Would they need to be ring magnets? Wouldn't multiple, small magnets be strong enough with an even clamping force?

Anyway, I just googled magnets and the advertising side-bar led me to these ferrite ring magnets with 1kg pull at about €1 each as shown on this page of ring magnets: Ring Magnets | first4magnets.com

Neodymium with 9kg pull could be good if you could remove them without pulling the mech apart (and not stop it moving either) !

Anyway, I just googled magnets and the advertising side-bar led me to these ferrite ring magnets with 1kg pull at about €1 each as shown on this page of ring magnets: Ring Magnets | first4magnets.com

Neodymium with 9kg pull could be good if you could remove them without pulling the mech apart (and not stop it moving either) !

Of course ring magnets are easy to find!

Wasted a week or so designing a clamper

based on neodymmagbets from ebay.

Problem is inner diameter. If you want decent

thickness of material i.e1,5 to 2mmm , 16 is hard to implemen

on a 15mm hole even with cone.

Those magnets had 15mm.

For now 20mm inner, 24 to 25 outer diameter preferred.

Thickness not more than 5mm.

All the best

Wasted a week or so designing a clamper

based on neodymmagbets from ebay.

Problem is inner diameter. If you want decent

thickness of material i.e1,5 to 2mmm , 16 is hard to implemen

on a 15mm hole even with cone.

Those magnets had 15mm.

For now 20mm inner, 24 to 25 outer diameter preferred.

Thickness not more than 5mm.

All the best

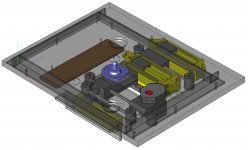

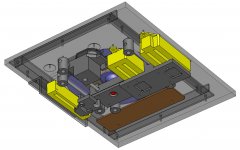

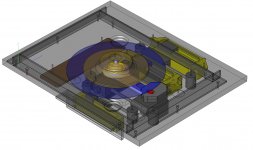

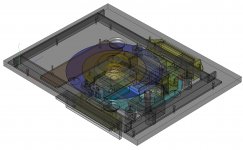

Here we go - almost finished drawing of a "Frankenstein"- Drive -

Built from a CDP-103 / 502 and CDP-X5000.

Does not look much different from earlier drawings, but is based on real world measurements -

hell of a work, sometimes 3 hours besides regular work, sometimes up to 12 hours in my spare time.

Must have been 10 days now working like this since the first draft

Could be milled right away. New parts are a traverse for the disc motor,

base plate and poles for fastening the rails. Stabilizer and Teflon inlay.

The rest is already there but had to be measured very carefully to make things fit and interact.

What is still missing are drawings some off the shelf spacers and fasteners.

That´s all. Maybe one or two bores to be repositioned.

About the "organs":

The X5000 will provide the BSL-motor and laser.

Magnets and colis from the CDP-105/502.

Laser is a KSS-273A. It has the RF-Amp on board.

All the best,

Salar

Built from a CDP-103 / 502 and CDP-X5000.

Does not look much different from earlier drawings, but is based on real world measurements -

hell of a work, sometimes 3 hours besides regular work, sometimes up to 12 hours in my spare time.

Must have been 10 days now working like this since the first draft

Could be milled right away. New parts are a traverse for the disc motor,

base plate and poles for fastening the rails. Stabilizer and Teflon inlay.

The rest is already there but had to be measured very carefully to make things fit and interact.

What is still missing are drawings some off the shelf spacers and fasteners.

That´s all. Maybe one or two bores to be repositioned.

About the "organs":

The X5000 will provide the BSL-motor and laser.

Magnets and colis from the CDP-105/502.

Laser is a KSS-273A. It has the RF-Amp on board.

All the best,

Salar

Attachments

Hi Chris!

Any head can be put in later. This is why the CD is being moved,

you don´t have to redesign the traverse.

As this is #606 already, I´ve got to start with something.

This drive is to check whether moving the CD with magnets is definately possible an reliable.

And I do not have to cope with APC-circuits and RF Amps but only need too adapt the outgoing signals.

The baseplate has a thickness of 8mm, enough material to bolt in almost any head later.

But I will need help in gluing the electronics of the X5000 and CDP-103/502 together!!!

The X5000 Servoboard has more or less to drive coils now.

Disc BSL-motor and Laser coils will be kept untouched.

BTW, anyone with access to 3D-Metal printing appreciated!

All the best,

Salar

Any head can be put in later. This is why the CD is being moved,

you don´t have to redesign the traverse.

As this is #606 already, I´ve got to start with something.

This drive is to check whether moving the CD with magnets is definately possible an reliable.

And I do not have to cope with APC-circuits and RF Amps but only need too adapt the outgoing signals.

The baseplate has a thickness of 8mm, enough material to bolt in almost any head later.

But I will need help in gluing the electronics of the X5000 and CDP-103/502 together!!!

The X5000 Servoboard has more or less to drive coils now.

Disc BSL-motor and Laser coils will be kept untouched.

BTW, anyone with access to 3D-Metal printing appreciated!

All the best,

Salar

Last edited:

Well, those have to be made fit:

For driving the the sled the fifth generation CXD2515AQ

servo control IC of the CDP-X5000 will provide the sled signals for the linear drive instead of the first generation CX20108 of the CDP-103/502. I assume

sled signals have changed...?

Datasheets attached...

Manuals are to be found here:

SONY CDP-X5000 Service Manual free download, schematics, eeprom, repair info for electronics

SONY CDP-502ES 620ES SM Service Manual free download, schematics, eeprom, repair info for electronics

For driving the the sled the fifth generation CXD2515AQ

servo control IC of the CDP-X5000 will provide the sled signals for the linear drive instead of the first generation CX20108 of the CDP-103/502. I assume

sled signals have changed...?

Datasheets attached...

Manuals are to be found here:

SONY CDP-X5000 Service Manual free download, schematics, eeprom, repair info for electronics

SONY CDP-502ES 620ES SM Service Manual free download, schematics, eeprom, repair info for electronics

Attachments

@589

My best guess is that both discs were manufactured at Blackburn UK around 2002-2003. One disc on line/mould 33, the other on 49.

If the discs are muting during playback then the concealment is also failing. Does the player have problems with other discs? Is it only a problem with discs that have a longer than average playtime?

Mark, Apols for the slow response, been tied up a while. So do you think that both of those discs come from the same stamper?

Not muting during playback, I didn't say that, I said the DSP was active. But in the case of one disc considerably more frequently that the other. It's not anything specifically related to disc program length as they DSP is (randomly) active throughout the disc program.

Jon.

anatech...and others.

So I'm still being a bit of a slug here, but why not start with a Sanyo SF-91. It seems that these have been used for a long time in some reasonably high end players. Good enough for a Nakamichi Dragon cdp, good enough for stew...

Still wish I had my old SLP-8 cd player...still wish I had my old SLP-8 cd ...still wish I had my old SLP-8 cd ...still wish I had my old SLP-8 cd player.

So I'm still being a bit of a slug here, but why not start with a Sanyo SF-91. It seems that these have been used for a long time in some reasonably high end players. Good enough for a Nakamichi Dragon cdp, good enough for stew...

Still wish I had my old SLP-8 cd player...still wish I had my old SLP-8 cd ...still wish I had my old SLP-8 cd ...still wish I had my old SLP-8 cd player.

Hi Stew,

The SF-90 and SF-91 do give a relatively clean eye pattern. I'm not sure about the SF-91, but the SF-90 has no bearing and they tend to kill themselves mechanically due to high wear. It's frustrating to have to replace otherwise good laser heads because they were too cheap to use a sleeve bearing like everyone else (except for the horrible Hitachi HOP-M3).

The Sanyo heads are expensive as well.

-Chris

The SF-90 and SF-91 do give a relatively clean eye pattern. I'm not sure about the SF-91, but the SF-90 has no bearing and they tend to kill themselves mechanically due to high wear. It's frustrating to have to replace otherwise good laser heads because they were too cheap to use a sleeve bearing like everyone else (except for the horrible Hitachi HOP-M3).

The Sanyo heads are expensive as well.

-Chris

A little more thought...

Salar and anatech,

So an in production optics block is required. What's out there that is any good? Can we use a dvd optics block and throw the rest of a dvd player away? Is the intent to get a completely new optics block designed and manufactured?

If an optics block is procured, then the mechanical transport needs to be made (great drawings by the way), which should be easier. What else am I missing?

stew

Salar and anatech,

Hi Stew,

The SF-90 and SF-91 do give a relatively clean eye pattern. I'm not sure about the SF-91, but the SF-90 has no bearing and they tend to kill themselves mechanically due to high wear. It's frustrating to have to replace otherwise good laser heads because they were too cheap to use a sleeve bearing like everyone else (except for the horrible Hitachi HOP-M3).

The Sanyo heads are expensive as well.

-Chris

So an in production optics block is required. What's out there that is any good? Can we use a dvd optics block and throw the rest of a dvd player away? Is the intent to get a completely new optics block designed and manufactured?

Because the head is stationary and the CD is moved, wear of the bearings is not an issue.

But I guess the SF-90 and SF-91 are not produced anymore...

So an optical engineer would be a benefit to this thread...

If an optics block is procured, then the mechanical transport needs to be made (great drawings by the way), which should be easier. What else am I missing?

stew

Last edited:

goal is still to make a new optical block.

btw something very great about first to

maybe third generation heads - the optica path

was very often sealed from dust! i.e a second

lens following the movable lens, sealing the rest.

Aomething really to reinvent. Any optica engeneers

in this forum?

btw something very great about first to

maybe third generation heads - the optica path

was very often sealed from dust! i.e a second

lens following the movable lens, sealing the rest.

Aomething really to reinvent. Any optica engeneers

in this forum?

optical block manufacturing...

Salar,

a while ago I came upon a manufacturer of CD/dvd ROM drives that seemed willing to work in small batches. I was looking for a completely different application, but if I can find them again I'll make an inquiry regarding the block and the complete transport mechanism, including a stationary block/moving spindle type of transport. I just remembered this...

Salar,

a while ago I came upon a manufacturer of CD/dvd ROM drives that seemed willing to work in small batches. I was looking for a completely different application, but if I can find them again I'll make an inquiry regarding the block and the complete transport mechanism, including a stationary block/moving spindle type of transport. I just remembered this...

Hi Stew,

This is Salar's deal, but I think any information will be helpful.

Looking at Salar's idea of a fixed optical head, I think there is some genius there. Almost all heads have a plane surface that will be orthogonal w.r.t. the CD playing surface. Adjusting for varying height is much easier than having everything an unknown. It also removes the entire question of sleeve bearings and wear since that will already be looked after.

A DVD head would probably work too. They do have units that play CDs and DVDs, so why not? Just make sure that head can play both.

-Chris

This is Salar's deal, but I think any information will be helpful.

Looking at Salar's idea of a fixed optical head, I think there is some genius there. Almost all heads have a plane surface that will be orthogonal w.r.t. the CD playing surface. Adjusting for varying height is much easier than having everything an unknown. It also removes the entire question of sleeve bearings and wear since that will already be looked after.

A DVD head would probably work too. They do have units that play CDs and DVDs, so why not? Just make sure that head can play both.

-Chris

just a recollection....

Chris (and Salar too),

I was just mentioning the recollection I had, as the folks I spoke to seemed willing to do most anything and IIRC seemed reasonably priced. In my case I was looking for an electronically controlled (but fully adjustable) motor/control circuit for use in a turntable project. But they were manufacturers of optical drive units.

Chris (and Salar too),

I was just mentioning the recollection I had, as the folks I spoke to seemed willing to do most anything and IIRC seemed reasonably priced. In my case I was looking for an electronically controlled (but fully adjustable) motor/control circuit for use in a turntable project. But they were manufacturers of optical drive units.

Salar and anatech, and any others interested...

I don't recall the name of the company, but it was located in the US. I may have an old email addy for them. I need to look. The reason I was mentioning it at all was to provide the contact information to you guys and see if they had the capabilities to help out salar and those interested in this thread.

Regarding my own turntable project, I am planning on using a "Japan Servo" branded AC induction motor, Close to 1/4 hp @ 3820 no load speed. It will need a stereo amplifier and a stable waveform to amplify, but should work out. It may also require a step up transformer to be able to get to the 115V, 60 Hz signal In addition to this I have the the same Maxxon DC motor as used by Origin Live in their turntable motor upgrades and a control board that was offered as a Group Buy years ago here at DIYaudio.com.

I keep seeing ridiculous prices of even quite mediocre used tables increasing to the point that many folks may not be able to afford one. The idea with the turntable was to do something similar in spirit as my "Nanook 219" tonearm. The large induction motor I purchased as new surplus, but I haven't seen anything like it available out on the Interweb. I was thinking something like the Thorens TD124 as a table to emulate. 1/4 HP should spin just about any platter regardless of the mass of it (short of being absolutely stupid. I do see that B&O did actually use a similar concept in one of their turntable (on of the "slim-line, fancy, smancy ones) whee the motor drove an intermediate stepped pulley, which drives the platter directly from the intermediate pulley to a driven pulley. I'll need to look into this further.

Thanks for the interest.

By the way, my nephew is looking at getting back into home audio. He gave away his cd player (a Marantz cd5000) to a buddy who needed one, so he's looking at a cd player. I have an old Sony cdp-990. What do you guys think? KSS-240. It works and is built like a tank, although not pretty by any means.

I don't recall the name of the company, but it was located in the US. I may have an old email addy for them. I need to look. The reason I was mentioning it at all was to provide the contact information to you guys and see if they had the capabilities to help out salar and those interested in this thread.

Regarding my own turntable project, I am planning on using a "Japan Servo" branded AC induction motor, Close to 1/4 hp @ 3820 no load speed. It will need a stereo amplifier and a stable waveform to amplify, but should work out. It may also require a step up transformer to be able to get to the 115V, 60 Hz signal In addition to this I have the the same Maxxon DC motor as used by Origin Live in their turntable motor upgrades and a control board that was offered as a Group Buy years ago here at DIYaudio.com.

I keep seeing ridiculous prices of even quite mediocre used tables increasing to the point that many folks may not be able to afford one. The idea with the turntable was to do something similar in spirit as my "Nanook 219" tonearm. The large induction motor I purchased as new surplus, but I haven't seen anything like it available out on the Interweb. I was thinking something like the Thorens TD124 as a table to emulate. 1/4 HP should spin just about any platter regardless of the mass of it (short of being absolutely stupid. I do see that B&O did actually use a similar concept in one of their turntable (on of the "slim-line, fancy, smancy ones) whee the motor drove an intermediate stepped pulley, which drives the platter directly from the intermediate pulley to a driven pulley. I'll need to look into this further.

Thanks for the interest.

By the way, my nephew is looking at getting back into home audio. He gave away his cd player (a Marantz cd5000) to a buddy who needed one, so he's looking at a cd player. I have an old Sony cdp-990. What do you guys think? KSS-240. It works and is built like a tank, although not pretty by any means.

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!