Hi Mark,

Aside from the better than average eye patterns with the test CD player, the additional information is clearly shown with the regular eye pattern as a second dual level so that both upper and lower portions have two distinct levels.

With the normal occurrence of degraded eye patterns I see these days, the extra 25% they are attempting to add wouldn't survive in today's players. The eye patterns are mostly closed these days and the additional information is lost in the noise.

The additional information that is added to a normal CD is designed to be invisible to a regular player. Therefore I am at a loss to decipher your request, considering the example material you linked to. That study, while slightly interesting was a waste of time to read past the first couple paragraphs. It was fairly obvious early on that this added modulation would not be recoverable by most new machines without a return to better transports and heads - just to attain the eye pattern they used as an example.

-Chris

Aside from the better than average eye patterns with the test CD player, the additional information is clearly shown with the regular eye pattern as a second dual level so that both upper and lower portions have two distinct levels.

With the normal occurrence of degraded eye patterns I see these days, the extra 25% they are attempting to add wouldn't survive in today's players. The eye patterns are mostly closed these days and the additional information is lost in the noise.

The additional information that is added to a normal CD is designed to be invisible to a regular player. Therefore I am at a loss to decipher your request, considering the example material you linked to. That study, while slightly interesting was a waste of time to read past the first couple paragraphs. It was fairly obvious early on that this added modulation would not be recoverable by most new machines without a return to better transports and heads - just to attain the eye pattern they used as an example.

-Chris

What I found interesting is that a disc with non standard pits had hardly any impact on the eye-pattern, only what looks like a more clear I3 land and pit amplitude. If they had supplied the BLER, E22 and E32 data, it would have also demonstrated the CD playback ability.

I think it is clear that different circuitry is needed to recover the extra data from the disc, the eye-pattern did show that.

I think it is clear that different circuitry is needed to recover the extra data from the disc, the eye-pattern did show that.

Hi Mark,

The extra information layer can be seen clearly, and the additional circuitry can take over in the RF amp section (still an analog RF signal at that point). The extra circuits can work in parallel to the standard layout until you get into dealing with data after the extra slice level detector is all done.

I do wish to call your attention to one fact though. You are in the CD manufacture business, and that means you are very aware of both advances and areas where cost cutting has impacted the product. One very nasty change has been the reduction in the Al coating, to the point where you can see fairly well through CDs from the silvered side to the label side and your hand beyond. What this means is a reduction in reflectivity and the attendant reduction in the RF signal. The eye pattern is closed by a certain amount the same as it would be if the laser diode had lost efficiency. This also directly impacts the quality of the product in a negative way, and exercises the C1 error correction most than it normally would be on a "good" disc.

Have you actually looked at the eye patterns on early vs lately manufactured CDs, enough to see an average, not just a hand picked group to study? Have you also had an opportunity to check the eye patterns on properly serviced and aligned older CD players vs the newer ones, and also the DVD players we now have to buy in order to get a "good" CD player.

A few years ago I was looking to get my parents a new, good machine to replace an old Yamaha CD player that was 10 years old (but still working well). When I asked several industry contacts for advice on what to get them, I was told by everyone that "we no longer manufacture good CD players, a DVD machine is your best bet and they are not as good as what I was used to seeing". They didn't use those exact words, but they all gave me the same information. This information came directly from the manufacturers and the service department heads. Even the technicians working there said the same thing. So we have lower quality players on the market and are being combined with lower quality CDs. Are there any plans to improve the quality of the CD product, as in the actual discs? At least a return to earlier, high quality CDs I used to see as the average.

Improved error correction will not make up for low quality CDs, and reducing CD quality as long as you are still in the accepted errors. For any read of the quality of the CD, you need to look at the eye pattern and servo signals. Looking at error flags can give you a very rough idea as problems increase, but they will not tell you what problems you are having, or combination of problems. I think all they are really good for is to have a measure of whether the product can be said to meet a "quality" standard, even if the test isn't really a measure of quality. Something to hide behind.

-Chris

-Chris

The extra information layer can be seen clearly, and the additional circuitry can take over in the RF amp section (still an analog RF signal at that point). The extra circuits can work in parallel to the standard layout until you get into dealing with data after the extra slice level detector is all done.

I do wish to call your attention to one fact though. You are in the CD manufacture business, and that means you are very aware of both advances and areas where cost cutting has impacted the product. One very nasty change has been the reduction in the Al coating, to the point where you can see fairly well through CDs from the silvered side to the label side and your hand beyond. What this means is a reduction in reflectivity and the attendant reduction in the RF signal. The eye pattern is closed by a certain amount the same as it would be if the laser diode had lost efficiency. This also directly impacts the quality of the product in a negative way, and exercises the C1 error correction most than it normally would be on a "good" disc.

Have you actually looked at the eye patterns on early vs lately manufactured CDs, enough to see an average, not just a hand picked group to study? Have you also had an opportunity to check the eye patterns on properly serviced and aligned older CD players vs the newer ones, and also the DVD players we now have to buy in order to get a "good" CD player.

A few years ago I was looking to get my parents a new, good machine to replace an old Yamaha CD player that was 10 years old (but still working well). When I asked several industry contacts for advice on what to get them, I was told by everyone that "we no longer manufacture good CD players, a DVD machine is your best bet and they are not as good as what I was used to seeing". They didn't use those exact words, but they all gave me the same information. This information came directly from the manufacturers and the service department heads. Even the technicians working there said the same thing. So we have lower quality players on the market and are being combined with lower quality CDs. Are there any plans to improve the quality of the CD product, as in the actual discs? At least a return to earlier, high quality CDs I used to see as the average.

Improved error correction will not make up for low quality CDs, and reducing CD quality as long as you are still in the accepted errors. For any read of the quality of the CD, you need to look at the eye pattern and servo signals. Looking at error flags can give you a very rough idea as problems increase, but they will not tell you what problems you are having, or combination of problems. I think all they are really good for is to have a measure of whether the product can be said to meet a "quality" standard, even if the test isn't really a measure of quality. Something to hide behind.

-Chris

-Chris

My experience, too.When I asked several industry contacts for advice on what to get them, I was told by everyone that "we no longer manufacture good CD players, a DVD machine is your best bet and they are not as good as what I was used to seeing".

Does Anyone of you have some "dead" lasers on the attic? (Dead means: diode dead/Dying. First/second gen types preferred. The ones I have are still working and i do not wand to kill them when disassembling a laser for getting it int my CAD program.

Also some things I would like to know:

What is zhe Focal length of the lens - I guess it is a standard, because it is based the refraction of the Polycarbonate of a disc?

Which parts -and why- will make alignment difficult within a 3-beam laser?

I have read that a diode has to be placed very precisely (and individually) in front of the diffraction grating. Correct? Wrong?

All the best,

Salar

I Have a Sony CDP 337ESD with the mighty and venerable KSS190A , the mech is amazing and still all in perfect working order but every time i use it i don't know if it is the last time the lazer will work.

I have dreamt of such a thread so maybe i could have a new lazer head on this amazing mech.

will follow with great interest.

These days i use more and more hires music files but still love the sound this CD player puts out.

I have dreamt of such a thread so maybe i could have a new lazer head on this amazing mech.

will follow with great interest.

These days i use more and more hires music files but still love the sound this CD player puts out.

Hi mlloyd1,

I couldn't help but notice this while doing warranty service, then doing work on my own things continue to deteriorate. They can say what they want (manufacturers), but it os clear the intention has been to limit performance and service life.

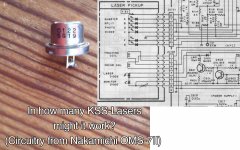

I thought I had some eye pattern photos, but I can't find any. I would love to show you a Nakamichi OMS-7 and some others. The OMS-7 is what is possible in quality and kills every other machine I have ever worked on. The Sony KSS-210A was a low quality head when it was introduced, and now I want to see heads like that and the KSS-240A and KSS-151A. These days those old heads are the high point in transports.

-Chris

I couldn't help but notice this while doing warranty service, then doing work on my own things continue to deteriorate. They can say what they want (manufacturers), but it os clear the intention has been to limit performance and service life.

I thought I had some eye pattern photos, but I can't find any. I would love to show you a Nakamichi OMS-7 and some others. The OMS-7 is what is possible in quality and kills every other machine I have ever worked on. The Sony KSS-210A was a low quality head when it was introduced, and now I want to see heads like that and the KSS-240A and KSS-151A. These days those old heads are the high point in transports.

-Chris

Hi Salar,

Yes, they have a focal length internally as well. The internal lens allows the objective lens to move and correct for external issues.

I think that pulling apart some cheaper, dead pick ups might be in order. If you can find one close to the design you are thinking of ... A KSS-123A might be an interesting victim, or a Sanyo SF-90. Some of those less expensive heads were actually good, its just the bearings riding on the rails wore out quickly. What a waste just to save a little on two sleeve bearings.

-Chris

Yes, they have a focal length internally as well. The internal lens allows the objective lens to move and correct for external issues.

I think that pulling apart some cheaper, dead pick ups might be in order. If you can find one close to the design you are thinking of ... A KSS-123A might be an interesting victim, or a Sanyo SF-90. Some of those less expensive heads were actually good, its just the bearings riding on the rails wore out quickly. What a waste just to save a little on two sleeve bearings.

-Chris

Hi Mark,

Geez, I wish you hadn't linked to You Tube. Those people do not know what they are doing!!!!

Okay, the eye pattern off the first video was normal for the KSS-240A and is substantially better than the average new heads. One thing I want to make perfectly clear is that you never, ever touch the laser power adjustment for most machines. The three trimmer controls have locking compound on them because they are factory adjust only!! There is only one I do (with tons of experience) and that is the E-F balance. That one is extremely touchy and most folks would end up with a non-working head if they attempted to play with any of these controls. You will not find these three controls listed in any manual, or you shouldn't.

The next video shows someone "testing" the laser diodes. No! Not that way. I have a laser power meter if I need to check if there is any output. That fellow was running lasers well above their maximum rated output. I have never seen a KSS series CD head running much above 60 mA, and most sit between 35 and 56 mA.

And there they are instructing other people. Sad. The third guy cleans laser lens with a pencil eraser!! He is scratching the lens and that will rarely work. Lens cleaner is the proper way, like for cameras. Use much less force than he did and don't expect success. You are better off not messing about inside stereo equipment without being specifically trained. Many do, and they charge for their "work" as they hack about.

Mark, from your earlier posts, you do have access to real machines with real instrumentation. Make a video of some current machines that you see please! I plan to save some eye pattern shots the next time I am in one. Please do the same.

Laser power. The current is printed on the head somewhere and you normally have a resistor to measure the voltage drop across. You are allowed a 10% increase before the laser is considered too worn to provide decent service. The only way to check laser power is with the service manual and using a good DVM, oscilloscope and laser power meter. There is a reason why we all had to buy that stuff to be authorized to work on CD Players. Those folks on You Tube haven't good a good clue as to what they are doing, please use them as examples of how to spot a bad technician.

-Chris

Geez, I wish you hadn't linked to You Tube. Those people do not know what they are doing!!!!

Okay, the eye pattern off the first video was normal for the KSS-240A and is substantially better than the average new heads. One thing I want to make perfectly clear is that you never, ever touch the laser power adjustment for most machines. The three trimmer controls have locking compound on them because they are factory adjust only!! There is only one I do (with tons of experience) and that is the E-F balance. That one is extremely touchy and most folks would end up with a non-working head if they attempted to play with any of these controls. You will not find these three controls listed in any manual, or you shouldn't.

The next video shows someone "testing" the laser diodes. No! Not that way. I have a laser power meter if I need to check if there is any output. That fellow was running lasers well above their maximum rated output. I have never seen a KSS series CD head running much above 60 mA, and most sit between 35 and 56 mA.

And there they are instructing other people. Sad. The third guy cleans laser lens with a pencil eraser!! He is scratching the lens and that will rarely work. Lens cleaner is the proper way, like for cameras. Use much less force than he did and don't expect success. You are better off not messing about inside stereo equipment without being specifically trained. Many do, and they charge for their "work" as they hack about.

Mark, from your earlier posts, you do have access to real machines with real instrumentation. Make a video of some current machines that you see please! I plan to save some eye pattern shots the next time I am in one. Please do the same.

Laser power. The current is printed on the head somewhere and you normally have a resistor to measure the voltage drop across. You are allowed a 10% increase before the laser is considered too worn to provide decent service. The only way to check laser power is with the service manual and using a good DVM, oscilloscope and laser power meter. There is a reason why we all had to buy that stuff to be authorized to work on CD Players. Those folks on You Tube haven't good a good clue as to what they are doing, please use them as examples of how to spot a bad technician.

-Chris

Chris, I am not advising anyone to try anything. To me it looked as if he adjusted the RF amplitude as indicated in the service Manuel, 1.2 +-0.3Vpp, that could mean that the current is above the maximum allowed.

There are decades of misinformation, giving people a closer look is a first step in the right direction.

There are decades of misinformation, giving people a closer look is a first step in the right direction.

Hi Mark,

There is no adjustment for RF amplitude, especially not with a factory configured head type. These Sony service manuals do not have any recommendation to set the RF amplitude either.

It's not like the first Philips mechanisms, and you need a specific test CD and the laser power meter to set the power. The OMS-5/7 is the same in that regard, but that is a single beam type head as well. The lock bond (white in colour on those heads) is a sure sign that those controls are not to be messed with in any way.

While I'll accept that you did not suggest anyone follow the advice in the You Tube clip, you did link to it where this activity was going on. Maybe look out for this in the future.

I hope this isn't an unfair question for you, but I am reacting to you as if you are an industry professional who has a first person knowledge and training on CD players. I'm seeing signs that you may not have hands on experience and may not have any training on CD players (DVD players also by extension).

Just how familiar are you with these devices? Not the code that runs in the micro-controllers, because they either work or they don't. All we can do is replace the chips that don't work.

Best, Chris

There is no adjustment for RF amplitude, especially not with a factory configured head type. These Sony service manuals do not have any recommendation to set the RF amplitude either.

It's not like the first Philips mechanisms, and you need a specific test CD and the laser power meter to set the power. The OMS-5/7 is the same in that regard, but that is a single beam type head as well. The lock bond (white in colour on those heads) is a sure sign that those controls are not to be messed with in any way.

While I'll accept that you did not suggest anyone follow the advice in the You Tube clip, you did link to it where this activity was going on. Maybe look out for this in the future.

I hope this isn't an unfair question for you, but I am reacting to you as if you are an industry professional who has a first person knowledge and training on CD players. I'm seeing signs that you may not have hands on experience and may not have any training on CD players (DVD players also by extension).

Just how familiar are you with these devices? Not the code that runs in the micro-controllers, because they either work or they don't. All we can do is replace the chips that don't work.

Best, Chris

Chris, you are looking at this as a service engineer and not as R&D. Salar has the right idea, gather information, dissect, inspect and abuse to further understanding. If in the process you break something, that is progress. Without posting that video, I would not have learnt what I did.

About replacing chips, I don't know, but this may be a good place to start a new design from. It would be a real headache to design the electronics around the newly designed optics, laser and motors.

About replacing chips, I don't know, but this may be a good place to start a new design from. It would be a real headache to design the electronics around the newly designed optics, laser and motors.

Last edited:

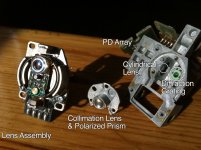

Before opening my "dead" KSS-123A, I searched the net and found photos of an open KSS-123A:

Open KSS-123

Chris, can you tell me, which optical elements reside in the detached "wheel"(the part carried by the pole piece)? The front lens for sure, anything else?

What seems to be missing in one photo (3rd from top) is the assembly leading the laser beam to the photodiodes, I assume hidden in the left.

All the best, Salar

Open KSS-123

Chris, can you tell me, which optical elements reside in the detached "wheel"(the part carried by the pole piece)? The front lens for sure, anything else?

What seems to be missing in one photo (3rd from top) is the assembly leading the laser beam to the photodiodes, I assume hidden in the left.

All the best, Salar

Last edited:

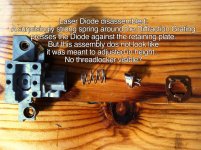

I checked myself - Here it is, a disassembled KSS-123A!

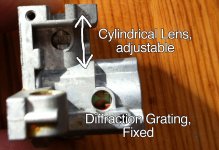

First question:

Is diffraction grating crucial in relation to the laser diode, and / or to

the polarised prism?

More comments on the pictures! Sorry for my strange capitalisation rules...

First question:

Is diffraction grating crucial in relation to the laser diode, and / or to

the polarised prism?

More comments on the pictures! Sorry for my strange capitalisation rules...

Attachments

-

KSS123A_Disassembled01.jpg341.6 KB · Views: 328

KSS123A_Disassembled01.jpg341.6 KB · Views: 328 -

KSS123A_Disassembled02.jpg376 KB · Views: 320

KSS123A_Disassembled02.jpg376 KB · Views: 320 -

KSS123A_Disassembled03.jpg325.4 KB · Views: 312

KSS123A_Disassembled03.jpg325.4 KB · Views: 312 -

KSS123A_Disassembled05.jpg325.5 KB · Views: 307

KSS123A_Disassembled05.jpg325.5 KB · Views: 307 -

KSS123A_Disassembled06.jpg133.6 KB · Views: 303

KSS123A_Disassembled06.jpg133.6 KB · Views: 303 -

KSS123A_Disassembled07.jpg527.2 KB · Views: 134

KSS123A_Disassembled07.jpg527.2 KB · Views: 134 -

KSS123A_Disassembled08.jpg561.4 KB · Views: 120

KSS123A_Disassembled08.jpg561.4 KB · Views: 120 -

KSS123A_Disassembled09.jpg336.2 KB · Views: 130

KSS123A_Disassembled09.jpg336.2 KB · Views: 130 -

KSS123A_Disassembled04a.jpg342.9 KB · Views: 129

KSS123A_Disassembled04a.jpg342.9 KB · Views: 129 -

KSS123A_Disassembled04b.jpg454.8 KB · Views: 121

KSS123A_Disassembled04b.jpg454.8 KB · Views: 121

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!