Knowing what I do the motors must have been selected. I must be honest they are of average quality which means nothing bad. The Lenco is better. If you think about it the motor if sold to others for perhaps non hi fi use ( a fan ). What trouble was it to put a strobe on it in final testing and perhaps a vibration test. If lets say the standard motor was $1 and Thorens would pay $5 all were happy. Garrard had no outlet for their motors. BTW. Balancing motors usually makes them worse. Make them right in the first place is better. Of all the things that matter on centre is the big one. If you see how the rotor is made it is a surprise this is true. 90 % it is. The balancing is a nightmare ( I have used the guys F1 people use and they failed ). When I see balancing on motors I often wonder if it is the least metal they could take without it doing harm. That is, just for show. The problem is most balancing machines work in 3D. What is more useful is to work side to side. I use static balance on razor blade runners ( my design ). I drill a tiny amount each time. Maybe the good guys also did this? Balancing machines often damage the shafts unless super hard. I did get to see the Mercades F1 engine for my trouble and a new Ford Diesel when I tried commersial balancing. 1950's text books suggest at less than 3000 RPM static balance is preferable.

Thorens did the so called dynamic balancing at the two planes and running of course the best and only way to get it right, that days.The rotor is driven not the shaft !

The static balanancing with razorblades comes from the model engineering world I used this for a Garrard synchromotor who lost his magnet Unfortunately no option other.

Am curious how you know Thorens select the motors read somewere ?

preferable or adequate?1950's text books suggest at less than 3000 RPM static balance is preferable.

I had a bash at winding and balancing a slot car rotor.

A good one revs to over 100krpm.

Mine was useless.

I bought my rewound and balanced motors after that.

Last edited:

I was given to understand it was a common Swiss motor. If that is true to select at the testing phase would not be difficult. It is also good for everyone to do this. It could even be Thorens were the same company and needed an industrial use. That would be totally normal 1950's engineering. Thorens were a famous company before 1888. I know the German side better. That is not a happy familly, not all was shared or known by Germany.

The big surprise is to get a two pole motor from an electic fan heater costing <$20 retail. The motors are usually a work of art. They are not the junk they should be. They even balance reasonably well. The bearings also self-aligning and good grade. They have to be as the customer hates noise and it must last at least 1 year. When you think the motor must cost $2 it is remarkable. The one I took apart last was made in Ireland. Without any insult to the TD124 the engineering distance between these motors is not vast, nor component sizes. 2 or 4 pole being a bigger question. To select any motor like this from thousands it not too difficult. To set up a low cost 4 pole production would make sense. I know these motors too well to think Thorens were different, not least it looks to be cheaply made ( sorry it does and that's no put down ). The Lenco looks better than Garrard or Thorens by some distance. I doubt the Lenco is as big as it needs to be as my only doubt. It is simply beautiful as engineering. The Lenco looks like a Lenco and not much else, although conforming to type.

I have seen the same with Teac CD players. They are said to be works of art and wonderful engineering. Not really. In the heart it is standard stuff and it does the same stuff. It is bolt on metal and fools many people. The older Phiilps CD drive was a work of art and nearly no one outside of the industry realised. They would say the Teac was better. Sorry guys you should have got your screwdrivers out and really looked. The Philips is a watch and the Teac a bicycle. The latter Philips also a bicycle. WD40 on the latter Philips runners can get the oil working again. That was the most stupid change in history. Belgium employment rules I am told closed the factory.

The big surprise is to get a two pole motor from an electic fan heater costing <$20 retail. The motors are usually a work of art. They are not the junk they should be. They even balance reasonably well. The bearings also self-aligning and good grade. They have to be as the customer hates noise and it must last at least 1 year. When you think the motor must cost $2 it is remarkable. The one I took apart last was made in Ireland. Without any insult to the TD124 the engineering distance between these motors is not vast, nor component sizes. 2 or 4 pole being a bigger question. To select any motor like this from thousands it not too difficult. To set up a low cost 4 pole production would make sense. I know these motors too well to think Thorens were different, not least it looks to be cheaply made ( sorry it does and that's no put down ). The Lenco looks better than Garrard or Thorens by some distance. I doubt the Lenco is as big as it needs to be as my only doubt. It is simply beautiful as engineering. The Lenco looks like a Lenco and not much else, although conforming to type.

