Good friend, you have several issues in here which are not quite right. Starting at the bottom since I can see it in quote form, a midrange driver is not simply a low frequency driver with extensive damping. A bespoke midrange driver is, just like a subwoofer vs. a woofer, designed completely differently from the ground up. It is no coincidence that it rolls off in the upper thousands and in the lower hundreds. It is not because of its damping. If it were, then you would see massive fluctuations in driver Q parameters between midranges and woofers. This don't be happenin'. In fact, the opposite occurs: if you look at midrange drivers, they have higher Qes and Qms values. Reason being, their motors and suspensions are designed for superb transient ability across a very wide range of frequencies. Your points about transforming the stiffness of a driver via air volume are also not true. A heavy, stiff driver might be ideally suited for a small sealed enclosure (I deal with these often). Just depends on the driver.@Everybody:

In my earlier posts I had advised the OP to go for a speaker having low moving mass and high compliance values. It remains just a statement so I want to present the following in support of it and in the process dispel myths. This post will also serve as good starting info for everybody wanting to choose a good driver, especially in India/Asia where there are overtly stiff locally made drivers available. I have encountered sub drivers which are so stiff that even 1/2 KG force on the cone will probably move all of 5mm. And then there was a driver manufacturer who tried to sell me a midrange by just replacing the plastic cone in a woofer with a paper cone(with suspension). So the situation here is a bit bleak. Use this to choose lesser of the evils. This post only concerns suspension compliance and moving mass. Other parts of the loudspeaker do affect the performance in an equal measure so please consult a concerned expert.

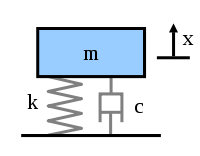

The best way to represent a loudspeaker is by a MASS-SPRING-DAMPER SYSTEM. It is represented as follows:

X=displacement of the loudspeaker cone.

K=Spring

C=Damper

Both K and C components are present in the surround and spider. The cone and the voice coil constitute the Mass denoted by M.

The Transfer function governing the force applied by the motor and displacement achieved by the cone is given by:

X(s)={1/(Ms2+Cs+K)}*F(s)...........It is simple dont get scared

X(s)=Laplace transform of the displacement. For simplicity take it as the displacement of cone.

F(s)=The laplace transform of the force applied by the motor.

1/(mass-spring-damper)=Denotes the cone+voice coil+surround+spider

ABOUT SPL

Take two similar drivers, (one with the correct damping and other stiff) and apply the above equation. As you can see, the stiffer and massive cone you have, the more force you have to apply to achieve the same displacement. In other words the same SPL!!!!!! Hence the lighter cone with correct damping will make more sound if the power applied to both is same. In short, the lighter one has higher efficiency so choose that.

ABOUT ACCURATE REPRODUCTION

An externally hosted image should be here but it was not working when we last tested it.

The X(dotdot) is the acceleration of the cone. As you can see, increase the mass (C & K =constant) and you decrease the acceleration. No this does not mean lower SPL! This means you get a different waveform. See the graph below:

The cone must accelerate as and when needed/instantly. Any delays will change the waveform.i.e the sound you will hear. Thus for a under-damped subwoofer,read loose suspension(the OP's observation is right) the bass lingers on. For tight suspension, there will be less SPL (if the comparison is at same input power). If you damp it even more you start turning a woofer into a midrange driver. Critically damped=near correct damped system=accurate sound. Remember, an under-damped driver can be corrected by using a sealed cabinet but you cannot make a over-damped driver to loose its stiffness, i.e unless you break it open.

I hope I have explained my self clearly. Thank you for listening to me.

You are also neglecting an incredibly important factor. A loudspeaker under an impulse could be modeled as a mass, stiffness and resistive system, yes. That is too simple to describe a loudspeaker's behavior, because the electrical components provide such an incredible amount of control. What determines the loudspeaker's damping is not its moving mass, stiffness and resistive losses, but the interaction between those three and the electrical portion which is causing it to move and change direction in the first place.

Your points are valid, but not fully relevant to this discussion. I still don't know why you're focusing so much on just a heavy cone, but I'll take that bit on first. F = ma is the differential equation you just posted. I purposely chose not to write it out because this discussion does not require actual mathematics to be understood. Looking at the equation, yes, increase the mass, and you decrease the acceleration. That's lovely, but all that means is that you've taken a driver and are probably wanting to lower its free air resonance. What other purpose have you for simply increasing the mass of an existing driver? My original point was that everything is designed wholly as a system to achieve a goal. If you need outright SPL, you will end up with a stiffer speaker with more mass. No one would ever just make a cone heavier for some performance advantage. Lighter, yes. Heavier? No. Stronger? Yes. Might that result in heavier? Absolutely!

Your about SPL section is not wrong, but incomplete. Yes, up to a certain point, more sensitivity is good. You are again singularly focusing on moving mass which is only a small portion of a speaker. Take said drivers, and push them until the sensitive one reaches failure. Your less sensitive SPL woofer will have been designed to take perhaps double the input power, and hence, will ultimately produce more SPL. Comes back again to not looking at everything as a whole.

I do not know if you've designed a loudspeaker driver before, but the design starts with the motor. Always. Specifying stiffness and mass are the easy part, but having the motor you want always is the most important to begin with. Once you have said motor (magnet, voice coil and former) that can take 3kW, the rest of the driver is designed then to use the motor force to achieve whatever goal it is you want. Note: more is not always better. You do not always want as much motor force as possible. You want as much as you need for the application. For a pure SPL woofer, however, then yes. You want as much as you can control with the suspension and cone you're able to design.

Long story short, cones are not designed to be massive simply outright. A cone which is heavier because it's stronger is perfectly fine because the designer knows that it will be handing a lot more electrically, which will make the increased mass a moot point.

Last edited:

I also need to point out about your "about SPL" section: two drivers at the same displacement, one with 2x the force input because it is stiffer and more massive = more SPL. Remember: pressure = force/area. The force is presented to the air by the surface area of the cone. More force = more pressure.

To the OP, apologies for the can of worms you inadvertently opened! To answer your question, a home theatre subwoofer is not only defined by stiffness. Let's use real world examples:

Dayton Reference HF 15"

Dayton Audio RSS390HF-4 15" Reference HF Subwoofer 4 Ohm 295-468

Dayton Reference HO 15"

Dayton Audio RSS390HO-4 15" Reference HO Subwoofer 4 Ohm 295-469

Now, the HF stands for high fidelity, and the HO for high output. First thing to note: the HF woofer can take 500W RMS, while the HO woofer can take 800W. Second thing to note: the HF has a resonance of 18Hz vs. 24.2 for the HO. Why? The moving mass of the HF cone is 282g vs. 380.6 for the HO. Wait, I thought higher mass meant lower resonance? Yep, look at stiffness (compliance): .28mm/N for the HF, vs. .11mm/N for the HO. The HO woofer is so much stiffer that the extra mass is completely offset. This shows up nicely in the Vas: nearly 10 cubic feet for the HF and a measly 3.87 cubic feet for the HO. Finally, note in the product description: the HO woofer has a much thicker cone for superb rigidity due to its more powerful motor compared to the HF's thinner cone for superior accuracy. The HO cranks over 21.5 teslameters of Bl, while the HF makes do with 14.7.

Going through this exercise, you can see that these two drivers, while sharing the exact same platform, were designed for completely different purposes. I own something like 10 of the Dayton Reference subwoofers, and I can tell you that the 10" HO is superbly loud in a car audio situation, and the 10" HF is my go-to 10" subwoofer for DIY in home audio. It just extends so stupidly low off less power. Could they swap roles? You bet, because they're not extremes. But you will not get the most out of either when you swap their roles because they were designed from the motor on up to the cone to be used differently.

Dayton Reference HF 15"

Dayton Audio RSS390HF-4 15" Reference HF Subwoofer 4 Ohm 295-468

Dayton Reference HO 15"

Dayton Audio RSS390HO-4 15" Reference HO Subwoofer 4 Ohm 295-469

Now, the HF stands for high fidelity, and the HO for high output. First thing to note: the HF woofer can take 500W RMS, while the HO woofer can take 800W. Second thing to note: the HF has a resonance of 18Hz vs. 24.2 for the HO. Why? The moving mass of the HF cone is 282g vs. 380.6 for the HO. Wait, I thought higher mass meant lower resonance? Yep, look at stiffness (compliance): .28mm/N for the HF, vs. .11mm/N for the HO. The HO woofer is so much stiffer that the extra mass is completely offset. This shows up nicely in the Vas: nearly 10 cubic feet for the HF and a measly 3.87 cubic feet for the HO. Finally, note in the product description: the HO woofer has a much thicker cone for superb rigidity due to its more powerful motor compared to the HF's thinner cone for superior accuracy. The HO cranks over 21.5 teslameters of Bl, while the HF makes do with 14.7.

Going through this exercise, you can see that these two drivers, while sharing the exact same platform, were designed for completely different purposes. I own something like 10 of the Dayton Reference subwoofers, and I can tell you that the 10" HO is superbly loud in a car audio situation, and the 10" HF is my go-to 10" subwoofer for DIY in home audio. It just extends so stupidly low off less power. Could they swap roles? You bet, because they're not extremes. But you will not get the most out of either when you swap their roles because they were designed from the motor on up to the cone to be used differently.

where you live, it almost happens by itself on a hot day

LOL, Not much energy bills to be paid then, Damn those software entrepreneurs who should have started factories spitting out composite speaker cones and other things composite.

Mostly in agreement with each other on the topic!

@BEN

1)"what you really want is lots of damping"

Hmmm...I have presented irrefutable proof to favour a 'correctly damped system', and still if you prefer "lots of damping" then I really dont know what to say...... Probably there is a very fundamental misunderstanding of 'DAMPING' here.

2)".... a heavy cone driver can be made to satisfy the nominal engineering requirements"

I fully and whole heartedly agree. No debate at all! My question all along was why the extra effort? Good driver=no correction needed!

@LEMANS23

1)"a midrange driver is not simply a low frequency driver with extensive damping."

I dont know of any other method. And I dont think there is any. Please present complete proof otherwise people will accuse me of spreading false info!!! About enclosure and the midrange driver construction, it belongs to a different thread, lets not discuss it here. But post that proof to negate my earlier post. Thank you in advance

2)"What determines the loudspeaker's damping is.....the interaction between those three and the electrical portion"

Good observation! And damping in a loudspeaker is the C in (M,K,C) and the control exerted by the electricity is damping part-2 which should be accounted if you want to get an even more accurate answer. Still the equations I have presented will give good enough guidelines on matching a cone,suspension and a motor.

3)"Lighter, yes. Heavier? No. Stronger? Yes. Might that result in heavier? Absolutely!"

We now are on the same page

4)"Your about SPL section is not wrong, but incomplete."

Sorry if I am offending you here but I find your argument shallow. I said two 'similar' drivers.... Besides if the heavier one is built for heavy duty why compare it with a weaker one?

5)"Long story short"......fully, whole heartedly agree with you

6)"Post no. 62"

No, you are making a fundamental mistake here!

If the displacement is same for both, then the mechanical force the cone is applying on the surrounding air is the SAME for both!You are confusing between the electrical force being applied on the cone with the mechanical force applied by the cone on the surrounding air. Go back to your own mobility diagram and see.

@BEN

1)"what you really want is lots of damping"

Hmmm...I have presented irrefutable proof to favour a 'correctly damped system', and still if you prefer "lots of damping" then I really dont know what to say...... Probably there is a very fundamental misunderstanding of 'DAMPING' here.

2)".... a heavy cone driver can be made to satisfy the nominal engineering requirements"

I fully and whole heartedly agree. No debate at all! My question all along was why the extra effort? Good driver=no correction needed!

@LEMANS23

1)"a midrange driver is not simply a low frequency driver with extensive damping."

I dont know of any other method. And I dont think there is any. Please present complete proof otherwise people will accuse me of spreading false info!!! About enclosure and the midrange driver construction, it belongs to a different thread, lets not discuss it here. But post that proof to negate my earlier post. Thank you in advance

2)"What determines the loudspeaker's damping is.....the interaction between those three and the electrical portion"

Good observation! And damping in a loudspeaker is the C in (M,K,C) and the control exerted by the electricity is damping part-2 which should be accounted if you want to get an even more accurate answer. Still the equations I have presented will give good enough guidelines on matching a cone,suspension and a motor.

3)"Lighter, yes. Heavier? No. Stronger? Yes. Might that result in heavier? Absolutely!"

We now are on the same page

4)"Your about SPL section is not wrong, but incomplete."

Sorry if I am offending you here but I find your argument shallow. I said two 'similar' drivers.... Besides if the heavier one is built for heavy duty why compare it with a weaker one?

5)"Long story short"......fully, whole heartedly agree with you

6)"Post no. 62"

No, you are making a fundamental mistake here!

If the displacement is same for both, then the mechanical force the cone is applying on the surrounding air is the SAME for both!You are confusing between the electrical force being applied on the cone with the mechanical force applied by the cone on the surrounding air. Go back to your own mobility diagram and see.

I went thru the entire thread again only to find some mistakes of mine. Sorry I have bad articulation. But the big picture I am trying to present matches with what bentoronto, lemans23 and sidewinder18x . Thank you all for your responses and above all for having patience with me Only at some details we dont match because we are on different pages, lots of words thrown around by different people, assuming different meanings,but that can be solved easily

Only at some details we dont match because we are on different pages, lots of words thrown around by different people, assuming different meanings,but that can be solved easily

If anybody has missed weltersys's simple explanation(post no 51), please read it .That is the starting point.....and in many ways the ending point too.

If anybody has missed weltersys's simple explanation(post no 51), please read it .That is the starting point.....and in many ways the ending point too.

Maths never liked me.

So with my little bit of laymans knowledge I have realized playing with loudspeakers since last 15 years, that Stiff suspension is required in its own place and soft suspension has its own.

I have heard good sounding hard suspension woofer as well good sound sounding soft suspension speakers.

It depends upon how the design as a whole is combined.

Without much of maths I do wind my own drivers as well ,some for my close pals as well.

Some times with given requirement I have to use a smaller dia stiffer spider,for a lighter cone as well as a bigger dia softer spider for a heavier cone or vice versa.

To an extend physically they both can be made to sound alike.

Resonance efficiency and every other parameter may required to be tweaked.

I for example have soft suspension kevlar woofer from peerless India and hard suspension Polycone woofer from Peerless denmark, as well as few others.

They all sound sweet and sane depending how we integrate them into cabinet.

it is not how soft or how hard but as a whole what is required,Q of 0.7?

Also I would like to add in laymans words,a soft woofer driven hard quickly distorts looses linearity and to control its cone movement becomes quite tricky ,say a small sealed box or a difficult bass reflex where it needs to be stiffened indirectly with q corrections.

I think it has more to do with timing of cone movement as well.

Sometimes it looks like a rocket science though!

So with my little bit of laymans knowledge I have realized playing with loudspeakers since last 15 years, that Stiff suspension is required in its own place and soft suspension has its own.

I have heard good sounding hard suspension woofer as well good sound sounding soft suspension speakers.

It depends upon how the design as a whole is combined.

Without much of maths I do wind my own drivers as well ,some for my close pals as well.

Some times with given requirement I have to use a smaller dia stiffer spider,for a lighter cone as well as a bigger dia softer spider for a heavier cone or vice versa.

To an extend physically they both can be made to sound alike.

Resonance efficiency and every other parameter may required to be tweaked.

I for example have soft suspension kevlar woofer from peerless India and hard suspension Polycone woofer from Peerless denmark, as well as few others.

They all sound sweet and sane depending how we integrate them into cabinet.

it is not how soft or how hard but as a whole what is required,Q of 0.7?

Also I would like to add in laymans words,a soft woofer driven hard quickly distorts looses linearity and to control its cone movement becomes quite tricky ,say a small sealed box or a difficult bass reflex where it needs to be stiffened indirectly with q corrections.

I think it has more to do with timing of cone movement as well.

Sometimes it looks like a rocket science though!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- stiff suspension or loose suspension for the home subwoofers?