Ok... I'm thinking build a tc9 foam coar trynergy to learn more then put that experience into a wood trynergy when we have a consensus on the driver.

Perhaps something with a flexible throat mount so new drivers won't require a complete rebuild. This may cause too many compromises though.

I can't help thinking of a stretched stocking and fiberglass resin solution for the round to square throat transition too.

I'll start on the foam coar trynegy build next week. Any ideas for the flh?

Perhaps something with a flexible throat mount so new drivers won't require a complete rebuild. This may cause too many compromises though.

I can't help thinking of a stretched stocking and fiberglass resin solution for the round to square throat transition too.

I'll start on the foam coar trynegy build next week. Any ideas for the flh?

Ok... I'm thinking build a tc9 foam coar trynergy to learn more then put that experience into a wood trynergy when we have a consensus on the driver.

Perhaps something with a flexible throat mount so new drivers won't require a complete rebuild. This may cause too many compromises though.

I can't help thinking of a stretched stocking and fiberglass resin solution for the round to square throat transition too.

I'll start on the foam coar trynegy build next week. Any ideas for the flh?

It's big but a University Classic gets 105 to 108dB sensitivity. Only 60Hz or so f3 but it hits hard and goes up to 500Hz so you can cross with just full range and no mid woofers.

Look in post #1 - links below.

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-10.html#post4049533

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-18.html#post4053078

You will need to scale the plans by 0.70x for 3in drivers.

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-10.html#post4049533

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-18.html#post4053078

You will need to scale the plans by 0.70x for 3in drivers.

Ah sorry mate I should have been more clear, I ment a link to the university classic design... I found some stuff but wanted to be sure we are looking at the same thing.

I guess if where to add the 850439's a`la synergy it would open up a lot more options for bass cabinets.

Starting work on the tops once I find more foam core and rereading this thread properly..

Cheers gents

I guess if where to add the 850439's a`la synergy it would open up a lot more options for bass cabinets.

Starting work on the tops once I find more foam core and rereading this thread properly..

Cheers gents

Ah sorry mate I should have been more clear, I ment a link to the university classic design... I found some stuff but wanted to be sure we are looking at the same thing.

I guess if where to add the 850439's a`la synergy it would open up a lot more options for bass cabinets.

Starting work on the tops once I find more foam core and rereading this thread properly..

Cheers gents

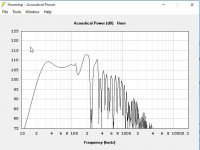

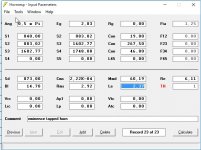

University Classic - these look like the official plans. I actually have a model in Akabak so let me know what driver you plan on using and I can run the sim for you. TS parameters of different than spec.

There is a discussion here for various drivers. It actually works well with dual 12's - there is enough room.

https://community.klipsch.com/index...n-horn-profile-need-driver-choice-help/page-3

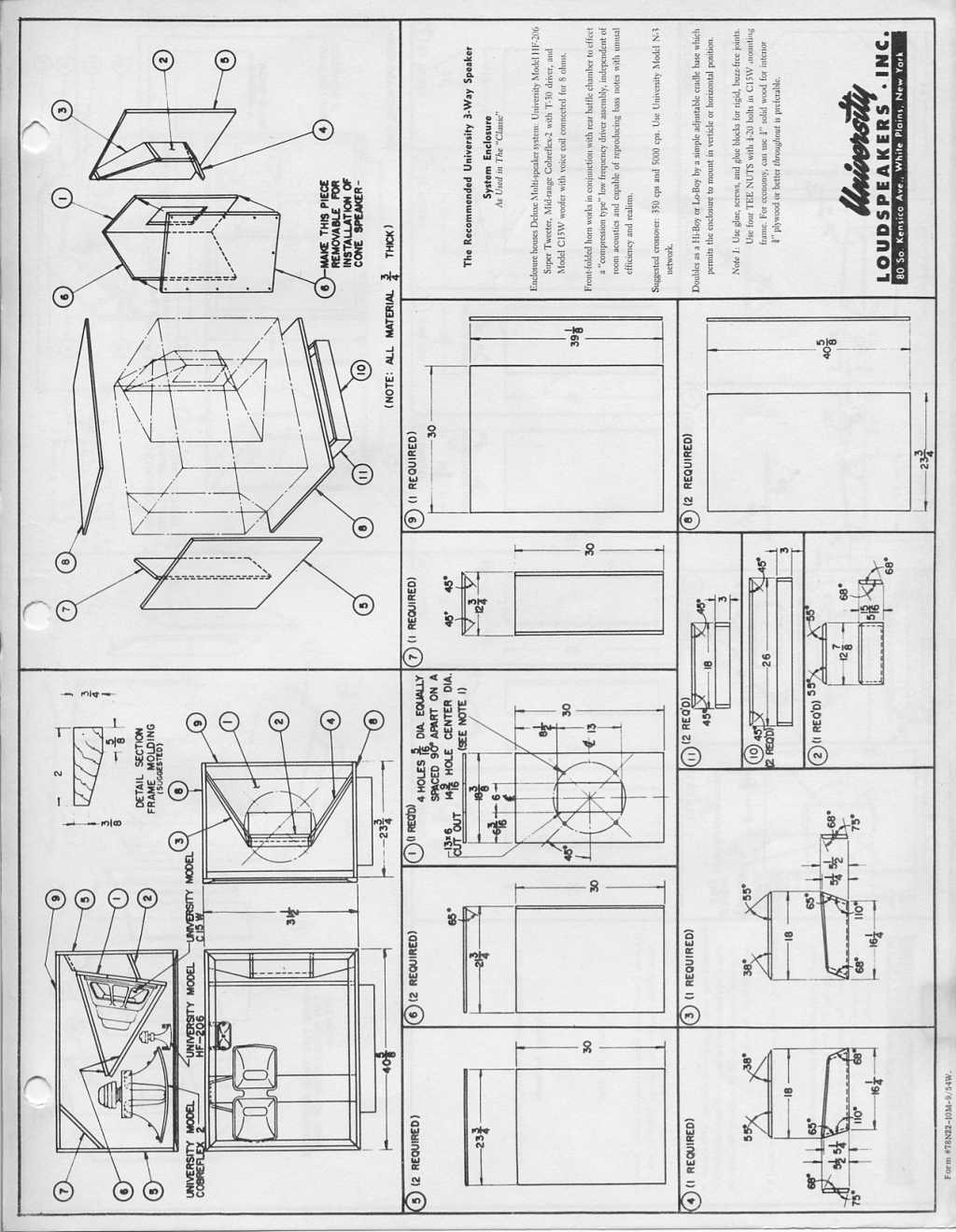

Measurements by some Russian guys:

They said that they never experienced such hurricane like bass with such depth.

A video of a Classic in action.

http://youtu.be/jv-n47yy-tE

Last edited:

I have prepared now the mic amp and the faseplug, if lathe is ready then I give it a go.

That university thing is very big, a trynergy horn with a tapped horn will be mucho smaller.

I gonna make a faseplug al la compression driver, difficult but with patient like always is a matter in electronics I will succeed.

regards

That university thing is very big, a trynergy horn with a tapped horn will be mucho smaller.

I gonna make a faseplug al la compression driver, difficult but with patient like always is a matter in electronics I will succeed.

regards

Yes big horn, but no TH will reach 500Hz from 60Hz with 108dB sensitivity. You would not need mid woofers on tractrix and can maintain overall system sensitivity at 108dB.

This is now exactly what I have tell before, the big correction of a tractrix like we do now do make more distortion, I do for that reason test fase plugs. This threat get professional and interesting. I have to say that still the 3 incher get 94 a 96 dB watt, still nice.

If i make a horn 80 hz to 300 hz and 300 hz (without faseplug) to 3kHz, and up a little horn, with a tapped horn I get a high sensitive system with low distortion.

But i like the wideband idea because that way we can make fase right more easely, a bessel crossover is possible but needs a lot of parts for steepness.

regards

I am a little confused about the volvotreter calculations, when I put the horn in a corner it get,s very small, even a basunit do not fit, when putting on a wall, horn get bigger, and in free air it is like I have build.

Because most men do corner or wall in there homes, why not make the small ones, special the one for a wall is suittable for a extra woofer on it and a small horn go further in extension for HF.

O do I have trouble with excel not calculate properly.

thanks for clearing this for me.

regards

Because most men do corner or wall in there homes, why not make the small ones, special the one for a wall is suittable for a extra woofer on it and a small horn go further in extension for HF.

O do I have trouble with excel not calculate properly.

thanks for clearing this for me.

regards

I have a wood lathe so will follow your phase plug closely kees.

The only reason I would consider something the size of the University horn (thanks for the link xrk) is to have a bass horn that goes up to 500Hz and let's me use a simple 3" like yours from 500Hz and up.

That being said, it may be a similar amount of work to built a tapped horn for 40Hz to 100Hz, then use 2 x 850439 mounted trynergy like for 100Hz to 500Hz'ish then 3" 500Hz to beyond.

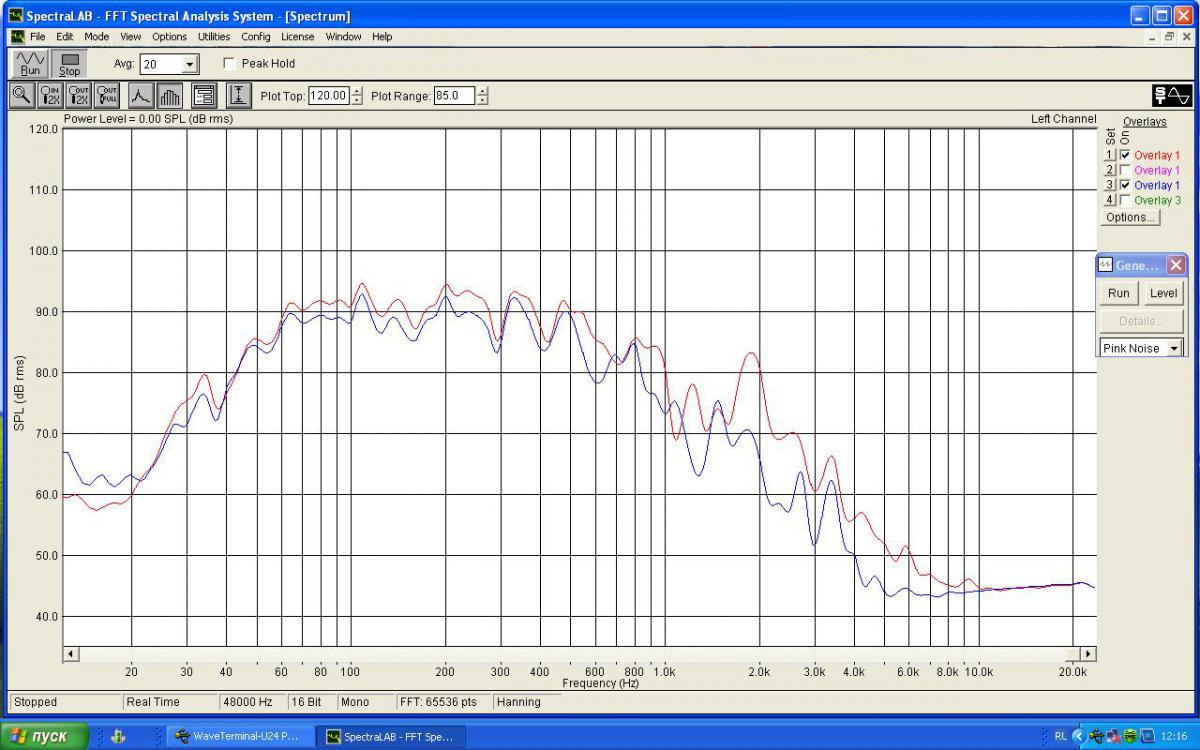

I am a little concerned that a driver like the Delta15LFA may not be well suited for a tapped horn. Its a paper cone on a pleated cloth roll surround with a pressed steel frame. I'll upload the spec sheet now.

The only reason I would consider something the size of the University horn (thanks for the link xrk) is to have a bass horn that goes up to 500Hz and let's me use a simple 3" like yours from 500Hz and up.

That being said, it may be a similar amount of work to built a tapped horn for 40Hz to 100Hz, then use 2 x 850439 mounted trynergy like for 100Hz to 500Hz'ish then 3" 500Hz to beyond.

I am a little concerned that a driver like the Delta15LFA may not be well suited for a tapped horn. Its a paper cone on a pleated cloth roll surround with a pressed steel frame. I'll upload the spec sheet now.

I think wall is 1/2pi space and corner is 1/4pi space and bottom or top corner is 1/8pi space. The horn gain is not needed so horns can be smaller for same SPL desired. I think the placement just changes size to reduce horn gain given wall or corner boundary.

It has to do with that, using walls as a extention of the horn so it is smaller. but it is little if it is in a corner, and a bass version with a 8 inch in it go also not really big.

Attachments

Some D15LFA Info

Delta 15 has qts of 0.48 and i think some people has use them in a tapped horn, if you want go to 100 hz as a top you can not go as low as 20 hz.

I can try it in hornresp.

regards

Hey kees, I'm slowly reading back through the thread but want to ask, do you have a final version of your cut plans for your woode trynergy? Can they be scaled and printed for a 3" driver?

I ask because the only fomecore I can find locally is $17AUD per sheet and I already have heaps of 12mm and 3mm ply from a bus fit out recently...

Cheers

Dean

I ask because the only fomecore I can find locally is $17AUD per sheet and I already have heaps of 12mm and 3mm ply from a bus fit out recently...

Cheers

Dean

Hey kees, I'm slowly reading back through the thread but want to ask, do you have a final version of your cut plans for your woode trynergy? Can they be scaled and printed for a 3" driver?

I ask because the only fomecore I can find locally is $17AUD per sheet and I already have heaps of 12mm and 3mm ply from a bus fit out recently...

Cheers

Dean

I have done it in sketchup and from there I did work on. I did use thin sheets gleued together for the flare with a mall.

Dit flatten the horn and print it for that purpose.

I have no plans so at hand because did it as a test first.

The eminence you use has to high qts, as a result the bump on 30 hz will nog go away except when make the box as big as your livingroom.

regards

Attachments

Some D15LFA Info

This Qts is too big for the Univ Classic - which likes strong motors and Qts below 0.4, and <0.3 if you can get it.

- Home

- Loudspeakers

- Multi-Way

- Presenting the Trynergy - a full range tractrix synergy.