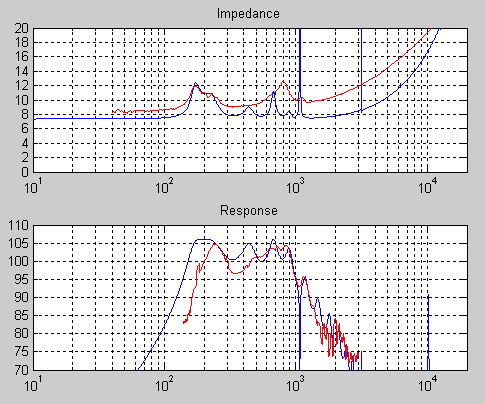

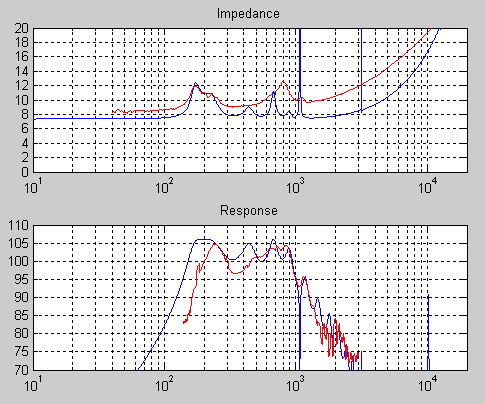

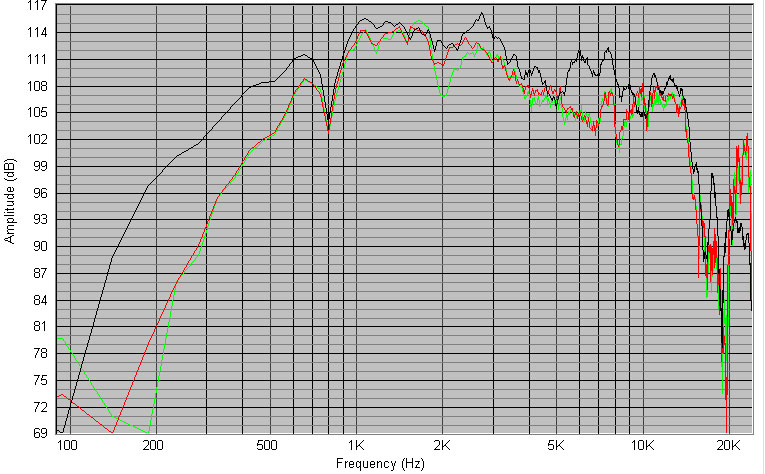

Here's a measurement versus matlab simulation from 2003 of my midranges:

I think this was with small midrange holes and 4x 5" MCM midranges, but it was so long ago I'm not 100% sure.

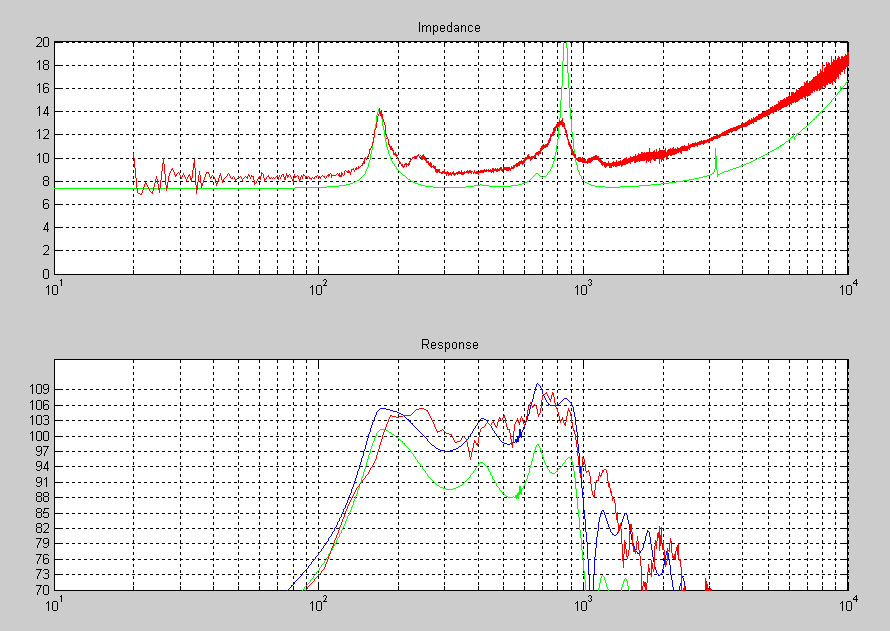

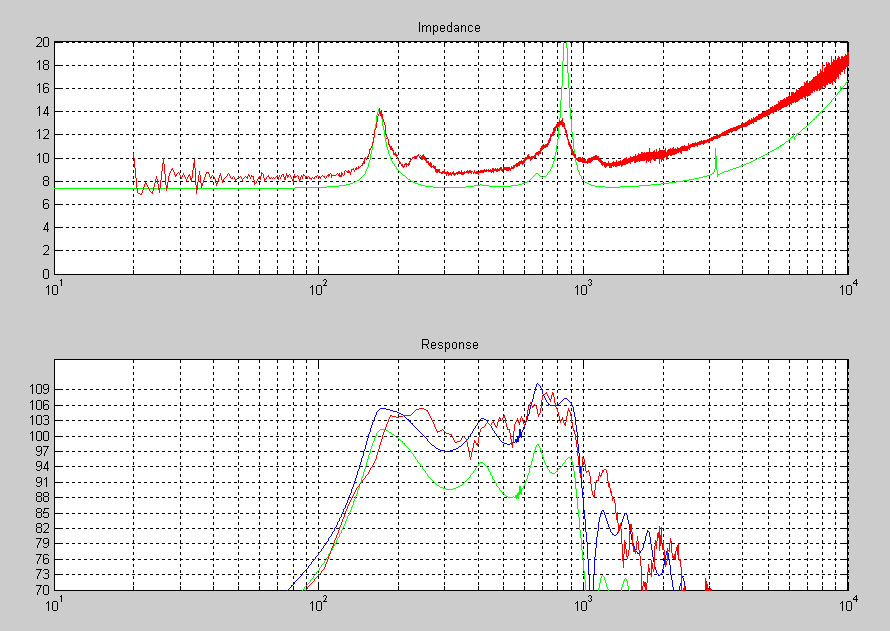

Here's a modification of the same horn a month later with larger midrange holes that worked better with the mids but messed up the compression driver's response more:

I still listen to this today in my garage:

I think this was with small midrange holes and 4x 5" MCM midranges, but it was so long ago I'm not 100% sure.

Here's a modification of the same horn a month later with larger midrange holes that worked better with the mids but messed up the compression driver's response more:

I still listen to this today in my garage:

Thanks for posting!Here's a modification of the same horn a month later with larger midrange holes that worked better with the mids but messed up the compression driver's response more:

When doing my Paraline project, I measured absolutely no HF difference with or without the mid driver holes. Different animal though, removing the upper and lower horn wall also made no difference to HF response, much to my amazement at the time.

Do you have a small/large hole measurement of the HF response?

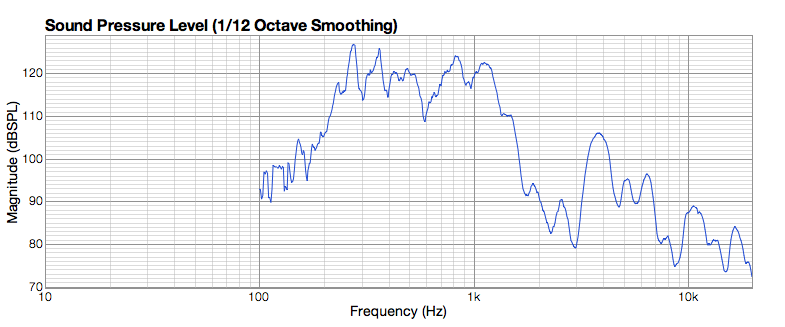

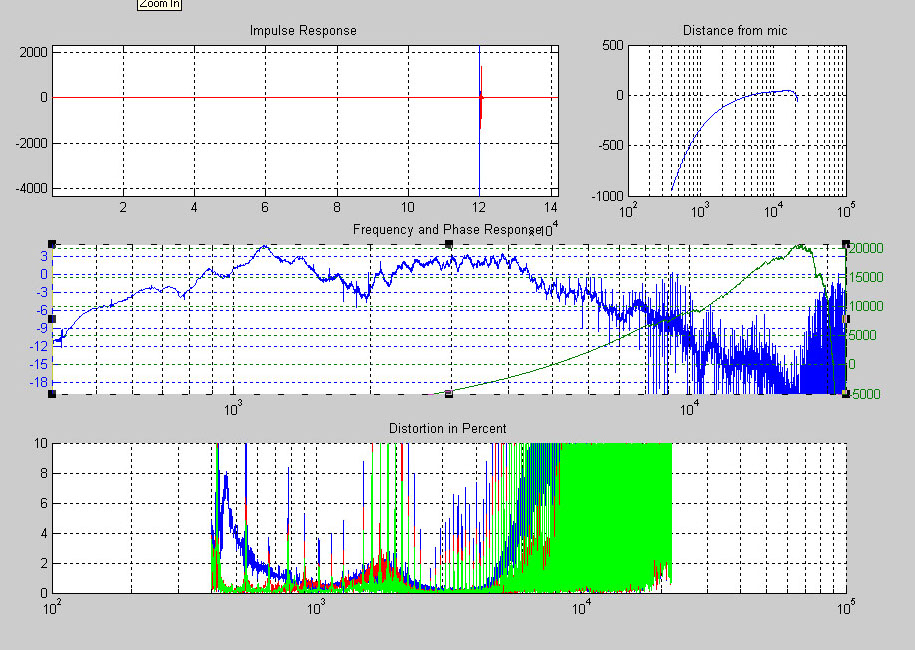

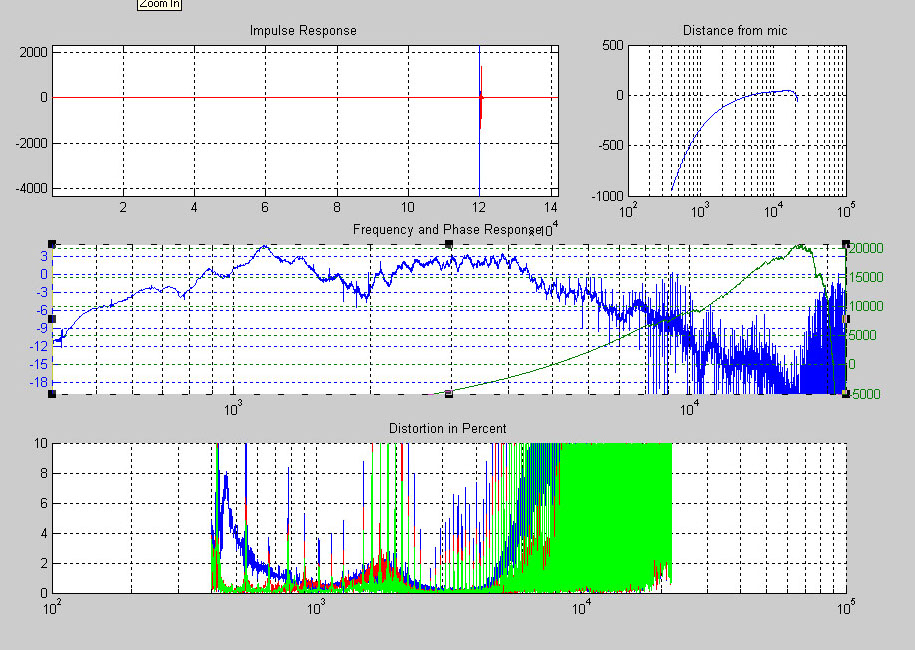

Here are a few more measurements. This is a TAD 2001 on the horn with small holes (very small - a single ~1/2" diameter hole only about 0.1" long for each mid with a larger hole going through the 3/4" wall to get to the short, small hole):

This is a completely unsmoothed response taken with a Farina sweep outdoors with the mic ~2m from the mouth of the horn. There are some dips in the response, but note that the response is pretty smooth between 2kHz and 10kHz (ignoring some of the noise at higher frequencies).

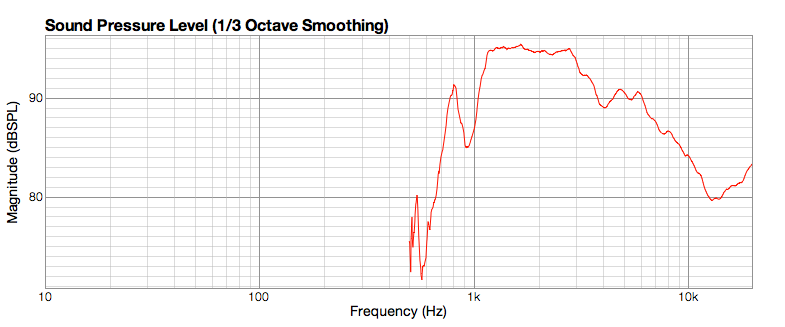

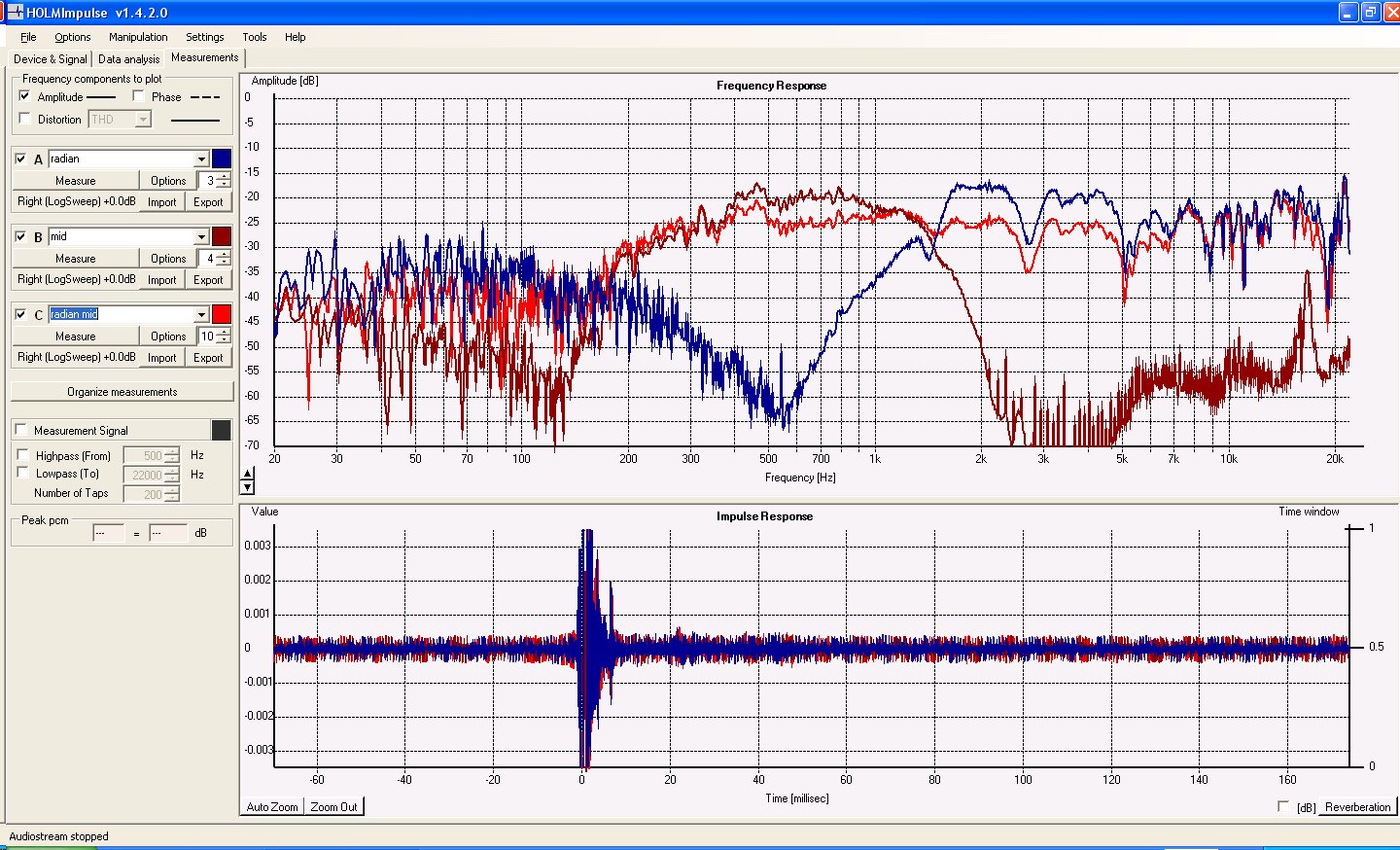

Here's a Radian 475 on the horn with the larger mid holes (holes are very large, like 2"x1" rectangular cutouts, 1 for each mid driver). These are outdoor measurements using a groundplane technique with the horn tilted forward so the mic is on-axis with the horn. I have before eq for the Radian and the mids and then the two combined after eq. Note all the dips in the tweeter's response.

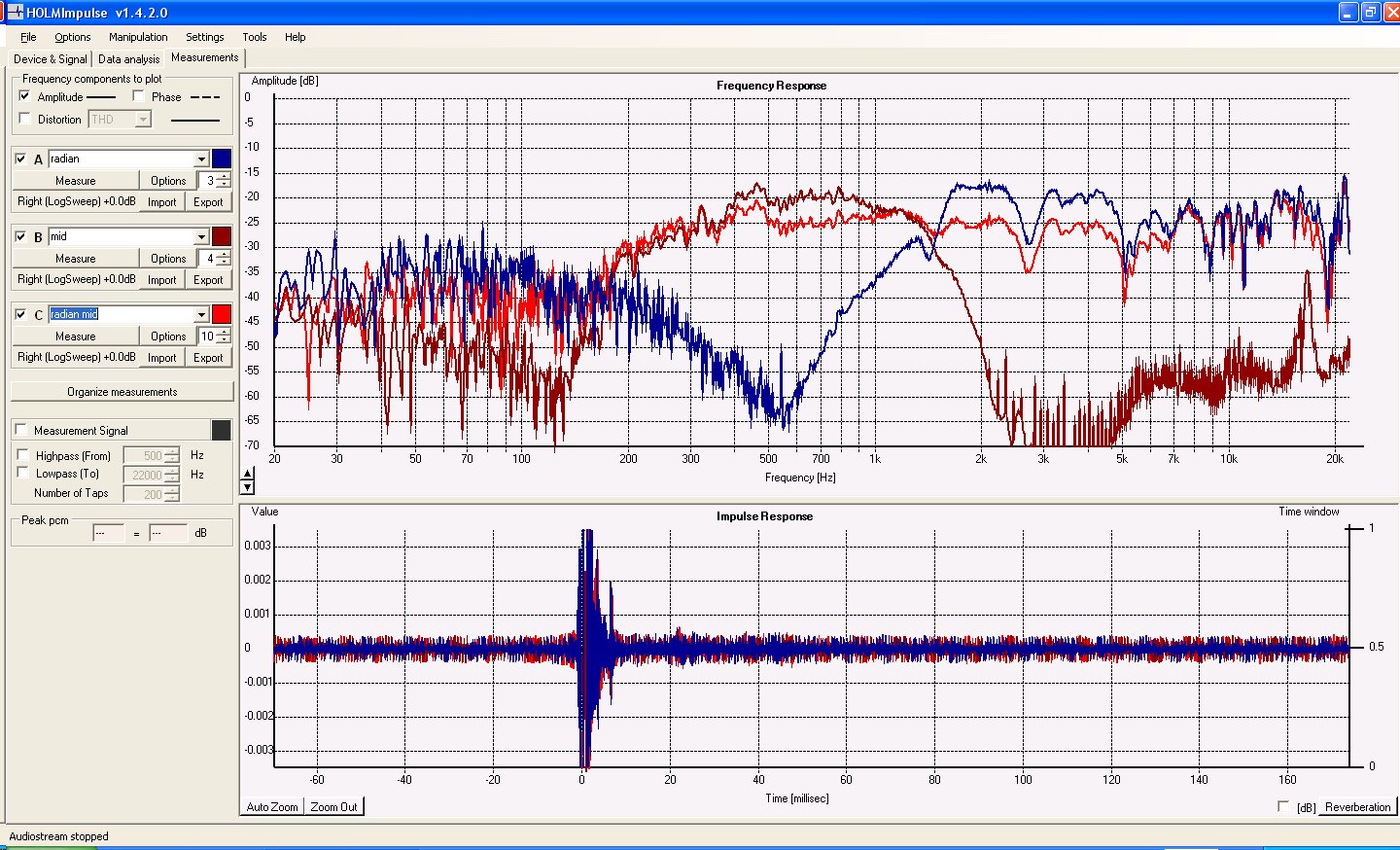

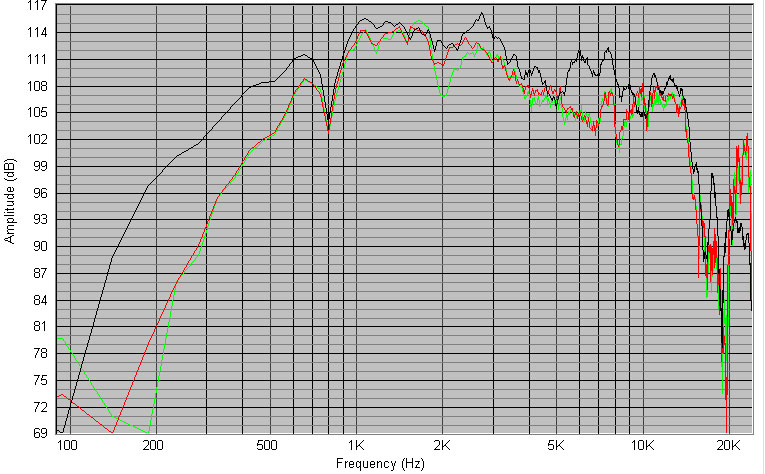

Here's an additional plot of the above TAD vs the above radian on a different horn (a 500Hz tractrix, I think) (edit) to show that the Radian (red/green) is actually smoother than the TAD.

Basically the mids I had at the time did not work very well to get a flat response with small holes or medium holes. I did lots of simulations of geometries that were in between the two extremes I tried before I cut the holes out to make them bigger but couldn't find anything that looked good so I went for the extreme to validate my simulations. It did smooth the mid response out and bring the sensitivity up, but the tweeter got rougher.

This is a completely unsmoothed response taken with a Farina sweep outdoors with the mic ~2m from the mouth of the horn. There are some dips in the response, but note that the response is pretty smooth between 2kHz and 10kHz (ignoring some of the noise at higher frequencies).

Here's a Radian 475 on the horn with the larger mid holes (holes are very large, like 2"x1" rectangular cutouts, 1 for each mid driver). These are outdoor measurements using a groundplane technique with the horn tilted forward so the mic is on-axis with the horn. I have before eq for the Radian and the mids and then the two combined after eq. Note all the dips in the tweeter's response.

Here's an additional plot of the above TAD vs the above radian on a different horn (a 500Hz tractrix, I think) (edit) to show that the Radian (red/green) is actually smoother than the TAD.

Basically the mids I had at the time did not work very well to get a flat response with small holes or medium holes. I did lots of simulations of geometries that were in between the two extremes I tried before I cut the holes out to make them bigger but couldn't find anything that looked good so I went for the extreme to validate my simulations. It did smooth the mid response out and bring the sensitivity up, but the tweeter got rougher.

Last edited:

Hi everyone,

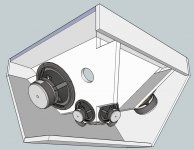

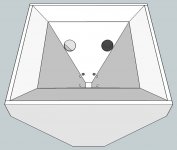

Since I last posted I have been playing with my Sketchup Model and Akabak.

I think once you look at Akabak you will quickly see that it is not nearly as intimidating as it first appears. Also maybe I was a bit quick to judge the interface which, albeit dated, is not too bad once you tile the windows (CTRL-Y: Simluate Again is your friend). If you have done even basic programming it will quickly make sense.

I have taken Sheldon's advice and offset the bass drivers enough to be able to fit 2x 10" drivers into the horn and have the input ports near/on the edge. I have modeled 2x 18 Sound 10W500 drivers trying to balance three things: reasonably flat acoustic power, low excursion (<5.5mm) and low port velocities (<17m/s).

To achieve a good balance of the three above I have had to adjust my design so that:

1. Only 2 ports per driver: 1 driver 'input' port and 1 bass 'tap' port.

2. 70mm Diameter of both ports.

3. Bass 'tap' port has to have a length of 100mm to tune the box to the correct frequency. I am not sure if Danley uses these?

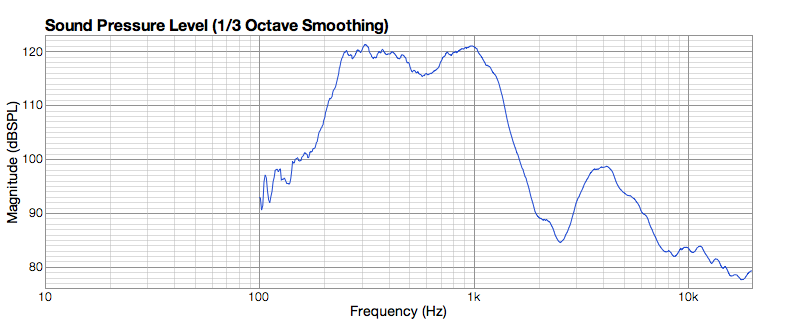

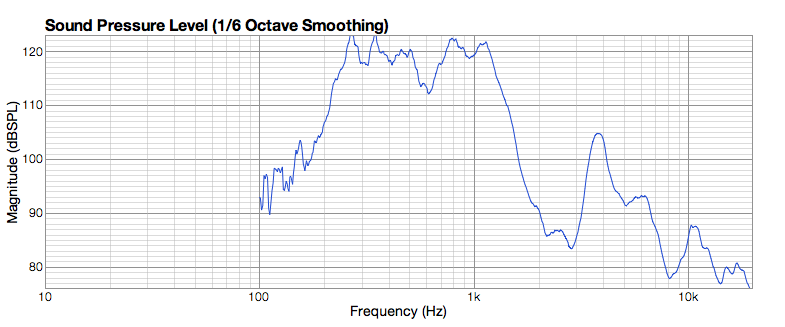

Within these constraints you can achieve 120db output to 100Hz with ~20W:

1. 17m/s velocity target is met (~16m/s) assuming you put a high pass at 100Hz to limit port velocity at tuning frequency of ~80Hz.

2. Within 5.5mm Xmax (~2.8mm)

3. This is only one speaker of two so >120db is achievable.

I assume that Danely must be putting a high pass filter in his crossover to reduce high port velocities and cone excursion at low frequencies. This makes sense in a pro audio setting but in a realistic livingroom setup you could lower the highpass frequency and still comfortably hit >110db peaks. The DEQX helps here again as it can save multiple profiles with different high-pass settings. E.g. you could change to a higher high-pass frequency profile for action movies and lower high-pass frequency profile for more day-to-day listening levels.

If anyone is interested in any of these designs I recommend playing with Sketchup and Akabak and you will quickly start to see the design choices that Danley Sound Labs has had to make for their products. Very impressive engineering.

I just wish I could build these things sooner. To answer a previous question, I am not in Australia at the moment but rather in Zambia where I doubt even one CNC router exists.

Cheers,

Mike

Since I last posted I have been playing with my Sketchup Model and Akabak.

I think once you look at Akabak you will quickly see that it is not nearly as intimidating as it first appears. Also maybe I was a bit quick to judge the interface which, albeit dated, is not too bad once you tile the windows (CTRL-Y: Simluate Again is your friend). If you have done even basic programming it will quickly make sense.

I have taken Sheldon's advice and offset the bass drivers enough to be able to fit 2x 10" drivers into the horn and have the input ports near/on the edge. I have modeled 2x 18 Sound 10W500 drivers trying to balance three things: reasonably flat acoustic power, low excursion (<5.5mm) and low port velocities (<17m/s).

To achieve a good balance of the three above I have had to adjust my design so that:

1. Only 2 ports per driver: 1 driver 'input' port and 1 bass 'tap' port.

2. 70mm Diameter of both ports.

3. Bass 'tap' port has to have a length of 100mm to tune the box to the correct frequency. I am not sure if Danley uses these?

Within these constraints you can achieve 120db output to 100Hz with ~20W:

1. 17m/s velocity target is met (~16m/s) assuming you put a high pass at 100Hz to limit port velocity at tuning frequency of ~80Hz.

2. Within 5.5mm Xmax (~2.8mm)

3. This is only one speaker of two so >120db is achievable.

I assume that Danely must be putting a high pass filter in his crossover to reduce high port velocities and cone excursion at low frequencies. This makes sense in a pro audio setting but in a realistic livingroom setup you could lower the highpass frequency and still comfortably hit >110db peaks. The DEQX helps here again as it can save multiple profiles with different high-pass settings. E.g. you could change to a higher high-pass frequency profile for action movies and lower high-pass frequency profile for more day-to-day listening levels.

If anyone is interested in any of these designs I recommend playing with Sketchup and Akabak and you will quickly start to see the design choices that Danley Sound Labs has had to make for their products. Very impressive engineering.

I just wish I could build these things sooner. To answer a previous question, I am not in Australia at the moment but rather in Zambia where I doubt even one CNC router exists.

Cheers,

Mike

Attachments

Last edited:

Hi SunRa,

There are no mids in this model as I have only put the bass drivers in. I am not sure of crossover frequency I will use but I suspect it would be in the 200-300Hz territory (which easily meets the wavelength/4 requirement) so the 800Hz dip is not relevant.

800Hz is 42.85cm but I cannot work out what that relates to. Hopefully someone with a better theoretical understanding can chime in.

BTW. I just realised my maths were bad with regard to power input to reach 120db. It should be much closer to 280W to reach 120db not 20W. Stupidity on my part.

Cheers,

Mike

There are no mids in this model as I have only put the bass drivers in. I am not sure of crossover frequency I will use but I suspect it would be in the 200-300Hz territory (which easily meets the wavelength/4 requirement) so the 800Hz dip is not relevant.

800Hz is 42.85cm but I cannot work out what that relates to. Hopefully someone with a better theoretical understanding can chime in.

BTW. I just realised my maths were bad with regard to power input to reach 120db. It should be much closer to 280W to reach 120db not 20W. Stupidity on my part.

Cheers,

Mike

Last edited:

Typically the first dip at the top end of the cone drivers' response is due to sound traveling from the cone drivers' entry holes to the throat of the horn, then returning (reflecting) to recombine with the sound exiting the horn. When the path traveled equals 1/2 wavelength, you get cancellation. Thus the closer to the throat you put the entry holes, the higher in frequency this notch moves. That's why using smaller midrange drivers would allow a higher crossover point to the compression driver. You encounter the same issue with midbass to midrange drivers if you turn it into a 3 way design.

For my build, I used nothing but Google Sketchup and a band saw.

Once I had the horn dimmensioned accurately in Sketchup, I "pulled it apart" and used the programs measurement tools to create cut sheets with the dimensions and miter angles. I drew each piece out on MDF with a ruler and square and then free-handed them on the band saw. It wasn't too tricky. Here's some pics of construction and my Sketchup file.

Expect a major update on my build this weekend.

Looks fantastic!

John

This is a very cool thread.

There are a few interesting-looking mid drivers right now on ebay, including that discontinued Jamo one, a pair of Magnavox's with alnico magnets and an interesting looking Yamaha one.

The Fs=491 mid from Misco is available with no apparent minimum.

Assuming Sheldon's corner mounting, why not use a high-power 2" dome midrange? They seem to come with either Fs=800 (Hi-Vi) or Fs=400 (Morel).

http://gallery.AudioAsylum.com/cgi/...serImages=4130&session=&invite=&w=1056&h=1063

I have the original Danley/Lambdacoustics 300hz horn (w/BMS 4550), and am moving from the passive speaker-level filter to individual SET amps on each pass-band. I'll be doing some measurements soon, to see how to proceed. The mids will probably be a simple first-order band-pass. The tweeters' filter is sure to be interesting

¡viva la unity/synergy! --keto

There are a few interesting-looking mid drivers right now on ebay, including that discontinued Jamo one, a pair of Magnavox's with alnico magnets and an interesting looking Yamaha one.

The Fs=491 mid from Misco is available with no apparent minimum.

Assuming Sheldon's corner mounting, why not use a high-power 2" dome midrange? They seem to come with either Fs=800 (Hi-Vi) or Fs=400 (Morel).

http://gallery.AudioAsylum.com/cgi/...serImages=4130&session=&invite=&w=1056&h=1063

I have the original Danley/Lambdacoustics 300hz horn (w/BMS 4550), and am moving from the passive speaker-level filter to individual SET amps on each pass-band. I'll be doing some measurements soon, to see how to proceed. The mids will probably be a simple first-order band-pass. The tweeters' filter is sure to be interesting

¡viva la unity/synergy! --keto

Last edited:

<snip>

So, as a thought experiment, phase plugs

Red Spade Audio: Synergy mid driver mounting and phase plugs

Do you see a problem here? We either eliminate the required bandpass chamber, or we try to add it back and end up with re-creating the problem we were trying to fix!

With a compression driver we are covering more than 4 octaves. With the Synergy mid, it's about 2.5. We don't need a phase plug and it removes one of the main features of the Synergy midrange!

Paul,

Work has been bananas for the past few weeks, and I haven't had a chance to upload any pix of my 'phase plugged' Unity.

The phase plugs I am using aren't remotely as small as what is in your illustration; in fact the phase plugs go about 2" into the horn.

Picture something like this, but with the midrange throat located about 3" away from the apex of the horn.

The results I am getting are quite good. For instance, the high frequencies went so high that a couple times I had to double check and see if my compression driver was connected!

I wish I had some measurements; I haven't had time.

I wouldn't be surprised to find that the Pyle midranges are going to 4500hz, give or take half an octave. (with the phase plugs.)

I'm a bit tempted to try a midrange like the Dayton RS75. The RS75 has some interesting advantages in a design like mine. In my current configuration, I have a wooden phase plug suspended a fraction of an inch in front of the Pyle. With the RS75, I can eliminate the wooden phase plug, and simply use the solid aluminum phase plug that's built into the woofer.

Another advantage of the RS75 is that the aluminum phase plug reduces the surface area of the cone. So the RS75 is a 3" driver, but due to the phase plug, the surface area is closer to something like a 2" driver.

In a horn, the small surface area of the driver helps 'smooth' out the frequency response. (Since the horn mouth is undersized, the smaller the driver is, the smoother the horn response is, generally.)

In your post, you said that I'm "eliminating the bandpass chamber."

That's not true; I'm simply making it extraordinarily small. Plus, I'm still getting a 'notch' due to reflection off the throat.

I'm not saying that my solution is the best, just that I'm juggling things a bit differently. Danley sells designs that are high power and quite large. My designs are ultra-optimized for a tiny footprint. I've even considered using 1" woofers.

As I see it, the only price you pay with smaller drivers is a reduction in efficiency and power handling. And we have efficiency to burn, which makes micro drivers compelling. Plus, small drivers allow me to make the horn much smaller.

Hi Patrick,

I wonder if you could use a sealed chamber like this one to easily close the back of one of these mid domes and make ourselves our own Synergy mid range driver.

SEAS K2851 1.7 Liter Chamber for D75MX41, D7608/9200: Madisound Speaker Store

Madisound claim they are perfect for this 3" dome:

ScanSpeak Discovery D7608/9200-10 3" Dome Midrange (D75MX41): Madisound Speaker Store

Maybe there is a similar product for the cheaper Daytons.

Cheers,

Mike

I wonder if you could use a sealed chamber like this one to easily close the back of one of these mid domes and make ourselves our own Synergy mid range driver.

An externally hosted image should be here but it was not working when we last tested it.

SEAS K2851 1.7 Liter Chamber for D75MX41, D7608/9200: Madisound Speaker Store

Madisound claim they are perfect for this 3" dome:

ScanSpeak Discovery D7608/9200-10 3" Dome Midrange (D75MX41): Madisound Speaker Store

Maybe there is a similar product for the cheaper Daytons.

Cheers,

Mike

Small horns have a high cutoff, 1" "woofers" would be working as sealed or ported below Fc, no "efficiency to burn" unless you use dozens per horn.My designs are ultra-optimized for a tiny footprint. I've even considered using 1" woofers.

As I see it, the only price you pay with smaller drivers is a reduction in efficiency and power handling. And we have efficiency to burn, which makes micro drivers compelling. Plus, small drivers allow me to make the horn much smaller.

Pattern control to around 400 Hz or so requires a large horn, having pattern control that low is a desirable feature lost with a small horn.

Small horns have a high cutoff, 1" "woofers" would be working as sealed or ported below Fc, no "efficiency to burn" unless you use dozens per horn.

Pattern control to around 400 Hz or so requires a large horn, having pattern control that low is a desirable feature lost with a small horn.

I should have noted, all of my ultra-small horns use boundaries to extend the curve. The ones I've made for the home are designed to be put in a corner, and the ones I've built for a car use the dash and/or windshield to extend two or three sides of the horn.

Parts Express is selling some neodymium drivers from Pyle that look promising:

The good:

- they're under $50

- they have an accordian surround, which tends to lower MMS and makes the front chamber on a Unity a bit easier

The bad:

- you'll have to seal off the back

- the driver diameter is too large to use with many compression drivers... this would be a good candidate for a Unity with a 1.5" throat

Here's the T/S, as measured by a forum member at diyma:

Vas Delta Mass completed: Wed Sep 08 21:13:01 2010

Drive level 100.000 % [ 3.271 mA]

;------------------------------------------------------------------

Re = 3.6804 ohms

Fs = 109.4246 Hz

Zmax = 39.8873 ohms

Qes = 0.5804

Qms = 5.7097

Qts = 0.5268

Le = 0.4773 mH (at 1 kHz)

Diam = 203.2000 mm ( 8.0000 in )

Sd =32429.2779 mm^2( 50.2655 in^2)

Vas = 14.8566 L ( 0.5247 ft^3)

BL = 9.6306 N/A

Mms = 21.2730 g

Cms = 99.4446 uM/N

Kms =10055.8535 N/M

Rms = 2.5616 R mechanical

Efficiency = 3.1514 %

Sensitivity= 97.0030 dB @1W/1m

Sensitivity= 100.3749 dB @2.83Vrms/1m

Krm = 15.969E-06 ohms Freq dependent resistance

Erm = 1.262E+00 Rem=Krm*(2*pi*f)^Erm

Kxm = 5.837E-03 Henries Freq dependent reactance

Exm = 734.591E-03 Xem=Kxm*(2*pi*f)^Exm

An externally hosted image should be here but it was not working when we last tested it.

The good:

- they're under $50

- they have an accordian surround, which tends to lower MMS and makes the front chamber on a Unity a bit easier

The bad:

- you'll have to seal off the back

- the driver diameter is too large to use with many compression drivers... this would be a good candidate for a Unity with a 1.5" throat

Here's the T/S, as measured by a forum member at diyma:

Vas Delta Mass completed: Wed Sep 08 21:13:01 2010

Drive level 100.000 % [ 3.271 mA]

;------------------------------------------------------------------

Re = 3.6804 ohms

Fs = 109.4246 Hz

Zmax = 39.8873 ohms

Qes = 0.5804

Qms = 5.7097

Qts = 0.5268

Le = 0.4773 mH (at 1 kHz)

Diam = 203.2000 mm ( 8.0000 in )

Sd =32429.2779 mm^2( 50.2655 in^2)

Vas = 14.8566 L ( 0.5247 ft^3)

BL = 9.6306 N/A

Mms = 21.2730 g

Cms = 99.4446 uM/N

Kms =10055.8535 N/M

Rms = 2.5616 R mechanical

Efficiency = 3.1514 %

Sensitivity= 97.0030 dB @1W/1m

Sensitivity= 100.3749 dB @2.83Vrms/1m

Krm = 15.969E-06 ohms Freq dependent resistance

Erm = 1.262E+00 Rem=Krm*(2*pi*f)^Erm

Kxm = 5.837E-03 Henries Freq dependent reactance

Exm = 734.591E-03 Xem=Kxm*(2*pi*f)^Exm

Hi,

A couple of questions for any Synergy Akabak guru's out there:

1. I have noticed in many of the Synergy scripts out there that people have added a small rear chamber to the script to cater for the closed back drivers. e.g.:

I am wondering if these should be included in the scripts given that the drivers' T/S parameters have already been measured with the effects of the rear chamber present.

Do you think this needs to be in the script? I assume not.

2. Regarding the wiring of multiple drivers (parallel/series). In HornResp this is easy as you can specify the number of Parallel and Series drivers (for example the wiring of the 4 midrange is 2 groups connected in parallel both containing two drivers in series).

How do you do this in Akabak as it is important to be able to determine power handling?

Thanks,

Mike

A couple of questions for any Synergy Akabak guru's out there:

1. I have noticed in many of the Synergy scripts out there that people have added a small rear chamber to the script to cater for the closed back drivers. e.g.:

Code:

Enclosure 'Mid Rear Chamber A' Node=60 Vb=1.8L Lb=5cmDo you think this needs to be in the script? I assume not.

2. Regarding the wiring of multiple drivers (parallel/series). In HornResp this is easy as you can specify the number of Parallel and Series drivers (for example the wiring of the 4 midrange is 2 groups connected in parallel both containing two drivers in series).

How do you do this in Akabak as it is important to be able to determine power handling?

Thanks,

Mike

Hi Keto

Hey I found one of the old Lambda Unity horns in a pile of old stuff this weekend. We used the same wood parts back then but Nick filed his corners in with bondo (nice job too) but that made our version and his behave slightly differently. Since I base the crossovers on the measured responses, what I could help with, would not been much help with your horn.

As the horn you have is the one that Lambda supplied and I found one here, I can put a 4550 on the one I found and measure it and maybe help with a suggestion for a crossover.

Fwiw, the mid measurements look (to me) like they might be noise limited.

I don’t recognize the software off hand but I would suggest trying a couple things.

First, sequence based systems in spite of claims can be very susceptible to noise.

Noise intrusion can make sharp features like those between 100 and 200 Hz as well as sharp peaks in systems which cannot easily produce them (such as a system with an acoustic low pass filter). I would suggest a couple things;

Average a number of measurements until one can see a clean response to say -30dB down from the flat part on the low corner side.

A typical appearance for noise is to produce a deep notch below the low corner and then appears as free bass response. Do the measurement so that the mic to speaker distance is at least 1/3 of the distance to any reflection. Have the microphone far enough away from the speaker so that you are not in the mouth bubble (at least 3X to 5X the mouth size). What happens in front of a speaker is a little more complicated than assumed if one wants accurate measurements.

A view of that problem;

http://community.klipsch.com/forums/storage/3/550738/FarFieldCriteriaLdspkrBalloonData.pdf

Lastly, some smoothing is desirable as ones ears have a “critical bandwidth” which is approximately 1/5 or 1/6 octave wide thus 1/6 or 1/10 octave smoothing shows more than what you can hear under the best case.

Best,

Tom

Fwiw Mike, we did use a sealed back cover like the one you show (but not having the cylindrical section) on our first Unity speakers in the way old days. That works just fine but soft domes are not usually a good bet because they are not a piston above some point (a damped traveling wave in the dome) while a hard dome would be fine (as long as it’s breakup is well above the acoustic low pass corner).

Good stuff guys, your letting what you measure point the direction.

Best,

Tom Danley

Hey I found one of the old Lambda Unity horns in a pile of old stuff this weekend. We used the same wood parts back then but Nick filed his corners in with bondo (nice job too) but that made our version and his behave slightly differently. Since I base the crossovers on the measured responses, what I could help with, would not been much help with your horn.

As the horn you have is the one that Lambda supplied and I found one here, I can put a 4550 on the one I found and measure it and maybe help with a suggestion for a crossover.

Fwiw, the mid measurements look (to me) like they might be noise limited.

I don’t recognize the software off hand but I would suggest trying a couple things.

First, sequence based systems in spite of claims can be very susceptible to noise.

Noise intrusion can make sharp features like those between 100 and 200 Hz as well as sharp peaks in systems which cannot easily produce them (such as a system with an acoustic low pass filter). I would suggest a couple things;

Average a number of measurements until one can see a clean response to say -30dB down from the flat part on the low corner side.

A typical appearance for noise is to produce a deep notch below the low corner and then appears as free bass response. Do the measurement so that the mic to speaker distance is at least 1/3 of the distance to any reflection. Have the microphone far enough away from the speaker so that you are not in the mouth bubble (at least 3X to 5X the mouth size). What happens in front of a speaker is a little more complicated than assumed if one wants accurate measurements.

A view of that problem;

http://community.klipsch.com/forums/storage/3/550738/FarFieldCriteriaLdspkrBalloonData.pdf

Lastly, some smoothing is desirable as ones ears have a “critical bandwidth” which is approximately 1/5 or 1/6 octave wide thus 1/6 or 1/10 octave smoothing shows more than what you can hear under the best case.

Best,

Tom

Fwiw Mike, we did use a sealed back cover like the one you show (but not having the cylindrical section) on our first Unity speakers in the way old days. That works just fine but soft domes are not usually a good bet because they are not a piston above some point (a damped traveling wave in the dome) while a hard dome would be fine (as long as it’s breakup is well above the acoustic low pass corner).

Good stuff guys, your letting what you measure point the direction.

Best,

Tom Danley

It is a place holder. Mainly, for the use of open back drivers.Hi,

A couple of questions for any Synergy Akabak guru's out there:

1. I have noticed in many of the Synergy scripts out there that people have added a small rear chamber to the script to cater for the closed back drivers. e.g.:

I am wondering if these should be included in the scripts given that the drivers' T/S parameters have already been measured with the effects of the rear chamber present.Code:Enclosure 'Mid Rear Chamber A' Node=60 Vb=1.8L Lb=5cm

Do you think this needs to be in the script? I assume not.

With a factory closed back driver you can remove it, or make it infinity large.

In Akabak you do this by adding the correct number of drivers into the script, and then connecting their nodes together into whatever configuration you need.2. Regarding the wiring of multiple drivers (parallel/series). In HornResp this is easy as you can specify the number of Parallel and Series drivers (for example the wiring of the 4 midrange is 2 groups connected in parallel both containing two drivers in series).

How do you do this in Akabak as it is important to be able to determine power handling?

Thanks,

Mike

Hi,

A couple of questions for any Synergy Akabak guru's out there:

1. I have noticed in many of the Synergy scripts out there that people have added a small rear chamber to the script to cater for the closed back drivers. e.g.:

I am wondering if these should be included in the scripts given that the drivers' T/S parameters have already been measured with the effects of the rear chamber present.Code:Enclosure 'Mid Rear Chamber A' Node=60 Vb=1.8L Lb=5cm

Do you think this needs to be in the script? I assume not.

2. Regarding the wiring of multiple drivers (parallel/series). In HornResp this is easy as you can specify the number of Parallel and Series drivers (for example the wiring of the 4 midrange is 2 groups connected in parallel both containing two drivers in series).

How do you do this in Akabak as it is important to be able to determine power handling?

Thanks,

Mike

The easiest way for me to figure out how to do series-parallel in Akabak was by doing a series-parallel wiring scheme in hornresp, then exporting it to Akabak

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn.