When I had a Lotus (Elan +2), we used to joke about over-weight Corvettes. Heavy wheels need heavier motors which need heavier frames, which need....

Keeping an eye on the ball and thinking only of playing music cleanly at home, seems to me there is no serious question that the ideal is to move towards lighter cones (ultimately electrostatic films) which require more flexible suspensions....

Sure, it is a system and you can cook up other bodies of parameters that look nice when modeled, but for most enclosures and purposes, hard not to prefer quality drivers with light cones and flexible suspensions.

Ben

Keeping an eye on the ball and thinking only of playing music cleanly at home, seems to me there is no serious question that the ideal is to move towards lighter cones (ultimately electrostatic films) which require more flexible suspensions....

Sure, it is a system and you can cook up other bodies of parameters that look nice when modeled, but for most enclosures and purposes, hard not to prefer quality drivers with light cones and flexible suspensions.

Ben

My good friend, this is not quite true. These drivers are designed from the ground up to perform at extremely high input levels. This means that focusing only on the suspension is a bit incomplete. The electrical parameters are of paramount importance. You have thick gauge, large diameter voice coils with extensive venting. Motor structures thus yielding 10s of teslameters of BL. Now, acoustics comes back to the same fundamental priciples as Newtonian physics, namely, his second law of motion: F=ma. In our case, a is the change in cone velocity with respect to time. Greater change in cone velocity = greater acceleration, and thus with fixed mass, equals greater force. The converse is what we're interested in: high SPL is not generated simply by displacement and surface area. If it were, a 10" radioshack driver moving 5mm one way would produce the same SPL level as 10" car audio subwoofer moving 5mm one way. What causes the difference is the force applied. I don't know if you've done any electrical - mechanical - acoustic transformation diagrams. Here is one below in my preferred mobility configuration:Thanks for you reply Mr. Sidewinder18x.

With all due respects to you sir, I still am not finding proof in your(or anybody else) statement that stiff suspension allows higher power handling capabilities. It remains an unsubstantiated statement. While in the real world, I find proof of the reverse. Two drivers(one stiff and other correct suspension rate) fed with same amount of power, the second one will make more sound!!!! If you do not want it to get damaged, then use stronger materials(and stronger does not have to mean heavy). This is about max power capability which I was not interested in discussing. I wanted to talk about quality of sound. The OP too wanted that.

And I will not accept it if you say physics behaves different in the manufacturing world. If it behaves different then I am missing some parameters in my evaluation and you are not disclosing those extra parameters. I do not think there is some 'super secret' deference between stiff and loose suspension drivers.

But I will go away now to take care of my other tasks. I think it would be appropriate to discuss this topic outside this thread at a later time, so that it doesn’t get hijacked and the OP gets his dilemma cleared by experts. I will invite you and others to that thread. And it would be better if it is in written form rather than discussing on the telephone. But thanks for your number, I would like to meet you some day to gain more insight into the loudspeaker industry.

I would close my comments with this post directed towards the OP. According to me, you should be selecting a driver with high compliance and low moving mass values. Only then you will get the correct/near correct sound without expending energy unnecessarily.

An externally hosted image should be here but it was not working when we last tested it.

What this is saying is that the input voltage and current pass through a transformer to become input force and velocity respectively. That transformer is the motor, which in this case, is represented by the motor force product of Bl * I, where I is the input current from the source and Bl is specified as in T/S parameters. As Bl is fixed, the higher input current, the more force that is passed along to the mechanical portion of the diagram.

After being applied to the mechanical mass, compliance and resistive losses, the same force and velocity become transformed again into pressure and volume velocity respectively. This new transformer is the cone surface area, which we know as Sd.

