It's been a long time since I tried spray-on positive photoresist... from what I remember, the coating tended to be very uneven. I had better luck with the liquid photoresist, thinned 50%, and spread with a disposable foam brush. Allow it to flow out for a while in a dark dustfree place, then bake if possible. Doing this in the kitchen oven proved to be unpopular with other people in the house, so I'd use a toaster oven or an improvised oven: 5 gallon metal bucket on its side with a heating element. Because it was curved, I could lay a double sided board in there and only the edges would touch.

The secret with printing positive artwork is to make two copies and overlay them. I used to do that with penplotter artwork on frosted mylar, and the same thing works for inkjet art.

A fiberglass "rust eraser" pen is invaluable for cleaning up the copper before soldering, if it has become tarnished. (Some auto parts stores sell these.)

With pre-coated boards, I mostly leave the resist on since it protects the copper and doesn't seem to impair solderability. I've used an "electroless tin" coating... it isn't very solderable. Sometimes I've tinned an entire board with solder... not such a great idea. There's usually some delamination in areas of heavy copper.

The secret with printing positive artwork is to make two copies and overlay them. I used to do that with penplotter artwork on frosted mylar, and the same thing works for inkjet art.

A fiberglass "rust eraser" pen is invaluable for cleaning up the copper before soldering, if it has become tarnished. (Some auto parts stores sell these.)

With pre-coated boards, I mostly leave the resist on since it protects the copper and doesn't seem to impair solderability. I've used an "electroless tin" coating... it isn't very solderable. Sometimes I've tinned an entire board with solder... not such a great idea. There's usually some delamination in areas of heavy copper.

Hi,

I am going to give the spray on stuff a go, I will stick a can on the next order. I have never seen it advertised as a liquid- mind you I have not really looked that hard.

How do you find the U/V exposure times, as compared to precoated and the same for the developer time as well.

Regards Karl

I am going to give the spray on stuff a go, I will stick a can on the next order. I have never seen it advertised as a liquid- mind you I have not really looked that hard.

How do you find the U/V exposure times, as compared to precoated and the same for the developer time as well.

Regards Karl

Nordic said:Hallo Gert, I have the memory of a goldfish, did you test that tinnig stuff eventualy...? We kind of lost contact in the wait.

Hoezit! I did try the tinning crystals and it actually works fantastic, but goes off almost as soon as you open the container! I wish it was possible to get them in smaller quantities so you don't waste as it's quite expensive. The c-boards guy sells it in 100ml pre mixed for around R100 I think. It should last a little though.

Coating the board with liquid flux and then tinning with solder looks almost as good though, especially on large areas. I then clean the flux off and viola!

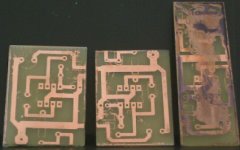

Tried the spray (Kontakt Photo 20) today. Not easy, tried on a few scrap pieces of PCB. As was said, getting it even is the big problem. Have to try Conrads suggestion of a spinner

The test boards were barely usable, lots of remaining copper both largeish areas and lots of small flecks. Tried upping the UV time to around 4 minutes (Twin tube box) --- bit better. Left two soaking in ferric chloride for two hours this afternoon for fun. 90 % O.K. after that -- strange. The resist bonds amazingly well to clean board and seems tough. The boards were quite purple in parts -- too much jalop on

Will keep trying.

The test boards were barely usable, lots of remaining copper both largeish areas and lots of small flecks. Tried upping the UV time to around 4 minutes (Twin tube box) --- bit better. Left two soaking in ferric chloride for two hours this afternoon for fun. 90 % O.K. after that -- strange. The resist bonds amazingly well to clean board and seems tough. The boards were quite purple in parts -- too much jalop on

Will keep trying.

If you can post closeups of the errors we may be able to point out errors like over/under exposure...

I have recently made some good boards with rather thick coats of the stuff... I just increased the exposure quite a bit... about 8 minutes sun exposure, which is double what I normally use...

I have recently made some good boards with rather thick coats of the stuff... I just increased the exposure quite a bit... about 8 minutes sun exposure, which is double what I normally use...

Hi Nordic,

Afraid I binned them. They were only very small ( about 2 by 3 cm ) for testing. The next ones I will take pictures of.

Will take much more care with the spraying --it's first time I had seen the stuff, and it's so thin ( thinner than water really ), it just wasn't even at all--most of that down to me--am sure I overdid it, it was nearly going into little "pools" in some parts.

Afraid I binned them. They were only very small ( about 2 by 3 cm ) for testing. The next ones I will take pictures of.

Will take much more care with the spraying --it's first time I had seen the stuff, and it's so thin ( thinner than water really ), it just wasn't even at all--most of that down to me--am sure I overdid it, it was nearly going into little "pools" in some parts.

remember you can give the boards a final light coat as it comes out of the oven to catch the little missed pinprics... the thickness of the stuff can catch you out... thicker coats will need longer exposures and visa versa, try to only change one variable at a time untill you get it right... even if the traces looks like it is a little thin, the etchant should not get through it in the time it takes to etch...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Spray on Photoresist- How Successful is it.