You may be wondering how this has anything to do with tapped horns. Firstly if you haven't read Tom Danley's white paper on tapped horns, you should check it out.

Secondly, you can play around on hornresp (or Win ISD) with drivers that couldn't exist in the real world (because they're 3 feet across and weigh 100 grams). Because you have less parameters to play with, this allows you to see the maximum potential sensitivity of a particular cab size, more quickly than you could by faffing about with multiple horn segments.

I've found that increasing the box size really only increases its sensitivity around the tuning frequency. You can use a large box and a small high strength driver to hit the tuning frequency HARD.

https://www.youtube.com/watch?v=W0QUloqPIyk

This works because the tuning frequency is a velocity minimum. Think of bouncing a yoyo or a slinky in one hand. The other end moves a lot but your hand barely moves.

The trouble with that driver and box is that you could produce deep bass notes from hell but it would have little to no help on the upper bass.

What you really want is a driver that could 'thin itself out' (get larger but retain the same mass/magnet structure) as the frequency increased.

The tapped horn is another arrangement that allows small powerful drivers to act like larger lighter drivers with more displacement for the mid and upper bass.

In the white paper, the analogy is done with quarter wave and half wave horns. You have a small powerful driver e.g. B&C 12BG100 driving the throat of a quarter wave tunnel. In the middle of the pass band, the tunnel is about a half wavelength long. Radiation from the front drives the horn throat as normal, radiation from the back can also travel back down the horn and drive the horn throat, having a similar effect to more compression ratio.

Example: the B&C 18SW115 that plays flat in 120 litres or so and has a maximum output of 130dB. What If I want to make 133dB? To get +3dB sensitivity, I'd need to double the box size, so I'd get the boost I'd like (133-134dB) at around 40-50Hz, but I'd be limited by the weight to surface area ratio of the cone at 60Hz and above. If I could design a tapped horn that fitted in that space, I could theoretically have the 133dB in the 240 litre box, or even 136dB in a 480 litre box (~TH118).

To get the efficiency and power of the 480 litre Tapped Horn with a vented box. I would require two 18s with 15mm Xmax each.

Assuming two ~8 ohm 18s in parallel would have the following properties:

Half the moving mass of the B&C

The same BL (with twice the Re) as the B&C

Twice the suspension compliance

Twice the coil inductance etc

Basically an isobaric pair of these would equal the B&C, but such woofers would be expensive to make and easier to damage due to the lighter components.

Secondly, you can play around on hornresp (or Win ISD) with drivers that couldn't exist in the real world (because they're 3 feet across and weigh 100 grams). Because you have less parameters to play with, this allows you to see the maximum potential sensitivity of a particular cab size, more quickly than you could by faffing about with multiple horn segments.

I've found that increasing the box size really only increases its sensitivity around the tuning frequency. You can use a large box and a small high strength driver to hit the tuning frequency HARD.

https://www.youtube.com/watch?v=W0QUloqPIyk

This works because the tuning frequency is a velocity minimum. Think of bouncing a yoyo or a slinky in one hand. The other end moves a lot but your hand barely moves.

The trouble with that driver and box is that you could produce deep bass notes from hell but it would have little to no help on the upper bass.

What you really want is a driver that could 'thin itself out' (get larger but retain the same mass/magnet structure) as the frequency increased.

The tapped horn is another arrangement that allows small powerful drivers to act like larger lighter drivers with more displacement for the mid and upper bass.

In the white paper, the analogy is done with quarter wave and half wave horns. You have a small powerful driver e.g. B&C 12BG100 driving the throat of a quarter wave tunnel. In the middle of the pass band, the tunnel is about a half wavelength long. Radiation from the front drives the horn throat as normal, radiation from the back can also travel back down the horn and drive the horn throat, having a similar effect to more compression ratio.