I have seen the same with Teac CD players. They are said to be works of art and wonderful engineering. Not really. In the heart it is standard stuff and it does the same stuff. It is bolt on metal and fools many people. The older Phiilps CD drive was a work of art and nearly no one outside of the industry realised. They would say the Teac was better. Sorry guys you should have got your screwdrivers out and really looked. The Philips is a watch and the Teac a bicycle. The latter Philips also a bicycle. WD40 on the latter Philips runners can get the oil working again. That was the most stupid change in history. Belgium employment rules I am told closed the factory.

Thorens bearing is good idea. I suppose they make bearing spindle and recess which holds the ball at the same time. So Ball is not off center. Steel Ball can be rotated if it develops a flat in long run. Which is good thing.

Shindo Bearing with many contact points can be curious concept. If allowed to hazard a guess. The Balls 'roll' instead of grinding and weight of platter is distributed at multiple points, compared to single point bearing. How much difference or improvement it makes may require measurements.

Shindo Bearing with many contact points can be curious concept. If allowed to hazard a guess. The Balls 'roll' instead of grinding and weight of platter is distributed at multiple points, compared to single point bearing. How much difference or improvement it makes may require measurements.

preferable or adequate?

I had a bash at winding and balancing a slot car rotor.

A good one revs to over 100krpm.

Mine was useless.

I bought my rewound and balanced motors after that.

Also for fractional horsepower motors my info comes from Pustola/Sliwinski -Kleine Einphasenmotoren 1962 !

Thorens bearing is good idea. I suppose they make bearing spindle and recess which holds the ball at the same time. So Ball is not off center. Steel Ball can be rotated if it develops a flat in long run. Which is good thing.

Shindo Bearing with many contact points can be curious concept. If allowed to hazard a guess. The Balls 'roll' instead of grinding and weight of platter is distributed at multiple points, compared to single point bearing. How much difference or improvement it makes may require measurements.

The more balls the more vibration components extra we don"t want that in spindle bearing .Pitty we can "t measure this wonder what we shall see.

I was given to understand it was a common Swiss motor. If that is true to select at the testing phase would not be difficult. It is also good for everyone to do this. It could even be Thorens were the same company and needed an industrial use. That would be totally normal 1950's engineering. Thorens were a famous company before 1888. I know the German side better. That is not a happy familly, not all was shared or known by Germany.

The big surprise is to get a two pole motor from an electic fan heater costing <$20 retail. The motors are usually a work of art. They are not the junk they should be. They even balance reasonably well. The bearings also self-aligning and good grade. They have to be as the customer hates noise and it must last at least 1 year. When you think the motor must cost $2 it is remarkable. The one I took apart last was made in Ireland. Without any insult to the TD124 the engineering distance between these motors is not vast, nor component sizes. 2 or 4 pole being a bigger question. To select any motor like this from thousands it not too difficult. To set up a low cost 4 pole production would make sense. I know these motors too well to think Thorens were different, not least it looks to be cheaply made ( sorry it does and that's no put down ). The Lenco looks better than Garrard or Thorens by some distance. I doubt the Lenco is as big as it needs to be as my only doubt. It is simply beautiful as engineering. The Lenco looks like a Lenco and not much else, although conforming to type.

I have seen the same with Teac CD players. They are said to be works of art and wonderful engineering. Not really. In the heart it is standard stuff and it does the same stuff. It is bolt on metal and fools many people. The older Phiilps CD drive was a work of art and nearly no one outside of the industry realised. They would say the Teac was better. Sorry guys you should have got your screwdrivers out and really looked. The Philips is a watch and the Teac a bicycle. The latter Philips also a bicycle. WD40 on the latter Philips runners can get the oil working again. That was the most stupid change in history. Belgium employment rules I am told closed the factory.

Yes thats the same I heard but never confirmed , the motor is not the same quality as the Garrard revision from the latter one is a lot easier .

Lenco better then Garrard why on what grounds ?

Teac driveunit in the VRDS series where ok ,but the Philips CDM drive < you can take this spindle motor apart !> were best imho.same build quality as the chassis TD124 !

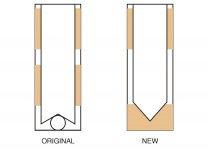

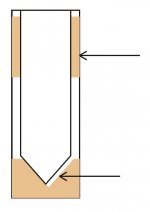

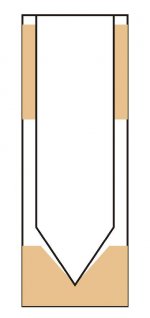

Would this be a good idea for TD-124 bearing? We can discard the bottom bush so we will have less surface area (less noise). And replace it with precision conical bush which holds conical shaft.

Regards.

Thorens did this at the TD150 -160 etc. and LINN .Only the platter from the TD124 is about 5kg.

The original using the single ball relies of the cup hole being in the middle.

If this is in the middle then the ball rotates on the contact point.

That is virtually noiseless, i.e. no rumble.

But we know that rumble is never zero, so that confirms that the hole is not central or there is another rumble mechanism.

The pointed cone is nearly impossible to make concentric.

That is virtually guaranteed to trace out a small circle as the shaft rotates.

This would be equivalent to an off centre hole for the left diagram.

I consider this version to have far more rumble.

And will have the other rumble mechanism as well.

The ball version can be rejuvinated by replacing the ball or moving the ball onto a new contact point. I'm not sure how you arrange that?

A worn spindle&cone is scrap.

If this is in the middle then the ball rotates on the contact point.

That is virtually noiseless, i.e. no rumble.

But we know that rumble is never zero, so that confirms that the hole is not central or there is another rumble mechanism.

The pointed cone is nearly impossible to make concentric.

That is virtually guaranteed to trace out a small circle as the shaft rotates.

This would be equivalent to an off centre hole for the left diagram.

I consider this version to have far more rumble.

And will have the other rumble mechanism as well.

The ball version can be rejuvinated by replacing the ball or moving the ball onto a new contact point. I'm not sure how you arrange that?

A worn spindle&cone is scrap.

OK. Don't know why a precision conical shape can not be made. But if shaft is perfectly center and perpendicular. the conical shape would self align. Will it not ?The pointed cone is nearly impossible to make concentric.

That is virtually guaranteed to trace out a small circle as the shaft rotates.

This would be equivalent to an off centre hole for the left diagram.

I consider this version to have far more rumble.

And will have the other rumble mechanism as well.

The ball version can be rejuvinated by replacing the ball or moving the ball onto a new contact point. I'm not sure how you arrange that?

A worn spindle&cone is scrap.

Even if one considers it to be little off center as shown in the picture (exaggerated) the movement at gap at the bottom will be restricted by that particular side of the bush.

Regards.

Attachments

The more balls the more vibration components extra we don"t want that in spindle bearing .Pitty we can "t measure this wonder what we shall see.

I had the same exact thought upon seeing that bearing design, I can't imagine it is the quietest design possible for the requirement.

I'm glad I posted the Shindo. It's good to show experiance can win the day. I said the Lenco better than Garrard to show that I am not devoted to my own brand. The Lenco shows magical finishing details that cost money to do. The TD124 motor end caps and laminations are very cheap. None of that is saying bad. just no one who saw a Lenco would guess it has gold in the engine room. Even the Lenco bad things have plenty of good reason behind them. The arms are not as awful as they look and the bearings are very different to most ( they do work in a logical way, it stops bearing chatter into the bargain ). Try my magnet trick. It is cheap and must work.

http://www.lencoheaven.net/forum/index.php?topic=2018.0

Vinyl Asylum

http://www.lencoheaven.net/forum/index.php?topic=2018.0

Vinyl Asylum

So it seems the Variac has solved the problem. The voltage in my apartment must be insanely high, because I have to set the Variac to about 105-110 in order for it to be just under 120 on the dial.

The sound is much more alive and vivid than when I had the table set to 125-150V. Thank you for all the help on this thread. Though I would still like to explore getting a new eddy magnet down the road, to help stabilize the speed a tad more. Does anyone know of where to find a new magnet?

The sound is much more alive and vivid than when I had the table set to 125-150V. Thank you for all the help on this thread. Though I would still like to explore getting a new eddy magnet down the road, to help stabilize the speed a tad more. Does anyone know of where to find a new magnet?

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII