 5 star rated and can handle 8x10x8 workpiece. Enough to make nice throat on synergy and 5in driver chambers with volume phase plugs.

The MakerGear M2: Amazon.com: Industrial & Scientific

Remember when good laser printers cost $1500?

Here is one I am thinking of getting. 5 star rated and can handle 8x10x8 workpiece. Enough to make nice throat on synergy and 5in driver chambers with volume phase plugs.

The MakerGear M2: Amazon.com: Industrial & Scientific

Basically I write software for a living, and the software on this thing isn't just bad, it's nonexistent.

No joke, when the printer arrives, there's no drivers, no software.

I'd expected that doing a 3D print would basically look like this:

1) plug printer into computer

2) install driver

3) print from 123D

But that's not the case at all. You literally have to pore through all kinds of bizarre settings to make anything work.

Imagine if you went and bought an HP laser printer, and there were no drivers in the box. And in order to get the printer to work, you had to manually enter about a hundred parameters into the software. (And remember, the software isn't even included.)

And just to add insult to injury, those parameters that I mentioned are open to debate. (Basically when you start digging around in forums, there's quite a bit of debate as to how to get a good print.)

It's totally mind boggling. I literally do this stuff for a living, and it's one of the most frustrating experiences I've ever had with a piece of software. I can't imagine how these things will ever get popular if the software situation is this terrible.

No joke, when the printer arrives, there's no drivers, no software.

I'd expected that doing a 3D print would basically look like this:

1) plug printer into computer

2) install driver

3) print from 123D

But that's not the case at all. You literally have to pore through all kinds of bizarre settings to make anything work.

Imagine if you went and bought an HP laser printer, and there were no drivers in the box. And in order to get the printer to work, you had to manually enter about a hundred parameters into the software. (And remember, the software isn't even included.)

And just to add insult to injury, those parameters that I mentioned are open to debate. (Basically when you start digging around in forums, there's quite a bit of debate as to how to get a good print.)

It's totally mind boggling. I literally do this stuff for a living, and it's one of the most frustrating experiences I've ever had with a piece of software. I can't imagine how these things will ever get popular if the software situation is this terrible.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Synergy horn - 3d printing entry?