got those Chinese IXYS in. I’m a little suspicious about them based on what you guys had to say about fake eBay parts so I’m going to hold out til the back ordered ones from digi-key show up. Feb 3rd if I remember correctly?

getting a mcmaster order together in the meantime

Nice! do you have crimp on ring lugs for the ground stud? ....and 1/4" female fastons? you'll need the fastons for the motor run cap..or you can just solder to the terminals.

..be sure to sand off the black oxide coating for the washers on your ground stud. All oxides are insulators.

..be sure to sand off the black oxide coating for the washers on your ground stud. All oxides are insulators.

Hey dudes! Thought I’d pop in for an update…

Still waiting on my backordered 10M45s to show up. I’m not optimistic about them coming any time soon so I may start looking again.

My copy of “Tube audio design” finally arrived and I’ve been reading thru that. Very cool book but definitely having a hard time following all the math

I was always more of a history/biology kind of student in school lol.

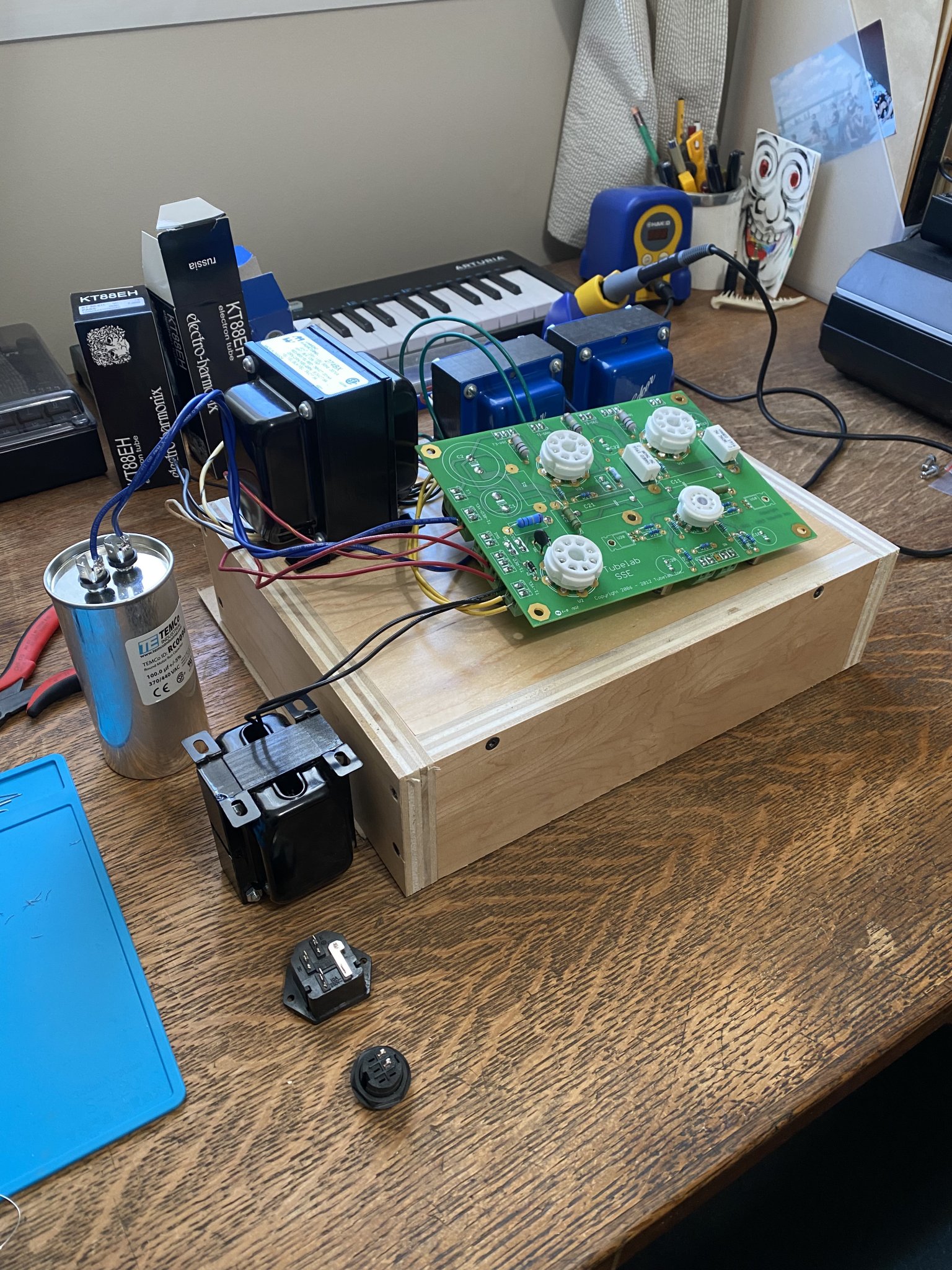

I knocked together this plywood box too see if I can jam the choke and the Cap under the hood and it all fits! I also did a little wiring in prep to do some testing when those last pieces come thru!

