Sorry mate, not got round to checking it yet, will do very soon!

About that bracing, it's apparently a good idea to let the bass driver press firmly against the bracing, to support/couple it. Just make sure the voice coil/magnet vent has some space around it

Also, it might or might not be worth applying some blue tac or bitumen to the driver frame, if you have some lying around.

-Simon

About that bracing, it's apparently a good idea to let the bass driver press firmly against the bracing, to support/couple it. Just make sure the voice coil/magnet vent has some space around it

Also, it might or might not be worth applying some blue tac or bitumen to the driver frame, if you have some lying around.

-Simon

SimontY said:Sorry mate, not got round to checking it yet, will do very soon!

About that bracing, it's apparently a good idea to let the bass driver press firmly against the bracing, to support/couple it. Just make sure the voice coil/magnet vent has some space around it

Also, it might or might not be worth applying some blue tac or bitumen to the driver frame, if you have some lying around.

-Simon

no rush

oh, ill put that into the design.

ill try that, isnt that called mass loading or summat.

Right, just got it out of the attic and tested it. It works fine, so it's sitting in it's box waiting for a new home now. It is an Eminence Beta 15a - I wonder if there is a newer revision, as this is the better part of 3 yrs old now...

Btw 98db efficiency somehow seems a tad optimistic - when playing from my amp in it's box it makes about as much sound as my 91db speakers. However, our ears are most sensitive to frequencies ~1-5khz - which is probably a tad high for a 15" to make. So I've just made my argument void

-Simon

Btw 98db efficiency somehow seems a tad optimistic - when playing from my amp in it's box it makes about as much sound as my 91db speakers. However, our ears are most sensitive to frequencies ~1-5khz - which is probably a tad high for a 15" to make. So I've just made my argument void

-Simon

Mass loading is adding ballast/mass to stuff like speaker enclosures I believe. Maybe this isn't quite the same idea, maybe it is. Works though I reckon. With the bracing, get as much contact area between sides as possible. I've seen people making braces from piddly pieces of wood, because it's easy, but I doubt the effectiveness of this. What you had in your pic looks right, like a scaled down version of B&W's "Matrix" bracing, or the Andromeda on www.speakerbuilding.com

However, one thing I'd make sure of is getting a slightly different distance between each set of braces, just in case standing waves have a part to play, though the wavelengths should be way too long to propogate standing waves, right?

Another thing to try is using gasket tape or blue tac between the driver and cabinet, though you'd probably already thought of that one...

-Simon

However, one thing I'd make sure of is getting a slightly different distance between each set of braces, just in case standing waves have a part to play, though the wavelengths should be way too long to propogate standing waves, right?

Another thing to try is using gasket tape or blue tac between the driver and cabinet, though you'd probably already thought of that one...

-Simon

SimontY said:Right, just got it out of the attic and tested it. It works fine, so it's sitting in it's box waiting for a new home now. It is an Eminence Beta 15a - I wonder if there is a newer revision, as this is the better part of 3 yrs old now...

Btw 98db efficiency somehow seems a tad optimistic - when playing from my amp in it's box it makes about as much sound as my 91db speakers. However, our ears are most sensitive to frequencies ~1-5khz - which is probably a tad high for a 15" to make. So I've just made my argument void

-Simon

cool.

SimontY said:Mass loading is adding ballast/mass to stuff like speaker enclosures I believe. Maybe this isn't quite the same idea, maybe it is. Works though I reckon. With the bracing, get as much contact area between sides as possible. I've seen people making braces from piddly pieces of wood, because it's easy, but I doubt the effectiveness of this. What you had in your pic looks right, like a scaled down version of B&W's "Matrix" bracing, or the Andromeda on www.speakerbuilding.com

However, one thing I'd make sure of is getting a slightly different distance between each set of braces, just in case standing waves have a part to play, though the wavelengths should be way too long to propogate standing waves, right?

Another thing to try is using gasket tape or blue tac between the driver and cabinet, though you'd probably already thought of that one...

-Simon

i have no idea about bracing, and my drawing was just the first idea that popped into my head. is bracing usually done with small pieces of wood between the sides of the box? looking at the Andromeda, should i use smaller holes, and have more of them? should i only leave ~50mm at the edges (of each brace (enlarging the hole to a rectangel))?

For sealed, you're right, but vented is a different story. Both work best in ~15.3ft^3, but the Delta is 3-4dB louder across the BW since it can linearly handle ~100W Vs the Beta's ~40W down low and has wider dynamic range up where it counts, in the midbass due to its higher power handling capability.

GM

GM

GM said:For sealed, you're right, but vented is a different story. Both work best in ~15.3ft^3, but the Delta is 3-4dB louder across the BW since it can linearly handle ~100W Vs the Beta's ~40W down low and has wider dynamic range up where it counts, in the midbass due to its higher power handling capability.

GM

kelticwizard said:Matttcattt:

Your graphs for the vented box are for a cubic meter. Do you really plan to build a box that is 6 Ft tall by 3 Ft wide by 2 Ft deep?

The 13 Ft³ enclosure we were talking about itself is considered enormous.

maybe not that big.

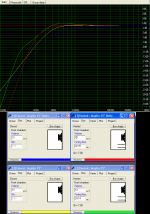

i have re-done the graph using 13Ft cubed boxes.

the Beta in a vented enclosure still beats the Delta...

Attachments

Matttcattt:

The Delta and Beta have identical F3's. For that matter, they both have identical F2's, F4's, and F5's as well.

The "advantage" of the Beta lies in a region that is below the passband. Generally, you can count on little good output in a vented box below the tuning frequency, which in our case will be 30 Hz.

The visual advantage of the Beta from 22 Hz on down just does not translate into any advantage in real-world performance.

Besides, these simulation programs are great, but they are only general guides. The fact is that there are going to be a variation in the specs from the printed specs, and even variation from driver to driver from the same batch. The simulations you see are merely meant to be a ballpark idea of what you can expect. Taking the comparison this far is a mistake.

The Delta and Beta have identical F3's. For that matter, they both have identical F2's, F4's, and F5's as well.

The "advantage" of the Beta lies in a region that is below the passband. Generally, you can count on little good output in a vented box below the tuning frequency, which in our case will be 30 Hz.

The visual advantage of the Beta from 22 Hz on down just does not translate into any advantage in real-world performance.

Besides, these simulation programs are great, but they are only general guides. The fact is that there are going to be a variation in the specs from the printed specs, and even variation from driver to driver from the same batch. The simulations you see are merely meant to be a ballpark idea of what you can expect. Taking the comparison this far is a mistake.

Matttcattt,

All this talk of Delta vs. Beta is null and void, because you are getting a free Beta.

When you get bored of it and want some serious lows, then you can start looking at high excursion drivers, big amps, and smaller boxes.

Also, surely when you were comparing the two drivers in a sealed box, you noticed the Delta had a very low Q, compared to the Beta's medium Q. This 'Q' defines the tightness/damping of the bass. This means in a 500l box the Beta would have 'correct' sounding bass, [with 0.71 iirc]. The Delta would sound undernourished in that big a box I believe, and there is it's big advantage: it could work well in a much smaller box (270l) ie. 1/2 the size.

Personally with this Beta, I would try a sealed 250l box with loads of stuffing to get the volume up a tad. If you can get 3-6db of boost at about 30-35hz, as on many plate amps, this might turn out ok. Vented would be massive, and probably make very muddy and distorted bass. (Your mother would surely go ape over a 700 litre cabinet!)

Feel free to e-mail me about the cost etc. of sending this thing, I don't know its weight or how you want it sending...

-Simon

All this talk of Delta vs. Beta is null and void, because you are getting a free Beta.

When you get bored of it and want some serious lows, then you can start looking at high excursion drivers, big amps, and smaller boxes.

Also, surely when you were comparing the two drivers in a sealed box, you noticed the Delta had a very low Q, compared to the Beta's medium Q. This 'Q' defines the tightness/damping of the bass. This means in a 500l box the Beta would have 'correct' sounding bass, [with 0.71 iirc]. The Delta would sound undernourished in that big a box I believe, and there is it's big advantage: it could work well in a much smaller box (270l) ie. 1/2 the size.

Personally with this Beta, I would try a sealed 250l box with loads of stuffing to get the volume up a tad. If you can get 3-6db of boost at about 30-35hz, as on many plate amps, this might turn out ok. Vented would be massive, and probably make very muddy and distorted bass. (Your mother would surely go ape over a 700 litre cabinet!)

Feel free to e-mail me about the cost etc. of sending this thing, I don't know its weight or how you want it sending...

-Simon

kelticwizard said:Matttcattt:

The Delta and Beta have identical F3's. For that matter, they both have identical F2's, F4's, and F5's as well.

The "advantage" of the Beta lies in a region that is below the passband. Generally, you can count on little good output in a vented box below the tuning frequency, which in our case will be 30 Hz.

The visual advantage of the Beta from 22 Hz on down just does not translate into any advantage in real-world performance.

Besides, these simulation programs are great, but they are only general guides. The fact is that there are going to be a variation in the specs from the printed specs, and even variation from driver to driver from the same batch. The simulations you see are merely meant to be a ballpark idea of what you can expect. Taking the comparison this far is a mistake.

so the beta is no better in real life?

SimontY said:Matttcattt,

All this talk of Delta vs. Beta is null and void, because you are getting a free Beta.

When you get bored of it and want some serious lows, then you can start looking at high excursion drivers, big amps, and smaller boxes.

Also, surely when you were comparing the two drivers in a sealed box, you noticed the Delta had a very low Q, compared to the Beta's medium Q. This 'Q' defines the tightness/damping of the bass. This means in a 500l box the Beta would have 'correct' sounding bass, [with 0.71 iirc]. The Delta would sound undernourished in that big a box I believe, and there is it's big advantage: it could work well in a much smaller box (270l) ie. 1/2 the size.

Personally with this Beta, I would try a sealed 250l box with loads of stuffing to get the volume up a tad. If you can get 3-6db of boost at about 30-35hz, as on many plate amps, this might turn out ok. Vented would be massive, and probably make very muddy and distorted bass. (Your mother would surely go ape over a 700 litre cabinet!)

Feel free to e-mail me about the cost etc. of sending this thing, I don't know its weight or how you want it sending...

-Simon

ok

Matttcattt:

Both the Beta and the Delta will produce similar results when their specs are graphed. If their specs hold up in the world, they will produce similar results when placed in a 13 Ft³ box.

The advantage of the Delta is that extended core which prevents the lopping off of the wave form near resonance. That is very necessary for good sound reproduction. The sealed boxes cut off way too high to qualify as "subwoofers".

Also, the Delta has a 50% bigger magnet than the Beta-56oz versus 38 oz-and a longer excursion as well.

Let me mention again that the Delta has a maximum excursion of 1 inch each way. Granted it is non linear, but when given sufficient push it will move that air. That is a lot of air, especially when you port the speaker.

As far as the talk of the Delta being "null and void", that is up to you. You might decide to try the free Beta and see how it sounds and if it is unsatisfactory, try the Delta. Or you might try something else. Or you might use the Beta for another project. As I see it, the goal of this project was to build a subwoofer using a high SPL speaker. Most subs are inefficient, but you wanted high SPL and were not fussy about audiophile measurements. Most PA systems do not go down to 30 Hz, as the size of this cabinet makes clear. This rather large cabinet should go down that low.

So I don't think the Delta is necessariy out of the running. I think it is basically up to you.

Both the Beta and the Delta will produce similar results when their specs are graphed. If their specs hold up in the world, they will produce similar results when placed in a 13 Ft³ box.

The advantage of the Delta is that extended core which prevents the lopping off of the wave form near resonance. That is very necessary for good sound reproduction. The sealed boxes cut off way too high to qualify as "subwoofers".

Also, the Delta has a 50% bigger magnet than the Beta-56oz versus 38 oz-and a longer excursion as well.

Let me mention again that the Delta has a maximum excursion of 1 inch each way. Granted it is non linear, but when given sufficient push it will move that air. That is a lot of air, especially when you port the speaker.

As far as the talk of the Delta being "null and void", that is up to you. You might decide to try the free Beta and see how it sounds and if it is unsatisfactory, try the Delta. Or you might try something else. Or you might use the Beta for another project. As I see it, the goal of this project was to build a subwoofer using a high SPL speaker. Most subs are inefficient, but you wanted high SPL and were not fussy about audiophile measurements. Most PA systems do not go down to 30 Hz, as the size of this cabinet makes clear. This rather large cabinet should go down that low.

So I don't think the Delta is necessariy out of the running. I think it is basically up to you.

kelticwizard said:Matttcattt:

Both the Beta and the Delta will produce similar results when their specs are graphed. If their specs hold up in the world, they will produce similar results when placed in a 13 Ft³ box.

The advantage of the Delta is that extended core which prevents the lopping off of the wave form near resonance. That is very necessary for good sound reproduction. The sealed boxes cut off way too high to qualify as "subwoofers".

Also, the Delta has a 50% bigger magnet than the Beta-56oz versus 38 oz-and a longer excursion as well.

Let me mention again that the Delta has a maximum excursion of 1 inch each way. Granted it is non linear, but when given sufficient push it will move that air. That is a lot of air, especially when you port the speaker.

As far as the talk of the Delta being "null and void", that is up to you. You might decide to try the free Beta and see how it sounds and if it is unsatisfactory, try the Delta. Or you might try something else. Or you might use the Beta for another project. As I see it, the goal of this project was to build a subwoofer using a high SPL speaker. Most subs are inefficient, but you wanted high SPL and were not fussy about audiophile measurements. Most PA systems do not go down to 30 Hz, as the size of this cabinet makes clear. This rather large cabinet should go down that low.

So I don't think the Delta is necessariy out of the running. I think it is basically up to you.

ok, thanks for all the advice. any advice for bracing?

Bracing? You might want to make that a separate thread. I have never built a box as large as 13 Ft³.

One thing I do know. If you are not going to build a cubic box-if you are going to have a long side-the bracing should be along the longest side. In other words, if a panel is 6 Ft by 2 Ft, don't bisect the panel and make it two 3 Ft by 2 Ft sections. Rather, take a long brace and make it two 6 Ft by 1 Ft sections.

It has been shown that is the best bracing.

One thing I do know. If you are not going to build a cubic box-if you are going to have a long side-the bracing should be along the longest side. In other words, if a panel is 6 Ft by 2 Ft, don't bisect the panel and make it two 3 Ft by 2 Ft sections. Rather, take a long brace and make it two 6 Ft by 1 Ft sections.

It has been shown that is the best bracing.

>One thing I do know. If you are not going to build a cubic bos-if you are going to have a long side-the bracing whould be along the longest side. In other words, if a panel is 6 Ft by 2 Ft, don't bisect the panel and make it two 3 Ft by 2 Ft sections. Rather, take a long brace and make it two 6 Ft by 1 Ft sections.

>It has been shown that is the best bracing.

====

Hmm, can't say as I agree with this. The majority of speaker cabs I've built have been fairly large, up to 40ft^3, with my current speakers being 20ft^3. If you study structural engineering or just look at a beam truss or bridge's construction, you'll see that triangulation is best since it offers the greatest stiffness by dividing a panel into a highly damped shape. As you note, dividing panels up into a series of unequal areas (golden ratio triangulation works well), then further triangulating the large 'panels' works extremely well. Note that none of the stiffeners should touch another or terminate at a corner/joint (leave a gap) since this creates a high pressure point where resonances can sum. I use whatever no-void plywood scraps I have laying around for stiffeners, they just need to be a few inches wide and glued on edge. Increasing stiffness by using at least 3/4" thick 13 ply no-void Baltic Birch or equal is an expensive, but major plus since it raises any resonances up to where the cab's mass can effectively damp them. FWIW, mine are made with 3/4" marine grade plywood from back when it was guaranteed no-void and dual 15" driven to Xsus doesn't vibrate over a nickel stood on edge.

Cabs designed for LF reproduction need to have all their sides tied to each other so that it can't 'breathe'. I prefer 2x4s or large closet pole hardwood dowels since they're easy to work with and cheap. Smaller cabs, I use 2x2s or smaller dowels. Just depends on what's laying around or on sale. The previously shown 'X' panel bracing works well, but a large cab needs two or more and they impede air flow in the cab to a greater or lesser extent depending on design, and are more work to make.

The previously shown 'X' panel bracing works well, but a large cab needs two or more and they impede air flow in the cab to a greater or lesser extent depending on design, and are more work to make.

Another concern when a cab's dimensions become large enough that standing waves can develop within its intended BW is its aspect ratio and where the driver(s) are located. A golden ratio cab is the smoothest overall since all its modes are averaged out, allowing the driver(s)/vent (if used) to be positioned most anywhere. This can make for a very obstrusive design though, so making it tall to keep the 'footprint' within reason requires that attention be paid to the driver(s)/vent location if used much beyond 100hz. I learned how to figure it out through experimentation, but now, MJK's MLTQWT or ported spreadsheet makes finding the optimum a quick/simple task.

Anyway, following these simple rules will net you a stiff/well damped (and heavy) cab that won't audibly 'color' the music.

GM

>It has been shown that is the best bracing.

====

Hmm, can't say as I agree with this. The majority of speaker cabs I've built have been fairly large, up to 40ft^3, with my current speakers being 20ft^3. If you study structural engineering or just look at a beam truss or bridge's construction, you'll see that triangulation is best since it offers the greatest stiffness by dividing a panel into a highly damped shape. As you note, dividing panels up into a series of unequal areas (golden ratio triangulation works well), then further triangulating the large 'panels' works extremely well. Note that none of the stiffeners should touch another or terminate at a corner/joint (leave a gap) since this creates a high pressure point where resonances can sum. I use whatever no-void plywood scraps I have laying around for stiffeners, they just need to be a few inches wide and glued on edge. Increasing stiffness by using at least 3/4" thick 13 ply no-void Baltic Birch or equal is an expensive, but major plus since it raises any resonances up to where the cab's mass can effectively damp them. FWIW, mine are made with 3/4" marine grade plywood from back when it was guaranteed no-void and dual 15" driven to Xsus doesn't vibrate over a nickel stood on edge.

Cabs designed for LF reproduction need to have all their sides tied to each other so that it can't 'breathe'. I prefer 2x4s or large closet pole hardwood dowels since they're easy to work with and cheap. Smaller cabs, I use 2x2s or smaller dowels. Just depends on what's laying around or on sale.

Another concern when a cab's dimensions become large enough that standing waves can develop within its intended BW is its aspect ratio and where the driver(s) are located. A golden ratio cab is the smoothest overall since all its modes are averaged out, allowing the driver(s)/vent (if used) to be positioned most anywhere. This can make for a very obstrusive design though, so making it tall to keep the 'footprint' within reason requires that attention be paid to the driver(s)/vent location if used much beyond 100hz. I learned how to figure it out through experimentation, but now, MJK's MLTQWT or ported spreadsheet makes finding the optimum a quick/simple task.

Anyway, following these simple rules will net you a stiff/well damped (and heavy) cab that won't audibly 'color' the music.

GM

GM:

Yes, you make great points.

As for the long brace for the 6' X 2' panels, let me explain.

I meant what is the best way to brace a 6' X 2' panel if all you have is horizontal or vertical bracing.

Strength comes from having any given area as close to a brace as possible.

I think we can count the corners as braces. So that 6' X 2' panel actually will have 3 braces-the one down the middle, plus the lengthwise ones at the ends where it joins the other pieces.

If you take that 6' X 2" panel, and bisect it so that becomes two 3' X 2" sections, then the middle of each panel has a whole area that is 1 foot away from a brace. The farther away from a brace, the weaker and the more likely to flex.

If you take that 6' X 2' panel and run a brace the entire 6' length, you have stiffened the panel more. With two 6' X 1' sections, there is no spot on that panel where a brace is farther away than 6 inches. This is a great improvement over the cross brace that divides the panel up into 3' X 2' sections.

Of course, X bracing and the other things you mentioned are great. I was talking about one brace.

I should add that the latest thinking is not to divide panels in half. So the lengthwise 6' brace should divide the panels up into something like 13" and 11", instead of 12" and 12".

Yes, you make great points.

As for the long brace for the 6' X 2' panels, let me explain.

I meant what is the best way to brace a 6' X 2' panel if all you have is horizontal or vertical bracing.

Strength comes from having any given area as close to a brace as possible.

I think we can count the corners as braces. So that 6' X 2' panel actually will have 3 braces-the one down the middle, plus the lengthwise ones at the ends where it joins the other pieces.

If you take that 6' X 2" panel, and bisect it so that becomes two 3' X 2" sections, then the middle of each panel has a whole area that is 1 foot away from a brace. The farther away from a brace, the weaker and the more likely to flex.

If you take that 6' X 2' panel and run a brace the entire 6' length, you have stiffened the panel more. With two 6' X 1' sections, there is no spot on that panel where a brace is farther away than 6 inches. This is a great improvement over the cross brace that divides the panel up into 3' X 2' sections.

Of course, X bracing and the other things you mentioned are great. I was talking about one brace.

I should add that the latest thinking is not to divide panels in half. So the lengthwise 6' brace should divide the panels up into something like 13" and 11", instead of 12" and 12".

Right, I understand and agree. All I'm saying is that the one long brace should be diagonal, and that it be offset so the two 'panels' can't complement each other. Further triangulating these two large areas into smaller ones of various sizes will dramatically stiffen it up. A diagonal brace also damps the potential TL modes that could occur in your two long parallel 'lines'.

It's not that what you propose is ineffective, quite the contrary, just that triangulation is superior to what you proposed as 'best'.

GM

It's not that what you propose is ineffective, quite the contrary, just that triangulation is superior to what you proposed as 'best'.

GM

GM said:Note that none of the stiffeners should touch another or terminate at a corner/joint (leave a gap) since this creates a high pressure point where resonances can sum.

GM

Hi GM, all

When using shelf braces should I make cutouts

so the shelf braces don't touch the corners of the speaker cabs?

Or each other?

Thanks

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Sub woofer questions