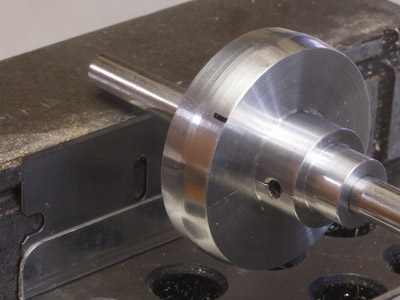

Turns out I did think of a way to balance the reduced speed pulley.

I polished the mandrel I used to turn the pulley a bit and rolled it on the edges of two razor blades. Since the setup still isn't what you would call precision I averaged many readings using different angles on the mandrel and places on the blades. I drilled holes in the pulley till the pulley rolls seemed random.

Note the mark scored through the set screw hole. The Thorens pulley has the unusual feature of having opposing set screws. Items such as this usually have only one set screw or the set at 90 degrees. I suspect they used opposing screws to maintain balance so I followed suit. However, this arrangement raises the possibility of the pulley settling on the motor differently depending on which screw is tightened first. I scored one set screw hole and throughout the build and testing tightened this one first. This practice should be followed when installing the pulley on the motor shaft.

Doug

It's on it's way Kevin.

Bare, I'm intrigued by your suggestion but having trouble understanding. I'm thinking one end of the mandrel would be stuck to the magnet and the other supported by the magnetic field. Wouldn't the ends of the mandrel have to be precision pointed? (and not be made out of stainless steel like this one.) Don't store bought mandrels have cupped ends for mounting between centers?

Bare, I'm intrigued by your suggestion but having trouble understanding. I'm thinking one end of the mandrel would be stuck to the magnet and the other supported by the magnetic field. Wouldn't the ends of the mandrel have to be precision pointed? (and not be made out of stainless steel like this one.) Don't store bought mandrels have cupped ends for mounting between centers?

Hi Doug,

It arrived tonight, and of course being the very patient and deliberate soul I am; I only slightly rushed to install and try it. Why I even took pictures.

The verdict: It works, and shows no signs of imbalance or other problems. I was able to double the distance from the stepped pulley to brake magnet. Definitely a bit quieter. It might be subjectively better than the stock pulley too since the motor is not working so hard against the brake. I certainly hear nothing untoward, if anything perhaps an overall improvement in coherence. Speed stability is fine, and warm up performance on my MKI is similar or perhaps no different at all.

Very nice! I hope you will consider making more - I'd be up for another frankly.

I've just added a picture of my test mule playing one of my recent scores.. This 124 came to me in pieces (cannibalized to upgrade a TD-121 to a 124) and was purchased by a friend for the paltry sum of $10 at an MIT ham radio flea market, unfortunately that is where cheap ended - all of the pieces to fix it so far have added up to more than I paid for my mint 124/II.

It arrived tonight, and of course being the very patient and deliberate soul I am; I only slightly rushed to install and try it. Why I even took pictures.

The verdict: It works, and shows no signs of imbalance or other problems. I was able to double the distance from the stepped pulley to brake magnet. Definitely a bit quieter. It might be subjectively better than the stock pulley too since the motor is not working so hard against the brake. I certainly hear nothing untoward, if anything perhaps an overall improvement in coherence. Speed stability is fine, and warm up performance on my MKI is similar or perhaps no different at all.

Very nice! I hope you will consider making more - I'd be up for another frankly.

I've just added a picture of my test mule playing one of my recent scores.. This 124 came to me in pieces (cannibalized to upgrade a TD-121 to a 124) and was purchased by a friend for the paltry sum of $10 at an MIT ham radio flea market, unfortunately that is where cheap ended - all of the pieces to fix it so far have added up to more than I paid for my mint 124/II.

Attachments

I finally rebuilt the motor with jec965's kit. I've tried two different eddy magnets with similar results. Both maxed out on the brake adjuster and running too fast. I remember Kevin saying he had an issue with one magnet, but two? Any thoughts?

Clearly the upside down (50Hz) pulley will result in gross speed errors on 60Hz power with a properly serviced and maintained motor. Note that some owners did this as the motors gummed up due to deteriorating lubricant. I've seen several!

What lubricants are you using? I have found using anything lighter than 20wt oil in the motor bearings may result in problems controlling the speed - this is exacerbated by high line, but I have generally found moving to the next tap (125 - 150V) kills the dynamics despite the fact that everything looks near ideal. I use an external bucking transformer on my MKII which does help the noise situation by allowing me to back the eddy current brake off a bit more than would otherwise be possible. (Line voltage to the motor is about 111V on average)

The magnet I referred to was clearly almost fully demagnetized, and of the slightly more than half dozen I have played with this was the only one, however that does leave me wondering whether the magnets as strong as they seem to be now were considerably stronger in the past?

The other thing that is important is the thickness of the belt, refer back to earlier posts where I provided measurements of belt thickness for a number of replacements I tried - almost if not all were thicker than the originals and make the speed issue worse.

John, I'm using an Ortofon Meister Silver GM to be specific on this arm which is a modified SME 3009 Series II unimproved. This SPU previously lived on the other table on a 12" Schick arm, but I now have an SPU Royal N on that table.

To run an SPU on this arm you need a 30gm supplemental weight like the one I use.. Remove the rubber grommets from the bed plate and mount it directly on the arm board - much better bass amongst other things. Ditch the lightweight S2 head shell and use an AT Technihard head shell with a low to moderate compliance cartridge. A modified DL-103 in a decent body (not the stock plastic one) would be ok, but for about the same money an AT33PTG/II would be a pretty significant improvement based on comments from friends. (I have not tried one yet, but it is on my list of non spu cartridges to try) Note that I am an unabashed fan of LOMC and can't honestly recommend anything else these days.

To run an SPU on this arm you need a 30gm supplemental weight like the one I use.. Remove the rubber grommets from the bed plate and mount it directly on the arm board - much better bass amongst other things. Ditch the lightweight S2 head shell and use an AT Technihard head shell with a low to moderate compliance cartridge. A modified DL-103 in a decent body (not the stock plastic one) would be ok, but for about the same money an AT33PTG/II would be a pretty significant improvement based on comments from friends. (I have not tried one yet, but it is on my list of non spu cartridges to try) Note that I am an unabashed fan of LOMC and can't honestly recommend anything else these days.

The verdict: It works, and shows no signs of imbalance or other problems.

Thanks for the compliments. I think the lack of the 50 Hz pulley is a plus. I saw the way Thorens had hollowed out both pulleys and figured they were trying to reduce mass. On one hand a massive pulley could provide a flywheel effect that would smooth out motor cogging irregularities but running at such a high RPM a slight imbalance could cause vibration.

You did me a great favor and the thing just works, complement well deserved imo..

I found the single pulley very easy to set up and I could not honestly tell any difference in noise and vibration between your custom pulley and the original. It runs just as quietly and is frankly much easier to set up so the belt runs properly on the crown.

Overall the table seemed a bit happier (yeah I know it is an inanimate object ) and in terms of all the attributes one associates with a TD-124 like drive, dynamics, etc were all at least the equal of the other pulley set up, and given this is a MKI with the stock motor suspension the reduced load on the motor may have slightly reduced vibration in the drive train - it seemed slightly smoother..

) and in terms of all the attributes one associates with a TD-124 like drive, dynamics, etc were all at least the equal of the other pulley set up, and given this is a MKI with the stock motor suspension the reduced load on the motor may have slightly reduced vibration in the drive train - it seemed slightly smoother..

If you are making more I'd recommend sending one to Volken as he'd be able to measure any resulting change in noise floor due to the reduced eddy current brake load. I suspect based on what I heard last night that it may be significant.

I found the single pulley very easy to set up and I could not honestly tell any difference in noise and vibration between your custom pulley and the original. It runs just as quietly and is frankly much easier to set up so the belt runs properly on the crown.

Overall the table seemed a bit happier (yeah I know it is an inanimate object

If you are making more I'd recommend sending one to Volken as he'd be able to measure any resulting change in noise floor due to the reduced eddy current brake load. I suspect based on what I heard last night that it may be significant.

John, I'm using an Ortofon Meister Silver GM to be specific on this arm which is a modified SME 3009 Series II unimproved. This SPU previously lived on the other table on a 12" Schick arm, but I now have an SPU Royal N on that table.

To run an SPU on this arm you need a 30gm supplemental weight like the one I use.. Remove the rubber grommets from the bed plate and mount it directly on the arm board - much better bass amongst other things. Ditch the lightweight S2 head shell and use an AT Technihard head shell with a low to moderate compliance cartridge. A modified DL-103 in a decent body (not the stock plastic one) would be ok, but for about the same money an AT33PTG/II would be a pretty significant improvement based on comments from friends. (I have not tried one yet, but it is on my list of non spu cartridges to try) Note that I am an unabashed fan of LOMC and can't honestly recommend anything else these days.

Kevin,

I've read some great reviews on the AT33PTG/II. I'm kinda new to matching a cartridge and tonearm and calculate the resonance to about 8 Hz. Think that's okay for the non-improved arm?

John

I think that is in the acceptable range, what head shell did you use for the calculation? Would not want it to be much lower though..

I used the standard SME one, which I assume is included in the effective mass(?).

Hi John,

If it is the standard Swiss Cheese S2 head shell I mentioned in a previous post you really need to get rid of it, it quite ruins the performance of this arm unfortunately. I learned this the hard way.. Even a cheap Ortofon head shell is better.

Even a cheap Ortofon head shell is better.

Here is an example of a cheap one that really works OK, there are better however and I really like the AT Technihard: ortofon eBay item # 131065322809 and AT: 271400078308 (13gm version) - might be too heavy with the AT33PTG/II on this arm. The Technihard comes in 13, 15, and 18 gm versions and has proven to be great with a number of LOMC.

Note that the Meister Silver weighs in at 32gms and I have no problems with infrasonic resonances in either plane. Tracks very nicely. Lateral compliance is 8um/nm - so quite low. The AT33PTG/II is about 10um/nm best I can figure out.. The 13gm AT and cartridge would come in at ~20gms which I believe would be a good match for the Series II unimproved. (You would need the supplemental counterweight.)

If it is the standard Swiss Cheese S2 head shell I mentioned in a previous post you really need to get rid of it, it quite ruins the performance of this arm unfortunately. I learned this the hard way..

Here is an example of a cheap one that really works OK, there are better however and I really like the AT Technihard: ortofon eBay item # 131065322809 and AT: 271400078308 (13gm version) - might be too heavy with the AT33PTG/II on this arm. The Technihard comes in 13, 15, and 18 gm versions and has proven to be great with a number of LOMC.

Note that the Meister Silver weighs in at 32gms and I have no problems with infrasonic resonances in either plane. Tracks very nicely. Lateral compliance is 8um/nm - so quite low. The AT33PTG/II is about 10um/nm best I can figure out.. The 13gm AT and cartridge would come in at ~20gms which I believe would be a good match for the Series II unimproved. (You would need the supplemental counterweight.)

Hi John,

If it is the standard Swiss Cheese S2 head shell I mentioned in a previous post you really need to get rid of it, it quite ruins the performance of this arm unfortunately. I learned this the hard way..Even a cheap Ortofon head shell is better.

Here is an example of a cheap one that really works OK, there are better however and I really like the AT Technihard: ortofon eBay item # 131065322809 and AT: 271400078308 (13gm version) - might be too heavy with the AT33PTG/II on this arm. The Technihard comes in 13, 15, and 18 gm versions and has proven to be great with a number of LOMC.

Note that the Meister Silver weighs in at 32gms and I have no problems with infrasonic resonances in either plane. Tracks very nicely. Lateral compliance is 8um/nm - so quite low. The AT33PTG/II is about 10um/nm best I can figure out.. The 13gm AT and cartridge would come in at ~20gms which I believe would be a good match for the Series II unimproved. (You would need the supplemental counterweight.)

Hi Kevin,

I didn't realize you meant dump the "swiss cheese", will do. My confusion is the ATs measure compliance at 100Hz rather than 10. And I've read to multiply by 2 and subtract 1-2. This would put it at 18-19um/nm. So, I'm not sure what to do.

John

I've always viewed that rule of thumb with some suspicion as I have no idea how accurate it is, (probably not at all) and it turns what manufacturers often bill as a low compliance cartridge into a medium to high compliance cartridge. I've not had a problem with anything I've stuck on this arm so far, but it is a hard judgment call to make.

You could also run a lighter head shell. I have run a Grado Platinum Reference which has no doubt higher compliance than the 33PTG/II without difficulty on a 3009 Series II unimproved. Don't cheap out though, look for something light, but very stiff.

You could also run a lighter head shell. I have run a Grado Platinum Reference which has no doubt higher compliance than the 33PTG/II without difficulty on a 3009 Series II unimproved. Don't cheap out though, look for something light, but very stiff.

I've always viewed that rule of thumb with some suspicion as I have no idea how accurate it is, (probably not at all) and it turns what manufacturers often bill as a low compliance cartridge into a medium to high compliance cartridge. I've not had a problem with anything I've stuck on this arm so far, but it is a hard judgment call to make.

You could also run a lighter head shell. I have run a Grado Platinum Reference which has no doubt higher compliance than the 33PTG/II without difficulty on a 3009 Series II unimproved. Don't cheap out though, look for something light, but very stiff.

Thanks Kevin. I'll to do more homework to get my head around this.

John

Rather that clutter this thread with a description of why I hesitate to commit to making more pulleys I started a thread showing how I made the first one.

Could you post a link to that thread? Thanks.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII