I'm at my wits end trying to figure out how to rewind this radio tuner string on a Philips AZ2000 Radio,CD,Tape player.Any help I can get with this will be greatly appreciated.If more photos are needed let me know.

Attachments

Find the service sheet for the radio. That will show you where the string goes.

I have the service manual and it doesn't show a diagram? Ive contacted Philips to see if they had anything like an exploded diagram and they just fobbed me off.They said that it is unrepairable? I replied saying Ive repaired it already I just need a diagram to put it back together.Ive had no reply.

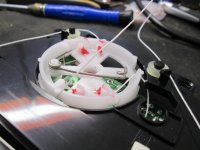

Ive tried Vintage Radio etc...etc... Ive downloaded a book with 500 odd diagrams of different restrings But this one just had to be different,its got a weird wire spring? that looks like only one string goes on it? I can manage to get it nearly on but I'm scared that Ill break the string if I stretch it too far to get the string over the pulley. Do you think it looks right, I have two winds around the tuner knob near the top between the pulleys? Ive tried three turns but that didn't work out either? This site will only let me upload one photo so Ill upload a detailed close-up next.

Attachments

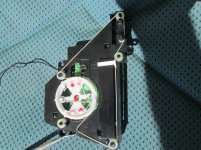

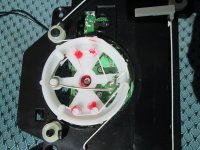

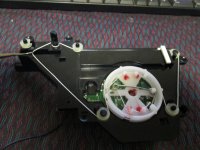

Ive tried all your suggestions fellas and more but it seems impossible to get it back on? You can see a pin on the end of the spring is locked in a hole so there is hardly any movement? When I put too much tension on the string the tuner board comes out of alignment,it needs to be screwed back down to the chassis but if I do that its upside down and I cant get at it? It must have been constructed by a robot with 5 arms.LOL The photos show one turn on the tuner knob.Looks like I may have to go without a station indicator and drill a hole in the case for another tuner knob?

Attachments

Last edited:

"You can see a pin on the end of the spring is locked in a hole so there is hardly any movement?"

Yes, I see your problem. It doesn't make any sense. That spring arrangement requires the arm (with the loop) to be able to move widely.

Maybe the vertical pin to the left of the loop is just "parked" in that slot, and needs lifting out into the lower segent. There you will have more tension but greater chord length.

That sort of looks right, but this is a cracking bottle of bordeaux ....

Yes, I see your problem. It doesn't make any sense. That spring arrangement requires the arm (with the loop) to be able to move widely.

Maybe the vertical pin to the left of the loop is just "parked" in that slot, and needs lifting out into the lower segent. There you will have more tension but greater chord length.

That sort of looks right, but this is a cracking bottle of bordeaux ....

Hi,

I have to admit I'm somewhat bemused by the spring, it

only makes sense if its bent back towards the back of the

hole /slot and one or both cords just go behind the vertical

drop, I'm pretty (very) sure the cord does not go in the loop.

rgds, sreten.

A clue is the range of movement of the white wheel, you

may have overwrapped it and need more turns on the

tuning knob. My best guess its 180 degrees parallel

to the two pulley's, and you don't need any cord

across the gap, that is the way I'd approach it.

There is no need to wrap the big pulley, the

gap gives the precision of the alignment.

If its miles too long unwrapping the big pulley

wrap all the smaller pulley's or some of them.

I have to admit I'm somewhat bemused by the spring, it

only makes sense if its bent back towards the back of the

hole /slot and one or both cords just go behind the vertical

drop, I'm pretty (very) sure the cord does not go in the loop.

rgds, sreten.

A clue is the range of movement of the white wheel, you

may have overwrapped it and need more turns on the

tuning knob. My best guess its 180 degrees parallel

to the two pulley's, and you don't need any cord

across the gap, that is the way I'd approach it.

There is no need to wrap the big pulley, the

gap gives the precision of the alignment.

If its miles too long unwrapping the big pulley

wrap all the smaller pulley's or some of them.

Last edited:

+1 post 12

unhook the spring from the slot , the emerging hook of the spring should tension against the cord and the cord should not go around the spiral .

I took the string off the spiral and unhooked the spring,then I had less string than before?

Hi,

I have to admit I'm somewhat bemused by the spring, it

only makes sense if its bent back towards the back of the

hole /slot and one or both cords just go behind the vertical

drop, I'm pretty (very) sure the cord does not go in the loop.

rgds, sreten.

A clue is the range of movement of the white wheel, you

may have overwrapped it and need more turns on the

tuning knob. My best guess its 180 degrees parallel

to the two pulley's, and you don't need any cord

across the gap, that is the way I'd approach it.

There is no need to wrap the big pulley, the

gap gives the precision of the alignment.

If its miles too long unwrapping the big pulley

wrap all the smaller pulley's or some of them.

The string will only wrap around the white wheel once each way?I feel like Ive done it every way that I can possibly cut it & dice it. This is doing my head in so I'm giving it a rest for a while,otherwise its liable to end up in the bin.

Hi,

IMO the cord does not go round the white

wheel and that is what you are doing wrong.

The cords go behind the pin in that slot.

From there they go through the gap

and directly to each of the pulley's IMO.

rgds, sreten.

If you mean that it goes on the inside of the white wheel? It wont work whichever way I look at it,there's way too much string left over.

Hi,

If there is too much left over wrap more on the tuning

knob, and / or wrap one or more of the small pulley's.

It can't be that difficult to get it to work.

The cord has no tension spring, and behind the pin

is the best way of applying tension to it, AFAICS.

rgds, sreten.

If there is too much left over wrap more on the tuning

knob, and / or wrap one or more of the small pulley's.

It can't be that difficult to get it to work.

The cord has no tension spring, and behind the pin

is the best way of applying tension to it, AFAICS.

rgds, sreten.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Rewinding radio tuner string?