The guy's talking about small coupling caps which make a light tapping sound when dropped on a hard surface. From your description I assume you were referring to large electrolytics which sound completely different. Generally speaking, capacitors which thud are not considered to be suitable for use in the signal path.

Sorry, my mistake.mach1 said:The guy's talking about small coupling caps which make a light tapping sound when dropped on a hard surface. From your description I assume you were referring to large electrolytics which sound completely different. Generally speaking, capacitors which thud are not considered to be suitable for use in the signal path.

If you can hear a coupling cap, then there is usually something wrong with either the circuit (typically, wrong value cap used) or the cap.

Stealth caps

I have heard first hand between the eel csps,dynsmuc,and stealth No competition ,

This us why all Aesthetics amps preamp get Stealth caps i have heard them in several builds

I just bought 2-3uf yo complement the outputs in my Pass labs amp much better then the VH limp caps this added yo the detail and refinement very natural sounding but take 300 hours

To fully Run in after 200 Very noticable.

I have heard first hand between the eel csps,dynsmuc,and stealth No competition ,

This us why all Aesthetics amps preamp get Stealth caps i have heard them in several builds

I just bought 2-3uf yo complement the outputs in my Pass labs amp much better then the VH limp caps this added yo the detail and refinement very natural sounding but take 300 hours

To fully Run in after 200 Very noticable.

I will give my opinion at great personal peril. I have used Dynamicap's in several projects. They take a long time to break in. (those who do not think there is such a thing need not reply). I like the sound a lot. I have a set up the Stealth caps that I have not used yet. I got them used on epay for a good price. The seller has another set up them on epay. I will report back when I have heard the Stealth caps in the same preamp as the Dynamicap's.

Sheer nonsense.They take a long time to break in.

Caps work, measure and "sound" exactly the same whether 5 minutes after soldering, or 1, 10, 100, 1000, 10000 hours after.

****IF parameters do not change, sound does not change****

And of course parameters do not change.

Caps work, measure and "sound" exactly the same whether 5 minutes

Waiting 5 minutes is a prime example of audiophoolery. Proper engineers listen within 5 seconds and within 10 already know that the caps sound just like any other cap.

Besides the audiophoolery of burn-in of caps, there exist real microphonic effects with multilayer-ceramic caps.

Wheter or not these are noticeable, depends on the circuit details.

I experienced this effect myself - without seeking for it- at some high gain guitar amp circuitry.

So I replaced the MLCCs by some film caps - problem solved.

Wheter or not these are noticeable, depends on the circuit details.

I experienced this effect myself - without seeking for it- at some high gain guitar amp circuitry.

So I replaced the MLCCs by some film caps - problem solved.

Normally I avoid these kind of interactions. But I do have to comment on this statement.

****IF parameters do not change, sound does not change****

And of course parameters do not change.

The first part is logically true. But the second part is not true, parameters always change in any dynamic system. How do you know that no parameter has changed with time. Have you done the measurements to show that the reaction of the capacitor is the same for every possible parameter. For example: Capacitance, resistance and inductance over the entire audio band. Then we have to throw in how all of these can be affected by temperature and maybe even air pressure.

Finally, if capacitors do not change, then why do they ever have to be replaced.

Logically, What you are saying is that a 100 year old capacitor should act like a brand new one.

All materials age in some way. Otherwise why would a part that was not exposed to friction ever have to be replaced.

****IF parameters do not change, sound does not change****

And of course parameters do not change.

The first part is logically true. But the second part is not true, parameters always change in any dynamic system. How do you know that no parameter has changed with time. Have you done the measurements to show that the reaction of the capacitor is the same for every possible parameter. For example: Capacitance, resistance and inductance over the entire audio band. Then we have to throw in how all of these can be affected by temperature and maybe even air pressure.

Finally, if capacitors do not change, then why do they ever have to be replaced.

Logically, What you are saying is that a 100 year old capacitor should act like a brand new one.

All materials age in some way. Otherwise why would a part that was not exposed to friction ever have to be replaced.

Besides the audiophoolery of burn-in of caps, there exist real microphonic effects with multilayer-ceramic caps.

Wheter or not these are noticeable, depends on the circuit details.

I experienced this effect myself - without seeking for it- at some high gain guitar amp circuitry.

So I replaced the MLCCs by some film caps - problem solved.

*SOME* MLCC caps.

C0G/NP0 capacitors are not microphonic. You will also not have any issues with X7R. Low-grade MLCC can have problems, but they are easy to avoid.

I think he meant to say "parameters do not change to any significant extent". Significant change in a component means that it is faulty or inappropriately used. For a well-chosen coupling cap even a significant change in the component may cause only an insignificant change in the signal. I have not noticed air pressure being a factor in hi-fi reviews or amplifier specifications, although of course I agree that air pressure may have a small effect on component parameters - especially poorly made components, which tend to be the more expensive ones.johnmarkp said:But the second part is not true, parameters always change in any dynamic system. How do you know that no parameter has changed with time. Have you done the measurements to show that the reaction of the capacitor is the same for every possible parameter. For example: Capacitance, resistance and inductance over the entire audio band. Then we have to throw in how all of these can be affected by temperature and maybe even air pressure.

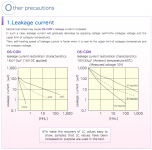

Well, with electrolytic caps, the leakage, which is a consequence of the dielectric layer re-forming at the circuit voltage, does change over the first few minutes of operation. Whether you can hear it or not depends upon the circuit, but you can easily measure (as I have) leakage current changes on most electrolytic caps when you first power them up, so I would count that as 'break in'.

Page 4 and 5 of this PDF from Vishay give a good background on what leakage current really is and what happens when an aluminum electrolytic is powered up: https://www.vishay.com/docs/25001/alucapsintroduction.pdf

Note that solid Tantalum caps also go through a leakage phase when they're powered up, as voids or thin spots in the dielectric oxide arc over and are burned up, consuming the manganese dioxide electrolyte to make new Tantalum pentoxide dielectric. In this case, the leakage is more of a shot noise than a continuous current, since specific regions of the oxide layer arc over and self-repair, with the leakage current a consequence of these small short circuits within the sintered mass of the capacitor.

Film caps can also change behavior with applied voltage. If the dielectric film is too thin, applied voltage can cause an arc-over that burns away a small portion of the metallization, restoring its high leakage resistance, but consuming a small bit of electrode plate area, slightly reducing its capacitance. This can happen when a newly manufactured cap is first powered up, or if an excessive voltage is applied, causing thin dielectric spots to arc over. If a cap has been 'cleared' with a high voltage, then this effect should not be ongoing - all of the weak spots have been cleared out and the cap should be stable. But, that is only if you know the history of the cap.

Anyway, if you dig into the literature, you can separate the possibly faulty perceptual observations and focus on what the physics and chemistry are doing. Using these ideas when you design in a component can give you a better idea of what to expect from the component, how it will fail, and where it will not fail.

Note that solid Tantalum caps also go through a leakage phase when they're powered up, as voids or thin spots in the dielectric oxide arc over and are burned up, consuming the manganese dioxide electrolyte to make new Tantalum pentoxide dielectric. In this case, the leakage is more of a shot noise than a continuous current, since specific regions of the oxide layer arc over and self-repair, with the leakage current a consequence of these small short circuits within the sintered mass of the capacitor.

Film caps can also change behavior with applied voltage. If the dielectric film is too thin, applied voltage can cause an arc-over that burns away a small portion of the metallization, restoring its high leakage resistance, but consuming a small bit of electrode plate area, slightly reducing its capacitance. This can happen when a newly manufactured cap is first powered up, or if an excessive voltage is applied, causing thin dielectric spots to arc over. If a cap has been 'cleared' with a high voltage, then this effect should not be ongoing - all of the weak spots have been cleared out and the cap should be stable. But, that is only if you know the history of the cap.

Anyway, if you dig into the literature, you can separate the possibly faulty perceptual observations and focus on what the physics and chemistry are doing. Using these ideas when you design in a component can give you a better idea of what to expect from the component, how it will fail, and where it will not fail.

I don't think electrolytic leakage is what most audiophiles mean by break-in. After all, electrolytic leakage can be measured and explained - it even appears in datasheets. True break-in must be something which engineers know nothing about: a rainbow with no differential refraction.

Sheer nonsense.

Caps work, measure and "sound" exactly the same whether 5 minutes after soldering, or 1, 10, 100, 1000, 10000 hours after.

****IF parameters do not change, sound does not change****

And of course parameters do not change.

I feel that's not true - soldering for example has a substantial impact on leakage current (amongst other!) values, and healing time is proportional to various conditions like applied voltage and operating temperature. This behaviour is also different between liquid electrolytics and solid polymer electrolytics but exists on both and is documented.

I'll share what I have saved in case it's useful. The first is an article from BC Components discussing liquid electrolytics (bit more detail than the Vishay PDF above), and the second is an exerpt from the OSCON application guide in case anyone is interested in their behaviour too. Interestingly, the recovery time increases substantially as the application gets further from the max voltage and temp rating, which makes me wonder if it's best to avoid gross voltage derating on these types.

If you read the documents fully, you can see that leakage current is not the only value affected, it's discussed how ESR and capacitance also see transient changes under soldering heat that takes time to heal (see attached image). I also think it would be naive to assume that LC can change drastically and all other specs magically remain dead constant.

Smaller capacitors (and SMD) are obviously affected more, but either way "zero change" is likely not the case.

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Stealth Capacitors