Thus, going through the entire circuit: high output pressure and volume velocity requires high input force. High input force requires high input current. Therefore, in order to get to the high output pressure, the middle portion must be able to effectively transfer the high input force to the cone. That requires a suspension and mass system able to deal with the huge amount of force applied to it via the huge amount of input power (via huge input current). Looking at the middle portion of the diagram, if you have a suspension which is stiffer, and a cone which is more massive, you have a more effective transducer of electrical input to acoustic output.

Long story short: yes, high output car audio subwoofers handle more power not because their suspensions are stiffer, but because they need said stiffer suspensions to transfer the high amount of input force generated by high input power to the air by moving the cone at higher velocities without failure. All of this is possible because the motor assembly and hence the voice coil is designed to also handle huge amounts of input power. As said previously: it all works as a system.

Hope this helps

+1... as far as lemans23 goes.

But the multiply configurable driver system he correctly characterizes also connects at both ends to other systems with their own constraints (amplifiers at one end, enclosures in the middle, and esp. heavy cones meeting thin air at the other end). And then there are the limits of materials, precision of gaps, shipping drivers on trucks, and so on.

Ben

But the multiply configurable driver system he correctly characterizes also connects at both ends to other systems with their own constraints (amplifiers at one end, enclosures in the middle, and esp. heavy cones meeting thin air at the other end). And then there are the limits of materials, precision of gaps, shipping drivers on trucks, and so on.

Ben

Last edited:

As said previously: it all works as a system.

Hope this helps

Excellent explanation. Thanks for backing up what I had said in post #3, lol.

Correct me if I'm wrong, I thought stiffer suspension, heavy cone and low fs meant for a smaller vas?

So, if you want lower bass from a small subwoofer enclosure, use a stiff heavy cone.

I maybe wrong though.

You have the correct general idea, but it is all about compromises as it is all one vicious circle that revolves around sensitivity, low bass extension, and box size requirements. What works well for one person will not be ideal for the next person. Hence why the system needs to be viewed as a whole and treated on a case by case basis for the end user.

@Lemans23

I had typed a really long reply but deleted it and hence spared you all some boredom Besides my professor used to say that Indians kiss hands a lot so I am going to be direct here, I hope I dont come across as a rude person. If I am please do correct me sternly!

Besides my professor used to say that Indians kiss hands a lot so I am going to be direct here, I hope I dont come across as a rude person. If I am please do correct me sternly!

As a disclaimer....

"This means that focusing only on the suspension is a bit incomplete."

Lets assume everything else to be perfect. Simplicity will fetch you an approximate answer faster. And There is only one goal to be met...Quality sound. High SPL spouting 'NOISE'/mangled waveform is of no use to anybody.

The most important point of all...

"That requires a suspension and mass system able to deal with the huge amount of force..................if you have a suspension which is stiffer, and a cone which is more massive, you have a more effective transducer..."

Why do you call it more 'EFFECTIVE' transducer? Just because it as more capacity to transfer force by being heavy, do you think it doesnt have side effects?

I have explained this earlier but I will do it again....using different words. You are saying the same things again and I will ask you the same question again!

In the LeMans 24 hr endurance race, I would like to be driving a car which is light yet strong and will make it to the finish line in one piece. Most probably that would be a Porsche or an Audi-quattro. But I can never imagine myself driving a Rolls Royce. I still can, but only after modifying it to take care of all the extra moments and swaying born out of extra weight. And just think how much extra fuel/power is needed to propel that car! But is that drudgery really needed? Just make the car lighter and some problems automatically disappear. Please note that lighter doesnt mean weaker!

In the field of acoustics, the most important thing of all is SPEED! If there is a small sine wave in the recording then the driver has to reproduce it in the same way but in scaled up size. And this means it has to cover more ground in the same time, which means it has to accelerate faster and reverse faster. The faster it vibrates, the more momentum it has and the bigger pain in the neck it becomes.

Make the cone heavier 'a bit' and according to ......

Monemtum=Mass * Velocity

.....the 'pain in the neck' gets multiplied several fold. And please note, by velocity we are talking about velocities of very high nature where even small masses generate super momentums! How do you reverse that much momentum in a so short span of time? It definitely is a tough problem to solve. Dont you agree to this??? A heavier cone and a stiffer suspension is akin to the old muscle cars in the USA which have been left in the dust by the new breed.

A very very good and useful and appropriate comparison to the driver is the piston in an IC engine. And I cannot for all the stars in this universe imagine someone telling me that a heavier cast iron piston would make the car behave the same way as a titanium one. Again it still can but it is no use going that route when titanium is available and somuch of momentum and extra chassis stress is taken care of. If titanium is expensive then there are alloys of aluminium but never go back to cast Iron pistons!!!

Why is everybody making the same mistake of saying high SPLs need heavier cones???? It definitely needs stronger cones but it does not need heavier...blah blah blah.

I had typed a really long reply but deleted it and hence spared you all some boredom

As a disclaimer....

"This means that focusing only on the suspension is a bit incomplete."

Lets assume everything else to be perfect. Simplicity will fetch you an approximate answer faster. And There is only one goal to be met...Quality sound. High SPL spouting 'NOISE'/mangled waveform is of no use to anybody.

The most important point of all...

"That requires a suspension and mass system able to deal with the huge amount of force..................if you have a suspension which is stiffer, and a cone which is more massive, you have a more effective transducer..."

Why do you call it more 'EFFECTIVE' transducer? Just because it as more capacity to transfer force by being heavy, do you think it doesnt have side effects?

I have explained this earlier but I will do it again....using different words. You are saying the same things again and I will ask you the same question again!

In the LeMans 24 hr endurance race, I would like to be driving a car which is light yet strong and will make it to the finish line in one piece. Most probably that would be a Porsche or an Audi-quattro. But I can never imagine myself driving a Rolls Royce. I still can, but only after modifying it to take care of all the extra moments and swaying born out of extra weight. And just think how much extra fuel/power is needed to propel that car! But is that drudgery really needed? Just make the car lighter and some problems automatically disappear. Please note that lighter doesnt mean weaker!

In the field of acoustics, the most important thing of all is SPEED! If there is a small sine wave in the recording then the driver has to reproduce it in the same way but in scaled up size. And this means it has to cover more ground in the same time, which means it has to accelerate faster and reverse faster. The faster it vibrates, the more momentum it has and the bigger pain in the neck it becomes.

Make the cone heavier 'a bit' and according to ......

Monemtum=Mass * Velocity

.....the 'pain in the neck' gets multiplied several fold. And please note, by velocity we are talking about velocities of very high nature where even small masses generate super momentums! How do you reverse that much momentum in a so short span of time? It definitely is a tough problem to solve. Dont you agree to this??? A heavier cone and a stiffer suspension is akin to the old muscle cars in the USA which have been left in the dust by the new breed.

A very very good and useful and appropriate comparison to the driver is the piston in an IC engine. And I cannot for all the stars in this universe imagine someone telling me that a heavier cast iron piston would make the car behave the same way as a titanium one. Again it still can but it is no use going that route when titanium is available and somuch of momentum and extra chassis stress is taken care of. If titanium is expensive then there are alloys of aluminium but never go back to cast Iron pistons!!!

Why is everybody making the same mistake of saying high SPLs need heavier cones???? It definitely needs stronger cones but it does not need heavier...blah blah blah.

Last edited:

@Lemans23:

Now coming to your diagram......It would have been better if you had presented the transfer function equations, I cannot write it by myself because it is an electrical representation and not a mechanical one with which I would have been familiar. Please present the equations here and kindly explain how, by increasing the mass, spring and damper values, you are creating a more effective transducer......or I will the present the mechanical representation here instead sometime soon. The equations will give you the answer instantly rather post ultra long explanations.

EDIT: I had closed it I thought but see again I get comments which I think are fundamentally wrong.......Ok tinitus, I thought it will make a significant difference to the quality of sound(and I did observe it in real also). But if the majority wants me to close it, let the majority win!

Now coming to your diagram......It would have been better if you had presented the transfer function equations, I cannot write it by myself because it is an electrical representation and not a mechanical one with which I would have been familiar. Please present the equations here and kindly explain how, by increasing the mass, spring and damper values, you are creating a more effective transducer......or I will the present the mechanical representation here instead sometime soon. The equations will give you the answer instantly rather post ultra long explanations.

EDIT: I had closed it I thought but see again I get comments which I think are fundamentally wrong.......Ok tinitus, I thought it will make a significant difference to the quality of sound(and I did observe it in real also). But if the majority wants me to close it, let the majority win!

Last edited:

Given any particular material to work with, heavier is stronger.Why is everybody making the same mistake of saying high SPLs need heavier cones???? It definitely needs stronger cones but it does not need heavier...blah blah blah.

Stronger and lighter always comes with a price premium which can be supported in the racing world, but less so in the world of consumer low frequency reproduction.

The more SPL required, the stiffer (stronger) the cone needs to be to avoid deformation and the attendant distortion as Xmax is increased.

The heavier the cone, the more magnetic force and electrical power needed to control it.

To achieve the same SPL and distortion one could choose to use more surface area using multiple light cones with less Xmax, or less surface area using a heavier cone with more Xmax to achieve the same displacement. Since enclosed volume of the cabinet is typically at a premium, the latter choice is generally preferred.

actually its quite cheap to make a strong carbon cone

use epoxy and bake it in an oven, and it hardens and gets very strong

if you know the process, the materials will cost a few dollar

problem is you cannot buy them in standard bundles

and if you have to pay a company to make them, forget about it

but thinking about it, such cones may not be that much lighter than paper coned

well, ok, I guess 200gr is a fair bit lighter than 500gr(half a kilo)

but you still struggle with the needed sturdy(and thus stiff) surround needed to support the cone at such large Xmax

so Fs may end being too high

EQ ? maybe

use epoxy and bake it in an oven, and it hardens and gets very strong

if you know the process, the materials will cost a few dollar

problem is you cannot buy them in standard bundles

and if you have to pay a company to make them, forget about it

but thinking about it, such cones may not be that much lighter than paper coned

well, ok, I guess 200gr is a fair bit lighter than 500gr(half a kilo)

but you still struggle with the needed sturdy(and thus stiff) surround needed to support the cone at such large Xmax

so Fs may end being too high

EQ ? maybe

I am not being rude. Sorry if I am, But unfortunately your assumption to what you think is correct is not happening@Lemans23:

Now coming to your diagram......It would have been better if you had presented the transfer function equations, I cannot write it by myself because it is an electrical representation and not a mechanical one with which I would have been familiar. Please present the equations here and kindly explain how, by increasing the mass, spring and damper values, you are creating a more effective transducer......or I will the present the mechanical representation here instead sometime soon. The equations will give you the answer instantly rather post ultra long explanations.

and are not taken into consideration by the loudspeaker industry.

In the real world, the fabrication will be based on the technology which is based on realist approach of developments and designs which are tested, approved and successful commercially and technically. Will be not based on assumption or personal opinions.

The electrical representation is the correct representation for the illustration.

It's very unfortunate that you do not understand it. How can some one translate that to simplify according to your style. You will have to do that yourself.

And again I apologize if I sounded harsh.

@tinitus: Even if you dont reduce weight much there is a possibility that you will improve rigidity. cone warping?

if you build a cone like I described it in post 52, but maintain the heavy weight, then you can run a big truck over it, and will still look like new without a scratch

@Everybody:

In my earlier posts I had advised the OP to go for a speaker having low moving mass and high compliance values. It remains just a statement so I want to present the following in support of it and in the process dispel myths. This post will also serve as good starting info for everybody wanting to choose a good driver, especially in India/Asia where there are overtly stiff locally made drivers available. I have encountered sub drivers which are so stiff that even 1/2 KG force on the cone will probably move all of 5mm. And then there was a driver manufacturer who tried to sell me a midrange by just replacing the plastic cone in a woofer with a paper cone(with suspension). So the situation here is a bit bleak. Use this to choose lesser of the evils. This post only concerns suspension compliance and moving mass. Other parts of the loudspeaker do affect the performance in an equal measure so please consult a concerned expert.

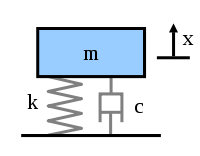

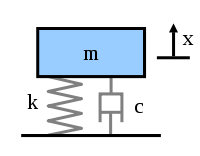

The best way to represent a loudspeaker is by a MASS-SPRING-DAMPER SYSTEM. It is represented as follows:

X=displacement of the loudspeaker cone.

K=Spring

C=Damper

Both K and C components are present in the surround and spider. The cone and the voice coil constitute the Mass denoted by M.

The Transfer function governing the force applied by the motor and displacement achieved by the cone is given by:

X(s)={1/(Ms2+Cs+K)}*F(s)...........It is simple dont get scared

X(s)=Laplace transform of the displacement. For simplicity take it as the displacement of cone.

F(s)=The laplace transform of the force applied by the motor.

1/(mass-spring-damper)=Denotes the cone+voice coil+surround+spider

ABOUT SPL

Take two similar drivers, (one with the correct damping and other stiff) and apply the above equation. As you can see, the stiffer and massive cone you have, the more force you have to apply to achieve the same displacement. In other words the same SPL!!!!!! Hence the lighter cone with correct damping will make more sound if the power applied to both is same. In short, the lighter one has higher efficiency so choose that.

ABOUT ACCURATE REPRODUCTION

The X(dotdot) is the acceleration of the cone. As you can see, increase the mass (C & K =constant) and you decrease the acceleration. No this does not mean lower SPL! This means you get a different waveform. See the graph below:

The cone must accelerate as and when needed/instantly. Any delays will change the waveform.i.e the sound you will hear. Thus for a under-damped subwoofer,read loose suspension(the OP's observation is right) the bass lingers on. For tight suspension, there will be less SPL (if the comparison is at same input power). If you damp it even more you start turning a woofer into a midrange driver. Critically damped=near correct damped system=accurate sound. Remember, an under-damped driver can be corrected by using a sealed cabinet but you cannot make a over-damped driver to loose its stiffness, i.e unless you break it open.

I hope I have explained my self clearly. Thank you for listening to me.

In my earlier posts I had advised the OP to go for a speaker having low moving mass and high compliance values. It remains just a statement so I want to present the following in support of it and in the process dispel myths. This post will also serve as good starting info for everybody wanting to choose a good driver, especially in India/Asia where there are overtly stiff locally made drivers available. I have encountered sub drivers which are so stiff that even 1/2 KG force on the cone will probably move all of 5mm. And then there was a driver manufacturer who tried to sell me a midrange by just replacing the plastic cone in a woofer with a paper cone(with suspension). So the situation here is a bit bleak. Use this to choose lesser of the evils. This post only concerns suspension compliance and moving mass. Other parts of the loudspeaker do affect the performance in an equal measure so please consult a concerned expert.

The best way to represent a loudspeaker is by a MASS-SPRING-DAMPER SYSTEM. It is represented as follows:

X=displacement of the loudspeaker cone.

K=Spring

C=Damper

Both K and C components are present in the surround and spider. The cone and the voice coil constitute the Mass denoted by M.

The Transfer function governing the force applied by the motor and displacement achieved by the cone is given by:

X(s)={1/(Ms2+Cs+K)}*F(s)...........It is simple dont get scared

X(s)=Laplace transform of the displacement. For simplicity take it as the displacement of cone.

F(s)=The laplace transform of the force applied by the motor.

1/(mass-spring-damper)=Denotes the cone+voice coil+surround+spider

ABOUT SPL

Take two similar drivers, (one with the correct damping and other stiff) and apply the above equation. As you can see, the stiffer and massive cone you have, the more force you have to apply to achieve the same displacement. In other words the same SPL!!!!!! Hence the lighter cone with correct damping will make more sound if the power applied to both is same. In short, the lighter one has higher efficiency so choose that.

ABOUT ACCURATE REPRODUCTION

An externally hosted image should be here but it was not working when we last tested it.

The X(dotdot) is the acceleration of the cone. As you can see, increase the mass (C & K =constant) and you decrease the acceleration. No this does not mean lower SPL! This means you get a different waveform. See the graph below:

The cone must accelerate as and when needed/instantly. Any delays will change the waveform.i.e the sound you will hear. Thus for a under-damped subwoofer,read loose suspension(the OP's observation is right) the bass lingers on. For tight suspension, there will be less SPL (if the comparison is at same input power). If you damp it even more you start turning a woofer into a midrange driver. Critically damped=near correct damped system=accurate sound. Remember, an under-damped driver can be corrected by using a sealed cabinet but you cannot make a over-damped driver to loose its stiffness, i.e unless you break it open.

I hope I have explained my self clearly. Thank you for listening to me.

Last edited:

@tinitus:

"if you build a cone like I described it in post 52, but maintain the heavy weight, then you can run a big truck over it, and will still look like new without a scratch"

Definitely yes!

Hmmm..it is not too easy to bake it. There is a set procedure and it probably requires good control but yes it can be achieved by a medium sized workshop.

"if you build a cone like I described it in post 52, but maintain the heavy weight, then you can run a big truck over it, and will still look like new without a scratch"

Definitely yes!

Hmmm..it is not too easy to bake it. There is a set procedure and it probably requires good control but yes it can be achieved by a medium sized workshop.

Last edited:

"Critical damping".... good engineering but bad "common sense." In a speaker, some elements of "damping" can be a kind of negative feedback, something badly needed for a component which otherwise has no corrective feedback (unless you've been following the motional feedback threads). For a ghastly mismatch of heavy cone weight pushing light air weight, lots of damping sounds like a better idea.

While the term "critical damping" sounds pretty, what you really want is lots of damping. And if your enclosure design model is meant to work with "critical damping" (or rather "critical undamping") to achieve a flat freq curve, maybe the choice of enclosure type needs rethinking.

Although I am still favourable to light cones and flexible suspensions, Prashanthb's presentation, accurate as far as it goes, still misses the point others have made: within the pass-band of the sub, a heavy cone driver can be made to satisfy the nominal engineering requirements, "critical damping" and otherwise.

Which brings us back to the Lotus versus the Corvette. Never much doubt which one was right for me*.

Ben

*and which one could be fixed at your local gas station if you didn't have those skills yourself.

While the term "critical damping" sounds pretty, what you really want is lots of damping. And if your enclosure design model is meant to work with "critical damping" (or rather "critical undamping") to achieve a flat freq curve, maybe the choice of enclosure type needs rethinking.

Although I am still favourable to light cones and flexible suspensions, Prashanthb's presentation, accurate as far as it goes, still misses the point others have made: within the pass-band of the sub, a heavy cone driver can be made to satisfy the nominal engineering requirements, "critical damping" and otherwise.

Which brings us back to the Lotus versus the Corvette. Never much doubt which one was right for me*.

Ben

*and which one could be fixed at your local gas station if you didn't have those skills yourself.

Last edited:

@tinitus:

"if you build a cone like I described it in post 52....

Definitely yes!

Hmmm..it is not too easy to bake it ...

I wouldn't even say 'piece of cake' ... it's easier than baking a cake

where you live, it almost happens by itself on a hot day

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- stiff suspension or loose suspension for the home subwoofers?