Still waiting on my backordered 10M45s to show up. I’m not optimistic about them coming any time soon so I may start looking again.

My copy of “Tube audio design” finally arrived and I’ve been reading thru that. Very cool book but definitely having a hard time following all the math

I was always more of a history/biology kind of student in school lol.

I knocked together this plywood box too see if I can jam the choke and the Cap under the hood and it all fits! I also did a little wiring in prep to do some testing when those last pieces come thru!

Nice! Coming along.......You could just mount the board to the top of your breadboard chassis using 1" +/- standoffs....Drill a few holes in the deck to feed the wires thru for motor run, power, etc. You don't have to kill yourself drilling accurate holes for the tubes in the wood deck. Just a thought. It won't be pretty but it'll work.

That’s a good idea! I’ll do that as soon as I solder those last pieces to my pcb.You could just mount the board to the top of your breadboard chassis

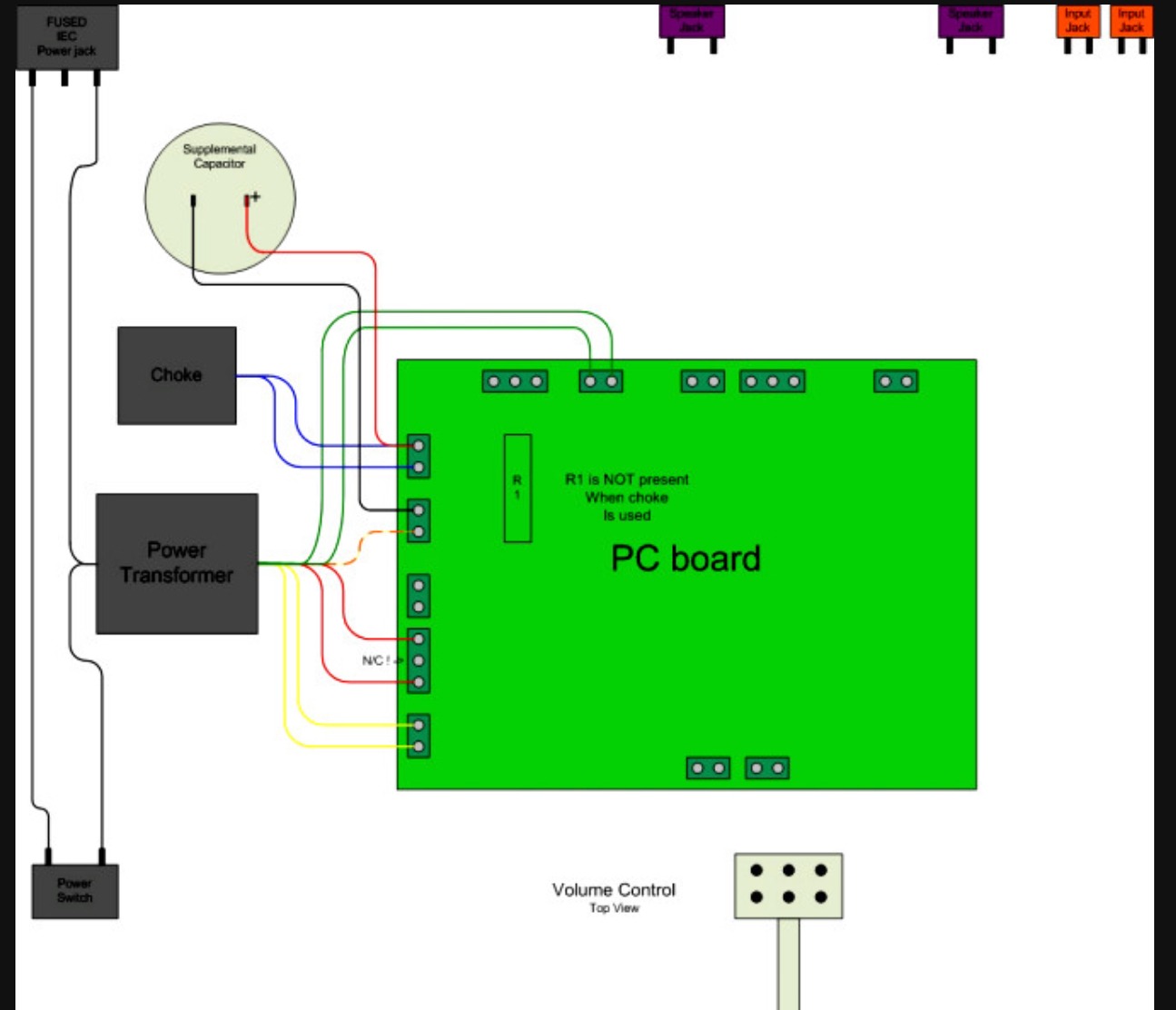

Now that I’ve begun making connections I have a few more questions I can resolve while I wait for the tube gods to grant me my semiconductors:

1. is there polarity on the motor run cap? I have it wired up as if there is none.

2. how do I wire the iec socket w/ fuse, the power switch and the power transformer? am I correct to assume the black and white wires off the power transformer are my starting point? I’ll attach a photo of my parts.

3. I have a choke attached to the terminal as indicated in the wiring diagram. Does that mean I have to jumper R1?

4. is this volume pot ok? The diagram seems to reflect a different one.

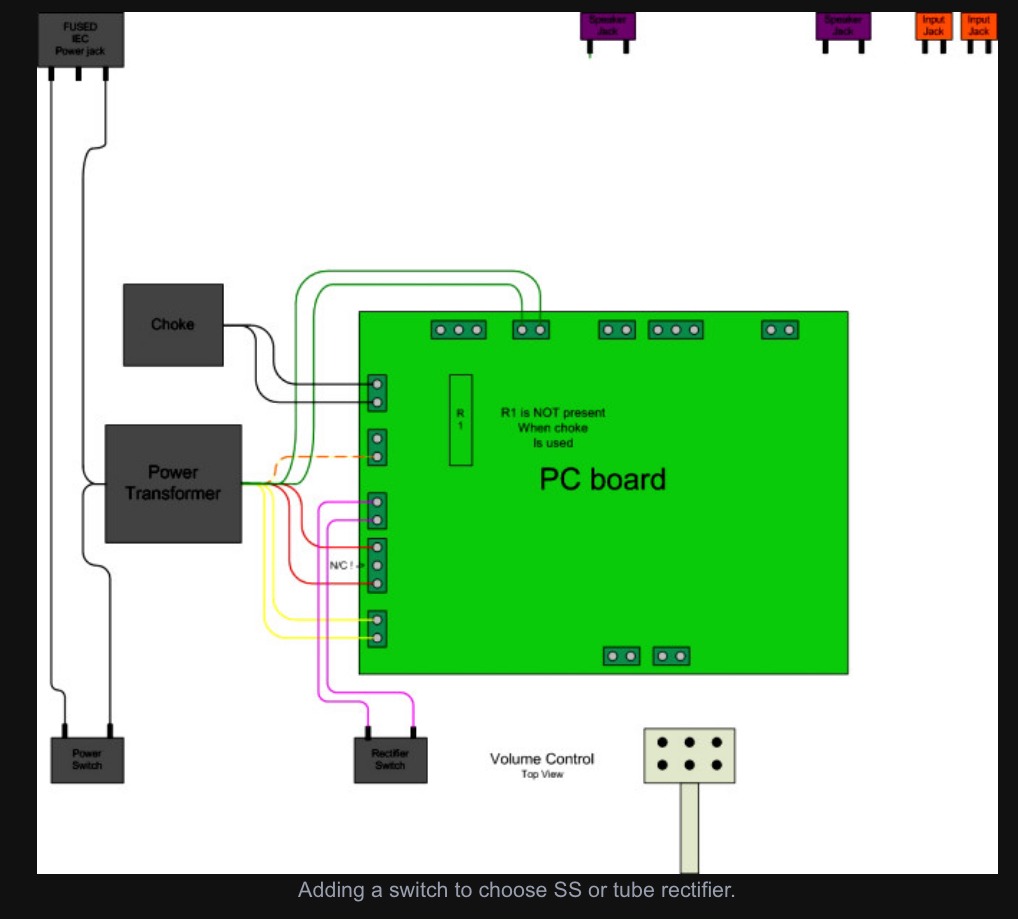

5. I noticed I’m the diagram an option to add a switch for SS rectification / tube rectification. If I don’t add this switch what is the default setting this amp will run? I was planning on running it with tube rectification so maybe this a thing I’ll need to add. If so, what are the requirements for this switch?

thanks again for the very useful advice!

1. is there polarity on the motor run cap? I have it wired up as if there is none.

2. how do I wire the iec socket w/ fuse, the power switch and the power transformer? am I correct to assume the black and white wires off the power transformer are my starting point? I’ll attach a photo of my parts.

3. I have a choke attached to the terminal as indicated in the wiring diagram. Does that mean I have to jumper R1?

4. is this volume pot ok? The diagram seems to reflect a different one.

5. I noticed I’m the diagram an option to add a switch for SS rectification / tube rectification. If I don’t add this switch what is the default setting this amp will run? I was planning on running it with tube rectification so maybe this a thing I’ll need to add. If so, what are the requirements for this switch?

thanks again for the very useful advice!

A few tidbits......In the US,mains black is hot, white is neutral and green is ground. In Europe and lots of other places they use brown as hot, blue as neutral and green as ground. We see lots of the brown/blue/green here these days because there is an effort to "harmonize" the various safety standards around the world. Typically, stuff that is designed for world-wide use will use the IEC (International Electrotechnical Commission) standards and colors. In the old days you would have a US model, a Europe model, a Japan model, etc......tons of part numbers and assemblies tested to different safety standards. All that inventory and testing costs $$.

These days we have universal (100-240V) power supplies with IEC 320 power inlets....this allows manufacturers to build one model that meets many worldwide standards........for Europe you toss in a Euro IEC modular power cord, for US a US modular power cord, etc. This is also why user manuals are in 6 different languages....only 1 part number to keep up to date. The same manual goes out with every device around the world (with a few exceptions).

These days we have universal (100-240V) power supplies with IEC 320 power inlets....this allows manufacturers to build one model that meets many worldwide standards........for Europe you toss in a Euro IEC modular power cord, for US a US modular power cord, etc. This is also why user manuals are in 6 different languages....only 1 part number to keep up to date. The same manual goes out with every device around the world (with a few exceptions).

Thanks for this intel!A few tidbits....

Oh you’re right! It certainly is. Thanks for catching this, I’m going to order the correct one now. Looks like I accidentally ordered one for a guitar? OopsThe volume pot looks like it's mono

It appears I’ve already unknowingly installed the diodes without really understanding what I was doingdo not install the rectifier didoes at all

So now it seems it might be worth putting a switch on there so I can use both. May as well since I have it set up. Do I have that right? Any recommendations for a decent toggle switch to use?

Ideally you should earth the exposed metal parts, so plan to have a 3 lead supply, and link the OPT cases to the earth point. I also think it is a good idea to have a DPDT power switch so you are insured against the case where live and neutral are reversed.

Also - your IEC has a 10A fuse, so makes me wonder whether relying on fused IEC sockets is a good idea? I have a seperate fuse on all the amps I have built, for the minimum that works - maybe 2A in the US - and then I also fit fuses on the secondary leads too - 250mA each leg as recommended here ...

Fuses - Valve Wizard

Power switches - Valve Wizard

Also - your IEC has a 10A fuse, so makes me wonder whether relying on fused IEC sockets is a good idea? I have a seperate fuse on all the amps I have built, for the minimum that works - maybe 2A in the US - and then I also fit fuses on the secondary leads too - 250mA each leg as recommended here ...

Fuses - Valve Wizard

Power switches - Valve Wizard

Woodchuck: A DPDT (double pole/double throw) switch breaks two circuits instead of one. So you can make/break both the hot and neutral of the mains 115V power. Breaking just the hot as you are planning on doing is perfectly acceptable for a home-built amp. As OldHector mentioned, breaking the neutral as well is a bit safer since some homes sometimes end up having the white neutral wire being the hot wire..it happens, esp in older homes.Ideally you should earth the exposed metal parts, so plan to have a 3 lead supply, and link the OPT cases to the earth point. I also think it is a good idea to have a DPDT power switch so you are insured against the case where live and neutral are reversed.

Also - your IEC has a 10A fuse, so makes me wonder whether relying on fused IEC sockets is a good idea? I have a seperate fuse on all the amps I have built, for the minimum that works - maybe 2A in the US - and then I also fit fuses on the secondary leads too - 250mA each leg as recommended here ...

Fuses - Valve Wizard

Power switches - Valve Wizard

Old Hector has also mentioned tying the output transformer cases to ground. I haven't specifically done this on amps that I have built but it doesn't hurt to have the transformer cases grounded. You could sand off the paint under one foot if you wanted to.

Hopefully you have a 2A fuse to replace the 10A fuse in the IEC inlet.

- Home

- More Vendors...

- Tubelab

- Simple Simple SE questions