Example: the B&C 18SW115 that plays flat in 120 litres or so and has a maximum output of 130dB. What If I want to make 133dB? To get +3dB sensitivity, I'd need to double the box size, so I'd get the boost I'd like (133-134dB) at around 40-50Hz, but I'd be limited by the weight to surface area ratio of the cone at 60Hz and above. If I could design a tapped horn that fitted in that space, I could theoretically have the 133dB in the 240 litre box, or even 136dB in a 480 litre box (~TH118).

To get the efficiency and power of the 480 litre Tapped Horn with a vented box. I would require two 18s with 15mm Xmax each.

Assuming two ~8 ohm 18s in parallel would have the following properties:

Half the moving mass of the B&C

The same BL (with twice the Re) as the B&C

Twice the suspension compliance

Twice the coil inductance etc

Basically an isobaric pair of these would equal the B&C, but such woofers would be expensive to make and easier to damage due to the lighter components.

Or, you could build *wait for it*. A dual 18. A rare breed, and get 136 db flat to 40hz in a 220liter package.

working with "theoretical" drivers is pretty much the same thing as working with drivers that actually exist that you cant afford.

if you are "adjusting" BL, and other parameters, you need to realize this is likely going to adjust other parameters in the real world, and recalculate all of those as well.

As member GM has pointed out, box size =VAS, tuning = FS is optimum flat response for a ported box. you can use a smaller box and a higher tuning for more sensitivity, but you cant really gain more "flat" sensitivity while maintining tuning once you hit box size =VAS.

This is why tapped horns and Front Loaded horns exist. It allows us to make an even bigger box than said optimum Vented alignment, to gain sensitivity, while maintaining excursion control.

I've read danleys white papers. In fact the 18sw115 is a popular driver in many Danley designs.

also they can be had much cheaper than the price you quoted. 4 ohm driver, and even a cheap bridged amp makes it not so hard to power.

working with "theoretical" drivers is pretty much the same thing as working with drivers that actually exist that you cant afford.

if you are "adjusting" BL, and other parameters, you need to realize this is likely going to adjust other parameters in the real world, and recalculate all of those as well.

As member GM has pointed out, box size =VAS, tuning = FS is optimum flat response for a ported box. you can use a smaller box and a higher tuning for more sensitivity, but you cant really gain more "flat" sensitivity while maintining tuning once you hit box size =VAS.

This is why tapped horns and Front Loaded horns exist. It allows us to make an even bigger box than said optimum Vented alignment, to gain sensitivity, while maintaining excursion control.

I've read danleys white papers. In fact the 18sw115 is a popular driver in many Danley designs.

also they can be had much cheaper than the price you quoted. 4 ohm driver, and even a cheap bridged amp makes it not so hard to power.

I'm guessing you're not a mathematician, I am. We deal with things that can't exist in thee real world all the time. I did it to help find the limits in efficiency and they are proportional to box volume. You can build a double 18 in 220 litres, but if you choose 2 18s that work well in 380 litres, you can have 105dB 2.83V 1m which is Martin Audio's claimed sensitivity. Interestingly though, if mutual coupling is anything to go by, if you have money burning a hole in your pocket 4 of the B&C 18s in series parallel in 440L would have the similar sensitivity as a tapped horn and 6dB more output due to the power handling of all the drivers.

PS I come from the land of the UK where eminence Kappalite 3012lfs are 175 quid each a even shipping from the USA adds to the nice looking prices overseas. A PD1850 can be had for 350 quid though and that has 13mm of Xmax.

PS I come from the land of the UK where eminence Kappalite 3012lfs are 175 quid each a even shipping from the USA adds to the nice looking prices overseas. A PD1850 can be had for 350 quid though and that has 13mm of Xmax.

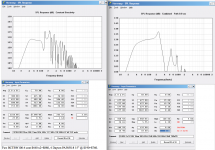

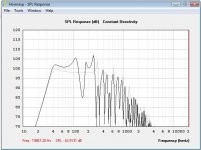

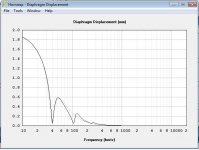

Okay, here it is: Here are 3 simulations

2.83V 1m, Impedance, and 2.83V diaphragm displacement for both a 360L tapped horn and the 190L 'DJ's Dream (TM)' 41.5Hz vented box.

They tapped horn runs a slightly lower average impedance, is 2-3dB more sensitive and has the same peak displacement.

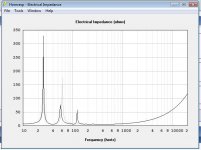

This is the first of my experimental procedures to design a tapped horn using the following algorithm I have conceived but have by no means mathematically proved:

1. Choose the response you want your tapped horn to do: eg flat to 40Hz

2. Choose the driver you want to use and design a vented box for said driver to make sure it is suitable for the above application. Note down the size (litres or cu ft) of the vented box that does what you want.

3. Pick the net volume of the tapped horn. It must be larger than the vented box.

4. The size ratio of the tapped horn and vented box forms the mouth area to throat area ratio of the horn.

5. The length of the horn will be about a quarter wave of the tuning frequency but has been known to get slightly longer (or shorter with a 1:1 I discovered) depending on the flare and expansion rate. If in doubt, check the displacement minima of the tapped horn and vented box line up. The 'compare captured' feature is useful here.

6. Experiment with different flare rates, scaling the throat and mouth parameters to get the total volume to the requirement. Experiment with driver positions within the horn. I found as close to either end as possible works well.

The box I simulated used a 2:1 ratio and an exponential flare. I've tried using 3:1 and more size ups with a 3015LF and also an HL10 which I presumed (being suitable for a 22L vented box at 40Hz) was farther from the efficiency limit and non linearity than a 3015LF, where you need even bigger boxes for that last 1dB. It ended up with the tuning and upper bass rising, and a smiling EQ shape, so mixed results for higher scale up ratios.

I've been looking through the collaborative Tapped Horn thread and told that Hornresp can't accurately simulate the half wave condition and that the 'dip' may be filled in by the reflection back down to the throat in the 'half wave' condition. I also found raising the Fs of the driver to about 55Hz filled in some of the dip on the simulation, but for a driver you already have, this is not possible to recreate.

I really need to buckle down and work out the math

P.S. what thiele small paramaters do you have for the B&C 18SW115 and also the paramaters of the box you used? Were you using Win ISD too as I couldn't find the high and low pass functions in Hornresp but the graph backgrounds looked similar to Hornresp.

I looked up a few documents that didn't have them but will have a more detailed search. I'm interested to see if I can do a 226L tapped horn that does 133dB using similar methodology.

2.83V 1m, Impedance, and 2.83V diaphragm displacement for both a 360L tapped horn and the 190L 'DJ's Dream (TM)' 41.5Hz vented box.

They tapped horn runs a slightly lower average impedance, is 2-3dB more sensitive and has the same peak displacement.

This is the first of my experimental procedures to design a tapped horn using the following algorithm I have conceived but have by no means mathematically proved:

1. Choose the response you want your tapped horn to do: eg flat to 40Hz

2. Choose the driver you want to use and design a vented box for said driver to make sure it is suitable for the above application. Note down the size (litres or cu ft) of the vented box that does what you want.

3. Pick the net volume of the tapped horn. It must be larger than the vented box.

4. The size ratio of the tapped horn and vented box forms the mouth area to throat area ratio of the horn.

5. The length of the horn will be about a quarter wave of the tuning frequency but has been known to get slightly longer (or shorter with a 1:1 I discovered) depending on the flare and expansion rate. If in doubt, check the displacement minima of the tapped horn and vented box line up. The 'compare captured' feature is useful here.

6. Experiment with different flare rates, scaling the throat and mouth parameters to get the total volume to the requirement. Experiment with driver positions within the horn. I found as close to either end as possible works well.

The box I simulated used a 2:1 ratio and an exponential flare. I've tried using 3:1 and more size ups with a 3015LF and also an HL10 which I presumed (being suitable for a 22L vented box at 40Hz) was farther from the efficiency limit and non linearity than a 3015LF, where you need even bigger boxes for that last 1dB. It ended up with the tuning and upper bass rising, and a smiling EQ shape, so mixed results for higher scale up ratios.

I've been looking through the collaborative Tapped Horn thread and told that Hornresp can't accurately simulate the half wave condition and that the 'dip' may be filled in by the reflection back down to the throat in the 'half wave' condition. I also found raising the Fs of the driver to about 55Hz filled in some of the dip on the simulation, but for a driver you already have, this is not possible to recreate.

I really need to buckle down and work out the math

P.S. what thiele small paramaters do you have for the B&C 18SW115 and also the paramaters of the box you used? Were you using Win ISD too as I couldn't find the high and low pass functions in Hornresp but the graph backgrounds looked similar to Hornresp.

I looked up a few documents that didn't have them but will have a more detailed search. I'm interested to see if I can do a 226L tapped horn that does 133dB using similar methodology.

Attachments

-

360l tapped horn vs 190L vented box 2.83v 1m.jpg48.1 KB · Views: 449

360l tapped horn vs 190L vented box 2.83v 1m.jpg48.1 KB · Views: 449 -

190L vented box vs 360L tapped horn displacement.jpg42.6 KB · Views: 444

190L vented box vs 360L tapped horn displacement.jpg42.6 KB · Views: 444 -

190L vented box vs 360L tapped horn impedance.jpg40.6 KB · Views: 439

190L vented box vs 360L tapped horn impedance.jpg40.6 KB · Views: 439 -

360L 3015lf tapped horn input.jpg51.1 KB · Views: 432

360L 3015lf tapped horn input.jpg51.1 KB · Views: 432 -

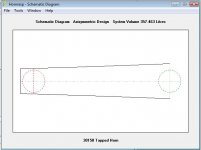

360l 3015lf tapped horn schematic.jpg29.4 KB · Views: 439

360l 3015lf tapped horn schematic.jpg29.4 KB · Views: 439

Last edited:

You can't build a 360L TH using a single 4x8 sheet of wood.Okay, here it is: Here are 3 simulations

2.83V 1m, Impedance, and 2.83V diaphragm displacement for both a 360L tapped horn and the 190L 'DJ's Dream (TM)' 41.5Hz vented box.

That is SO TRUE (apart from meticulous use of a split down the middle!) The 3015LF might be a poor choice for a flat 40Hz tapped horn for a single sheet, because a flat 40Hz vented box takes a single sheet if you include baffle backers and bracing, and I still couldn't get one of the ports in, unless you went with three larger ports. You could probably get some more efficiency out of the upper bass as in JBell's SS15, but he pointed out he was also getting 98dB 2.83V 1m at 40Hz. You would have to either use a higher tuning, or a different driver suited for a smaller box.

Strictly within the rules I can't get a 3015lf in my country for $200 equivalent, closer to $300! On another note, with more testing of my 'double it' method, I could try a driver with similar Vd that works well in about an 80-100L box, and add about 3dB to the MAX output in a 160-200L tapped horn, with sensitivity similar to the 3015lf Vented box. Car SPL woofers might make good tapped horn drivers. As I don't have much build room, I leave it open for others to test.

I'm not sure how to work out how much output from the driver gets reflected back down the horn, as it causes the driver to act like it is larger around the half wavelength point.

Also it might be better to start with a 1:1 TQWT rather than a vented box, they didn't have identical response in hornresp.

Strictly within the rules I can't get a 3015lf in my country for $200 equivalent, closer to $300! On another note, with more testing of my 'double it' method, I could try a driver with similar Vd that works well in about an 80-100L box, and add about 3dB to the MAX output in a 160-200L tapped horn, with sensitivity similar to the 3015lf Vented box. Car SPL woofers might make good tapped horn drivers. As I don't have much build room, I leave it open for others to test.

I'm not sure how to work out how much output from the driver gets reflected back down the horn, as it causes the driver to act like it is larger around the half wavelength point.

Also it might be better to start with a 1:1 TQWT rather than a vented box, they didn't have identical response in hornresp.

I've been looking through the collaborative Tapped Horn thread and told that Hornresp can't accurately simulate the half wave condition

???

I really need to buckle down and work out the math

Good luck with that...

Words from the creator of hornresp himself! I am confused though as to why I am getting less dip with a rear loaded horn (driver level with mouth) than a tapped horn with my above sim. I also don't know what proportion of the driver radiation is reflected back down the throat. Sine I was using an exponential flare because it provided the least dip though traditional parabolic will work fine too as well as conical. Also L45 or L34 in this 3 segment horn can be increased a bit but should be as short as possible.

As for a driver for a half size version, I was looking for a driver with thiele small parameters similar to 2 isobaric kappalite 3015lf (normalised to 8 ohms). I came across the Faital Pro 15HP1060 which works well in a half width version, taking up to 80 volts to reach its 12.5mm Xmax and giving between 127 to 130 dB from 40 to 130Hz before a dip.

As for a driver for a half size version, I was looking for a driver with thiele small parameters similar to 2 isobaric kappalite 3015lf (normalised to 8 ohms). I came across the Faital Pro 15HP1060 which works well in a half width version, taking up to 80 volts to reach its 12.5mm Xmax and giving between 127 to 130 dB from 40 to 130Hz before a dip.

for a a 15 inch driver, ina tapped horn, l45 needs to be long enough for at least half the drive to fit, as the l45 length determines where the rear tap is placed in the horn

if you want to sim a rear loaded horn, do an Nd sim, with no rear chamber (you can vtc and atc to sim the space behind the driver), not a tapped horn with no space for the rear tap.

if you want to sim a rear loaded horn, do an Nd sim, with no rear chamber (you can vtc and atc to sim the space behind the driver), not a tapped horn with no space for the rear tap.

did anyone ever get the sketchup from jwmbro for his dayton SS TH outlined here?

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge-200.html#post3762205

I messaged him a couple days ago but he hasnt been online since then. trying to build a pair in the coming week or 2.

I could just scale the othorn plans down I suppose, but I want to ask him some questions as well.

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge-200.html#post3762205

I messaged him a couple days ago but he hasnt been online since then. trying to build a pair in the coming week or 2.

I could just scale the othorn plans down I suppose, but I want to ask him some questions as well.

How does this driver look in the SS15?

PRV Audio's 15" 15SW2000 subwoofer performs at many levels above its price point. 12 mm of Xmax, a 4" diameter voice coil, woven surround, and side forced air cooling system all combine to form a subwoofer that remains linear at power levels up to 1,000 watts RMS!

PRV Audio's 15" 15SW2000 subwoofer performs at many levels above its price point. 12 mm of Xmax, a 4" diameter voice coil, woven surround, and side forced air cooling system all combine to form a subwoofer that remains linear at power levels up to 1,000 watts RMS!

did anyone ever get the sketchup from jwmbro for his dayton SS TH outlined here?

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge-200.html#post3762205

I messaged him a couple days ago but he hasnt been online since then. trying to build a pair in the coming week or 2.

I could just scale the othorn plans down I suppose, but I want to ask him some questions as well.

Sine143, I am glad to year you are going to try building a tapped horn. You have long been a proponent of the folded horn concept, and I am curious to see how your experience pans out.

Before you get started though, the T/S specs JWMPRO's used in his HR calculations are incorrect. They are the T/S specs that Parts-Express first published when the Dayton Pro PA385-S was first announced, but they were changed before it was actually released. When you put the new T/S specs into HR, that design is not so pretty. The low frequency response peaks at around 55 Hz and starts dropping rapidly after that. I don't think it's what you want for that booty-shakin' music you prefer.

I believe I challenged you to design a tapped horn of your own in a different thread earlier this year. I actually bought four of the Dayton Pro PA385-S drivers when Parts-Express had them on sale last month. I have been preoccupied with some other family problems lately, so now is your chance to get one designed before I do. So get off your *** young man and show this old man what you can do. Heck, If you can do a good design, maybe I will just build your design and save myself any more pain of trying to come up with the ultimate fold myself.

I dropped on of these Dayton PA385-S drivers into a Gallien-Kruegar bass guitar cabinet to do a preliminary test of it. The ported cab was about 3.5 or 4 cubic feet interior, ported a little higher that I would prefer, but the PA385-S proved to be a monster!!!! I put about 700 watts RMS into it and it wasn't farting out. Everything in my basement was shaking like crazy. My old lady thought it was the end of the world. Satan's is here!!!!!! Ahhhhhh!!!! HAHAHAHA!!!!!

Last edited:

Hey Gramps,Before you get started though, the T/S specs JWMPRO's used in his HR calculations are incorrect. They are the T/S specs that Parts-Express first published when the Dayton Pro PA385-S was first announced, but they were changed before it was actually released.

Heck, If you can do a good design, maybe I will just build your design and save myself any more pain of trying to come up with the ultimate fold myself.

I dropped on of these Dayton PA385-S drivers into a Gallien-Kruegar bass guitar cabinet to do a preliminary test of it.

While waiting for my big system to sell

http://www.diyaudio.com/forums/swap-meet/252064-complete-line-array-system-sale.html

had thoughts on revising my small system, reusing my 2x12" ported cabinet shells as either a 1 x18" TH or a 2x15" push push slot loaded bass reflex.

The PA385-S unfortunately is an 8 ohm driver, which won't get as much power from my amp as a four ohm woofer like the BC 18TBW100.

The TH is on the left, cabinet volume was reduced by the volume of wood used by the horn.

Art

Attachments

Last edited:

I'd been wonder where you had been DHAA, your threads havnt been as lively without you.

The TH wouldnt be for personal use, and the person using them has (honda civic) size restraints for their subs, and only requires response to 40/45hz, making the original JWMpros cab kind of perfect for them. givin my wholesale account with PE, anything branded dayton is CHEAP (way lower than even the sale price you snagged them at).

It looks like with the new specs, increasing s2 helps bring back the low end resp (driver no longer requires 4:1 CR for "flat" response), however, doing this also increases driver excursion considerably (high compression ratio helps keep excursion down), thus decreasing max spl, while also resulting in a larger box. I was initially worried about the high CR requirements anyways, so I guess this isnt too bad (although it means I really will be doing a complete refold....)

I believe I can afford to add at least 2 inches to the internal width (bringing it to 19") as I've found thats generally the sweet spot for the back seat of a civic.

and art, the 385 has almost twice the cone weight of the 3015lf, almost the same as the 15tbw100 (within 5grams)... you think its still too low?

The TH wouldnt be for personal use, and the person using them has (honda civic) size restraints for their subs, and only requires response to 40/45hz, making the original JWMpros cab kind of perfect for them. givin my wholesale account with PE, anything branded dayton is CHEAP (way lower than even the sale price you snagged them at).

It looks like with the new specs, increasing s2 helps bring back the low end resp (driver no longer requires 4:1 CR for "flat" response), however, doing this also increases driver excursion considerably (high compression ratio helps keep excursion down), thus decreasing max spl, while also resulting in a larger box. I was initially worried about the high CR requirements anyways, so I guess this isnt too bad (although it means I really will be doing a complete refold....)

I believe I can afford to add at least 2 inches to the internal width (bringing it to 19") as I've found thats generally the sweet spot for the back seat of a civic.

and art, the 385 has almost twice the cone weight of the 3015lf, almost the same as the 15tbw100 (within 5grams)... you think its still too low?

Last edited:

My mistake (was looking at the 18TBW100and art, the 385 has almost twice the cone weight of the 3015lf, almost the same as the 15tbw100 (within 5grams)... you think its still too low?

Considering the lesser Xmax, it should be as stiff as the BC15TBW100.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge

lol @david mcbean.

lol @david mcbean.